Simple CFD Paper

Uploaded by

Ibrahim AllamSimple CFD Paper

Uploaded by

Ibrahim AllamCFD Analysis and Optimization of Three Phase Oil

Separator

Abhijith Joshy, Adithya B, Anfal M A, Anirudh Nambiar

Dept. of Mechanical Engineering, GEC Thrissur

Abstract: The multiphase separators are usually the primary up to 80-90% of the cross-sectional area of the vessel

and largest technical devices inoil manufacturing platforms, (Smith, 1987). The configuration of the internal devices

furthermore this primary separation step is a key element in the

is a factor that determines the oil removal efficiency

oil and gas industries in the downstream equipment, together

with compressors, are absolutely dependent on the efficient which is related to the minimum required volume of the

performance of those multiphase separators. This project is separators (Mostafaiyan et al., 2014). Therefore, in order

concerned with CFD simulation of three phase oil-separator to enhance the separation efficiency, gravity separators

consisting of all the internal parts. The VOF model was used to are equipped with different types of internals (Han et al.,

simulate the phase behaviour and fluid flow patterns. The 2017; Kharoua et al., 2013, Simmons et al., 2004).

project also evaluated conventional separation design

methodologies using detailed CFD simulations, and The phase separation process is always accomplished in

adjustments in the design. This project studies various models

three zones, in spite of the variety of design

of the separator and the best optimized model has been

obtained. The CFD model consisted of the momentum, configurations proposed for multiphase separators. In the

continuity and standard k-𝜀turbulence equations. Assumptions first zone, that is the primary separation zone, an inlet

and effective model configurations were used to establish diverter is used so that an abrupt change in flow

design criteria for new or modified separators. These criteria direction and velocity causes the largest liquid droplets to

will be combined with an algorithmic design method used in

impinge on the diverter and then drop by gravity. The

industry to specify a realistic optimum separator design. This

allows you to lay down an effective most suitable separator, a bulk of the liquid phase is separated from the gas phase,

beneficial approach become settled for estimation of the droplet in this zone. The next zone is the secondary separation

sizes used to calculate sensible separation velocities for zone. In the secondary separation zone, the liquid

numerous oil refinery conditions. In difference with classic droplets settle outof the gas stream due to gravity and

design techniques, the conclusions of the CFD simulation

gravity separation of fine droplets occurs as the vapor

implied enhancement in design. In this extra settling time is

critical for droplets to penetrate through the interfaces. As a and liquid phases flow through the main section of the

result, this research project does display the advantages that separator at relatively low velocities. Because of gravity

CFD analyses can provide in optimizing the design of new and buoyancy, the liquid collection section in the bottom

separators and fixing troubles with present design. half of separator provides the retention time required for

Key words: CFD; Oil Separator; Coalescer; Baffles; VOF entrained gas bubbles or other liquid droplets to join their

corresponding phases. While small accumulated liquid

INTRODUCTION droplets are again separated by gravity, gas flows above

The simultaneous flow of oil, water, and gas is of the liquid phase. The final zone is the coalescing media

practical significance for the oil and gas industry. Crude zone. It is designed for mist elimination in which very

oil is actually produced with water in the form of a fine droplets that could not be separated in the gravity

mixture of water droplets in oil and it is important to settling zone are separated by passing the gas stream

remove water from the oil for economic and operational through a mist eliminator. Vanes, wire mesh pad, or

reasons. Various physical treatment methods including coalescing plates may be used in this zone, to provide

pH adjustment, centrifugation, and gravitational settling very fine droplets to coalesce and form larger droplets

have been employed (Zolfaghari et al., 2016) which can which can be separated out of gas stream by gravity. By

improve phase separation by helping, collision, changing the inlet device of the separator, the opening

migration, and subsequent coalescence of droplets area and position of the perforated plate, the

(Xie et al., 2015). At the beginning of the separation performance of the separator can be improved

process, the three-phase separator is used for the (Kharoua et al., 2012a; Kharoua et al., 2012b; Lee et al.,

separation of oil, gas, and water in the petroleum 2008; Vilagines and Akhras, 2010).The single perforated

industry. In order to determine the capacity of plate installed in the separator was modeled as porous

subsequent equipment such as heat exchangers, liquid media of finite thickness with directional permeability,

extractors, and distillation columns,a proper sizing of the and the CFD results showed that the flow streamlines

oil separator is crucial (Laleh et al., 2012c). The three- developed quickly downstream of the perforated plate

phase oil separator has mainly two parts: a gas-liquid were short circuiting (Frankiewicz and Lee, 2002). It

section and an oil- water section. A large equipment is was recommended that the fluids could choose the path

used in the gravity settling approach for separation, which of least resistance for travelling of least resistance for

is not convenient, practical, and economical for offshore travellingand could anticipate the outlet zone. . As a result

conditions. The liquid level can vary from 0.20-0.27 m of this behaviour, the result was a significant loss in the

Electronic copy available at: https://ssrn.com/abstract=4294436

curved end plate and 2 baffles. The developed CFD

the effective liquid retention time. According to the CFD

model using coalescer and demister was used to run

studies, a second perforated plate just upstream of the

Fluent analysis.

outlet nozzle was required to prevent this problem.

Practical considerations such as location, configuration MODELLING

of the inlet nozzle, position of the weir and water outlet

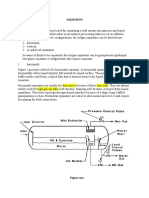

A three phase oil-water-gas separator has a primary

nozzle, and the vessel dimensions were taken into

separation zone, including a feed inlet for liquid-gas

account in determining the position of the perforated

separation, a zone where water-oil separation takes place

plate. It was emphasized that a fully symmetric setting

by gravitational separation with the help of coalescer,

of the internal baffles was not effective. A dual mist

and a mist elimination zone along with a gas outlet as

eliminator system composed of a vane-type demister at a

shown in Figure 1. The cylindrical gravity settling vessel

lower level and a wire mesh pad at higher level with a gap

is 2.1 m long, 0.6 m in diameter and is horizontal in

of 0.15 to 0.30 m between them is usually used for

geometry. There are three outlets and one inlet. The

separators suffering from liquid carryover while

separator has various internals such as coalescer, weir

processing foamy crude oils, or glycols, amines, and

plate, perforated plate, and demister. In the primary

similar materials (with high foaming tendency) (Lyons

separation zone, the mixture with oil, water, and air

and Plisga, 2005). The GPSA Engineering Data Book

was injected at the top of the separator,and the liquid

(1998) states while horizontal separators are most

and gas phases were separated. In order to remove the

efficient for high-capacity operations, where large

liquid droplets containedin the gas flow, the demister was

amounts of solution of gas are in the liquid phase, vertical

placed at the gas outlet. The liquid phase drops down to

separators are usually used if the gas to liquid ratio is

the bottom. To maintain a good fluid flow distribution

high or total gas volumes are low. To remove smaller

and to moderate liquid sloshing, the perforated plate was

droplets from the gas phase, mist eliminators are usually

used. Oil-droplets were captured, coalesced, and rose to

required (Smith, 1987).

the surface (American Chemical Society [ACS], 2014)

The efficiency can be increased to around 100% by in the corrugated plate-type coalescer. The height and

installing mist eliminators as 95% of droplets entrained length of the semi cylindrical coalescer used was 0.4 m

in the gas stream can be separated in economically- and 0.5 m respectively (PETROL 5181-Journal of

sized separators without coalescing media (Walas, 1990; Petroleum Science and Engineering). The weir plate

Sinnott, 1997; Arnold and Stewart, 2008). To modify used was 0.35 min height. The water outlet was located

the design and to improve the operation of process between the weir plate and the coalescer. Oil flowing over

equipment, Computational fluid dynamics (CFD) has the weir plate was discharged through the oil outlet. The

been used (Laleh et al., 2012c; Pham et al., 2017). Two

pressure at which the separator was operated was,10 bar

CFD methods have been used to simulate a three Phase

and at room temperature

separator. Eulerian and Volume of fluid (VOF) method.

The VOF method is based on the assumption that two .

phases do not interpenetrate (Ngo et al.,2018), while

in the Eulerian method the two phases are treated as

interpenetrating continuaand also solving continuum and

momentum equation for each phase (Kharoua et al.,

2013; Laleh et al., 2012a; Lim, 2013; Pham et al., 2015b).

Liang et al. (2013) examined the effect of the flow rate,

gas ratio, and water ratio on the separation efficiency

using a VOF CFD model with a k-ε turbulence equation

(Liang et al., 2013) for a horizontal three phase

separator. Fewel and Kean (1992) emphasised that CFD

analysis of separator internals is very similar to a

physical test because laboratory tests performed on

Figure 1: Geometric model of three phase oil separator

various arrangements usually match CFD results

remarkably well. 9 different models with internals of Table 1:Physical properties of air, water and oil

different configurations have been considered in the is

paper. Same boundary condition was used in carrying out Compon Phase Densi Viscosity Surface

the simulation on each model. The flow parameters of the ents ty(kg/ (Pa-s) Tension(N/

separator internals were also observed. CFD simulation 𝑚 3) m)

was conducted for inspecting separation efficiency of the Air Gas 1.1 1.8*10–5 -

separator with only baffles by Tathagata Acharya, Lucio Water Liquid 980 2.42*10–3 73*10–3

Casimiro et al. (2019). Primary phase was oil with Oil Liquid 831 7.21*10–3 27.2*10–3

volume fraction of 0.652 in the crude oil mixture.

The model used by Tathagata Acharya,Lucio Casimiro

was not sufficient to provide enough separation It was assumed that, the perforated plate, demister, and

efficiency for validating the CFD simulation model. So, the coalescer were porous media offinite thickness and

CFD simulation model for separator was developed using directional permeability (Frankiewicz and Lee, 2002).

Electronic copy available at: https://ssrn.com/abstract=4294436

To capture mist,the demister was composed of fibro

matrix. Because of high permeability, the porous

resistance of the perforated plate was ignored, but due to

high velocity, the inertial resistance (Cr.x) was

considered in the x- direction. Loss coefficient was used

to obtain the inertial resistance (Cr.x) (Weber et al.,

2000). The inertial resistance (Cr.x) was assumed to be

of large value in the y or z direction, which means that

there is no flow in the two directions. Inthe CFD model,

the porous and inertial resistances were used (see table

2(Le, T.T., Ngo, S.I., Lim, Y.-I., Park, C.-K., Lee, B.-D,

Three-phase Eulerian computational fluid dynamics of

Figure 2: Meshed Model

air–water–oil separator under off-shore operation,

Journal of Petroleum Science and Engineering (2018))). GOVERNING EQUATIONS

The inertial resistance in the y- or z-directions was

assumed to be a large value, which means that there is Continuity equation

almost no flow in the two directions. The porous and 𝜕 𝜕

inertial resistances were used in theCFD model (see (𝜌𝛼) + (𝛼𝜌𝑢) + 𝜕⁄𝜕𝑦 (𝛼𝜌𝑣) = 0

Table 2). 𝜕𝑡 𝜕𝑥

Table 2: Material properties Momentum equation

𝜕 𝜕 𝜕

(𝛼𝜌𝑢), +𝑢 (𝑎𝜌𝑢) + 𝑣 (𝛼𝜌𝑢)

𝜕𝑡 𝜕𝑥 𝜕𝑦

Material Coalescer Demister Perforated 𝜕𝑃 𝜕 𝜕𝑢 𝜕 𝜕𝑢

plate = −𝛼 + 𝛼𝜌𝑔𝑥 + (𝛼𝜇 ) + (𝛼𝜇 )

𝜕𝑥 𝜕𝑥 𝜕𝑥 𝜕𝑦 𝜕𝑦

𝜕 𝜕 𝜕

(𝛼𝜌𝑣), +𝑢 (𝑎𝜌𝑣) + 𝑣 (𝛼𝜌𝑣)

𝜕𝑡 𝜕𝑥 𝜕𝑦

Porosity (𝜀P) 0.954 0.980 0.25 𝜕𝑃 𝜕 𝜕𝑣 𝜕 𝜕𝑣

= −𝛼 + 𝛼𝜌𝑔𝑦 + (𝛼𝜇 ) + (𝛼𝜇 )

𝜕𝑦 𝜕𝑥 𝜕𝑥 𝜕𝑦 𝜕𝑦

Porous

resistance 0 For the three-phase mixture, the momentum and

continuity equations were solved. The concentration

(1/𝑚2) 3.76*105 2.57*106

1 fields of dispersed phase were obtained by tracking their

( ) volume fractionand relative motions of the dispersed

Kx

phase were approximated by algebraic equations. It is

Porous 0 considered that, the Reynolds number of the liquid phase

at the inlet was up to 58,000. The flow in the separator

resistance(1/𝑚2) 0 2.57*106

1 also involved in significant

( ) turbulence under the operating conditions. The k-ε model

ky

was implemented to account for the turbulent effects. The

Inertial 0 0 turbulence model was applied to all the three phases.

The oil phase was set as the primary phase because

resistance (1/m) 1.03*104

(𝑐rx) it is the phase, with highest mass and volume fraction

among the three phases at the inlet. The gas and water

were the secondary phases ( or dispersed phases),

Inertial 0 0 which were assumed to form droplets or bubbles within

resistance (1/m) 1*106 the continuous phase. For the three-phase mixture, the

(𝑐ry) momentum and continuity equations were solved. The

Because of high flow velocity, a high density mesh was concentration fields of the dispersed phase were obtained

applied to one inlet and the three outlets. A perforated by tracking their volume fraction and the relative

plate with a thickness of 3 mm was used to concentrate the motions of the dispersed phase were approximated by

mesh on it. Owing to the porous media assumption, the algebraic equations. It is considered that, the Reynolds

fluid flows of the coalescer and the demister were not number of the liquid phase at the inlet was up to 58,000.

sensitive. At the interfaces of the gas and the liquid, a The flow in the separator also involved significant

relatively high mesh density was used. The domain of the turbulence under the operating conditions. The k-ε model

gas phase had a relatively low mesh density. To attain was implemented to account for the turbulent effects. The

skewness of 0, element size was made to 0.005 m. With turbulence model was applied to all the three phases. The

default size and angle with medium smoothing, capture oil phase was set as the primary because it is the phase,

curvature was applied. with highest mass and volume fraction among the three

phases at the inlet. The gasand water were the secondary

phases (or dispersed phases), which were assumed to form

Electronic copy available at: https://ssrn.com/abstract=4294436

droplets or bubbles within the continuous phase. Using boundaries, volume fractions and outlet velocities

the standard k-ɛ turbulence equation and Reynolds- were set. 10 bar pressure was fixed as the outlet static

averaged multiphase VOF(Volume of fraction) CFD pressure (or 0 bar in gauge pressure). To the wall, the

approach, the air–water–oil separator was modelled(Lim no-slip condition was applied. At P=10 bar and

et al., 2017).VOF is used if there are more than two T=20℃, the separator was initially filled with air,

immersible fluids, where interface position is of water, and oil where the initial liquid level of the water

importance and is actually a type of surface tracking was 0.37 m. The gas phase had 100% air. When setting

technique. It also has a set of momentum equations, shared the flow regime in the inlet and outlet nozzles, the

by all fluids and volume fraction of each of the fluid in turbulence intensity and hydraulic diameter of the

each computational cell is tracked. nozzles were determined.

The standard k − ε (Launder and Spalding, 1972) model The flow regime of the three-phase horizontal

was selected for a wide range of turbulent flows in separator is dominantly stratified flow (Taitel et al.,

industrial flow simulations and also for its robustness, 1995) of diluted oil, released gas and it produced water

economy and accuracy. After importing the mesh file and in longitudinal direction, which was accompanied by

making the modification to it, the necessary material vertical settling and floating motions of fluids which

properties for various phases were input. Mesh results in the separation of the phase. Therefore, actual

modification consisted of convertingthe highly skewed flow is a combination of stratified and dispersed flow.

grids to polyhedral grids which resulted in a minor Table 4: Boundary conditions

reduction in the number of cells.

Inlet BC Phase Mass Volume Pressure(

Table 3: Standard k-ɛ turbulence model flow fraction P)

rate(m,kg (α) &Temper

Parameters Value or reference

/s) ature(T)

Turbulence intensity 5 (Secondary) Air 0.001829 0.1852 P=10 bar,

of inlet velocities (%) T=20℃

Turbulent Prandtl 1 (Secondary) Water 2.1 0.1630 P=10 bar,

number for k T=20℃

Turbulent Prandtl 1.3 (Primary) Oil 4.2 0.6518 P=10 bar,

number for ε T=20℃

Outlet BC Air - - P(gauge)=

Dispersion Prandtl 0.75

0KPa

number

Turbulence energy 1.44,1.92 The transient VOF CFD model was solved using a

dissipation commercial code, ANSYS Fluent 21.0 (ANSYS Inc.,

coefficients USA). As explained by Anderson (1995), the

Turbulent viscosity 0.09 incompressible Navier Stokes equations cannot be

coefficient solved explicitly because of some stability issues and

solution techniques for the incompressible equations

are usually different from those used for solution of the

The plate-type coalescer is assumed to be the porous Navier-Stokes equations for compressible flow. To

medium having a uniform porosity instead of the real overcome this difficulty, the pressure correction

geometry. The porous media model does not represent the approach has been proposed. With good success, this

fundamental phenomena such as capturing, aggregation, accepted and widely used approach has been applied to

and rising of droplets on the plate. Since the coalescer, both compressible and incompressible flows (Anderson,

demister, and the perforated plate are considered as 1995). The phase-coupled SIMPLE (Semi-Implicit

porous media, the number of computational cells is Method for Pressure-Linked Equations) method was

reduced. selected for the pressure–velocity coupling. QUICK

BOUNDARY CONDITIONS AND CFD SIMULATION (Quadratic Upwind Interpolation for Convective

MODEL Kinetics) schemes andsecond-order upwind were used

for the spatial discretization of the momentum and

In table 4, the inlet and outlet boundary conditions for volume fraction, respectively. For the transient

each phase is represented. The volumefraction (α) and simulation the time was taken as 0.001 sec and the

the inlet mass flow rates (m) were given at P= 10 bar maximum number of iterations was limited to 20 at

and T=20℃. In order to set theboundary conditions for each time step. Having set all the CFD parameters for

inlet, the velocity and volume fractions of phases were the redesigned separator, approximately 10,000

set. The oil phase wasset as the primary phase because iterations are required for continuous phase solution

it had the highest mass and volume fraction among the convergence. A personal-computer (PC) run time of

three phases at the inlet. The gas and water phases are approximately 36 hours is required per solution of the

the secondary phases or dispersed phases, which were continuous phases and each iteration takes

assumed to form droplets within the continuous phase. approximately 30 seconds. For simulation of interactions

between the dispersed droplets and continuous phases,

For the gas-outlet boundary, volume fractions and a further PC run time of approximately 4 hours is also

outlet pressures were set while for the liquid-outlet required. To set the position of interface between

Electronic copy available at: https://ssrn.com/abstract=4294436

phases, the volume fractions of phases above and MODEL 2 (With curved deflector)

below the assumed interface planes were set to the

reasonable values by the Patching tool of Fluent.

The iterations need to be stopped regularly again, and if

necessary, by patching the volumefractions of phases, the

position of interfaces should be checked and corrected.

RESULTS AND DISCUSSION

Effect of internal elements

(a)

CFD study on different models and effect of internal

elements such as baffles,coalescer, demister, deflector are

studied through simulation.

Deflector shape

For studying the effect of deflector shape in separating

efficiency, two models were selected. One model was

designed using a curved plate deflector and the other

using a flat one. Both models had weir plate designated

(b)

in base geometry and consisted of single baffle. For

boththe models, CFD simulation was carried out applying

the same boundary conditions and operating parameters.

Contours of volume fraction of oil, air, and turbulent

kinetic energywere calculated

MODEL 1 (With flat deflector)

(c)

Figure 4. (a) Volume fraction of oil (b) Volume

fraction of air (c) Turbulent kineticenergy

The conclusion that can be obtained from the plots is that

significant turbulence occurs at the curved portion

compared to the flat portion. Air-oil interface is higher

in model 2 compared to model 1 which leading to

significance of deflector in separator efficiency. Hence

(a) flat plate deflector can be preferred over curved one for

greater efficiency.

Number of baffles

The distribution baffles generally improve the quality of

liquid flow distribution in the vessel, break the large scale

circulations into smaller ones, and reduce the short-circuiting

flow streams. This was shown in the recent CFD-based study

by Lu et al. (2007). Hence the flat plate deflector gives

greater efficiency compared to the curved one.

MODEL 3 (Two baffles)

(b)

Figure 5: Volume fraction of oil

(c)

Figure 3. (a) Volume fraction of oil (b) Volume

fraction of air (c) Turbulent kinetic energy

Electronic copy available at: https://ssrn.com/abstract=4294436

MODEL 4 (3 Baffles) outlets in latter design conclude this fact. There is normal

distribution of mixture at coalescing zone while

comparing the velocity distribution. It ensures the

smoother running of equipment and reduces

maintenance requirements.

Optimized models

Based on conclusions from above, three optimized models

were created

Figure 6: Volume fraction of oil Model Internal elements

Results concluded that the efficiency of the separator

can be increased using baffles. Tracesof water can be

seen at oil outlet of model 3, whereas 100% oil at oil One baffle,

outlet of model 4. It canbe expected that the baffles will Model 6 coalescer,

improve the quality of liquid flow distribution in the demister, flat

vessel and increase the separation efficiency as concluded platedeflector

by Lu et al. (2007) in their recent CFD- based study. Three baffle,

Model 7 coalescer,

Effect of coalescer

demister, flat

The droplet coalescence and breakup were again modelled, platedeflector

and the simulation results confirmed that droplet Three baffle,

coalescence at a rate of less than 1% was not a common Model 8 coalescer, demister,

phenomenon. Based on the simulation case study results, a flat plate deflector,

general conclusion for droplet coalescence could not be additional outlet at oil

reached. However, droplet breakdown was a common outlet for water

phenomenon and did show significant variations to removal

operating conditions. Highest velocities usually

intensified the number of droplet breakups in horizontal

separators, based on the simulation results

Model 5 (With coalescer) MODEL 6

(a) (a)

(b)

Figure 7. (a)Volume fraction of oil

(b)Velocity distribution

The Coalescer is a oil-water separator that uses (b)

coalescing material to remove up to 95% of all floating

Figure.8 (a)Volume fraction of oil (b)Turbulent

oil from the water's surface. The Coalescer is also very

kineticenergy v/s position

helpful in removing sludge, scum, and dirt particles

which are often found floating on coolant or degrease

solution surfaces. From volume fraction of oil plot, it is

clear that efficiency is improved compared to previous

model. Significant rise of oil & water level at respective

Electronic copy available at: https://ssrn.com/abstract=4294436

Model 7 Comparing the three optimized models, it can be

concluded that turbulence distribution is fairin case of

model 7 & 8. Turbulence kinetic energy (TKE) is one of

the most crucial variables in micrometeorology. It has a

direct bearing on the movement of momentum, heat, and

moisture across the boundary layer .Higher turbulent

energy creates mixed flow which causes vibration to

walls resulting in crack. Oil and air interface is higher in

7&8 compared to model 6 which results in greater

(a) separation. Influence of baffles can be seen clearly from

the plot of turbulent kinetic energy v/s position. More

separation of water takes place in models 7 &8, although

oil separation takes place in three models . Exclusively

considering Model 8,it have two oil outlets-vertical &

horizontal where pure oil can be obtained from horizontal

outlet. Since there is a chance of water being

accumulated atthe oil outlet, model 8 can be applied for

mixtures containing significant amount of water.

CONCLUSION

(b) The performance of the separator was enhanced when

modifications as a result of the CFD simulation of the

Figure 9 (a)Volume fraction of oil (b)Turbulent research project were made. The redesigned separator

kineticenergy v/s position. dealt satisfactorilywith 1988 production conditions, in

that the total separation efficiency was as high as 99.1%

Model 8

(a bit higher than the original separator efficiency) with

its components of 100% and 98.7% as separation

efficiencies for oil and water droplets, respectively. There

would be no droplet carry-over in the gas phase outlet,

i.e. all the injected droplets exited in either the oil outlet

or the water outlet as was the case with the original

separator. The distribution of baffles had a minor effect

on the separation efficiency. This was pointed out by

the results generated forthe original separator and its

modified versions. They are helpful in improving flow

distribution quality, however, poor designs cannot be

(a) overcome by installing distributing baffles. Only VOF

approach was used in the CFD simulation of the three-

phase separator, based on the obtained results for the

CFD simulation for the three-phase separator. The

developed model did provide high-quality details of fluid

flow profiles, leading to a very realistic overall picture of

phase separation in all zones of the separator compared

to the original study of Hansen et al. (1993). An

understanding of both the microscopic and macroscopic

features of the three-phase separation phenomenon was

(b) obtained by the realistic CFD simulation of the three-

phase separator. The water outlet as was the case with the

original separator. The distribution of baffles had a minor

effect on the separation efficiency. This was pointed

out by the results generated forthe original separator

and its modified versions. They are helpful in improving

flow distribution quality, however, poor designs cannot

be overcome by installing distributing baffles. Only VOF

approach was used in the CFD simulation of the three-

phase separator, based on the obtained results for the

CFD simulation for the three-phase separator. The

(c) developed model did provide high-quality details of fluid

Figure.10 (a)Volume fraction of oil (b)Volume flow profiles, leading to a very realistic overall picture of

fraction of water (c) Turbulent kinetic energy v/s phase separation in all zones of the separator compared

position to the original study of Hansen et al. (1993). An

Electronic copy available at: https://ssrn.com/abstract=4294436

understanding of both the microscopic and macroscopic [4] Fluent, A.N.S.Y.S,2013,ANSYS fluent theory guide 15.0

features of the three-phase separation phenomenon was [5] Gas Processors Suppliers Association, GPSA Engineering Data

obtained by the realistic CFD simulation of the three- Book, 11th Edition, Vol. 1, Gas Processors Association, 1998.

phase separator.

[6] Gerunda, A., “How to Size Liquid-Vapor Separators”, Chemical

Engineering, May 4, 1981, 81-84.

Nomenclature

[7] Ghaffarkhah, A., Shahrabi, M., Moraveji, M., and Eslami, H.,

Cr=inertial resistance factor (m-1) 2017, “Application of CFD for designing conventional three phase

oilfield separator.” Egyptian Journal of Petroleum, 26 (2), pp. 413-420.

G= gravitational acceleration (m/𝑠2))

[8] Grødal, E. O., and Realff, M. J., 1999, “Optimal Design of Two-

𝐼t = turbulence intensity (%) and Three-Phase Separators: A Mathematical Programming

Formulation,” Society of Petroleum Engineering, pp. 56645, 1 – 16.

K= turbulence kinetic energy (J/kg or 𝑚2/𝑠2)K=

[9] Hallanger, A., Soenstaboe, F., Knutsen, T. 1996. A Simulation

permeability (𝑚2) Model for Three-Phase Gravity Separators. Paper SPE 36644

presented at the SPE Annual Technical Conference and Exhibition,

L =length of separator (m) Denver, Colorado, 6-9 October.

m =inlet mass flow rate (kg/s)P= pressure (Pa) [10] Hinze, J.O., “Fundamentals of the Hydrodynamic Mechanism of

Splitting in Dispersion Processes”, AIChE J., 1(3), 1955, 289-295.

𝑃exit= exit pressure (Pa)

[11] Hooper, W.B. 1997. Decantation. In Handbook of Separation

𝑃gage =gage pressure (Pa) Techniques for Chemical Engineers, third edition, ed. P.A.

Schweitzer, Part 1, Section 1.11 519–529. New York: McGraw-Hill.

Re =Reynolds numbert =flow time (s or min) [12] Kharoua, N., Khezzar, L., Saadawi, H., 2013. CFD modeling of

a horizontal three- phase separator: A population balance approach.

T =temperature or period (℃)

Am. J. Fluid Dyn. 3(4), 101-118.

𝑢=velocity in x direction [13]Kim, H., Burgess, D.J., “Prediction of Interfacial Tension between

Oil Mixtures and Water”, J. Collide Interface Sci., 241, 2001, 509-

𝑣=velocity in y direction 513.

𝑥=longitudinal direction (m) [14]Kokal, S.L., 2005. Crude oil emulsions: A state-of-the-art

review. SPE Product. Facilit. 20(1), 5-13. Laleh, A.P., Svrcek, W.Y.,

𝑦=gravitational direction (m) Monnery, W., 2012a. Computational fluid dynamics-based study of an

oilfield separator-Part I: A realistic simulation. SPE- 161036-PA 1(6),

𝑧=transversal direction (m) 57-68.

Greek letters [15] Kolodzie, P.A., Van Winkle, M., “Discharge Coefficients through

Perforated Plates”, AIChE J., 3(3), 1957, 305-312.

α= volume fraction

[16] Lakehal, D., Vilagines, R., Narayanan, C., Rahman, A. 2009.

ε= dissipation rate of k (𝑚2/𝑠3) A Simplified Approach for the Simulation of Water-In-Oil

µ =viscosity (kg/m/s)ρ =density (kg/𝑚3) Emulsions in Gravity Separators. Paper presented at the Fourth

International Conference on Thermal Engineering Theory and

σ =surface tension (N/m) Applications, Abu Dhabi, 12-14, January.

[17] Laleh, A.P., Svrcek, W.Y., Monnery, W.D., 2012b. Design and

α - Volume fraction of first phase in the two phase mixture CFD studies of multiphase separators-a review. Can. J. Chem. Eng.

90(6), 1547-1561

β - Volume fraction of second phase in the two phase

[18] Li, J., Gu, Y., 2005. Coalescence of oil-in-water emulsions in

mixture fibrous and granular beds. Sep. Purif. Technol. 42(1), 1-13.

[19] Li, Y., Gong, H., Dong, M., Liu, Y., 2016. Separation of water-

ρ - Density (kg/𝑚3) in-heavy oil emulsions using porous particles in a coalescence

column. Sep. Purif. Technol. 166, 148-156.

µ - Dynamic viscosity, (Pa-s)

[20] Lu, Y., Lee, J.M., Phelps, D., and Chase, R. 2007. Effect of

u - Fluid velocity in horizontal direction (m/s) Internal Baffles on Volumetric Utilization of an FWKO--A CFD

Evaluation. Paper SPE 109944 presented at the SPE Annual

ν - Fluid velocity in vertical direction (m/s) Technical Conference and Exhibition, Anaheim, California

g - Acceleration due to gravity (m/𝑠2) [21] Smith, H. V., 1987, "Oil and Gas Separators," Petroleum

Engineering Handbook, Society of Petroleum Engineering,

P- Pressure (Pa) Richardson, TX.

REFERENCES

[1] Abernathy, M.W.N., “Gravity Settlers, Design”, in “Unit Operation

Handbook”, J.J.McKetta (Ed.), Vol. 2, Marcel Dekker, 1993.

[2] ACS, 2014. Liquid-Liquid Coalsescer Design Manual. ACS Industries,

Houston.

[3] El-Dessouky, H.T., Alatiqi, I.M., Ettouney, H.M., Al-Deffeeri, N.S.,

“Performance of Wire Mesh Mist Eliminator”, Chemical Engineering and

Processing, 39, 2000, 129- 139.

Electronic copy available at: https://ssrn.com/abstract=4294436

You might also like

- Three-Phase Separator Design for Crude OilNo ratings yetThree-Phase Separator Design for Crude Oil11 pages

- Gas/Liquid Separator Performance InsightsNo ratings yetGas/Liquid Separator Performance Insights10 pages

- 3 Phase Separators ( Separators') : Design Philosophy: 4 Sections of A SeparatorNo ratings yet3 Phase Separators ( Separators') : Design Philosophy: 4 Sections of A Separator2 pages

- Coshgun Humbatov 630.19E - Oil SeparatorsNo ratings yetCoshgun Humbatov 630.19E - Oil Separators19 pages

- Chapter 3 Two-Phase Oil and Gas SeparationNo ratings yetChapter 3 Two-Phase Oil and Gas Separation115 pages

- Gas Liquid Separators Quantifying Separation Performance Part 2 SPE MEBNo ratings yetGas Liquid Separators Quantifying Separation Performance Part 2 SPE MEB13 pages

- Chapter 4 (A) General Theory & Two Phase Separators100% (3)Chapter 4 (A) General Theory & Two Phase Separators139 pages

- Seperation Process - Two Phase and Three Phase100% (1)Seperation Process - Two Phase and Three Phase139 pages

- Three Phase Separator - Liquid InternalsNo ratings yetThree Phase Separator - Liquid Internals7 pages

- Separator Classification and PrinciplesNo ratings yetSeparator Classification and Principles35 pages

- Gas/Liquid Separator Performance AnalysisNo ratings yetGas/Liquid Separator Performance Analysis10 pages

- Gas/Liquids Separators Performance InsightsNo ratings yetGas/Liquids Separators Performance Insights14 pages

- Module 4 - Phase Separation Theory and Separator Design - LectNo ratings yetModule 4 - Phase Separation Theory and Separator Design - Lect23 pages

- Oil and Gas Separation Process OverviewNo ratings yetOil and Gas Separation Process Overview50 pages

- SPE 101010 Crude Stabilizer Using Localized Underpressure GenerationNo ratings yetSPE 101010 Crude Stabilizer Using Localized Underpressure Generation13 pages

- Oil and Gas Separation System and Process: Unit-4No ratings yetOil and Gas Separation System and Process: Unit-418 pages

- Understanding Linear Momentum ConservationNo ratings yetUnderstanding Linear Momentum Conservation30 pages

- Question Bank Problems Grade 11 Physics T.3No ratings yetQuestion Bank Problems Grade 11 Physics T.33 pages

- Atomic Absorption Spectroscopy (AAS) : in This LectureNo ratings yetAtomic Absorption Spectroscopy (AAS) : in This Lecture11 pages

- Electrical Resistance Calculations and ConceptsNo ratings yetElectrical Resistance Calculations and Concepts2 pages

- 13-04-2025 - SR - Super60, Elite, Target & LIIT BT'S - Jee-Adv (2024-P1) - Second Year Syllabus - GTA-26 - Q.papeRNo ratings yet13-04-2025 - SR - Super60, Elite, Target & LIIT BT'S - Jee-Adv (2024-P1) - Second Year Syllabus - GTA-26 - Q.papeR22 pages

- Understanding Physical Quantities and UnitsNo ratings yetUnderstanding Physical Quantities and Units37 pages

- (F) SR Elite - SET - 2 - NEET - 2026 Teaching ScheduleNo ratings yet(F) SR Elite - SET - 2 - NEET - 2026 Teaching Schedule12 pages

- Chapter 1 Atomic Structure and Periodicity-2017No ratings yetChapter 1 Atomic Structure and Periodicity-201737 pages

- CHM 406 Lecture Electronic Spec1-2025 - 050256No ratings yetCHM 406 Lecture Electronic Spec1-2025 - 05025620 pages

- Thermalization of Local Observables in the $$/alpha $$ α -FPUT ChainNo ratings yetThermalization of Local Observables in the $$/alpha $$ α -FPUT Chain23 pages