Professional Documents

Culture Documents

Pulveriser-Power Plant

Uploaded by

ARUNGREESMAOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pulveriser-Power Plant

Uploaded by

ARUNGREESMACopyright:

Available Formats

PERFORMANCE ANALYSIS OF COAL MILLS

P M V Subbarao

Associate Professor

Mechanical Engineering Department

IIT Delhi

Correct Size, shape and quantity of Diet For Complete Digestion..

Combustion Limits on Furnace Design

The lower limit of the furnace volume is dominated by the space

required for burning the fuel completely, or

to an extent less than the allowable unburned fuel loss.

To complete the fuel combustion within the furnace space, the fuel

injected into the furnace has to reside there for a time longer than

critical time t

*

r

.

The fuel residence time can also be estimated by the residence time of

the combustion gas produced in the furnace.

An average residence time t

r

can be proposed.

e unit volum per generation heat of rate Allowable Max. furnace the of Volume

furnace the entering energy Fuel

=

r

t

v

c

r

Vq

LHV m

t >

gas. of density

generated gas of mass

= V

v

g

g

c

r

q

m

LHV m

t

|

|

.

|

\

|

>

v

c

g

g

r

q

m

m

LHV

t

|

|

.

|

\

|

>

v

g

r

q

F

A

LHV

t

|

.

|

\

|

+

|

.

|

\

|

>

1 c

Fuel combustion time is mainly dominated by the combustion

reaction velocity and the rate at which oxygen is supplied into the

reaction zone.

The combustion reaction velocity depends on chemical

characteristics of the fuel.

Main technical factors that affect the combustion time are:

Combustion characteristics of the fuel.

Mixing characteristics.

Fluid flow characteristics of the furnace.

The combustion velocity of an oil fuel droplet is generally less

than 0.1 msec.

In the case of coal combustion time is much longer.

Typical Combustion Reaction Velocity ( Flame Speed) of

Pulverized Coal : Effect of Ash Fraction

30%VM & 5 % Ash

30%VM & 15 % Ash

30%VM & 30 % Ash

30%VM & 40 % Ash

F

l

a

m

e

s

p

e

e

d

m

/

s

A/F ratio

Typical Combustion Reaction Velocity ( Flame Speed) of

Pulverized Coal: Effect of VM Fraction

30%VM & 5 % Ash

20%VM & 5 % Ash

15%VM & 5 % Ash

F

l

a

m

e

s

p

e

e

d

m

/

s

A/F ratio

Coal Mill : A Controller of Combustion Time

Hot Air

~ 250

0

C

Coal 10 to 25 mm Size

Roller

Bowl

Coal pulverizers

Coal pulverizers are essentially volumetric devices, because the

density of coal is fairly constant, are rated in mass units of tons/hr.

A pulverizer accepts a volume of material to be pulverized which

is dependent on the physical dimensions of the mill and the ability

of coal to pass through the coal pulverizing system.

The furnace volume and mill capacity in a specific power station

may dictate the need to purchase coals which are reactive and easily

grind.

The common measure of mass in tons enables matching of energy

requirements with available coal properties and mill capacity.

Increased combustible loss can occur if the furnace volume or mill

capacity is less than desirable for a particular coal.

There are a number of possible remedial actions.

Operators can correct some deficiencies in the combustion system :

Biasing the performance of the coal pulverizing for variable coal

qualities.

Use the spare mill into service for peak periods to ensure full

output.

Size reduction is energy intensive and generally very inefficient with

regard to energy consumption.

In many processes the actual energy used in breakage of particles is

around 5% of the overall energy consumption.

Pulverizing coal is no exception to this.

There are basically four different types of pulverizing mills which are

designed to reduce coal with a top particle size of about 50 mm to the

particle size range necessary for fairly complete combustion in a

modern pulverized coal fired boiler.

Each type has a different grinding mechanism and different operating

characteristics.

There are four unit operations going concurrently within the mill body,

coal drying, transport, classification and grinding.

For coal pulverizers the capacity of a mill is normally specified as

tonnes output when grinding coal with a HGI of 50, with a particle size

of 70% less than 75 micron and 1 % greater than 300 micron and with

a moisture in coal of less than 10%.

A few manufacturers specify 55 instead of 50 with respect to HGI.

This standardization enables selection of an appropriate mill for a

specific duty.

Ball & Tube Mill

The oldest pulverizer design still in

frequent use.

25% to 30% of cylinder volume is

filled with wear resistant balls of 30

60mm.

The cylinder is rotated at a speed of

about 20 rpm.

Specific power consumption 22

kWh per Ton.

Suitable for hard coals.

Highly reliable in requires low

maintenance.

Bulky and heavy in construction.

mg+me

2

R

mg-me

2

R

mg <me

2

R : Ball will never fall down

Critical Angular Velocity e

c

me

c

2

R = mg

e

c

2

= g/R

mg+me

2

R

me

2

R

mg

(me

2

R+mg Cos o) > mg sin o

o

me

2

R

mg

me

2

R

mg

(me

2

R+mg Cos o) < mg sin o

o

Pulverization due to ATTRITION

me

2

R

mg

(me

2

R-mg Cos o) = 0

o

Pulverization due to Impact

Bowl Mill

The most widely used mill for

grinding coal.

The raw coal is fed into the

center of the mill.

This is an intermediate speed

pulverizer.

The vertical shaft rotates at a

speed 30 50 rpm.

Specific power consumption 12

kWh/ton.

Schematic of typical coal pulverized system

A Inlet Duct;

B Bowl Orifice;

C Grinding Mill;

D Transfer Duct to Exhauster;

E Fan Exit Duct.

The primary airflow measurement by round cross-

sectional area venturis (or flow nozzles) should be

provided to measure and control primary airflow to

improve accuracy

Aerodynamic Lifting of Coal Particles

Carrying of Particles by Fluid Drag

In view of the age of the technique it would be presumed that the

subject of concurrent fluid-solid flow would be quite well defined

and understood.

Investigation of the published literature indicates, however, that such

conveying is still an extremely empirical art.

Pneumatic Carrying of Particles

The major goal of pneumatic conveying of solids is to maximize the

carrying capacity of the installation and carry flows with high-solids

concentration ("dense-phase flow").

In pulverized coal combustion, the ratio of coal to carrying gas is

usually in the range of y = 0.5-0.6 kg/kg.

Assuming a coal density

c

= 1.5 x 10

3

kg/m

3

, and the density of the

carrying gas as

g

= 0.9 kg/m

3

, the volume fraction of the coal can be

shown to be very small, 0.036 % .

Dilute Phase Transport

The inter particle effects can therefore be neglected for steady state

operation.

An important aerodynamic characteristic of the particles is their

terminal velocity (the free-fall velocity in stagnant air) which for a

spherical particle of d = 0.1 mm has an approximate value of 0.3m/sec.

Experience shows that due to non-uniformities of flow behind bends,

and to avoid settling of solids in horizontal sections of the transport

line, a gas velocity of ~ V = 16 -- 20 m/sec has to be chosen.

Pulverizer Capacity

Mill manufacturers provides a set of data or curves, which enable the capacity of a mill

to be determined with a coal with specific properties.

The properties, which are of concern, are specific energy, HGI, moisture, particle size

and reactivity.

Specific energy is necessary to determine the required nominal maximum mill capacity

in tons/hour to ensure sufficient coal is delivered to the boiler.

A curve linking HGI and mill capacity provides information on mill performance with

that coal.

A curve linking moisture content of the coal with mill capacity shows what reduction

in capacity will arise if the moisture is excessive.

This is particularly important with ball mills.

The particle size distribution and top size may be of importance.

For ball mills there is a curve linking mill capacity with the top size of coal fed to the

mill.

The reactivity of the coal, measured in the first instance by volatile matter is needed to

determine if the mill can be set to provide standard 70% less than 75 micron or

a finer or coarser setting is necessary with corresponding alteration to mill capacity.

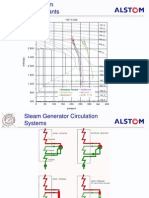

Pulverizer Capacity Curves

Moisture content, %

T

h

r

o

u

g

h

p

u

t

,

t

o

n

s

/

h

r

Grindability

Coal Mill : A Controller of Combustion Time

Hot Air

~ 250

0

C

Coal 10 to 25 mm Size

Roller

Bowl

Sizing of Pulverizers

Feeder capacity is selected to be1.25 times the pulverizer capacity.

Required fineness, is selected to be

60% through a 200 mesh screen for lignite(75 m),

65% for sub-bituminous coal,

70-75% for bituminous coal, and

80-85% for anthracite.

Heat input per burner is assumed to be to 75 MW for a low

slagging coal and

40 MW for a severely slagging coal,

With intermediate values for intermediate slagging potentials.

General Capacity of A Coal Mill : 15 25 tons/hour.

Power Consumption: 200 350 kW.

Performance Calculations

Several performance parameters are calculated for

the pulverizer train.

These include the following:

Effectiveness of Coal drying requirements.

Pulverizer heat balance.

Primary air flow requirements.

Number of pulverizers required as a function of

load.

Auxiliary power requirements.

Prediction of Coal Drying

For predicting the amount of coal drying which is needed

from the pulverizers the following methods were accepted.

For very high rank coals (fixed carbon greater than 93

percent), an outlet temperature of 75 to 80 C appeared most

valid.

For low- and medium-volatile bituminous coals, an outlet

temperature of 65 - 70 C appeared most valid.

Bituminous coals appear to have good outlet moisture an

outlet temperature of 55 to 60 C is valid.

For low-rank coals, subbituminous through lignite (less than

69 percent fixed carbon, all of the surface moisture and one-

third of the equilibrium moisture is driven off in the mills.

Energy Balance across pulverizer is very critical for satisfactory

operation of Steam Generator.

Hot air

Coal

Dry pulverized coal +

Air + Moisture

Puliverizer frictional

dissipation

Motor Power Input

Heat loss

Suggested Primary air fuel ratio

Mill Energy Balance

Hot air

Coal

Dry pulverized coal +

Air + Moisture

Puliverizer frictional

dissipation

Motor Power Input

Heat loss

Tempering Air, T

atm

Pulverizer Heat Balance

To perform the necessary pulverizer heat and mass balance

calculations, the following parameters are required:

Primary air temperature.

Primary air/fuel ratio.

Fuel burn rate.

Coal inlet temperature.

Coal moisture entering the mills.

Coal moisture content at the mill exit.

Mill outlet temperature.

Minimum acceptable mill outlet temperature.

Tempering air source temperature.

Tempering air flow.

Heat Losses and Gains in A Mill

Convection and Radiation Losses from the surface of the

mill.

Heat losses are generally found to be at 5 percent of total

thermal energy available.

Mills consume an electric energy of 60 kJ/kg.

The mill grinding heat dissipation, varies from 20 to 40

kJ/kg of coal.

Mill Heat Balance: Energy for Drying of Coal

Determine the latent heat per kg of water evaporated.

Calculate the total energy absorbed by evaporating the

required amount of water from the coal.

{ } ( ) { }

fg amb p out in coal dry

h T c M M m Q + = 100

Mill Heat Balance: Energy for heating of dry Coal

Determine the sensible heat increase of the coal.

{ } ( )

coal in out in coal coal heat

C T T M m Q = 100

,

Mill Heat Balance: Energy for heating of remaing

Moisture

Determine the increase in sensible heat of remaining

moisture.

{ } ( )

moisture coal in out out coal moisture heat

C T T M m Q =

, ,

Mill Heat Balance: Energy available

Determine the sensible heat available in the mill inlet air.

( )

air p out air in air air pri air pri

C T T m Q

, , ,

=

Calculate the the mill grinding heat generation

disspation coal gen

q m Q =

Mill Heat Balance: Energy gained by Tempering Air

Determine the sensible heat increase in tempering air air.

( )

air p in tair out tair air temp air pri

C T T m Q

, , ,

=

Mill Heat Balance: Energy losses

Calculate the heat lost from the surface of the

purlverizer:

{ }

100

5

+ =

gen air pri losses

Q Q Q

Mill Energy Balance: Verification

Total Energy Available:

{ }

gen air pri available

Q Q Q

+ =

{ }

air temp losses moisture heat coal heat dry consumed

Q Q Q Q Q Q

, , ,

+ + + + =

Calculate the difference:

Total Energy Consumed:

Divide the difference by the total available to obtain

the fraction

{ }

consumed available suspense

Q Q Q

+ = A

available

suspense

Q

Q

X

A

=

Validation of Design

For best desingn: X = 0.

Acceptable designs: X = +/- 0.05.

If X is not in the limits above, the design and performance

calculations should be repeated.

At any time during Operation above conditions should be

maintained for most efficient and reliable operation of mill.

Derate Analysis and Operating Concerns

Pulverizer capacity limitation : A derate is due to the fuel

burn rate exceeding predicted pulverizer capacity with all

pulverizers in service.

Feeder capacity limitation : A derate is due to the fuel burn

rate is greater than the total actual feeder capacity with all

pulverizers in service.

An exhauster mill limitation: A derate is due to the

calculated airflow required with all pulverizers in service is

greater than the actual exhauster fan flow.

Improper pulverizer outlet temperature: A derate is due to

the heat available in the primary air for drying coal in the

pulverizers is less than that required.

Auxiliary Power Requirements

The pulverizer system annual auxiliary power requirements are

calculated in a multistep process.

The first step is to calculate the fractional load per pulverizer in

service (Milllod) at load point i.

where

FBR

i

= fuel burn rate, t/h, at load i,

N

mill,i

= calculated number of pulverizers in service at load i, and

C

mill

= calculated capacity, t/h, per pulverizer.

The second step is to calculate the power required per pulverizer.

mill i mill

i

i

C N

FBR

Milllod

=

,

( )

|

|

.

|

\

|

|

.

|

\

|

=

j mill i mill

Milllod

dld

dP

RP P 1 1

,

where

RP

mill

= Rated Power Consumption of mill, and

dP/dld = slope of pulverizer power Vs fractional pulverizer

load curve based on manufacturer data.

The third step is to calculate the power required (MWh/yr) for the

pulverizer system at load point i.

where

q

motor

= motor efficiency.

Finally, the auxiliary power requirements for each load point are

summed to obtain the total auxiliary power requirements for the

pulverizer system.

motor

i i mill mill

i y sys

Hours P N

P

q

=

,

, ,

=

=

K

i

i y sys tot sys

P P

1

, , ,

The Control of Coal Mills

Mill PA /Differential Pressure Control

Closed Loop Control of PA Flow

Parallel Control of Feeder Speed & PA Flow

Control of Suction Mills

Mill Temperature Control

A comprehensive Mill Control System

Steam Temperature control with 2 stage

Attemperation

OPERATIONS AND MAINTENANCE CONTROLLABLE FACTORS

Four controllable heat rate factors are directly related with

furnace performance and furnace flue gas uniformity.

These are: superheater temperature, reheater temperature,

desuperheating spray water flow to the superheater, and

desuperheating spray water flow to the reheater

Balancing of the fuel and air to each burner has much to do with

furnace combustion efficiency, and the completeness of

combustion at the furnace exit.

The residence time of the products of combustion from the

burners to the superheater flue gas inlet is about one or two

seconds.

Not very long for furnace mixing of fuel rich and air rich lanes of

combustion products.

Optimized combustion at the superheater inlet can be quantified

by use of a water-cooled high velocity thermocouple probe.

Slagging at the superheater flue gas inlet has been a problem in a

number of boilers due to stratified flue gas.

Slagging at the lower furnace results in large boulder sized

clinkers blocking the lower ash hopper.

Tube spacing becomes ever closer as the heat transfer changes

from radiant in the furnace, to convective in the back pass.

Recall the typical tube spacing of pendant superheater and

reheater tubes.

If lanes in the furnace outlet flue gas approach the ash softening

or even the ash fluid temperature, upper furnace slagging and

blockage can result in a very short time.

Several cases studies should be reviewed to show how the

application of the Thirteen Essentials will improved slagging,

heat-rate, capacity factor, reliability, NOx and/or flyash carbon

content.

AIRFLOW AND FUEL FLOW OPTIMIZATIONS : A Case Study

Design Data Used

On Going Problems

Erratic performance and severe slagging problems in

both the upper furnace and the lower ash hopper.

It was concluded that the furnace exit gas temperature

was varying due to non-uniform products of combustion

entering the superheater gas side.

Ash fusion temperatures are often lower in a reducing

atmosphere than in an oxidizing atmosphere.

Since many of the opportunities for improvement that

were experienced on this boiler were slagging related,

this was a significant factor.

For example, the peak furnace exit gas temperatures

were above 2472F. (the maximum point indicated on

the digital thermometer, the true temperature was even

higher.)

Also, the reducing ash fluid temperature from is

2400F.

The combination of the fuel richness and ash chemistry

together is the root cause of severe slagging.

A highly localized temperature is also usually due

to fuel rich and creates a reducing atmosphere.

Therefore, this peak temperature corresponds to a

reducing atmosphere.

It is this combined effect of lower ash fusion

temperature in a reducing atmosphere (chemistry

effect) and the poor fuel and air balance

(mechanical effect) that greatly accelerates

slagging.

The furnace exit, excess oxygen and temperature

stratifications were found to be the result of a non-

homogeneous mixing of the combustion air and fuel in the

burner belt zone.

Zero oxygen points at the furnace exit could be due to either

an abundance of fuel, or a shortage of combustion air.

The Comprehensive Diagnostic Test technique was utilized

to quantify the opportunities for each.

Upon completion of the Comprehensive Diagnostic Tests,

the following changes were implemented:

Fuel lines were balanced

Flow nozzles were installed for primary airflow measurement

and control

Pulverizer classifier changes

Secondary air duct changes to balance combustion airflows

to each of the four corners.

You might also like

- Coal Mill1Document28 pagesCoal Mill1MY NAME IS NEERAJ..:):)No ratings yet

- Combustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasFrom EverandCombustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasNo ratings yet

- Thermal Power PlantsDocument47 pagesThermal Power Plantsbbhabal67% (3)

- DPG Coal FeederDocument11 pagesDPG Coal FeederPanimanPalengaiNo ratings yet

- Pulverized Coal and Igcc Plant Cost and Performance EstimatesDocument22 pagesPulverized Coal and Igcc Plant Cost and Performance EstimatesVinod DahiyaNo ratings yet

- Industrial BurnersDocument23 pagesIndustrial Burnerskarthikeyan5000No ratings yet

- Circulating Fluidized Bed Boilers: Prabir BasuDocument9 pagesCirculating Fluidized Bed Boilers: Prabir BasuAshwinShowabiWabiNo ratings yet

- Mechanical StokersDocument6 pagesMechanical StokersAnonymous mRBbdopMKfNo ratings yet

- Air Pollution Prevention and Control: Dr. Wesam Al MadhounDocument52 pagesAir Pollution Prevention and Control: Dr. Wesam Al MadhounAIZAZ SHAIKHNo ratings yet

- Fluidized Bed CombustionDocument32 pagesFluidized Bed CombustionAbdul AhadNo ratings yet

- Kombinasi Hukum I Dan II Termodinamika - enDocument17 pagesKombinasi Hukum I Dan II Termodinamika - enEkok Ec100% (1)

- Combustion CalculationDocument22 pagesCombustion CalculationTejas T S TejasNo ratings yet

- Supercritical-RDocument40 pagesSupercritical-RshhhhhhhhhhhhhhhNo ratings yet

- Steam Power Plant PDFDocument20 pagesSteam Power Plant PDFarchitNo ratings yet

- Anti DumpingDocument30 pagesAnti DumpingSHekhar sachdevNo ratings yet

- Coal Combustion ProcessDocument14 pagesCoal Combustion Processdevilturn70100% (1)

- Supercritical Turbine Analysis & DesignDocument29 pagesSupercritical Turbine Analysis & DesignEngr Imtiaz Hussain GilaniNo ratings yet

- Coal Was Her y ReportDocument76 pagesCoal Was Her y ReportravibelavadiNo ratings yet

- Pulverizers PDFDocument6 pagesPulverizers PDFOscar DorantesNo ratings yet

- Super Critical PresentationDocument46 pagesSuper Critical PresentationSam100% (1)

- Principle of Boiler CombustionDocument20 pagesPrinciple of Boiler Combustionvasanth11kv100% (2)

- Ahn2002 Elbow FractureDocument13 pagesAhn2002 Elbow FractureKurra SrikanthNo ratings yet

- Pulverized Coal TechnologyDocument7 pagesPulverized Coal TechnologyRi KoNo ratings yet

- BoilerDocument45 pagesBoilerEr Prem PrincepsNo ratings yet

- Pulverized CoalDocument11 pagesPulverized CoalAdrian ManzanoNo ratings yet

- Thermal Power Plant Layout and OperationDocument77 pagesThermal Power Plant Layout and OperationAlexNo ratings yet

- Boiler Device and Accessories p1Document60 pagesBoiler Device and Accessories p1OsamaEhmaid100% (2)

- Gas Power Cycles Sivakumar.E VITDocument47 pagesGas Power Cycles Sivakumar.E VITmohan govindasamyNo ratings yet

- Study of Circulating Coal Fluidized BoilersDocument5 pagesStudy of Circulating Coal Fluidized BoilersSwaraj BiswasNo ratings yet

- High Temperature CO2 Sorbents and Their Application For Hydrogen Production by Sorption Enhanced Steam Reforming ProcessDocument25 pagesHigh Temperature CO2 Sorbents and Their Application For Hydrogen Production by Sorption Enhanced Steam Reforming ProcessserchNo ratings yet

- Coal BlendingDocument2 pagesCoal BlendingpvkrishnajiNo ratings yet

- Boiler Tube FailureDocument4 pagesBoiler Tube FailurenileshNo ratings yet

- Boilers of Thermal Power PlantsDocument150 pagesBoilers of Thermal Power PlantsanasawaisNo ratings yet

- Heat Required in Kcal For Unit Generation of ElectricityDocument18 pagesHeat Required in Kcal For Unit Generation of ElectricityAyan ChattarajNo ratings yet

- Fluidized Bed CombustionDocument23 pagesFluidized Bed CombustionHawk EyeNo ratings yet

- Flame StabilityDocument11 pagesFlame StabilityMir Reza Negahban100% (1)

- Design and Commisioning 700 MW CFB PDFDocument5 pagesDesign and Commisioning 700 MW CFB PDFUntung SetiawanNo ratings yet

- Presentation: Feasibility Study of Integrated Gasification Combined Cycle (IGCC) in Terms of The Following Parameters: Technology, Reliability and Economy For High High-Ash Content Indian Coal.Document14 pagesPresentation: Feasibility Study of Integrated Gasification Combined Cycle (IGCC) in Terms of The Following Parameters: Technology, Reliability and Economy For High High-Ash Content Indian Coal.Prithvi JawaharNo ratings yet

- Thermal Power PlantDocument29 pagesThermal Power PlantSiri VenniNo ratings yet

- C&I in CFBC-1Document25 pagesC&I in CFBC-1Prudhvi RajNo ratings yet

- Suspension (PC) Combustion: Chungen YinDocument47 pagesSuspension (PC) Combustion: Chungen YinAakash RanjanNo ratings yet

- Linear Absorption Coefficient: ObjectiveDocument5 pagesLinear Absorption Coefficient: ObjectiveFilip Angelovski100% (1)

- Thermal Power Plant BasicDocument19 pagesThermal Power Plant Basicravikant singhNo ratings yet

- Foundrybench D19 Good Practice GuideDocument196 pagesFoundrybench D19 Good Practice GuideGangadharKasinathSastryNo ratings yet

- Low Rank Coal UtilizationDocument22 pagesLow Rank Coal Utilizationarjmandquest100% (1)

- InterlocksDocument26 pagesInterlocksFelipe SandovalNo ratings yet

- Write Up For Boiler Interlock System (TCL) - Rev.1Document26 pagesWrite Up For Boiler Interlock System (TCL) - Rev.1raveekas6148No ratings yet

- Governing System of TurbineDocument8 pagesGoverning System of Turbinebimal213100% (1)

- 7.summary of Boiler PerfDocument46 pages7.summary of Boiler PerfRAJESH KUMARNo ratings yet

- Coal MillDocument6 pagesCoal MillAnonymous NxpnI6jCNo ratings yet

- Boiler Heat Transfer Theory-02Document18 pagesBoiler Heat Transfer Theory-02Sai SwaroopNo ratings yet

- Boiler and Its Efficiency-1Document38 pagesBoiler and Its Efficiency-1Madhu KamshettyNo ratings yet

- Energy Performance Assessment of Boiler at P.S.S.K. LTDDocument12 pagesEnergy Performance Assessment of Boiler at P.S.S.K. LTDPajooheshNo ratings yet

- Internal Circulation CFB Boiler PDFDocument11 pagesInternal Circulation CFB Boiler PDFAkhilesh Kumar0% (1)

- Performanece Ananlysis of CoalDocument67 pagesPerformanece Ananlysis of Coalsen_subhasis_58No ratings yet

- Ball Mill PulveriserDocument67 pagesBall Mill PulveriserMURALIGOCAM_29070605100% (1)

- Analysis of Pulverizers: Multi Task Machines To Meet The Rate of Rapid Coal CombustionDocument23 pagesAnalysis of Pulverizers: Multi Task Machines To Meet The Rate of Rapid Coal CombustionHemant PatilNo ratings yet

- Fuels and Combustion-Part2 PDFDocument57 pagesFuels and Combustion-Part2 PDFSugan NallaNo ratings yet

- PKR MillsDocument37 pagesPKR Millsnetygen1No ratings yet

- Coal Mill and Coal FeedersDocument97 pagesCoal Mill and Coal Feederspartha halder67% (3)

- Global WarDocument4 pagesGlobal WarARUNGREESMANo ratings yet

- Thermal Conduction4Document32 pagesThermal Conduction4ARUNGREESMANo ratings yet

- Thermal II Lab Manual AnnauniversityDocument77 pagesThermal II Lab Manual AnnauniversityAravindha KrishnaNo ratings yet

- Thermal II Lab Manual AnnauniversityDocument77 pagesThermal II Lab Manual AnnauniversityAravindha KrishnaNo ratings yet

- HMT Lab Manual2013Document37 pagesHMT Lab Manual2013ARUNGREESMANo ratings yet

- Importance of Measurement On Science & TechnologyDocument14 pagesImportance of Measurement On Science & TechnologyARUNGREESMANo ratings yet

- Advaces Ic Engine SyllabusDocument2 pagesAdvaces Ic Engine SyllabusARUNGREESMANo ratings yet

- ME401 Combustion CIDocument6 pagesME401 Combustion CIBalvinderNo ratings yet

- Maximizing Auditory SlidesDocument18 pagesMaximizing Auditory SlidesARUNGREESMANo ratings yet

- Advance Ic Me2401Document2 pagesAdvance Ic Me2401Magesh WaranNo ratings yet

- Air ChargingDocument4 pagesAir ChargingARUNGREESMANo ratings yet

- ME1354 Power Plant Engineering Apr May 2008Document3 pagesME1354 Power Plant Engineering Apr May 2008ARUNGREESMANo ratings yet

- Maximizing Auditory SlidesDocument18 pagesMaximizing Auditory SlidesARUNGREESMANo ratings yet

- Advanced Ic EngineDocument19 pagesAdvanced Ic EnginebibhusaketsinhaNo ratings yet

- Signal System ObjectiveDocument82 pagesSignal System ObjectiveNitin Kathuria100% (3)

- Advance Ic Me2401Document2 pagesAdvance Ic Me2401Magesh WaranNo ratings yet

- Advance Ic Me2401Document2 pagesAdvance Ic Me2401Magesh WaranNo ratings yet

- Engineering Graphics - Model QN PapeerDocument2 pagesEngineering Graphics - Model QN PapeerkameshvvNo ratings yet

- Engineering Graphics Question January 2006 Bibin'sDocument2 pagesEngineering Graphics Question January 2006 Bibin'sBIBIN CHIDAMBARANATHANNo ratings yet

- Engineering Graphics Question January 2006 Bibin'sDocument2 pagesEngineering Graphics Question January 2006 Bibin'sBIBIN CHIDAMBARANATHANNo ratings yet

- Ece 3sem 147303nolDocument12 pagesEce 3sem 147303nolsirapuNo ratings yet

- Total Points Noted in Each Section Must Clearly Show Equations With Values and Units, Drawings, Assumptions, Etc.Document7 pagesTotal Points Noted in Each Section Must Clearly Show Equations With Values and Units, Drawings, Assumptions, Etc.ARUNGREESMANo ratings yet

- NUCLEAR SyllabusDocument1 pageNUCLEAR SyllabusARUNGREESMANo ratings yet

- Fields of Applicatio1Document5 pagesFields of Applicatio1ARUNGREESMANo ratings yet

- ME132 Thermodynamics Nov Dec 2007Document4 pagesME132 Thermodynamics Nov Dec 2007ARUNGREESMANo ratings yet

- Kjhlisdfj ShdfopaswDocument1 pageKjhlisdfj ShdfopaswARUNGREESMANo ratings yet

- NUCLEAR SyllabusDocument1 pageNUCLEAR SyllabusARUNGREESMANo ratings yet

- Planning The Lecture: Suggested Format For A Lecture PlanDocument3 pagesPlanning The Lecture: Suggested Format For A Lecture PlanGaurav SharmaNo ratings yet

- Planning The Lecture: Suggested Format For A Lecture PlanDocument3 pagesPlanning The Lecture: Suggested Format For A Lecture PlanGaurav SharmaNo ratings yet

- Planning The Lecture: Suggested Format For A Lecture PlanDocument3 pagesPlanning The Lecture: Suggested Format For A Lecture PlanGaurav SharmaNo ratings yet

- 640ccc774a2a28001898f001 ## AITS 04 Question Paper Yakeen 2 0 2023Document28 pages640ccc774a2a28001898f001 ## AITS 04 Question Paper Yakeen 2 0 2023wjgv4nwcz6No ratings yet

- INGM 427 Slides - 5 Cooling TowersDocument17 pagesINGM 427 Slides - 5 Cooling TowersCornelius RheedersNo ratings yet

- Sorption Isotherms and Moisture Sorption Hysteresis of Intermediate Moisture Content BananaDocument7 pagesSorption Isotherms and Moisture Sorption Hysteresis of Intermediate Moisture Content BananaWilliam RaNo ratings yet

- ChemistryDocument4 pagesChemistryMalik Ameer Hamza BalochNo ratings yet

- IGCSE Physics Getting Started GuideDocument22 pagesIGCSE Physics Getting Started GuidesaipkNo ratings yet

- Chemical Inventory List: Responsible Person: Update Date: January, 2018 P: Physical, H: Health, E: EnvironmentalDocument1 pageChemical Inventory List: Responsible Person: Update Date: January, 2018 P: Physical, H: Health, E: Environmentalratu nurhaliza syamNo ratings yet

- The Charge of The ElectronDocument3 pagesThe Charge of The ElectronSaeed AlMheiriNo ratings yet

- Science 7 3rd Quarter Edited LeaPDocument18 pagesScience 7 3rd Quarter Edited LeaPcristine joy hirangNo ratings yet

- Corrosion Monitoring Methods (Chevron)Document65 pagesCorrosion Monitoring Methods (Chevron)Sergey KichenkoNo ratings yet

- Lecture 1Document23 pagesLecture 1meku44No ratings yet

- Chem HSSC 1 Model PaperDocument8 pagesChem HSSC 1 Model PaperPikoNo ratings yet

- Unit 1: Atomic Structure: AP ChemistryDocument39 pagesUnit 1: Atomic Structure: AP ChemistrykawarriorNo ratings yet

- Photon noise: τ σ = σ hf n wattsDocument24 pagesPhoton noise: τ σ = σ hf n wattssiddhanta69No ratings yet

- BIOCIDEDDocument2 pagesBIOCIDEDBhoomi KapadiaNo ratings yet

- 20 GK Questions and Answers On Everyday ScienceDocument2 pages20 GK Questions and Answers On Everyday Scienceamankumar sahu100% (3)

- Cristian Pavéz Et Al - Progress in Z-Pinch Research Driven by The Megaampere Device SPEED2Document5 pagesCristian Pavéz Et Al - Progress in Z-Pinch Research Driven by The Megaampere Device SPEED2Imsaa4No ratings yet

- Growth and Characterization of L-Alanine Potassium Nitrate Single Crystals For Nonlinear Optical ApplicationsDocument5 pagesGrowth and Characterization of L-Alanine Potassium Nitrate Single Crystals For Nonlinear Optical ApplicationsPalaniswamy SankariahNo ratings yet

- Completion Fluid Services Liquid Viscosifier: DescriptionDocument2 pagesCompletion Fluid Services Liquid Viscosifier: DescriptionpaimanNo ratings yet

- 9science 9 Force and Laws of MotionDocument27 pages9science 9 Force and Laws of MotionMohammed AadilNo ratings yet

- Grade 3 Energy Summary Grade 3 Learning Standards (From Bced Curriculum)Document4 pagesGrade 3 Energy Summary Grade 3 Learning Standards (From Bced Curriculum)Akbar KurniawanNo ratings yet

- Nitoflor EPU100Document4 pagesNitoflor EPU100Allan DerickNo ratings yet

- Chemistry FileDocument9 pagesChemistry Filemrharshityadav01No ratings yet

- Journal of Physics & AstronomyDocument12 pagesJournal of Physics & Astronomysnigdha shromaNo ratings yet

- Rubber Process Oils NewDocument4 pagesRubber Process Oils NewVaradrajan jothiNo ratings yet

- RADIOIMMUNOASSAYDocument4 pagesRADIOIMMUNOASSAYJansen MunioNo ratings yet

- Hladnjaca DefrostingDocument6 pagesHladnjaca DefrostingDzana KadricNo ratings yet

- Yag ManualDocument43 pagesYag ManualMi Sinziana100% (1)

- 2021 08 06 Nasa STD 5020b - Final PDFDocument114 pages2021 08 06 Nasa STD 5020b - Final PDFGianluca FacchiniNo ratings yet

- Topworx ValvetopDocument24 pagesTopworx ValvetopaleNo ratings yet

- Zainal (2001) - Prediction of Performance of A Downdraft Gasifier Using Equilibrium Modeling For Different Biomass MaterialsDocument17 pagesZainal (2001) - Prediction of Performance of A Downdraft Gasifier Using Equilibrium Modeling For Different Biomass MaterialsAbraham AvNo ratings yet