Professional Documents

Culture Documents

Soft and Hard Water, Temporary and Permanent

Uploaded by

Raqib Noman0 ratings0% found this document useful (0 votes)

38 views21 pagesSoft and hard water and water softening techniques.

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSoft and hard water and water softening techniques.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

38 views21 pagesSoft and Hard Water, Temporary and Permanent

Uploaded by

Raqib NomanSoft and hard water and water softening techniques.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 21

SOFT AND HARD WATER,

TEMPORARY AND PERMANENT

HARDNESS AND SOFTENING OF

HARD WATER

Submitted to :- Dr SNEHA SHENDE MAM

Submitted by :- ABDUL RAQUIB ABDUL HALIM

INTRODUCTION

Water is basic renewable and natural resource.

Quality of water.

Water in food industry.

(steam, cleaning , heat exchange medium in heating and

cooling, cleaning plant and equipment,

water must be in adequate supply, safer and of high

quality.

TYPES OF WATER

HARD AND SOFT WATER

Water hardness is due to presence of di-cations

including Ca2+ and Mg2+.

HARDNESS OF WATER

There are two types of water hardness

1] Temporary hardness

- caused by carbonates and bicarbonates of calcium

and magnesium.

- removed by boiling.

2] Permanent hardness

- caused by sulfates and chlorides of calcium and

magnesium.

- not removed by boiling.

The combined effect of temporary and permanent

hardness is called as TOTAL HARDNESS.

PROBLEMS CAUSRD BY HARD WATER

Deposition of scales in and on the pipes.

In boilers the deposits acts as insulation that impairs

the flow of heat into water.

Reducing the heating efficiency

Allowing the metal boiler components to overheat

Leads to failure of the boiler

Composition of scales

CaCO3, Mg(OH2), CaSO4, Calcium and magnesium

carbonates

principally caused by thermal decomposition of bi

carbonates ions.

formation of calcium carbonate scales

CaCO3 + CO2 + H2O = Ca+2 + 2HCO3

Hard water forms scum with soap solution.

di-cations destroy the surfactant properties of soap by

forming solid precipitate.

2 C17H35COO- + Ca2+ → (C17H35COO)2 Ca

(soap) (calcium ions) (calcium stearate-

majour component of scum)

SOFTENING OF HARD WATER

To use in boilers, cooling towers and similar

equipment.

To control corrosion and formation of scale on

equipment, to remove turbidity caused by solids,

to eliminate staining, odor and flavor problems,

and to assure safety for consumption

1] By boiling the water

by boiling the soluble bicarbonate is decompose

into insoluble carbonates.

Chemical methods

1] Cold lime method

Lime soda process has two types

_cold lime process. 25-30°c

_hot lime process. 95-100°c

-The soluble calcium and magnesium salts in water

are chemically converted into insoluble

compounds (PPT) by adding calculated amount

of lime[Ca(OH)2] and soda (Na2CO3).

- precipitates off CaCO3 and MgOH2

- These precipitates are filterd off.

2] BASE EXCHANGE SOFTENING METHOD

-More practical and controllable method

- Natural or synthetic zeolite which are

hydrous silicate or styrene based resins are

used.

- Sodium zeolite softening is most widely

applied use of ion exchange.Sodium from or

resin displaces equivalent quantity of calcium

and magnesium.

- Water is passes through resin bed

containing SAC(Strong Acid Cation)resin in

the sodium form.The hardness ions are

exchanged with sodium , and the sodium

diffuses into bulk water solution.

- SAC function well at all pH.

- zeolite softening process

Nowadays commonly

used resins are of

sulfonated styrene

divinylbenzene

structure.

3] DEMINERALIZING WATER SUPPLIES

- Demineralization is the process of

removing mineral salts from Water by using

the ion exchange process.Demineralised

Water is Water completely free ( or almost )

of dissolved minerals

- systems for demineralizing are basically of

two types

✓ multi-bed ion ex-changers

✓mixed-bed ion ex-changers

Mixed bed units requires less space and

produce high quality water.

4] FILTRATION

-Water is passed through a series of filters

with a different filtering media to achieve a

special purpose.

-For removal of particulate matter sand and

gravel filter is effective.

-Activated carbon filters

(Useful for improving taste and odor,

absorbs phenols , chlorine and similar

compounds)

- oxidizing filter medium removes iron and

manganese and raise the pH of acidic water.

-Gravel is a loose aggregation of rock

fragments

5] REVERSE OSMOSIS SYSTEMS

- RO separates one component of a

solution from another by placing the

solution under pressure against a

semipermeable membrane.

- pore size 5-20 A°

- membrane material is cellulose acetate.

Chlorination of water supplies

Addition of small amount of chlorine to

water acts as a safeguard against water

borne disease.

Food processing plants chlorinating water

to improve sanitation.

THANK YOU

You might also like

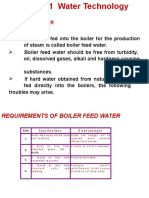

- Unit-I Water TechnologyDocument22 pagesUnit-I Water TechnologyManivannanVenkatesan100% (1)

- Module 2Document85 pagesModule 2Suhil IrshadNo ratings yet

- Module 1Document23 pagesModule 1PARTH SUNIL CHAVAN 20BCI0055No ratings yet

- 2 - Water N TreatmentDocument47 pages2 - Water N TreatmentdarshanNo ratings yet

- Water SofteningDocument6 pagesWater SofteningHuda ShahNo ratings yet

- Environmental Chemistry - Causes of Hardness in WaterDocument87 pagesEnvironmental Chemistry - Causes of Hardness in WaterVikas KabburiNo ratings yet

- Water SofteningDocument6 pagesWater SofteningHuda ShahNo ratings yet

- Water TreatmentDocument66 pagesWater Treatment22cs103No ratings yet

- Module V LecDocument21 pagesModule V LecAman John TuduNo ratings yet

- Water SofteningDocument20 pagesWater SofteningHassan AliNo ratings yet

- Water Treatment Operation: The Object of Boiler Feed Water Treatment Is To AvoidDocument27 pagesWater Treatment Operation: The Object of Boiler Feed Water Treatment Is To AvoidAmarendra Mani TiwariNo ratings yet

- Chemistry ProjectDocument12 pagesChemistry Projectpaul1656No ratings yet

- Water Softening MethodsDocument34 pagesWater Softening MethodsAjitsingh Jagtap100% (1)

- Hardness in WaterDocument6 pagesHardness in WaterMaku MichaelNo ratings yet

- Lecture 30 Boil WaterDocument4 pagesLecture 30 Boil WaterMuhammad AhmedNo ratings yet

- Removal of ImpuritiesDocument27 pagesRemoval of ImpuritiesAbdullah ZaidNo ratings yet

- Unit-4 Water TechnologyDocument22 pagesUnit-4 Water TechnologymaheshkancherlajobNo ratings yet

- Water - OfficialDocument62 pagesWater - OfficialPushp BahukhandiNo ratings yet

- Unit-2 Water ChemistryDocument15 pagesUnit-2 Water ChemistryKunjal singhNo ratings yet

- Chem Mod1Document10 pagesChem Mod1baritone.exhaustNo ratings yet

- Applied Chemistry Unit 1 Notes - Water TechnologyDocument18 pagesApplied Chemistry Unit 1 Notes - Water TechnologyKhaushik KumaarNo ratings yet

- Technology of Water - Unit IDocument61 pagesTechnology of Water - Unit I21MEB358 Kunal AryaNo ratings yet

- UNIT-III ChemistryDocument12 pagesUNIT-III ChemistrySivaprasad GanjiNo ratings yet

- Soft and Hard Water, Temporary and PERMANENT HARDNESS, Treatments of WaterDocument27 pagesSoft and Hard Water, Temporary and PERMANENT HARDNESS, Treatments of WaterPradnyesh VishwasraoNo ratings yet

- Anthony M. Wachinski - Environmental Ion Exchange - Principles and Design-Taylor & Francis, Chapman and Hall - CRC (2016) (1) (032-042)Document11 pagesAnthony M. Wachinski - Environmental Ion Exchange - Principles and Design-Taylor & Francis, Chapman and Hall - CRC (2016) (1) (032-042)HARDY EDDISONNo ratings yet

- 3Document66 pages3Nikhil AroraNo ratings yet

- Hardness of WaterDocument3 pagesHardness of WaterDamola JonathanNo ratings yet

- Boiler Water Treatment: Deposit ControlDocument5 pagesBoiler Water Treatment: Deposit ControlKrishna RayuduNo ratings yet

- Water Its Treatment Part2Document43 pagesWater Its Treatment Part2netsanet mesfinNo ratings yet

- Hardness RemovalDocument18 pagesHardness RemovalRuang RenungNo ratings yet

- Ill Effects of Water in Steam GenerationDocument15 pagesIll Effects of Water in Steam GenerationCHARITHANo ratings yet

- Watertreatmentandanalysis 2Document19 pagesWatertreatmentandanalysis 2O MNo ratings yet

- 1 Water TechnologyDocument27 pages1 Water TechnologyB MohanNo ratings yet

- Softening FinalDocument23 pagesSoftening FinalSonali Jahagirdar100% (1)

- Introduction-: Hard WaterDocument6 pagesIntroduction-: Hard WaterUtkarsha KudaveNo ratings yet

- Hard Water: O-LevelDocument9 pagesHard Water: O-LevelMUSINGUZI AARON CHOSENNo ratings yet

- Unit - 1 Water TechnologyDocument72 pagesUnit - 1 Water TechnologySanath S PatilNo ratings yet

- HARDNESSDocument18 pagesHARDNESSK33Prathvi S KundarNo ratings yet

- Water Technology 2015 2016 1Document86 pagesWater Technology 2015 2016 1Srinivas AkHilNo ratings yet

- WaterDocument40 pagesWaterhimanshuchawla654No ratings yet

- DUREZA 1sssssDocument14 pagesDUREZA 1sssssCarolina HerreraNo ratings yet

- UNIT IIDocument22 pagesUNIT IIDhilsanth SLNo ratings yet

- UICP CH 1 HardnessDocument42 pagesUICP CH 1 HardnessPatel JayNo ratings yet

- Water ChemistryDocument19 pagesWater ChemistryNupur ChoudharyNo ratings yet

- Water Softening: Removal of Hardness Hardness Is?..Document38 pagesWater Softening: Removal of Hardness Hardness Is?..Pradhumna AdhikariNo ratings yet

- Unit 4-Water TreatmentDocument11 pagesUnit 4-Water Treatmentgopi nath sahuNo ratings yet

- Water ChemistryDocument25 pagesWater ChemistryMayank TiwariNo ratings yet

- Handout BOILER FEED WATERDocument9 pagesHandout BOILER FEED WATERMuhammad Omar AzadNo ratings yet

- Boiler WaterDocument70 pagesBoiler WaterDarius DsouzaNo ratings yet

- Chemistry Unit-3Document17 pagesChemistry Unit-3santanu janaNo ratings yet

- CY6251 Engineering Chemistry II Lecture NotesDocument55 pagesCY6251 Engineering Chemistry II Lecture NotesAravind Phoenix100% (1)

- Water and Its TreatmentDocument25 pagesWater and Its TreatmentsumitNo ratings yet

- Unit Ii-Iv & V 26-02-2021Document94 pagesUnit Ii-Iv & V 26-02-2021vgangire3No ratings yet

- Removal of Hardness 1Document35 pagesRemoval of Hardness 1KISHAN PATELNo ratings yet

- Boiler Water TreatmentDocument22 pagesBoiler Water TreatmentTarun Patel100% (1)

- Hardness of Water and TreatmentDocument16 pagesHardness of Water and TreatmentQaisar GillNo ratings yet

- PDF Document 3Document37 pagesPDF Document 3miriam harriottNo ratings yet

- QADocument5 pagesQATejas Yadav100% (1)

- SoftenerDocument10 pagesSoftenerJosé Helí Vallejos CoronadoNo ratings yet

- Test Prep Rep Sanitary SolutionsDocument31 pagesTest Prep Rep Sanitary SolutionsVincent SantamariaNo ratings yet

- Tcbe 1202-5 LimeDocument48 pagesTcbe 1202-5 LimeshafikNo ratings yet

- BWA - Alternative Chemistry For Cooling Water Formulation, Speciality Chemicals, Mar 2014Document4 pagesBWA - Alternative Chemistry For Cooling Water Formulation, Speciality Chemicals, Mar 2014Shrikant S. Barkade100% (1)

- UCAR™ Latex UCAR™ Latex UCAR™ Latex UCAR™ Latex UCAR™ Latex D 161Document4 pagesUCAR™ Latex UCAR™ Latex UCAR™ Latex UCAR™ Latex UCAR™ Latex D 161sriatul2006No ratings yet

- Scale and Deposit Formation in SAGD FacilitiesDocument8 pagesScale and Deposit Formation in SAGD FacilitiesSebastián BarahonaNo ratings yet

- LIME Perspective by Vaishali Latkar (Compatibility Mode)Document28 pagesLIME Perspective by Vaishali Latkar (Compatibility Mode)Vaishali LatkarNo ratings yet

- Calcite Ficha TecnicaDocument2 pagesCalcite Ficha TecnicaOscar Eduardo Manco CuevaNo ratings yet

- Fluid Flow Assurance Issues Literature ReviewDocument12 pagesFluid Flow Assurance Issues Literature ReviewMatahari SenjaNo ratings yet

- Well Stimulation 2Document66 pagesWell Stimulation 2Aditya Singh100% (1)

- Acidsbases and Indicators - Chem - f1 - V1Document11 pagesAcidsbases and Indicators - Chem - f1 - V1Lubanga N JamesNo ratings yet

- 218 FinalDocument17 pages218 FinalmhaymourNo ratings yet

- Dairy Chemistry 2 PDFDocument114 pagesDairy Chemistry 2 PDFUmesh Poudel JoJoNo ratings yet

- Omyacarb 10Document1 pageOmyacarb 10Cristobal J. RiveraNo ratings yet

- Exogenic ProcessesDocument61 pagesExogenic ProcessesQueen PajulasNo ratings yet

- 1-Mix Design UHPGC (W-B (0.35) (Ca 0.3) - Effect of MolarityDocument93 pages1-Mix Design UHPGC (W-B (0.35) (Ca 0.3) - Effect of MolaritySawa Zayia MichaelNo ratings yet

- Environment of Calcium Carbonate Deposition West of Andros Island BahamasDocument170 pagesEnvironment of Calcium Carbonate Deposition West of Andros Island BahamasMuhammad HidayatNo ratings yet

- Fly Ash Soil Blocks PDFDocument42 pagesFly Ash Soil Blocks PDFTahir KhalidNo ratings yet

- Best Practice Guide On Metals Removal From Drinking Water by Treatment - Prof. DR Mustafa Ersoz, Dr. Lisa Barrott (IWA, 2012) PDFDocument138 pagesBest Practice Guide On Metals Removal From Drinking Water by Treatment - Prof. DR Mustafa Ersoz, Dr. Lisa Barrott (IWA, 2012) PDFiulbujNo ratings yet

- AdditivsDocument40 pagesAdditivsMohsin MalikNo ratings yet

- BMC-2.Binding MaterialsDocument16 pagesBMC-2.Binding MaterialsMeenu Priya100% (1)

- Cohen R - Happer W 2015 - Fundamentals of Ocean PHDocument12 pagesCohen R - Happer W 2015 - Fundamentals of Ocean PHjms_martins6920No ratings yet

- Chemistry Form Three Q&a1Document110 pagesChemistry Form Three Q&a1MajaningumbaoNo ratings yet

- Air in Pulp & PaperDocument72 pagesAir in Pulp & PaperGirish Shenai100% (1)

- Chapter 6 Physical and Chemical Changes - Free PDF AvailableDocument2 pagesChapter 6 Physical and Chemical Changes - Free PDF AvailableVicky SharmaNo ratings yet

- 1.6 Calculations Involving MassesDocument53 pages1.6 Calculations Involving MassesShriep kebabaNo ratings yet

- 12 MolstoichwsDocument2 pages12 MolstoichwsDiamond실비No ratings yet

- Stimulation by Acidizing BPDocument77 pagesStimulation by Acidizing BPStan Andrei100% (4)

- Project Report On Hydrated LimeDocument5 pagesProject Report On Hydrated LimeEIRI Board of Consultants and PublishersNo ratings yet

- Performance of A Novel Green Scale InhibitorDocument9 pagesPerformance of A Novel Green Scale InhibitorJulio PulidoNo ratings yet

- Ion Exchange With Natural Zeolites: An Alternative For Water Softening?Document7 pagesIon Exchange With Natural Zeolites: An Alternative For Water Softening?Yana ElzyNo ratings yet