100% found this document useful (1 vote)

429 views44 pagesCompressed Air System Energy Audit Guide

This document discusses compressed air systems and energy management. It covers the fundamentals of air compressors including operational mechanisms and types. It then discusses compressed air systems and how to assess system performance through energy and capacity audits. Key factors that affect compressor performance are outlined. Improvement measures like avoiding misuse, leak reduction, and optimizing piping layouts are presented. The document concludes with examples of energy savings and cost reductions from such measures.

Uploaded by

Nur HazirahCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

429 views44 pagesCompressed Air System Energy Audit Guide

This document discusses compressed air systems and energy management. It covers the fundamentals of air compressors including operational mechanisms and types. It then discusses compressed air systems and how to assess system performance through energy and capacity audits. Key factors that affect compressor performance are outlined. Improvement measures like avoiding misuse, leak reduction, and optimizing piping layouts are presented. The document concludes with examples of energy savings and cost reductions from such measures.

Uploaded by

Nur HazirahCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

- Introduction: An overview of the topics covering air compressors, performance assessment, and improvement methods.

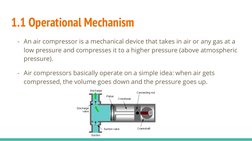

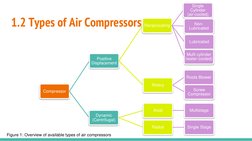

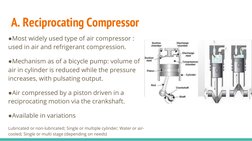

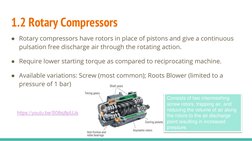

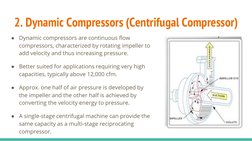

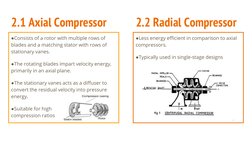

- 1. Fundamentals of Air Compressors: Describes the basic operational principles and types of air compressors.

- 2. Compressed Air System: Addresses the components and operation of compressed air systems.

- Considerations in Performing Energy Audit: Outlines assessments and specific power considerations in energy audits.

- Improvement Measures: Presents measures for optimizing air compressor performance and energy savings.

- Case Studies: Provides case studies showcasing practical applications and results from energy audits.

- Sample Energy Audit Report: Shares links to sample energy audit reports for reference.

- References: Lists references and resources used in preparing the document contents.