Professional Documents

Culture Documents

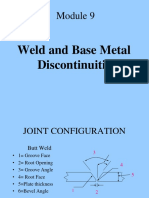

Visual Inspection of Welds

Uploaded by

Imran Muhamed0 ratings0% found this document useful (0 votes)

25 views19 pagesMechanical

Original Title

Visual Defects

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentMechanical

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

25 views19 pagesVisual Inspection of Welds

Uploaded by

Imran MuhamedMechanical

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 19

Visual Inspection of Welds

Butt Weld Size

a) excess weld metal height

b) root penetration

c) weld width

d) root bead width

Fillet welds (size)

Consider:

a) z minimum (and maximum) leg length

size

b) a minimum design throat

thickness

Shape (Butt Welds)

Ideally, (a) is the most desirable but

very often it may be difficult to

achieve. Because of this, one should

assess the excess weld height in

conjunction with the weld profile and

perhaps the toe blending.

Consider:

Shape (Fillet Welds)

In normal practice, (a) is the most desirable

but, again, in many instances it is difficult to

achieve. Acceptance levels, therefore, allow

tolerances on weld shape.

Consider:

Toe Blend (Butt Welds)

Depending on the service conditions

of the product, the toe blend may be

of greater importance than the size

and shape of the weld. A poor toe

blend may reduce service life by a

considerable margin if the product is

under a cyclic load.

For butt welds, consider:

In normal practice, (a) is the most

desirable but, again, in many

instances it is difficult to achieve.

Acceptance levels, therefore, allow

tolerances on weld shape.

Toe Blend (Fillet Welds)

For fillet welds, consider:

In normal practice, (a) is the most

desirable but, again, in many

instances it is difficult to achieve.

Acceptance levels, therefore,

allow tolerances on weld shape.

Root Defects

Incomplete root penetration

Failure of weld metal to extend into the root of a joint

Lack of root fusion

Lack of union at the root of a joint

Excess penetration bead

Excess weld metal protruding through the root of

a fusion weld made from one side only

Root Defects

Root concavity

(suck-back; underwashing - non-standard terms)

A shallow groove which may occur in the root of a

butt weld, but full fusion is evident

Shrinkage groove

A shallow groove caused by contraction in the metal

along each side of a penetration bead or along the

weld centreline

Burnthrough

(melt through)

A localised collapse of the molten pool due to

excessive penetration, resulting in a hole in the

weld run

Contour Defects

Incompletely filled groove

A continuous or intermittent channel

in the surface of a weld, running

along its length, due to insufficient

weld metal. The channel may be

along the centre or along one or

both edges of the weld

Bulbous Contour

Bulbous contour

A non-standard term used to

describe poor appearance

Unequal Legs

Unequal legs

(non standard term)

Variation of leg length on a fillet weld

Note: Unequal leg lengths may be

specified as part of the design - in which

case they are not imperfections

Undercut

Undercut

An irregular groove at a toe of a run in the

parent metal or in previously deposited

weld metal

The inspector must determine if the

undercut is continuous or intermittent, or

sharp or smooth

Overlap

Overlap

An imperfection at the toe or root of a

weld caused by metal flowing on to the

surface of the parent metal without fusing

to it

Gas Pore

Gas pore

A cavity, generally under

1.5mm in diameter, formed by

trapped gas during the

solidification of molten metal

Porosity

A group of gas pores

Crater Pipe

Crater pipe

A depression due to shrinkage at the end of a

run where the source of heat was removed.

Crater pipes may also lead to micro-cracking

Surface Cracks

Crack

A linear discontinuity produced by fracture

Cracks may be ...

a) ... longitudinal, in the weld metal, i.e. centreline

b) ... longitudinal, in the parent metal or heat affected zone

c) ... transverse

d) Crater crack

(star cracking)

Arc Strike

Stray flash/arc burn/arc strike

(stray arcing)

1. The damage on the parent material

resulting from the accidental striking of an

arc away from the weld

2. The accidental striking of an arc away

from the weld

Note that the same term is used for both

the action and the result

Weld Width

For butt welds and fillet welds,

consider:

Weld width and consistency of weld width

You might also like

- Century 21 South Western Accounting Answer Key Free PDF Ebook Download Century 21 South Western Accounting Answer Key Download or Read Online Ebook Century 21 SouthDocument8 pagesCentury 21 South Western Accounting Answer Key Free PDF Ebook Download Century 21 South Western Accounting Answer Key Download or Read Online Ebook Century 21 SouthJohn0% (4)

- Assignment 2 Grammar Lesson PlanDocument26 pagesAssignment 2 Grammar Lesson PlanKesia Kerspay100% (1)

- 6000 Most Common Korean Words - For All TOPIK Levels PDFDocument232 pages6000 Most Common Korean Words - For All TOPIK Levels PDFZac67% (3)

- Welding Imperfection and Material InspectionDocument62 pagesWelding Imperfection and Material Inspectionintfarha10No ratings yet

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Welding - Visual DefectsDocument19 pagesWelding - Visual Defectsbasita2No ratings yet

- Cswip PracticalDocument57 pagesCswip Practicaltulasirao.nammiNo ratings yet

- Common Weld DiscontinuitiesDocument43 pagesCommon Weld DiscontinuitiesNader GaafarNo ratings yet

- Figure 1: Groove Weld TerminologyDocument28 pagesFigure 1: Groove Weld TerminologyAmyNo ratings yet

- WeldingDocument41 pagesWeldinggigiphiNo ratings yet

- Casting Process Design GuidelinesDocument8 pagesCasting Process Design GuidelinesSanjay ShahNo ratings yet

- Welding DefectsDocument38 pagesWelding Defectssajeev27100% (4)

- Requirme Assignment3Document4 pagesRequirme Assignment3Cyber RoseNo ratings yet

- Design of Gravity Die CastingsDocument25 pagesDesign of Gravity Die CastingsM PraveenNo ratings yet

- Forging Defects and Extrusion DefectDocument8 pagesForging Defects and Extrusion DefectVenkat KrishnaNo ratings yet

- Welding PresentationDocument65 pagesWelding PresentationVasil YordanovNo ratings yet

- InspectionDocument17 pagesInspectionRishu GuptaNo ratings yet

- Seam DefectDocument4 pagesSeam DefectPatrick Dominguez100% (2)

- Defects in WeldsDocument6 pagesDefects in WeldsSaran KumarNo ratings yet

- Weld DefectsDocument47 pagesWeld DefectsPratikNo ratings yet

- Ultrasonic Testing HandbookDocument29 pagesUltrasonic Testing HandbookRafael HernandezNo ratings yet

- Defects WeldingDocument206 pagesDefects WeldingJayesh100% (1)

- Welding Defect: Hydrogen EmbrittlementDocument8 pagesWelding Defect: Hydrogen EmbrittlementShajin Mohammed ShamsudhinNo ratings yet

- Acceptable Weld ProfilesDocument14 pagesAcceptable Weld ProfilesMark Miano100% (1)

- Visual 001Document11 pagesVisual 001kattabommanNo ratings yet

- 3 Welding Imperfections and Materials InspectionDocument31 pages3 Welding Imperfections and Materials InspectionSampath KumarNo ratings yet

- Welding Defects and Remedies: Lack of Fusion Incomplete Penetration Undercutting Porosity Longitudinal CrackingDocument9 pagesWelding Defects and Remedies: Lack of Fusion Incomplete Penetration Undercutting Porosity Longitudinal Crackinglakshmigsr6610No ratings yet

- Welding TerminologyDocument18 pagesWelding Terminologymahi1437100% (1)

- You May Continue To Read On CSWIP 3.1: Question With Answer and Explanation - Part 2Document12 pagesYou May Continue To Read On CSWIP 3.1: Question With Answer and Explanation - Part 2Akram AlhaddadNo ratings yet

- 1 Sand CastingDocument21 pages1 Sand CastingMayank GroverNo ratings yet

- Exp 11Document22 pagesExp 11ManavNo ratings yet

- Welding DefectsDocument122 pagesWelding DefectsqaNo ratings yet

- AnswersDocument30 pagesAnswersTanay NaikNo ratings yet

- Rivets, Welded Joints, Pin JointsDocument69 pagesRivets, Welded Joints, Pin JointsSiddharth KotechaNo ratings yet

- Casting Defects in SteelsDocument4 pagesCasting Defects in SteelsShamsur Rahman Russell100% (1)

- Gating System For Casting2 - WT7 PDFDocument87 pagesGating System For Casting2 - WT7 PDFAzaad Maverick100% (1)

- Introduction To Welding TechnologyDocument9 pagesIntroduction To Welding Technologyibnu.asad984No ratings yet

- Visual TestingDocument95 pagesVisual TestingLeon Heart FCNo ratings yet

- 21 Casting Defects and How To Prevent Them in Your ProductsDocument1 page21 Casting Defects and How To Prevent Them in Your ProductsmkmkhairiNo ratings yet

- Welding TerminologyDocument5 pagesWelding TerminologyKaruppiah ArunachalamNo ratings yet

- Weld Defect - WikeepidiaDocument5 pagesWeld Defect - Wikeepidiapuri16No ratings yet

- WeldingDocument60 pagesWeldingMorad AJNo ratings yet

- Giao Trinh English For WeldingDocument43 pagesGiao Trinh English For WeldingThe Normal HeartNo ratings yet

- 4Document24 pages4Sameer SonuNo ratings yet

- Radiography PresentationDocument28 pagesRadiography PresentationmqasimqasimNo ratings yet

- Acabado Bridas PDFDocument5 pagesAcabado Bridas PDFjast111No ratings yet

- MOULDINGDocument35 pagesMOULDINGsumitNo ratings yet

- Defect TrainingDocument16 pagesDefect Trainingdedikartiwa_dk100% (1)

- Weld and Base Metal DiscontinuitiesDocument74 pagesWeld and Base Metal DiscontinuitiesMohamed Saleh100% (1)

- Welding TolerancesDocument3 pagesWelding Tolerancessaeedsaeed31No ratings yet

- Weld Defects TWIDocument96 pagesWeld Defects TWISabir Shabbir100% (7)

- Classic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersFrom EverandClassic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersRating: 3.5 out of 5 stars3.5/5 (2)

- An Introduction to Metal-Working (Illustrated)From EverandAn Introduction to Metal-Working (Illustrated)Rating: 2.5 out of 5 stars2.5/5 (2)

- A Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesFrom EverandA Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesNo ratings yet

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkFrom EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNo ratings yet

- American Blacksmithing, Toolsmiths' and Steelworkers' Manual - It Comprises Particulars and Details Regarding:: the Anvil, Tool Table, Sledge, Tongs, Hammers, How to use Them, Correct Position at an Anvil, Welding, Tube Expanding, the Horse, Anatomy of the Foot, Horseshoes, Horseshoeing, Hardening a Plowshare and BabbitingFrom EverandAmerican Blacksmithing, Toolsmiths' and Steelworkers' Manual - It Comprises Particulars and Details Regarding:: the Anvil, Tool Table, Sledge, Tongs, Hammers, How to use Them, Correct Position at an Anvil, Welding, Tube Expanding, the Horse, Anatomy of the Foot, Horseshoes, Horseshoeing, Hardening a Plowshare and BabbitingNo ratings yet

- XXth Century Sheet Metal Worker - A Modern Treatise on Modern Sheet Metal WorkFrom EverandXXth Century Sheet Metal Worker - A Modern Treatise on Modern Sheet Metal WorkNo ratings yet

- Rock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesFrom EverandRock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesNo ratings yet

- Mensuration for Sheet Metal Workers - As Applied in Working Ordinary Problems in Shop PracticeFrom EverandMensuration for Sheet Metal Workers - As Applied in Working Ordinary Problems in Shop PracticeNo ratings yet

- (English (Auto-Generated) ) Intraday Trading On Nifty (2nd September, 2021) 8 Lakhs Profit Shreyas Bandi Trade Ideas Live (DownSub - Com)Document41 pages(English (Auto-Generated) ) Intraday Trading On Nifty (2nd September, 2021) 8 Lakhs Profit Shreyas Bandi Trade Ideas Live (DownSub - Com)YaaroNo ratings yet

- Budget of Work Inquiries Investigations and Immersion 19 20Document1 pageBudget of Work Inquiries Investigations and Immersion 19 20alma florNo ratings yet

- Full TextDocument167 pagesFull Textjon minanNo ratings yet

- Framework For A Digital Twin in Manufacturing Scope and RequirementsDocument3 pagesFramework For A Digital Twin in Manufacturing Scope and RequirementsJoão Vitor100% (1)

- BFISDocument1 pageBFISEverestNo ratings yet

- 141-203 Solar 660 60 - 40 - 30 - 225 Amp Fleet Battery ChargerDocument10 pages141-203 Solar 660 60 - 40 - 30 - 225 Amp Fleet Battery Chargerjose alberto alvarezNo ratings yet

- Focus On Teaching - Jim KnightDocument213 pagesFocus On Teaching - Jim KnightFernando TeixeiraNo ratings yet

- 12.07.20. O&M Manual 41013 - New PLCDocument41 pages12.07.20. O&M Manual 41013 - New PLCFranco Sebastián GenreNo ratings yet

- 1802SupplementaryNotes FullDocument235 pages1802SupplementaryNotes FullCourtney WilliamsNo ratings yet

- MHSS ItalyDocument9 pagesMHSS Italyromedic36No ratings yet

- pm2 5 Sensor 201605Document6 pagespm2 5 Sensor 201605Vennela NandikondaNo ratings yet

- VSR Trans. PPT3Document16 pagesVSR Trans. PPT3VSR TRANSNo ratings yet

- Exposure: The PhotoreactionDocument16 pagesExposure: The PhotoreactionGeetha ThiruvengadamNo ratings yet

- Presentation DelcorteDocument15 pagesPresentation Delcortecarlos2685No ratings yet

- ASME Geometric Dimension Ing and Tolerance Professional CertificationDocument20 pagesASME Geometric Dimension Ing and Tolerance Professional CertificationPaul Anthony Red60% (5)

- Systematic Literature Review SvenskaDocument6 pagesSystematic Literature Review Svenskafihum1hadej2100% (1)

- NCR Supplier PPAP Training PresentationDocument166 pagesNCR Supplier PPAP Training PresentationRajeev ChadhaNo ratings yet

- Occupational Therapy Examination Review Guide 4th Edition Ebook PDFDocument57 pagesOccupational Therapy Examination Review Guide 4th Edition Ebook PDFrobert.campbell485No ratings yet

- Statistical MethodsDocument77 pagesStatistical MethodsGuruKPO100% (1)

- Generic StructureDocument6 pagesGeneric StructureAndre AlvarezNo ratings yet

- Alignment Technique - The Steam TurbineDocument2 pagesAlignment Technique - The Steam TurbineRajeswar KulanjiNo ratings yet

- Bibliography and FootnotesDocument2 pagesBibliography and FootnotesHannah de VeraNo ratings yet

- Palmiye Leaflet 2015 enDocument4 pagesPalmiye Leaflet 2015 ensaraju_felixNo ratings yet

- The Magical Number 5: Towards A Theory of Everything?Document27 pagesThe Magical Number 5: Towards A Theory of Everything?cesarfrancaNo ratings yet

- Individual Performance Commitment and Review Form (Ipcrf) : Annex EDocument8 pagesIndividual Performance Commitment and Review Form (Ipcrf) : Annex Emenzi magnoNo ratings yet

- 141 ISACA NACACS Auditing IT Projects Audit ProgramDocument86 pages141 ISACA NACACS Auditing IT Projects Audit Programkautaliya100% (6)

- Application Bright Ideas Education Grant Program For TeachersDocument6 pagesApplication Bright Ideas Education Grant Program For Teachersapi-320983699No ratings yet