Introduction

MKK1123 ADVANCED PROCESS CONTROL

Semester II 2011/2012

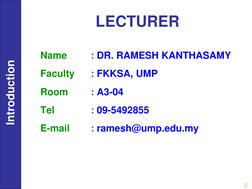

�LECTURER

Introduction

Name Faculty Room Tel E-mail : DR. RAMESH KANTHASAMY : FKKSA, UMP : A3-04 : 09-5492855 : ramesh@ump.edu.my

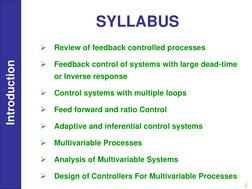

�SYLLABUS

Review of feedback controlled processes

Introduction

Feedback control of systems with large dead-time

or Inverse response

Control systems with multiple loops Feed forward and ratio Control Adaptive and inferential control systems

Multivariable Processes

Analysis of Multivariable Systems Design of Controllers For Multivariable Processes

3

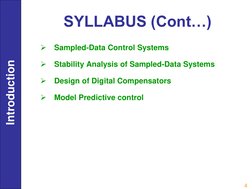

�SYLLABUS (Cont)

Sampled-Data Control Systems

Introduction

Stability Analysis of Sampled-Data Systems

Design of Digital Compensators Model Predictive control

�Importance of Process Control

safety and reliability of a process

Introduction

Quality of the products produced by a process

Operating a process efficiently (Operational constraints) Environmental regulations Bottom Line: PC has a major impact on the profitability of a company

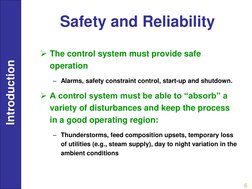

�Safety and Reliability

Introduction

The control system must provide safe operation

Alarms, safety constraint control, start-up and shutdown.

A control system must be able to absorb a variety of disturbances and keep the process in a good operating region:

Thunderstorms, feed composition upsets, temporary loss of utilities (e.g., steam supply), day to night variation in the ambient conditions

�Why Safety important?

Introduction

Bhopal Disaster (December 1984)

- Union Carbide factory (US based company) - 40 tons of Methyl Isocyanate (MIC) leaked - MIC boiling point 39.50C

- Water leaked into MIC storage tank

- 22000 people died and 500,000 injured in 72 hours - The refrigeration unit shut off due to coolant drained off - The gas scrubber designed to neutralize escaping MIC vapors

shut off for maintenance 3 weeks prior

- Lack of effective warning system (Alarm failed)

�Bhopal Disaster

Introduction

�Better Control Means Products with Reduced Variability

Introduction

For many cases, reduced variability products

are in high demand and have high value added Product certification procedures (e.g., ISO 9000) are used to guarantee product quality and place a large emphasis on process

control

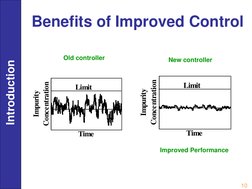

�Benefits of Improved Control

Introduction

Old controller

New controller

Impurity Concentration

Impurity Concentration

Limit

Limit

Time

Time

Improved Performance

10

�Constraint Control Example

Consider a reactor temperature control

Introduction

example for which at excessively high

temperatures the reactor will experience a temperature runaway and explode.

But the higher the temperature the greater

the product yield Therefore, better reactor temperature

control allows safe operation at a higher

reactor temperature and thus more profit

11

�Environmental Regulations

Various federal and state laws may specify

Introduction

that temperatures, concentrations of

chemicals and flow rates of the effluents from a plant be within certain limits.

PC is necessary to maintain those variables

within the limit For example the quality of the waste water

returned to a river or lake should follow

certain norms

12

�Maximizing the Profit of a Plant

Introduction

Many times involves controlling against constraints.

The closer that you are able to operate to these constraints, the more profit you can make. For example, maximizing the product production rate usually involving controlling the process against one or more process constraints.

13

�Importance of Process Control for the Chemical &Bio-Process Industries

Introduction

Improved product quality Faster and less expensive process validation Increased production rates.

14

�LEARNING RESOURCES

Reference Books: 1. Donald Coughnowr and Steven LeBlanc, Process Systems Analysis and Control, Mc Graw Hill 2010. 2. Seborg, D.E., Edgar, T.F. and Mellichamp., Process Dynamic and Control, John Wiley 2004. 3. Marlin, T.E., Process Control: Designing Processes and Control Systems for Dynamic Performance, Mc Graw Hill 2000. 4. Smith, C.A., Corripio, A.B., Principles and Practice of Automatic Process Control, John Wiley 1997. 5. Stephanopoulos, G., Chemical Process Control: An Introduction to Theory and Practice, Prentice-Hall 1984.

15

Introduction

�Elements of control system

Process Equipment together with physical or

Introduction

chemical operations that occur there Measuring instruments or sensors Thermocouples, flow meters, Gas chromatography

Transducers Temp, flow rate etc. to electric voltage

or current Controller Receives information from measuring

devices and decides what action to be taken

Final control element Implement the decision taken by the controller

16

�Control Terminology

Introduction

Controlled variable (Output variable) The process variable that we want to maintain at a particular value (set point) Manipulated variable (Input variable) Process variable that is adjusted to bring the controlled variable back to the set-point Disturbance variable (Input variable) Any process variables that can cause the controlled variable to deviate from its set point. Also called as "load" variable

�Flow Diagram for a Feedback Control Loop

Introduction

Disturbance

Setpoint

+-

Controller

c

Actuator

Process

CV

Sensor

18

�Temperature Control for a Heat Exchanger

Introduction

Steam Setpoint Product Stream TT TC

Feed

Condensate

19

�Heat Exchanger Control

Controlled variable- Outlet temperature of product stream Manipulated variable- Steam flow Actuator- Control valve on steam line Sensor- Thermocouple on product stream Disturbance- Changes in the inlet feed temperature

Introduction

20

�Control Diagram of a Typical Control Loop (Blending Process)

Introduction

Actuator System

F1 T1

F2 T2

Sensor System

Controller

TC TT

T F

�Components and Signals of a Typical Control Loop

Introduction

Actuator System

F1 T1

3-15 psig

F2 T2

Thermowell

T F

Air I/P 4-20 mA D/A Thermocouple millivolt signal

Operator Console

Tsp

DCS Control Computer Controller

A/D

4-20 mA

Transmitter

Sensor System

�Types of Control Problems

Servo Problem

Introduction

Set point changes and load remains constant. The ability to move process from one set point to a new set point (This is termed as Set Point Tracking)

Regulator Problem Load changes and set point remains constant. The ability to maintain the process variable at its desired value (set point) in spite of disturbances that might be experienced (This is termed as Disturbance Rejection)

�DIGITAL COMPUTER CONTROL

Introduction

�MULTIPLEXER

It quite often happens, in the design of large-scale digital systems, that a single line is required to carry two or more different digital

Introduction

signals. Of course, only one signal at a time can be placed on the one

line. What is required is a device that will allow us to select, at different instants, the signal we wish to place on this common line. Such a circuit is referred to as a Multiplexer. A multiplexer performs the function of selecting the input on any one of 'n' input lines and feeding this input to one output line.

�MULTIPLEXER

Multiplexers are used as one method of reducing the number of integrated circuit

Introduction

packages required by a particular circuit design. This in turn reduces the cost of the system. Assume that we have four lines, C0, C1, C2 and C3, which are to be multiplexed on a single line, Output (f). The four input lines are also known as the Data Inputs. Since there are four inputs, we will need two additional inputs to the multiplexer, known as the Select Inputs, to select which of the C inputs is to appear at the output. Lines A and B are called Select Inputs

�Sampler

Introduction

Green Line Continuous Signal

Blue Dots Discrete Signal

27

�Sampler

Sampler is a switch, which closes every T seconds and

Introduction

remains closed for an infinitesimally short period of time.

As the sampling period tends zero, the sampled representation comes closer to the continuous signal but requires an explosively large number of sampled values.

On the other hand, as the sampling period increases,

fewer sampled values are required, but the sampled representation of a continuous signal deteriorates, and the reconstruction of the original signal becomes poor or

sample.

�Introduction

Sampler

�Sampler

Introduction

t 0 ___ 0 0.632 0.865 0.950 0.982 0.993

2 3 4 5

Response of first-order system to a step of magnitude, M

�Sampling of oscillating signal

Introduction

Sampling an oscillating signal more than 2 times per cycle of oscillation; otherwise its impossible to reconstruct the original signals from its sampled values.

�Hold Element

Introduction

�First-order Hold Element

Introduction

�Comparison of Zero and First-order Hold Elements

Introduction

Slowly varying Signals

�Comparison of Zero and First-order Hold Elements

Introduction

Rapidly Changing Signals

�Analog-to-Digital Converter

Introduction

03 07 10 14 09 02 00 04

�Analog-to-Digital Converter

Resolution:

Introduction

Suppose a binary number with N bits is to represent an analog value ranging from 0 to A There are 2N possible numbers (including zero).

Resolution = A / (2N 1)

For example, consider a voltage range of 0 to 10V and 12 bit converter. The 12 bits define 4096 integer numbers, which in turn defines 4095 voltage intervals between 0 and 10. ADC used for process control allow 20,000 to 100,000 conversions per second

�Digital-to-analog converter

Digital-to-analog converter (DAC) function in the reverse manner to ADC. The 12 bits define 4096 integer numbers, which in turn defines 4095 voltage intervals between 0 and 10. Then the integer number 516 causes an analog output of (516/4095) X 10 = 1.26V

Introduction

�Time Delay or Dead-time

Let, u fluid property (e.g., temperature or composition) at point 1 fluid property at point 2

Introduction

Fluid In

Fluid Out

Point 1

Point 2

Assume that the velocity profile is flat, that is, the velocity is uniform over the cross-sectional area.

�Time Delay or Dead-time

Introduction

�Feedback control of systems with large dead-time

Introduction

�Feedforward Control

Introduction

In some cases, the major disturbance to a process is measured and utilized to adjust the manipulated variable The advantage feedforward control is that corrective action is taken for a change in a disturbance input before it affects the control parameter Feedforward control is used in conjunction with feedback control to provide multipleinput single output (MISO) control

�Feedforward Temperature Control

Introduction

�Feedforward and Feedback Temperature Control

Introduction

�Analysis of Feedforward and Feedback Temperature Control

Feedback - only must absorb the

Introduction

variations in exit temperature by feedback

action Feedforward - only handle variation in exit

temperature by measuring the warm liquid

flow into the tank Combined feedforward and feedback has best features of both controllers

�Ratio Control

Ratio control is a special type of feedforward

Introduction

control where both manipulated variable and

disturbance (load) are measured and held in a constant ratio to each other Useful when the manipulated variable scales directly with the feed rate to the process Both flow rates are measured but only one can be controlled The stream whose flow rate is under control is known as wild stream

�Ratio Control for Wastewater Neutralization

Introduction

FT

RSP

FC FT

Acid Wastewater

pHC pHT

NaOH Solution

Effluent

�Analysis of Ratio Control Example

The flow rate of base scales directly with the

Introduction

flow rate of the acidic wastewater The output of the pH controller is the ratio of NaOH flow rate to acid wastewater flow rate Here, the product of the controller output and the measured acid wastewater flow rate become the setpoint for the flow controller on the NaOH addition.

�ADAPTIVE CONTROL

Adaptive control is the one in which the controller parameters are

Introduction

adjusted automatically to compensate for changing process

conditions. control method used by a controller which must adapt to a controlled system with parameters which vary, or are initially

uncertain.

Examples: - Changes in equipment characteristics (eg. Heat exchanger fouling) - Large frequent disturbances (feed composition, fuel quality etc.) - Unusual operational status such as failure, start up, and shut down)

�ADAPTIVE CONTROL

Introduction

�Inferential Control

Inferential control is the one where the primary variables are difficult to measure or slow sampling then the fast

Introduction

sampling secondary variables are measured and using a

mathematical model (soft sensor) to infer the value of the controlled variable.

�Inferential Control

Introduction