Professional Documents

Culture Documents

Application Newsletter Molten Sulfur

Uploaded by

shantanusamajdarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Application Newsletter Molten Sulfur

Uploaded by

shantanusamajdarCopyright:

Available Formats

Molten Sulfur Pumps

Elemental sulfur is an amorphous yellow solid used as a raw material for manufacture of sulfur dioxide, sulfuric acid, and related products. It is also used to formulate a sulfur cement for some corrosive services. It occurs in nature both in the free state and as a sulfide ores of iron, zinc, and copper/iron ore. Although about 90% of sulfur production is used to manufacture sulfuric acid, it also finds process applications in the rubber, chemical, paper, and pharmaceutical industries. The two main processes are the Frasch process, in which sulfur is produced by mining with hot water (320 degF) down a concentric pipe arrangement to melt the sulfur, which is then forced up to the surface by hydraulic pressure. The other process is the by-product sulfur that is recovered from gas, petroleum, coal, and sulfide ores. Pump Model Horizontal ANSI pumps have been used for this service but the success rate has been limited because of problems keeping the Sulfur in the stuffing box in the molten state. Vertical sump pumps with steam jacketing or heat tracing are ideally suited for this difficult application. Taber Series 1000 is the pump of choice. Speeds of 1150, 1750, or 3600 rpm are available depending upon the service conditions. Remember that a slower speed pump can be more competitive in this service because of the lesser intermediate bearings. The Taber has hundreds of installations on this demanding service and a wealth of experience and success that we should leverage. Pump Selection and Application Materials of Construction: Wetted end parts constructed of ductile iron with steel support column and discharge pipe, along with a cold rolled steel pump shaft. Bearing Materials: Graphitar and Carbon Graphite bearings up to 500degF. Also recommend ductile iron or Ni-resist #2 bearings. All compatible with the cold rolled steel shaft. Bearings are lubricated by the product. Steam Jacketed Support Column and Discharge Pipe: See attached drawing. Steam jacketed support column and discharge pipe below as well as above the support plate is a Must!! Steam inlet and outlet provided above the support plate. Stuffing Box and Sealing: A packed stuffing box is highly recommended to contain the fumes and keep the heat away from the motor. Grease lube is used to seal the product from moisture laden air. The packing type that we recommend is either a grease lubricated Graphite or a non lubricated Grafoil. Couplings: Flexible all metal non-spacer couplings, such as Falk Steelflex T20 or Thomas DBZ are preferred because of the relatively high service temperature. Motors: Standard TEFC or TEFC Chem Duty are generally used. Any enclosure can be considered. Make sure that the motor insulation is sufficient for heat resistance. We recommend F or H insulation. Make sure that you account for the high specific gravity.

Application Considerations 95% of all the sulfur handling in North America is in the molten state Most customers are using sulfur in its molten state so it is more economical to receive sulfur in the molten form and pump it directly into a storage tank or pit Sulfur solidifies at about 238degF, and become very viscous above 320degF. The successful handling of molten sulfur in the molten state depends upon restricting the temperature to 260-300degF For economical reasons, most pipelines and pumps handling sulfur are heated with steam at pressures between 35 and 85 psig. Either steam jacketing or steam tracing is used. Sulfur is a very poor conductor of heat, and is very difficult to reheat in piping once the temperature has dropped below 240 deg F. So temperature above that must be maintained. The most common material of construction for pipe, valves and pumps in sulfur service is steel or ductile iron. Pumps moving molten sulfur must be steam jacketed. Also, as a result of the high specific gravity (1.78), larger motors are required. Large quantities of molten sulfur are stored in tanks, which are usually made of steel. For small quantities, pits are used which are generally rectangular. A steam jacketed sump pump should pump the molten sulfur out of the tanks or pits.

Competition Lewis; Lawrence; Goulds Reference List and Installation List The following are the companies that have successfully applied these pumps BASF Texas Gulf Georgia Gulf Sulfur Freeport Sulfur Ethyl Dow Technicas Reunidas Chevron Unocal Monsanto Haifa Refining Tennessee Valley Chemithon BF Goodrich Exxon Witco Parker Fertilizer Westvaco Akzo Nobel

LaBour Pump Company 901 Ravenwood Drive, Selma, Alabama 36701 Ph: (317) 924-7384 - Fax: (317) 920-6605 - www.labourtaber.com

A Product of Peerless Pump Company Copyright 2005 Peerless Pump Company

You might also like

- Blacksmithing on the Farm - With Information on the Materials, Tools and Methods of the BlacksmithFrom EverandBlacksmithing on the Farm - With Information on the Materials, Tools and Methods of the BlacksmithNo ratings yet

- Nickel Alloys For Sulfuric Acid ProductionDocument5 pagesNickel Alloys For Sulfuric Acid ProductionHeanjiaAlloysNo ratings yet

- SulphurDocument3 pagesSulphurbonda_gtvNo ratings yet

- Gate Valve Trim ChartDocument5 pagesGate Valve Trim ChartWaseem IqbalNo ratings yet

- Materials Selection Guide for Sulfuric Acid PlantsDocument6 pagesMaterials Selection Guide for Sulfuric Acid PlantsrivrsideNo ratings yet

- Amines PDFDocument1 pageAmines PDF최승원No ratings yet

- Common Metallurgical Defects in Grey Iron English (1Document1 pageCommon Metallurgical Defects in Grey Iron English (1sateeshkori100% (2)

- Gas Cooling Systems For Steam Reforming PlantsDocument12 pagesGas Cooling Systems For Steam Reforming Plantsrajaramc100% (1)

- JacketDocument1 pageJacketNirmal SubudhiNo ratings yet

- Bycast Folder 1106 LRDocument20 pagesBycast Folder 1106 LRmarloplenNo ratings yet

- Alfa Laval FACTS-8Document4 pagesAlfa Laval FACTS-8microco4No ratings yet

- Centrifugal Pumps For Molten Sulphur & H2so4 ProductionDocument6 pagesCentrifugal Pumps For Molten Sulphur & H2so4 ProductionSamir Ganguli100% (2)

- Sulphur RecoveryDocument8 pagesSulphur RecoveryprthrNo ratings yet

- Liquid SO2.1Document13 pagesLiquid SO2.1Musyafa WiryantoNo ratings yet

- Pumping High Temperature LiquidsDocument4 pagesPumping High Temperature LiquidsFrancisco GarcíaNo ratings yet

- Allegheny High Perf AlloysDocument8 pagesAllegheny High Perf Alloyspipedown456No ratings yet

- Liquid NitridingDocument7 pagesLiquid NitridingSenthil_kumar_palaniNo ratings yet

- Cryogenic MaterialsDocument7 pagesCryogenic Materialsstudent1No ratings yet

- Ld#2 OverviewDocument7 pagesLd#2 Overviewsatish_trivedi100% (1)

- Heat Exchangers, Suction Heaters & Heating Coils: HEAT EXCHANGER Product DescriptionDocument6 pagesHeat Exchangers, Suction Heaters & Heating Coils: HEAT EXCHANGER Product DescriptionhamedpdmsNo ratings yet

- Gas NitridingDocument4 pagesGas NitridingPaul Joseph MonsaludNo ratings yet

- Pumping BrineDocument2 pagesPumping Brinecoppi4No ratings yet

- 01 - Chemetics Gas-Gas Heat Exchanger InfoSheetDocument2 pages01 - Chemetics Gas-Gas Heat Exchanger InfoSheetWeb LogueandoNo ratings yet

- Catalog Pak KuntoDocument10 pagesCatalog Pak Kuntopt tabNo ratings yet

- Pipesteel API 5l x80Document52 pagesPipesteel API 5l x80Vera Yulia RachmawatyNo ratings yet

- Air Fin Cooler CatalougeDocument14 pagesAir Fin Cooler Catalougesammar_10No ratings yet

- 1973 BACKER Shaped Heat 20111009Document50 pages1973 BACKER Shaped Heat 20111009Hank MarvinNo ratings yet

- Tool SteelsDocument53 pagesTool SteelsMuhamad KahfaNo ratings yet

- A Holding and Treatment Furnace: FurnacesDocument1 pageA Holding and Treatment Furnace: FurnacesVijaykumar SharmaNo ratings yet

- Topsoe wet gas sulphuric acid technology reduces sulfur emissionsDocument8 pagesTopsoe wet gas sulphuric acid technology reduces sulfur emissionstsaleh100% (1)

- Oschatz Non-Ferrous Metallurgy enDocument12 pagesOschatz Non-Ferrous Metallurgy enSelene Acosta MauricciNo ratings yet

- Bar Basics and TerminologyDocument24 pagesBar Basics and TerminologyEdwin MPNo ratings yet

- HT ManualDocument17 pagesHT ManualAkhilesh KumarNo ratings yet

- Liquid NitridingDocument7 pagesLiquid NitridingSenthil_kumar_palaniNo ratings yet

- BallValve Body Trim MaterialDocument3 pagesBallValve Body Trim Materialsabes26No ratings yet

- Integral Low Fin TubeDocument16 pagesIntegral Low Fin TubePeter_Phee_341No ratings yet

- Superheaters: Reason For Superheating SteamDocument7 pagesSuperheaters: Reason For Superheating SteamMeghanath AdkonkarNo ratings yet

- Sulfur Tank Case StudyDocument18 pagesSulfur Tank Case StudyMajdi BelguithNo ratings yet

- AlfaDisc ENGDocument4 pagesAlfaDisc ENGSimEnzNo ratings yet

- DG Immersion Heaters Over The SideDocument3 pagesDG Immersion Heaters Over The SideadrianahoukiNo ratings yet

- Penthouse Spring 1998Document2 pagesPenthouse Spring 1998John M. CavoteNo ratings yet

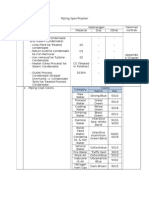

- Piping Specification DocumentDocument5 pagesPiping Specification DocumentShandi Hasnul FarizalNo ratings yet

- Application Note: Sentry Spiral Tube Heat Exchanger Vent Condenser ApplicationDocument2 pagesApplication Note: Sentry Spiral Tube Heat Exchanger Vent Condenser ApplicationraritylimNo ratings yet

- Heatexchanger Brochure PDFDocument18 pagesHeatexchanger Brochure PDFdesignstuioNo ratings yet

- 13 New MaterialsDocument92 pages13 New MaterialsShankar JhaNo ratings yet

- Hydrogen, Ammonia, Methanol Plant Material Selection: Educational Institute For Equipment and Process DesignDocument11 pagesHydrogen, Ammonia, Methanol Plant Material Selection: Educational Institute For Equipment and Process Designyusif samNo ratings yet

- BoilerDocument14 pagesBoilerantony1993No ratings yet

- High Temperature Corrosion Problems in Waste Heat BoilersDocument2 pagesHigh Temperature Corrosion Problems in Waste Heat BoilersEdenrafaNo ratings yet

- AF Flue Gas Ex ChangersDocument12 pagesAF Flue Gas Ex ChangersVikrant SharmaNo ratings yet

- Types of Boilers Classification and Hydrostatic Test OverviewDocument10 pagesTypes of Boilers Classification and Hydrostatic Test OverviewIbrahim MustafaNo ratings yet

- Boiler Pressure PartsDocument3 pagesBoiler Pressure PartsBedabyas DehuryNo ratings yet

- SG-39 Safety Guideline For Steel Melting ShopDocument32 pagesSG-39 Safety Guideline For Steel Melting ShopKìràñ ÀryàNo ratings yet

- HRST Boiler Biz - Volume 15 Issue 1 - 2014Document8 pagesHRST Boiler Biz - Volume 15 Issue 1 - 2014IlkuNo ratings yet

- Temperature The: Ford FoundryDocument4 pagesTemperature The: Ford FoundrySathis PavithNo ratings yet

- CalorifierDocument12 pagesCalorifierNay Myo OoNo ratings yet

- NitridingDocument9 pagesNitridingVijay AnandNo ratings yet

- Condition Based Maintenance Theory MethoDocument24 pagesCondition Based Maintenance Theory MethoshantanusamajdarNo ratings yet

- IELTS PreparationDocument9 pagesIELTS PreparationshantanusamajdarNo ratings yet

- Monitoring Repairs For PumpsDocument18 pagesMonitoring Repairs For PumpsshantanusamajdarNo ratings yet

- API Plans PosterDocument1 pageAPI Plans Posterskdalalsin100% (1)

- Vibrasi AnalisisDocument72 pagesVibrasi AnalisisyogacruiseNo ratings yet

- BearingsDocument33 pagesBearingsBrajendra Kumar100% (1)

- NTN Bearing Bpfo&BpfiDocument61 pagesNTN Bearing Bpfo&BpfishantanusamajdarNo ratings yet

- Planning and Design of Underground Hydropower StructuresDocument41 pagesPlanning and Design of Underground Hydropower StructuresshantanusamajdarNo ratings yet

- Mechanical Seal Sept10Document4 pagesMechanical Seal Sept10sureshbabu7374No ratings yet

- Property Modifiers PDFDocument1 pageProperty Modifiers PDFraj vaddiNo ratings yet

- AATS Technical Services ProfileDocument6 pagesAATS Technical Services Profileimzee25No ratings yet

- Pdfcoffeecom Vibrating Screens Training For Maint 230601 225223Document18 pagesPdfcoffeecom Vibrating Screens Training For Maint 230601 225223khaled saadnehNo ratings yet

- Bolt Length Calculation: IS 6392-Table 11Document3 pagesBolt Length Calculation: IS 6392-Table 11sumit_b123No ratings yet

- 4 Basic Elements for Intelligent Building SystemsDocument3 pages4 Basic Elements for Intelligent Building SystemsAhmad FaridNo ratings yet

- Ladder PDFDocument144 pagesLadder PDFAung MinsoeNo ratings yet

- (CQHP) Guidelines For ArchitectureDocument23 pages(CQHP) Guidelines For ArchitectureZEC LIMITEDNo ratings yet

- Shopnochura EbrochureDocument56 pagesShopnochura EbrochureMd Forhad HossainNo ratings yet

- Engeurocode Training En1994-1-1Document34 pagesEngeurocode Training En1994-1-1aerodangerNo ratings yet

- Concrete Mix Design CodeDocument33 pagesConcrete Mix Design Codeshyamalthakkar100% (1)

- TDS-GEOPROTEC-GS3000S-22-01 Rev.01Document1 pageTDS-GEOPROTEC-GS3000S-22-01 Rev.01AMINNo ratings yet

- Catalogue Dai ADocument16 pagesCatalogue Dai AHD TalababuNo ratings yet

- ACI 3 - 08 Rec Sec. MX - Q-Torsion Design Rev06 02-May-2013Document14 pagesACI 3 - 08 Rec Sec. MX - Q-Torsion Design Rev06 02-May-2013Andy SunjayaNo ratings yet

- Concrete Jacket Construction Detail Effectiveness When Strengthening RC ColumnsDocument13 pagesConcrete Jacket Construction Detail Effectiveness When Strengthening RC ColumnsAbhishek ShatagopachariNo ratings yet

- General Guidelines Eco Build HEMP MORTARS Using St. Astier LimesDocument4 pagesGeneral Guidelines Eco Build HEMP MORTARS Using St. Astier LimesScufita RosieNo ratings yet

- Ind PamDocument47 pagesInd PamAbhishek PandaNo ratings yet

- Lesson 4. Boiler MountingsDocument4 pagesLesson 4. Boiler MountingsalexdenychenkoNo ratings yet

- Jetty AreaDocument6 pagesJetty AreashrieersNo ratings yet

- Structural Analysis & Design for the Proposed School BuildingDocument5 pagesStructural Analysis & Design for the Proposed School BuildingJoseph Cloyd Lamberte79% (39)

- Hydrostatic TestDocument6 pagesHydrostatic TestalfredoNo ratings yet

- Final GreekDocument20 pagesFinal GreekMageshwarNo ratings yet

- Twi Hardness TestingDocument8 pagesTwi Hardness TestingchungndtNo ratings yet

- Waterproof Planiseal 288Document3 pagesWaterproof Planiseal 288Chezy629No ratings yet

- Connections ManualDocument90 pagesConnections ManualNiko Ništić100% (1)

- Alform System Formwork Procedures October 2016Document40 pagesAlform System Formwork Procedures October 2016Syerifaizal Hj. MustaphaNo ratings yet

- AISE No7 Ladle Hooks 1991Document9 pagesAISE No7 Ladle Hooks 1991Zhifan FuNo ratings yet

- Rivian Normal Il Report February 2021Document2 pagesRivian Normal Il Report February 2021Joey KlenderNo ratings yet

- Typeofhigh RisebuildingDocument31 pagesTypeofhigh Risebuildingsujan pokhrelNo ratings yet

- Upright Pendent SprinklersDocument5 pagesUpright Pendent SprinklersDammakNo ratings yet

- DIY Wiring A Three Phase Consumer Unit-Distribution Board and Wiring DiagramsDocument5 pagesDIY Wiring A Three Phase Consumer Unit-Distribution Board and Wiring DiagramsAshNo ratings yet