100% found this document useful (1 vote)

2K views9 pagesLayout Planning Procedure

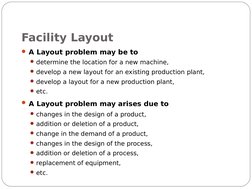

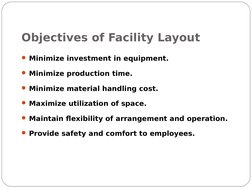

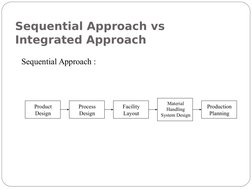

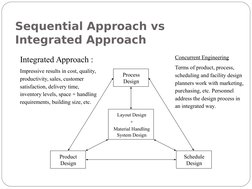

This document outlines various facility layout planning procedures and approaches. It discusses the objectives of facility layout such as minimizing costs and maximizing space utilization. Two main approaches to layout are described: sequential, where product, process, and layout design occur in stages; and integrated, where teams work concurrently on all aspects. Specific layout procedures are also mentioned, including Naddler's ideal system approach, Immer's basic steps, and Muther's systematic layout planning.

Uploaded by

pradeepCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

2K views9 pagesLayout Planning Procedure

This document outlines various facility layout planning procedures and approaches. It discusses the objectives of facility layout such as minimizing costs and maximizing space utilization. Two main approaches to layout are described: sequential, where product, process, and layout design occur in stages; and integrated, where teams work concurrently on all aspects. Specific layout procedures are also mentioned, including Naddler's ideal system approach, Immer's basic steps, and Muther's systematic layout planning.

Uploaded by

pradeepCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd

- Title Page: Provides the title for the presentation focused on layout planning procedures.

- Facility Layout: Introduces the concept of facility layout, exploring why layout problems occur and their potential solutions.

- Approaches to Layout Planning: Compares sequential and integrated approaches to layout planning with flowchart explanations.

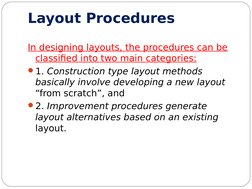

- Layout Procedures: Defines the two main categories of layout procedures and their applications.

- Historical Procedures: Describes historical facility layout procedures developed by Naddler, Immer, Apple, Reed, and Muther.

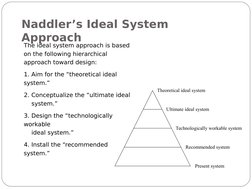

- Detailed Procedures: Details specific layout design approaches such as Naddler’s Ideal System and Immer’s Basic Steps.