Professional Documents

Culture Documents

LOB, Work Study

Uploaded by

Arun MishraOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LOB, Work Study

Uploaded by

Arun MishraCopyright:

Available Formats

PRODUCTION AND OPERATIONS MANAGEMENT

LOB Technique

By Arun Mishra

LOB Technique

Line-of

-Balance Technique: A technique used in production scheduling and control to determine at a review date, not only how many of an item should have been completed by that date, but also how many should have passed through the up-stream operation stages by that time, so as to ensure the completion of the required delivery schedule. It is a chart & computational technique for monitoring & controlling products & services that are made to meet specific delivery schedule.

Benefits of LOB Technique

Enforces planning discipline & enables control to be exercised at each stage of the production line. Prevents any feeling of false security which might be engendered if the delivery of an item is on schedule but unappreciated shortfalls at early stages are building up trouble. Enables identification of short falls or even excessive production or purchasing levels, so that corrective action can be taken in good time. Products and services are produced to specific delivery schedules, production involves many processing steps & production lead times are long.

Stages of LOB Technique

Preparation of operation programme or assembly chart. Preparation of cumulative completion/ delivery schedule or objective chart. Construction of LOB chart. Analysis of progress and corrective action.

Work Study-Method Study

Work Study-Method Study

Work study method was developed to improve performance of a given work. Work study is defined as the body of knowledge concerned with analysis of the work methods, and the standard of proposed work methods. The purpose of work study is to determine the best or most effective method of accomplishing a necessary operation. Objectives of work study are:

To analyse the present method of doing a job, in order to develop a new & better method. To measure the work content of a job by measuring the time required by a qualified worker & to establish standard time. To increase the productivity by ensuring the best possible use of human, machine & material resources. To improve operational efficiency.

Relationship of Time and Motion Study to Work Study

Time

study and motion study are results of practices developed by F.W. Taylor, Frank and Lillian Gilbreth. Time study: Exercising control over the output in respect of a job by setting standards for performance. Time study may be used to compare the effectiveness of alternative work methods.

Steps Involved in Work Study

Method Study or Methods Analysis

Method

study is a scientific technique of observing, recording & critically examining the present method of performing a job or operation with the aim of improving the present method. It is also known as methods improvement. It is a means of developing and applying easier & more effective method & reducing cost. Prime objectives of method study is to eliminate wasteful and inefficient motions.

Method Study Procedure

Method study procedure involves six steps. Select the work to be studied. Record all relevant facts pertaining

to

existing method. Examine the recorded facts critically. Develop the improved method by generating the several alternatives. Install the improved method in 3 phases planning, arranging & implementing. Maintain the new method by ensuring the effective functioning of it.

Recording Techniques Used in Method Study

Process Charts used in Method Study 1. Outline process chart 2. Operation process chart 3. Flow process charts 4. Two handed process chart 5. Multiple activity chart 6. The man machine chart or worker-machine chart 7. Flow diagram 8. String diagram 9. Cyclic graph 10.SIMO chart (Simultaneous motion Chart)

You might also like

- Production and Operations Management: Method Study & Maintenance ManagementDocument56 pagesProduction and Operations Management: Method Study & Maintenance ManagementBhargav KanjariyaNo ratings yet

- Work Study Is A GenericDocument31 pagesWork Study Is A GenericJoseph Rana SangpangNo ratings yet

- Method Study Work StudyDocument14 pagesMethod Study Work StudyBhavesh Jain100% (1)

- Pre-Production Planning & Apparel Engineering: WorkshopDocument36 pagesPre-Production Planning & Apparel Engineering: WorkshopraiyanduNo ratings yet

- Topic 12&13 - Work Study & Costs-SDocument30 pagesTopic 12&13 - Work Study & Costs-SsteyvohmannaNo ratings yet

- Pom PPT 1Document81 pagesPom PPT 1Aman HariNo ratings yet

- Production and Operations Management: Time and Motion StudyDocument11 pagesProduction and Operations Management: Time and Motion StudyMd. Osman AliNo ratings yet

- Time StudyDocument11 pagesTime StudyHarpreet SinghNo ratings yet

- PEM M C02: Operations Management: Post Graduate Programme in Project Engineering and ManagementDocument63 pagesPEM M C02: Operations Management: Post Graduate Programme in Project Engineering and Managementchandanprakash30No ratings yet

- UNIT-2 Industrial Management PDFDocument27 pagesUNIT-2 Industrial Management PDFGaurav Mishra100% (2)

- Industrial Engineering ServicesDocument27 pagesIndustrial Engineering ServicesPrabakaran ManickamNo ratings yet

- Operations Management Unit-3Document53 pagesOperations Management Unit-3sadafahmed007No ratings yet

- Unit 2Document10 pagesUnit 2Mani KrishNo ratings yet

- 2 Control Method StudyDocument32 pages2 Control Method StudyNarmathaNo ratings yet

- Work Study Method Study Work MeasurementDocument53 pagesWork Study Method Study Work MeasurementPrabhu VelidindiNo ratings yet

- Iv UnitDocument3 pagesIv Unitpavan kumarNo ratings yet

- Work StudyDocument56 pagesWork StudyMuslima MohammedNo ratings yet

- Unit - Ii: Dr. Umang SoniDocument44 pagesUnit - Ii: Dr. Umang SoniNITIN NAUTIYALNo ratings yet

- Me 404 Industrial Engineering: Santhu Varghese Thomas Assistant Professor Mangalam College of EngineeringDocument80 pagesMe 404 Industrial Engineering: Santhu Varghese Thomas Assistant Professor Mangalam College of Engineeringe tutorNo ratings yet

- WE-LIKE HPGDAP160791 Final Year ProjectDocument26 pagesWE-LIKE HPGDAP160791 Final Year ProjectNageshNo ratings yet

- Work StudyDocument21 pagesWork StudysivainamduguNo ratings yet

- WSM Lec1PRODUCTIVITY 2Document24 pagesWSM Lec1PRODUCTIVITY 2TRISTAN JOY DEDUQUE FURAQUENo ratings yet

- WSM Lec1PRODUCTIVITY 2Document24 pagesWSM Lec1PRODUCTIVITY 2TRISTAN JOY DEDUQUE FURAQUENo ratings yet

- Operations Management Unit-IiiDocument6 pagesOperations Management Unit-IiiPatel RuchitaNo ratings yet

- PPC PDFDocument77 pagesPPC PDFAkshay sachanNo ratings yet

- Work Study ProjectDocument26 pagesWork Study ProjectNagesh100% (1)

- Work Study, Motion Study, Time StudyDocument8 pagesWork Study, Motion Study, Time StudyParvathy Suresh0% (1)

- MethodsDocument3 pagesMethodssunidhimishra2375No ratings yet

- Production Planning and ControlDocument15 pagesProduction Planning and Controlsumitauppal5542No ratings yet

- An Effort By: Neelkanth Prashant Rishav: CompanyDocument35 pagesAn Effort By: Neelkanth Prashant Rishav: CompanyNeel Kanth100% (1)

- IEM-Module 3Document12 pagesIEM-Module 3Sunil Kumar KashyapNo ratings yet

- Unit - IiDocument167 pagesUnit - IiDhamotharan SNo ratings yet

- Notes POM Module 4Document15 pagesNotes POM Module 4api-3698486100% (2)

- Unit 2-3 3Document111 pagesUnit 2-3 3ethanNo ratings yet

- Production Planning & Control: Unit - IDocument17 pagesProduction Planning & Control: Unit - IL SANDEEP REDDYNo ratings yet

- Work MeasurementDocument24 pagesWork MeasurementKhryzz Claudine CabañeroNo ratings yet

- Test ManagementDocument11 pagesTest ManagementMuzammil BalochNo ratings yet

- Work Study Including Method Study and Time StudyDocument21 pagesWork Study Including Method Study and Time StudyPrudhvi Sairam ChundruNo ratings yet

- Prof. V.B.Shah Insitute of Management, Amroli, Surat: Course: S.Y.Bba (Sem - Iv)Document24 pagesProf. V.B.Shah Insitute of Management, Amroli, Surat: Course: S.Y.Bba (Sem - Iv)Vasu PatelNo ratings yet

- Work Study: Engr. Lamia AnzumDocument34 pagesWork Study: Engr. Lamia Anzumইমরানুল শহীদ আলভীNo ratings yet

- Work Design and MeasurementDocument35 pagesWork Design and MeasurementJezeil Dimas100% (1)

- Work StudyDocument16 pagesWork StudyAkanksha kondaNo ratings yet

- Work Study1Document11 pagesWork Study1thenameisyash118No ratings yet

- Unit IPPCDocument65 pagesUnit IPPCRajbir SinghNo ratings yet

- (POM) Unit 4 Short NoteDocument9 pages(POM) Unit 4 Short NoteSourabh GuhaNo ratings yet

- Work Measurements and Methods: Uses of Setting Work StandardsDocument3 pagesWork Measurements and Methods: Uses of Setting Work StandardsSonaNo ratings yet

- Unit No. 2 Work StudyDocument46 pagesUnit No. 2 Work Studyyash.salunkhe20No ratings yet

- UNIT-2: Management FunctionDocument35 pagesUNIT-2: Management FunctionShikha DubeyNo ratings yet

- Pom Unit IV April 15 2014Document26 pagesPom Unit IV April 15 2014divya dawdaNo ratings yet

- Work Study and Method Study: Dairy Plant Management (Dtt421) AkjhaDocument11 pagesWork Study and Method Study: Dairy Plant Management (Dtt421) AkjhaShrutiNo ratings yet

- Work Measurement: Part II of Work StudyDocument45 pagesWork Measurement: Part II of Work StudyAbhinav AnandNo ratings yet

- Blank Hundred ChartDocument3 pagesBlank Hundred ChartMenkent Santisteban BarcelonNo ratings yet

- Overview of Predetermined Motion Time SystemDocument35 pagesOverview of Predetermined Motion Time SystemRizza SangcoNo ratings yet

- CH - 6 Test ManagementDocument32 pagesCH - 6 Test ManagementUmesh MahajanNo ratings yet

- Unit Iv OmDocument29 pagesUnit Iv Om1234 KrjrNo ratings yet

- Practical Guide To Work Study [Revised Edition]From EverandPractical Guide To Work Study [Revised Edition]Rating: 4 out of 5 stars4/5 (1)

- Practical Guide To Production Planning & Control [Revised Edition]From EverandPractical Guide To Production Planning & Control [Revised Edition]Rating: 1 out of 5 stars1/5 (1)

- Marketing Mix and Branding Competitive Hypermarket StrategiesDocument19 pagesMarketing Mix and Branding Competitive Hypermarket StrategiesArun MishraNo ratings yet

- Service Product Life CycleDocument20 pagesService Product Life CycleArun MishraNo ratings yet

- The Effect of Retailer Concentration and Store FormatDocument62 pagesThe Effect of Retailer Concentration and Store FormatArun MishraNo ratings yet

- Impact of Packaging On The Buying Behaviour of ConsumersDocument12 pagesImpact of Packaging On The Buying Behaviour of ConsumersArun MishraNo ratings yet

- Unit III Decision Making ConceptsDocument16 pagesUnit III Decision Making ConceptsArun MishraNo ratings yet

- WTO & Its Importance For Indian Business: Prof. Arun MishraDocument25 pagesWTO & Its Importance For Indian Business: Prof. Arun MishraArun MishraNo ratings yet

- Service Complaints & Recovery U5Document16 pagesService Complaints & Recovery U5Arun MishraNo ratings yet

- Multinationals: Unit I As Global IntermediariesDocument18 pagesMultinationals: Unit I As Global IntermediariesArun MishraNo ratings yet

- People in Services: Human Resources ManagementDocument15 pagesPeople in Services: Human Resources ManagementArun MishraNo ratings yet

- Exchange Rate Determination: Arun Mishra 9893686820Document21 pagesExchange Rate Determination: Arun Mishra 9893686820Arun MishraNo ratings yet

- U3 Regional Integration & Trade ArrangementsDocument40 pagesU3 Regional Integration & Trade ArrangementsArun MishraNo ratings yet

- International Monetary Fund (IMF) Role and Function of Imf: Arun Mishra 9893686820Document27 pagesInternational Monetary Fund (IMF) Role and Function of Imf: Arun Mishra 9893686820Arun MishraNo ratings yet

- The Instruments of Trade Policy: Arun Mishra 9893686820Document13 pagesThe Instruments of Trade Policy: Arun Mishra 9893686820Arun MishraNo ratings yet

- International Business Environment: Unit - IIDocument35 pagesInternational Business Environment: Unit - IIArun MishraNo ratings yet

- Theories of International Trade: Unit - IDocument24 pagesTheories of International Trade: Unit - IArun Mishra100% (1)

- Joint VentureDocument23 pagesJoint VentureArun MishraNo ratings yet

- International Business: An Overview & Types: Unit - IDocument55 pagesInternational Business: An Overview & Types: Unit - IArun MishraNo ratings yet

- U4 Database Management System (DBMS)Document31 pagesU4 Database Management System (DBMS)Arun MishraNo ratings yet

- U5 Dialog Generation SystemDocument17 pagesU5 Dialog Generation SystemArun MishraNo ratings yet

- Decision Making TechDocument22 pagesDecision Making TechArun MishraNo ratings yet

- The Systems Development Methodologies: Unit - IIDocument24 pagesThe Systems Development Methodologies: Unit - IIArun MishraNo ratings yet

- Influence of Personality and Self Concept On BuyingDocument19 pagesInfluence of Personality and Self Concept On BuyingArun MishraNo ratings yet

- System Analysis & Design: Unit - IIDocument33 pagesSystem Analysis & Design: Unit - IIArun MishraNo ratings yet

- U3 Decision Making ConceptsDocument27 pagesU3 Decision Making ConceptsArun MishraNo ratings yet

- DSS - Relevance, Scope, Characteristics, Components: Dss & Mis - Unit IvDocument15 pagesDSS - Relevance, Scope, Characteristics, Components: Dss & Mis - Unit IvArun MishraNo ratings yet

- Diffusion of Innovation and Opinion LeadershipDocument17 pagesDiffusion of Innovation and Opinion LeadershipArun MishraNo ratings yet

- Management Information System Overview & Characteristics: Prof. Arun Mishra Mobile: 9893686820Document22 pagesManagement Information System Overview & Characteristics: Prof. Arun Mishra Mobile: 9893686820Arun MishraNo ratings yet

- MIS - Subsystems & Types: Prof. Arun MishraDocument47 pagesMIS - Subsystems & Types: Prof. Arun MishraArun MishraNo ratings yet

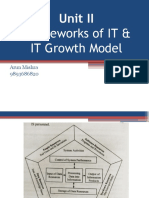

- Frameworks of IT & IT Growth Model: Unit IIDocument12 pagesFrameworks of IT & IT Growth Model: Unit IIArun MishraNo ratings yet

- Consumer Behaviour (MBA III Sem)Document25 pagesConsumer Behaviour (MBA III Sem)Arun MishraNo ratings yet

- 15-001 Final PDFDocument44 pages15-001 Final PDFMorgen GumpNo ratings yet

- Floor Gullies and Access Covers PDFDocument91 pagesFloor Gullies and Access Covers PDFMonevenNo ratings yet

- Eriks Epdm 70 Compound 55985Document2 pagesEriks Epdm 70 Compound 55985chethanNo ratings yet

- ABC Cma ProjectDocument5 pagesABC Cma ProjectAakash BhotikaNo ratings yet

- 873003.Vw - How To Read Wiring Diagrams. (USA)Document83 pages873003.Vw - How To Read Wiring Diagrams. (USA)Fernando García100% (3)

- Electrical Calculator EngineeringDocument16 pagesElectrical Calculator Engineeringfuziadithia188No ratings yet

- Freno de Mano AveoDocument18 pagesFreno de Mano AveoORLANDONo ratings yet

- Fiber Optic Exam 1Document7 pagesFiber Optic Exam 1eaay007No ratings yet

- Cisco ME 3600X Series Ethernet Access Switches - Support in CiscoDocument3 pagesCisco ME 3600X Series Ethernet Access Switches - Support in CiscoĐỗ TháiNo ratings yet

- How To Balance Traffic Between 900Document3 pagesHow To Balance Traffic Between 900saeedtarkianNo ratings yet

- Spliced Girder BridgeDocument15 pagesSpliced Girder BridgePartha Pratim RoyNo ratings yet

- RepairDiagnostics PT 01 C0G36Z008E 3MBDocument6 pagesRepairDiagnostics PT 01 C0G36Z008E 3MBJosé Da Silva MataNo ratings yet

- IEEE Standards Interpretations For IEEE STD C37.04™-1999, IEEE STD C37.06™-2000, and IEEE STD C37.09™-1999Document2 pagesIEEE Standards Interpretations For IEEE STD C37.04™-1999, IEEE STD C37.06™-2000, and IEEE STD C37.09™-1999Hamylto PamoNo ratings yet

- ZTE CRBT SpecificationsDocument10 pagesZTE CRBT SpecificationsMirza Zaheer AhmedNo ratings yet

- Optimizing Oil (Caterpillar Engine) PDFDocument8 pagesOptimizing Oil (Caterpillar Engine) PDFKurniadi Setyanto100% (1)

- TTM4137 EssayDocument4 pagesTTM4137 EssayMark SuarezNo ratings yet

- Commissioning Water Systems A BSRIA Guid PDFDocument11 pagesCommissioning Water Systems A BSRIA Guid PDFAnurag Kumbhare33% (3)

- Auditing Test Bank Chapter 15Document34 pagesAuditing Test Bank Chapter 15Heejin Kwon100% (10)

- Xanthan Gum E415Document4 pagesXanthan Gum E415sharemwNo ratings yet

- Lab 2 HardnessDocument8 pagesLab 2 HardnessMuhammad Zulhilmi0% (1)

- Відповіді до ЄвчукDocument8 pagesВідповіді до ЄвчукAnastasijaNo ratings yet

- Core StackingDocument5 pagesCore StackingWaseem KambohNo ratings yet

- Data AbelDocument91 pagesData AbelDinar DirhamNo ratings yet

- JCHT35K9 EngDocument5 pagesJCHT35K9 EngRodica PuscauNo ratings yet

- HT-25 Service Manual 2009Document37 pagesHT-25 Service Manual 2009Plumberguy101No ratings yet

- Efficiency Audit, Internal Audit & Management AuditDocument10 pagesEfficiency Audit, Internal Audit & Management Auditankitkhetan2007100% (2)

- Chapter 2 Design For ServiceabilityDocument29 pagesChapter 2 Design For ServiceabilityJoena Linda100% (1)

- Marketing Mix Kuat HarimauDocument11 pagesMarketing Mix Kuat HarimauFakhriHamzah100% (1)

- Chemical Resistance of Coatings Used in Light-Water Nuclear Power PlantsDocument2 pagesChemical Resistance of Coatings Used in Light-Water Nuclear Power PlantsdorsaNo ratings yet

- IS: 2911 (Part I/Sec 1) - 1979 CODE OF PRACTICE FOR DESIGN AND CONSTRUCTION OF PILE FOUNDATIONSDocument33 pagesIS: 2911 (Part I/Sec 1) - 1979 CODE OF PRACTICE FOR DESIGN AND CONSTRUCTION OF PILE FOUNDATIONSranjith6688100% (2)

![Practical Guide To Work Study [Revised Edition]](https://imgv2-2-f.scribdassets.com/img/word_document/245836753/149x198/e8597dfaef/1709916910?v=1)

![Practical Guide To Production Planning & Control [Revised Edition]](https://imgv2-1-f.scribdassets.com/img/word_document/235162742/149x198/2a816df8c8/1709920378?v=1)