0 ratings0% found this document useful (0 votes)

64 views8 pagesJSA For

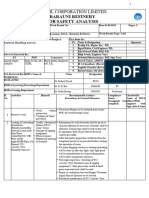

The document is a Job Safety Analysis Record Sheet for the Shaybah NGL Recovery Plant, focusing on safety protocols for mechanical equipment operations using crawler cranes. It outlines various hazards, safety measures, and responsibilities for personnel involved in lifting tasks, emphasizing the importance of compliance with safety standards and procedures. The document includes specific stop work triggers to ensure safety during operations, highlighting the need for proper training, equipment inspection, and environmental considerations.

Uploaded by

Rech GepitulanCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF or read online on Scribd

0 ratings0% found this document useful (0 votes)

64 views8 pagesJSA For

The document is a Job Safety Analysis Record Sheet for the Shaybah NGL Recovery Plant, focusing on safety protocols for mechanical equipment operations using crawler cranes. It outlines various hazards, safety measures, and responsibilities for personnel involved in lifting tasks, emphasizing the importance of compliance with safety standards and procedures. The document includes specific stop work triggers to ensure safety during operations, highlighting the need for proper training, equipment inspection, and environmental considerations.

Uploaded by

Rech GepitulanCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF or read online on Scribd

Ga JOB SAFETY ANALYSIS RECORD SHEET Recen

SHAYBAH NGL RECOVERY PLANT DEPARTMENT

JOB SAFETY ANALYSIS RECORD SHEET

PLANT/EQUIPMENT: DEPARTMENT: Gas Facility Projects Dept. Revised No. / Date: Rev. A / 09-Sep-2024

« DIVISION/UNIT: SNGL No: SNGLO: [36% 1944/5 [2024

SHAYBAH SNGL. SAGPD/ DPCU Shaybah JSANO.: 19162-HS06028A-094

DESCRIPTION OF JOB/TASK: Critical

LOCATIONS: D-69, B-94 Area,

iting for Mechanical Equipment using Crawler Cranes (Tailing /Tandem Lift specifically for Stripper Column D69-C-0006)

creer Se

- eo! - . o

ce CSC onl Ber One oe VION onlenlee

Rep. REVIEWED BY/PMT Safety Rey ‘APPROVED BY: Operation Foreman SP"

A MEA foo,

OL & FQUIPN

an Povier Tools

Equipment Operator Te

Types and Procedures

Use and Maintenance of Below-the-hook Lifting

Extinguishers

Gas Detector

ing/ Lining Mask/ Face mask

Sleeve FRC Clothing

Face Shield

Ear Plugs/Mutts

Full body Harness |

ty Vest (orange, Green, Red)

12.100 Permit to Work (PTW) guidelines

CSM Part Il - 02 Mechanical and Heavy Equipment

CSM - Part - 03 Personal Protective Equipment PPE

Part |-04 Work Permit System and Stop Work Authority,

Spreader Beam

ete

1. | Work Preparation | 1.1 Slip trip

154

155

LLL Removing all obstacles from walkways and keeping walkways free of cluter. Site supervisor

(Manpower, 1.1.2 Avoid stringing cords, cables or air hoses across walkways or in any designated aisle.

ernest) 1.1.3 Maintain good housekeeping & material management

‘STOP work trigger: any of the abovementioned requirements didn't meet the work willbe stopped

1.2 Struck by moving | 1.2.1 Separate pedestrians from moving vehicles and equipment by providing pedestrian walkways | Site supervisor

equipment and 1.22 Provide trained flagman for all man-machine moving equipment. Driver

vehicles 1.23 The equipment movement area shall be properly cordon-off. operator

1.24 Human Machine Interface shall be controlled and escort vehicle shall be assigned for vehicle Elagman

movementin the main road. Safety OfRear

1.2.5 Inspect all equipment and vehicles prior to use: Operator shall have valid certificate and/or

license

STOP work rigger: iany of the abovementioned requirements didnt meet the work willbe stopped

41.3. Exposure to 13.1 Constant supply and safe accessibility of cool drinking water. Wer

uunhygienic 13.2 Clean drinking water igloos frequently and seal it with marking the delivery time. Site supervisor

conditions of welfare | 1.3.3 srand tollets at all times. Provide full ime cleaner to maintain good cleanliness | Safety officer

area, with hand soap

134 the toilet areas and rest shelter.

135 Remove all food waste and other wastes on daily bass.

STOP work trigger ITany ofthe abovementioned requirements didn't meet, the work

14 Fire Hazards 1.4.1 Fire extinguisher and other firefighting equipment shall be available all times,

142 mntinuous or periodic gas testing as per the Issuer's assessment af the location of the

activity, Fire Watcher

| 143 is continuous, the certified gas tester from the operation shall be available at the work location

ime to ensure safe atmosphere.

144 ssigned for the hot works till completion of activity.

145 Grounding of equipment shall be done prior to start the activity.

‘STOP work trigger: Ifany ofthe abovementioned requirements did't meet, the work willbe stopped

15 Exposure to 1.5. Follow the Gl 2.709, Gas Testing Procedure

atmospheric 4552 Conduct comlnuous or period as testing as per the sve’ assesment of the cation of the

hazardous gas SAGas Tester

1.53 Thitis continuous, the cerifed gas tester from the operation stall be avallable atthe work action | Ste sparse

ime to ensure safe atmosphere. Operator

Only certified gas testers perform gas tests.

‘Tests for hydrogen sulfide (H2S), oxygen concentration, flammable gases, LEL and/or any

scenes, JOB SAFETY ANALYSIS RECORD SHEET Recon |

" S| serens

applicable toxic substances shall be performed before starting the activity and periodic:

SA requirements.

Hot work is not permitted ifthe a

shi

immediately evacuate to the assembly area

ich work permit issued, provide 2 Per

All safety officer and site supervision shal

(2S monitor to the WPR and one crew member

ein possession of the Personal H2S Monitor.

‘STOP work rigger: any ofthe abovementioned requirements dda’t meet, the work will be stopped

2 | Prectitpreparation | 2.1 Equipment 24.1 Alllifting activities shall be planned by competent crew wer

of Crawler Cranes breakdown due to 2.1.2 Lifting equipment shall be selected according to the approved lifting plan with enough rated ‘Task Supervisor

for Stripper Column poor maintenance capacity and Equipment shall be Inspected & certified by Competent authority. Operator

‘D69-C-0006) 2.1.3. Equipment to be inspected as per project requirements prior to deploy at site. Also provided with | Rigger?

erection a SA approved third party inspection sticker.

(Positioning of the 24.4 Pre-use inspection of equipment shall be done by the operator on daily basis

Hiei STOP work trigger: any ofthe abovementioned requirements didn't meet, the work will be stopped

2.24 Operator must be trained & holding valid license, certified, $A approved & fit for the job ‘Task Supervisor

signaling while 222 Make sure the boom is in down position; hook is in locked position & no os mnwhile moving | Operator/Rigger 1

moving the the crane, Flagman

equipment 22.3 Very slow movement to be maintained at site and Equipment to be provided with PWAS

22.4 SA Certified operator must only be assigned for the task

225 Removal of nearby structure power lines or provide barriers ifnecessary.

22.6 — Make sure that audible reverse horn is available and in working condition.

227 Availability of bunting pole to caution from overhead power cables

STOP work trigger: any ofthe abovementioned requirements dida't mest, the work

Ibe stopped

23 Lack of enough space | 2.3.1

fey personnel and to the whole crew prior

ler the boom swing radius of crane and ensure adequate distance preventing ct |

1g zone shall be properly barricaded and warning signs shall be posted, |

STOP work trigger: any ofthe abovementioned requirements dldat meet, the work will be topped

|

24 Unsuitable ground | 2.4.1 Monitoring the position of crane wer

condition forthe | 2.4.2 Identify the area of work. Ground condition is leveled, firm and compacted Task Supervisor

crane settlement | 2.4.3 Load testing of surface should be done, Operator/Rigger 1

ety fice

| ‘STOP work trigger: Ifany of the abovementioned requirements dda’ meet, the work willbe stopped Flagman

maar

casters Mil

JOB SAFETY ANALYSIS RECORD SHEET

—rvison

|serens

25 Unbalancing of 28. Verify that the crane i level before operating, Use leveling devices and ensure all outriggers are

equipment deployed properly.

2.5.2 Ensure the crane is on a stable surface and use outrigger pads or matting to distribute the weight

evenly.

25.3 Verify that the crane is level before operating, Use leveling devices and ensure all outriggers are

deployed properly

STOP work trigger: any ofthe abovementioned requirements didn't meet, the work wil be stopped

3. | Attaching Spreader | 3.1 Misapplied Rigging | 3.1.1 Ensure the load is securely attached and balanced before lifting, ‘Task Supervisor

Beam and Lifting Procedures 31.2 — Use appropriate lifting gears. Operator/Rigger 1

‘Tackle to the 3.1.3 Train workers on the correct use of rigging gear and ensure they are familiar with proper rigging

Stripper Column

procedures, Use only equipment that is suitable for the speci

‘STOP work trigge

load and task

any ofthe abovementioned requirements dida’t meet, the work willbe stopped.

3.2 Inadequate Rigging

Equipm

4) Improperly Rated

Gear

»)

or Damaged

Equipment

Always ensure that slings, hooks, and.

Inspect all rigging equipment for signs

equipment shall be removed from site

Work from the hook in the direction ofthe load

‘Work always under the supervision of a competent person

er rigging gear are properly rated and in good cond!

‘wear or damage before use. Damaged rigging/|

‘STOP work trigger: Ifany ofthe abovementioned requirements did't meet, the work willbe stopped

‘Task Supervisor

Operator

dimensions.

STOP work trigger: any ofthe abovementioned requirements didn’t meet, the work wil be stopped

3.3 Incorrect set-up of, Spreader heads shall point down Lift Supervi

| spreader bar. Shackles need to be used to connect the slings with the spreader bar Crane Operato

Itis strictly forbidden to attach slings, chains, chain blocks, etc. atthe intermediate beams ofthe | Rigser

spreader bar

3.34 Itis strictly forbidden to use the intermediate beams as anchor point for lifting

3.35 — Ensure the spreader bar is securely attached and properly aligned,

3.36 Ensure that the load is properly centered and balanced on the spreader bar to prevent shifting or

upping

STOP work rigger: Ifany ofthe abovementioned requirements dide’t meet. the work will estopped

34 Equipmentfailure | 3.41 shall be certified by third-party approved vendors and a sticker issued thats valid | Lif Supe

(spreader bar) Crane Operators

3.4.2 Conduct thorough pre-lift inspections ofthe spreader bar, rigging gear, and lifting equipment. | Rigger1

Check for signs of wear, damage, or defects Ofcer

3.43 Verify thatthe spreacler bar and lifting equipment are rated (SW.L) for the load weight and

Pestice

oro |

JOB SAFETY ANALYSIS RECORD SHEET

—Person

S|serens

Crawler Cranes

(tailing Tandem)

4.1 Nowork permits

4.2 Crane operator

ly unit

4.3 Unstable load

saa

412

413

aaa

42a

43a

432

Issuance of a work permit related to the activity.

shall be commenced without t

bbe available at the area where the activity is performed,

tthe working area atall times

PTW hazards shall be discussed with all workers

STOP work trigger: fany ofthe abovementioned requirements didn’t meet, the work will be stopped

Crane operators

be in possession of a medical fitness assessment as required by GL

‘STOP work trigger: any ofthe abovementioned requirements didn't mect, the work willbe stopped

Rigger shall determine the load’ center of gravity (COG) to ensure the slings are attached and

joned correctly

be stopped

wer

LifeSupervisor

Operators

1

44a

48 Overloading

asa

452

453

454

455

456

Define the swing radius prior to the lift to ensure that no obstacles are in the way when sleuthing.

‘STOP work rigger: Kany ofthe abovementioned requirements dda meet, the work

Ibe stopped

Do not exceed 85% of the rated capacity ofthe crane for any loading/unloading works and or as

per manufacturer standards under any circumstances

supervisor. This wil

Lifting supervi

Crane driver

1e considered the first hold point.

compares the measured loads with the weights used in the lifting study.

lows the evolution ofthe capacity and reports regularly

Load moment indicator and Detailed calculation of the COG and COG e

‘STOP work trigger: fany ofthe abovementioned requirements didn’t meet, the work’

4.6 Adverse weather

conditions,

461

462

463

464

Crane lifts shall not be performed in wind speeds exceeding 32 km/h unless otherwise specified

by the crane manufacturer as per CSM III-7.7.3.10.

Do not attempt any lifting operations on an extreme weather conditions e.g. heavy sandstorm

strong wind blows, thick fogs, Rains, Lighting etc.

‘Assess weather conditions before starting the

conditions that could impact stability or I

In the event that adverse weather conditions (sandstorm, strong wind blows, thick fogs, Rains,

Lighting, etc,) are experienced, the load will be lowered and placed back onte its holding

and avoid lifting operations in adverse weather

stands/supports as per the contingency plan.

Lift Supervisor

Crane Operators

Rigger 1/HSEO

ogee eseut Kil |

JOB SAFETY ANALYSIS RECORD SHEET ieee |

_ _ S|serens

T

465 stands/supportsat the |

ons allows for the placement thereof.

any ofthe abovementioned requirements didn’t meet, the work:

47 Lateral loading of | 4.7.1

crane ift sequences and the 4007 Crane shall follow the movements of the p! Life Supervisor

7507 Crane movement

ings and tackle at alltime during

474 Assistants shall be assigned to support the Lifting supervisor to function as spotters.

‘STOP worktriger: any of the abovementioned requirements dat meet, the work wll estopped

4.8 Cranes not 481 Crane operators shall hold a valid SA Certification for Tandem /Talling Lifting. Life Supervisor

hronized during | 482 Preclife discussion shall be conducted to ensure that all employees involved in the activity Grane Op

ing activity ‘understand their roles and responsibilities and to emphasize the fact that Rigger 1 will be the only | Rigger?

one to give signals to the operators.

483 Rigger I shall be positioned at a location that he is visible to both the crane operators during the

entire operation of lifting.

| 484 The lifting team shall be using radios as means of verbal communication in addition to hand

signals from Rigger 1.

STOP werkt any ofthe avementned requirements nt met he work wl stoped

| 49 Obscured 491 ed in the crane windows to allow for a 360-degree vist WPR

492 thout cracks and cleaned with water prior to the st Lift Supervisor

493 ‘the crane operator and in the event where the Crane Operators

es shill be supplied eg inrinsi safe two-way radios Niger

494 formed during a sandstorm or’ raining, safety Officer,

‘STOP work trigger: any ofthe abovementioned requirements dldn't meet, the work’

Ibe stopped

4.10 Touching/colliding | 410.1 4007 Crane shall boom up and lower the load at an angle of 3-4 degrees to ensure that the boom | Lift Supervisor

| of the booms during ends shall not touch/collide. Crane Operators |

lifting Rigger 1

‘STOP work trigger: any ofthe abovementioned requirements dt meet, the work willbe topped Safety omer |

4,11 Simultaneous aaa

Operations

weI/WeR

Lift Supervisor

Crane Operators

Rigger 1

ye issued for the D69 and B94 areas except for the:

4112 Contractor supervisor shall ensure the employees are outs

employees are in the rest shelters.

C

rpouneces Rial JOB SAFETY ANALYSIS RECORD SHEET sfieron

S\sarens

‘STOP work trigger: fany ofthe abovementioned requirements didn't meet, the work willbe stopped

|

|

442. Dual 412. Employee who holds both a SA Rigger and Crane certification shall not be allowed to actin both | we/wer

responsibilities capacities a the time during the lift Lift Supervisor

Crane Operators

cr: Many f the abovementioned requirements dda meet, the work willbe stopped Rieger

safety Oicer

443, Heat Stress Sufficient and cold drinking water shall be supplied and regularly refed. wet

Frequent rest cycles shall be implimented in accordance with the heat index chart wer

Operation to support with cool down vest for the employ. Lift Supervisor

Shaded rest shelters with mist fans shall be provided to allow employees to cool down. ‘Safety Officer

STOP work rg: Hany ofthe abovementioned requirements didn't meet the work wil be stopped

444 Plant Emergency | 4141 Allemployees shall receive plant safety orientation training and be in possession of proof of wet

ing recei

4142 _ Employees shall be made aware ofthe location ofthe nearest assembly points

4143. Allemployees shall immediately evacuate to a nearest and safest assembly pi Safety Ofcer

Employees,

STOP work rigger

5 | Crawler rane Pick | §.1 Unstable crane 5.11 Wooden mats sh Lift Supervisor

& Carry with 7507 movement during consistently safe Grane Operator |

Crawler Crane crawling. ‘stoP work trigger Rigger 1 |

before placement of - Safety Officer

Column,

travel speed | 5.2.1 Travel speed shall not exceed 0.18 km/h, Life Supervisor

‘STOP work trigger: any ofthe abovementioned requirements didn't meet, the work willbe stopped

Safety Officer

5.3 Swinging load 5.3.1 While movement of the crane isin progress, the load shall be controlled with a minimum oftwo | Lift Supervisor

taglines to prevent swinging. Crane Operator

| Rigger

| ‘STOP work trager: any ofthe abovementioned requirements dida’t meet the work willbe stopped Safety Oficer

6 | Installing 64 Pinch Points 6.1.2 Do not place your hands or any part of your body under or near the load where it can be pinched Supervisor

Equipment onto especially when handling the oad. Rigger 1

foundation with 6.4.3 Only the rigger, rigger assistants and mechanical team are allowed to directly touch and guide the | Saety Officer

threaded anchor load into posi

|

You might also like

- Job Safety Analysis for Structural ErectionNo ratings yetJob Safety Analysis for Structural Erection10 pages

- HS0602 Jsa 017 RTR, Gre, GRP Pipe FabricationNo ratings yetHS0602 Jsa 017 RTR, Gre, GRP Pipe Fabrication14 pages

- JSA-016 (REV-00) - Lifting Activity UGPNo ratings yetJSA-016 (REV-00) - Lifting Activity UGP10 pages

- 19162-HS0602-JSA-104 - Equipment (Mobile-Stationary) Maintenance, Services and Repair Works in Laydown Yard Rev. A-02!23!25No ratings yet19162-HS0602-JSA-104 - Equipment (Mobile-Stationary) Maintenance, Services and Repair Works in Laydown Yard Rev. A-02!23!257 pages

- Job Safety Analysis for Roof ReplacementNo ratings yetJob Safety Analysis for Roof Replacement4 pages

- Job Safety Analysis Record Sheet: Shaybah NGL Recovery Plant DepartmentNo ratings yetJob Safety Analysis Record Sheet: Shaybah NGL Recovery Plant Department22 pages

- 19162-HS0602-JSA-014 - UG RTR GRE GRP Pipe InstallationNo ratings yet19162-HS0602-JSA-014 - UG RTR GRE GRP Pipe Installation14 pages

- JHA for OXAGON Port Dredging Lift OperationsNo ratings yetJHA for OXAGON Port Dredging Lift Operations8 pages

- JSA For Lifting Shfting Installation of Electrical Breakers Disconnecting Switches Support Insulators Etc. Accessories - PDFNo ratings yetJSA For Lifting Shfting Installation of Electrical Breakers Disconnecting Switches Support Insulators Etc. Accessories - PDF10 pages

- Cable Pulling, Laying, Termination Conduct Installation and Tie in &testingNo ratings yetCable Pulling, Laying, Termination Conduct Installation and Tie in &testing16 pages

- Daily Safety Compliance Report For InterviewNo ratings yetDaily Safety Compliance Report For Interview7 pages

- Job Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)100% (2)Job Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)5 pages

- JSA For Fired Heaters Installation (1201-H-01 & 1701-H-01) .No ratings yetJSA For Fired Heaters Installation (1201-H-01 & 1701-H-01) .15 pages

- 19162-HS0602-JSA-012 - Installation of Electrical Instrument Control System and Telecommunication SystemNo ratings yet19162-HS0602-JSA-012 - Installation of Electrical Instrument Control System and Telecommunication System22 pages

- Safety Guidelines for Vessel Lifting OperationsNo ratings yetSafety Guidelines for Vessel Lifting Operations7 pages

- Job Safety Analysis for Material HandlingNo ratings yetJob Safety Analysis for Material Handling4 pages

- JFGP PKG.03 JSA STL STR 2023 11 Crane DismantlingNo ratings yetJFGP PKG.03 JSA STL STR 2023 11 Crane Dismantling19 pages

- SWP of Lifting, Shiftinng & Loading, Unloading and Line AlignmentNo ratings yetSWP of Lifting, Shiftinng & Loading, Unloading and Line Alignment16 pages

- JSA Mobile Crane Pipe Installation Tandem Lift100% (2)JSA Mobile Crane Pipe Installation Tandem Lift3 pages

- 19162-PI0303-H00-026 DPCU - General Camp and Office Safety Rules For Porta-CabinNo ratings yet19162-PI0303-H00-026 DPCU - General Camp and Office Safety Rules For Porta-Cabin11 pages

- 19162-HS0602-JSA-112 - Piping Internal Cleaning (Air Blowing-Water Flushing For Ground and Above Ground Piping) Activity Rev. A-B90-B53No ratings yet19162-HS0602-JSA-112 - Piping Internal Cleaning (Air Blowing-Water Flushing For Ground and Above Ground Piping) Activity Rev. A-B90-B5312 pages

- 19162-HS0602-JSA-103 - Piping Internal Cleaning (Air Blowing-Water Flushing For Ground and Above Ground Piping) Activity Laydown Rev. A-ApprovedNo ratings yet19162-HS0602-JSA-103 - Piping Internal Cleaning (Air Blowing-Water Flushing For Ground and Above Ground Piping) Activity Laydown Rev. A-Approved12 pages