0% found this document useful (0 votes)

231 views64 pagesWarehouse Machinery Safety Guide

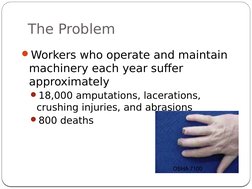

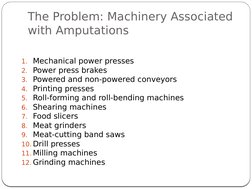

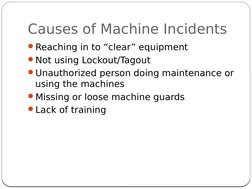

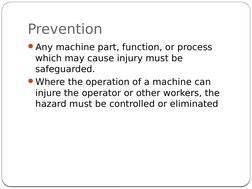

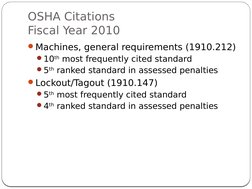

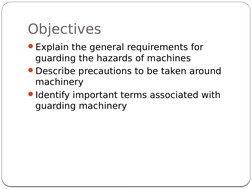

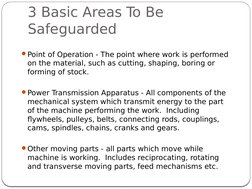

This document discusses machinery safety and machine guarding. It notes that approximately 18,000 workers suffer injuries from machinery each year, including 800 deaths. It identifies the top 10 types of machinery associated with amputations. Effective prevention includes guarding all machine parts and functions that could cause injury. OSHA requires guarding of point of operation hazards, power transmission apparatus, and other moving machine parts. Common types of guards and safety devices are also outlined.

Uploaded by

Marinel SesbrenoCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

231 views64 pagesWarehouse Machinery Safety Guide

This document discusses machinery safety and machine guarding. It notes that approximately 18,000 workers suffer injuries from machinery each year, including 800 deaths. It identifies the top 10 types of machinery associated with amputations. Effective prevention includes guarding all machine parts and functions that could cause injury. OSHA requires guarding of point of operation hazards, power transmission apparatus, and other moving machine parts. Common types of guards and safety devices are also outlined.

Uploaded by

Marinel SesbrenoCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd