Professional Documents

Culture Documents

Plug Gauge

Plug Gauge

Uploaded by

Akash Kumar0 ratings0% found this document useful (0 votes)

14 views9 pagesPlug Gage

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPlug Gage

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views9 pagesPlug Gauge

Plug Gauge

Uploaded by

Akash KumarPlug Gage

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 9

PLUG GAUGE

Plug gauges are used to measure holes/bores to determine if

they are within the specified tolerance (limits of size).

Plug gages determine if a part should be accepted or rejected in

a fast and relatively accurate manner.

It is provided with a suitable handle for holding & is made in a

variety of styles.

A typical plug gauge resembles a rod whose ends are carefully

fashioned so that one end is the upper limit while the other end

is the lower limit.

Each end is offered up to the bore, if the bore is correct then the

GO end will slide into the bore and the NO GO end will not

slide in, if both ends slide in then the bore is too large, if neither

end slides in then the bore is too small.

CLASSIFICATION ACCORDING TO DESIGN

These gauges may be either double, progressive or single ended.

Double ended plain gauges have GO and NO GO members

assembled on opposite ends.

Progressive gauges have both gauging sections combined on one

side so that diameter can be checked in single insertion and time

could be saved.

Single ended plug gauges may have end member either GO or

NO GO.

CLASSIFICATION ACCORDING TO DESIGN

SOLID AND RENEWABLE END TYPE

PLUG GAUGES

Solid end type plug gauges have their ends fixed to the handle.

Renewable end type plug gauges are made such that the end

member if worn out can be replaced with a new one of same or

different size.

The end members are removed out with the help of a tappered

shaped pin that is inserted into the hole of handle.

Renewable plug gauge ends

CLASSIFICATION ACCORDING TO

WORK SURFACE

1) Plain Plug Gauge :

A plain plug gauge is an accurate cylinder having plain GO and

NO GO end surfaces.

It is used as an internal gauge for size control of plain holes and

bores.

2) Thread/Screw Plug Gauge :

A screw plug gauge is similar to plain plug gauge but instead of

having flat parallel faces, it has a screw profile matching that of

the thread type/pitch to be measured.

It is used in a similar way as the plug gauge but is screwed in

rather than pushed in.

It assures assembly of mating parts, inspect pitch diameter and

the functional thread.

LIMITATIONS OF PLUG GAUGES

Hole conditions like a tapper hole, bell mouth, out of round hole are

difficult to distinguish.

Square edges of gauging surfaces become rough and hence they

must be handled and stored carefully.

They may get corroded if not properly protected by a grease/oil

layer.

The threads of a screw plug gauge get blunt if little bit more is

pressure applied while measuring i.e. they are more sensitive.

ADVANTAGES OF PLUG GAUGES

They are small and extremely portable.

They are inexpensive when compared to complex precision

equipment such as universal gage machines or optical comparators.

Another primary use of these plain plug gages is in the calibration of

other precision equipment such as micrometers and callipers.

THANKS

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- CS Pipe Fab & Erect CostsDocument6 pagesCS Pipe Fab & Erect Costswally55bear69% (16)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Photo Guide - Make A Wooden TableDocument41 pagesPhoto Guide - Make A Wooden TableSkorrogan Skontar100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

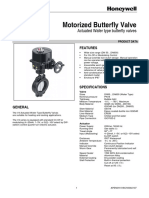

- Motorized Butterfly Valve: Actuated Wafer Type Butterfly ValvesDocument6 pagesMotorized Butterfly Valve: Actuated Wafer Type Butterfly ValvesMOSTAFA HabibNo ratings yet

- TM 43-0104 InsertadoresDocument182 pagesTM 43-0104 InsertadoresJuan Carlos Romero SusunagaNo ratings yet

- Mechanical VentilationDocument22 pagesMechanical VentilationesagcojrNo ratings yet

- Strike-Bar Crusher - Draft1Document5 pagesStrike-Bar Crusher - Draft1Luis CaballeroNo ratings yet

- 13 Tool Cutter GrinderDocument26 pages13 Tool Cutter GrinderAnonymous ITnkbIEFNo ratings yet

- 876JJ6P722 - Partner 200 12-4 (Fini)Document5 pages876JJ6P722 - Partner 200 12-4 (Fini)LefialgaNo ratings yet

- Tormek T-8 Custom: Add JigsDocument2 pagesTormek T-8 Custom: Add JigsGustavo Gonzalez ToledoNo ratings yet

- TM 9-395, 4.5 Inch Aircraft Rocket MaterialDocument30 pagesTM 9-395, 4.5 Inch Aircraft Rocket MaterialVlad VladNo ratings yet

- Anti-Tank Rifles of The Second World WarDocument4 pagesAnti-Tank Rifles of The Second World WarTimia TalashekNo ratings yet

- Q11What Are The Construction Requirement of A Good Sine BarDocument4 pagesQ11What Are The Construction Requirement of A Good Sine Baramal lohchabNo ratings yet

- Service Manual: Service Manual Section Heat Ventilation Air Conditioning (Hvac) SystemDocument191 pagesService Manual: Service Manual Section Heat Ventilation Air Conditioning (Hvac) SystemLuciano NavarreteNo ratings yet

- Safari Grade "Extra Finish" .450/.400 Ne: 150 JAHREDocument2 pagesSafari Grade "Extra Finish" .450/.400 Ne: 150 JAHRErisang akrima fikri100% (2)

- Sabroe TNE508Document91 pagesSabroe TNE508Mike IzelaarNo ratings yet

- Alignment & LevellingDocument4 pagesAlignment & LevellingyuwantoniNo ratings yet

- Rajednra 2022 Price List PDFDocument28 pagesRajednra 2022 Price List PDFMurali YNo ratings yet

- Dual Flush Cistern Valve Installation GuideDocument2 pagesDual Flush Cistern Valve Installation GuideAr ChuNo ratings yet

- HPEDM CatalogDocument72 pagesHPEDM Catalogsuherman agusNo ratings yet

- Pilots and Accessories: Features: ApplicationDocument2 pagesPilots and Accessories: Features: ApplicationVictorIbañezNo ratings yet

- CNC Turning NoteDocument45 pagesCNC Turning NotecoronaqcNo ratings yet

- WelchAllyn Aneroid Sphygmomanometer - Service ManualDocument67 pagesWelchAllyn Aneroid Sphygmomanometer - Service ManualPablo Millaquén GNo ratings yet

- Aeg Fav80800Document48 pagesAeg Fav80800Anonymous WluxrtKaBNo ratings yet

- Rheinmetall Weapon Ammunition - Infantry - 05-2011Document22 pagesRheinmetall Weapon Ammunition - Infantry - 05-2011hodhodhodsribdNo ratings yet

- Precision Measuring ToolsDocument4 pagesPrecision Measuring Toolsabyzen100% (1)

- Rangematic 1000 ManualDocument4 pagesRangematic 1000 ManualPeter SimpsonNo ratings yet

- Sudden Strike 2 ManualDocument12 pagesSudden Strike 2 Manualstartfrage0% (1)

- From Wikipedia, The Free EncyclopediaDocument1 pageFrom Wikipedia, The Free Encyclopediawdm00No ratings yet

- Set-Up Approval Report-Bar PillionDocument1 pageSet-Up Approval Report-Bar Pillionswaran autoqaNo ratings yet

- Booster Pump Head Calculation - AaDocument5 pagesBooster Pump Head Calculation - AaAdnan AttishNo ratings yet