Professional Documents

Culture Documents

Gearless Transmission Seminar

Uploaded by

utkarsh67%(3)67% found this document useful (3 votes)

3K views21 pagesstudy of gearless transmission

Original Title

Gearless Transmission Final Ppt

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentstudy of gearless transmission

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

67%(3)67% found this document useful (3 votes)

3K views21 pagesGearless Transmission Seminar

Uploaded by

utkarshstudy of gearless transmission

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 21

Seminar on

Gearless Transmission using Elbow

Mechanism

Presented by: Under the supervision of

Utkarsh Srivastava Mr. Ayush Trivedi

Roll no :1616440122 Assistant professor

rd

Student Mechanical 3 year

Pranveer Singh institute of Mechanical Department

technology PSIT Mechanical Engineering

1

Department

Need of Gearless Mechanism

Today’s world require speed in each and every field.

Engineers’s are constantly confronted to the challlenges of

efficient transmission of power.

Gears are costly to manufacture.

It is needed to further increase the efficiency of transmission

which cannot be done using geared transmission.

Gearless transmission mechanism is capable of transmitting

power at any angle without any gear being manufactured.

PSIT Mechanical Department 2

Introduction Of Gearless

Transmission

It is also known as Elbow Mechanism.

It is an ingenious link mechanism of slider and kinematic

chain principle.

Transmits power at any angle without utilising gears.

Elbow Mechanism is being compact and portable equipment,

which is skilful and is having something practice in the

transmitting power at right angle without any gears being

manufactured.

This mechanism can be used for any diameter of the driving

and driven shaft.[1] Maximum efficiency of gear drive is only

up to 42% but, by this mechanism we can get up to 90 to 92%

of efficiency.[2]

PSIT Mechanical Department 3

SYSTEM STUDY

In this transmission system numbers of pins used are

between 3,4,5,…which were inserted into the hole drilled on

the cylindrical disc. If we use less than 3 pins it will not

work and cause jamming.[3]

The motion is transmitted by sliding and rotating movement

of the L pins simultaneously.

The elbow mechanism consist of the following parts:

L-Pins

Cylindrical discs

Shafts

Base plates

Arm supports(Bearings)

PSIT Mechanical Department 4

• Figure: General Layout of Elbow Mechanism

PSIT Mechanical Department 5

WORKING PRINCIPLE OF

ELBOW MECHANISM

After studying synthesis of mechanism it get revealed that

this system consist of 3,4,…up to 8 pins and increasing the

Nos. of pins mechanism will work more smoothly. Power to

this mechanism is supplied with motor. Motion is transmitted

from driving to driven shaft with the help of L-pins. This L-

pins starts TO and FRO motion when power is supplied. The

motion is transmitted through the S-RR-S pair made by L-

pins and cylindrical disc.[4]

Transmits the power between two shafts whose axes are at

90 degree through bent links.

Three links slide relatively according to the motion given to

the input shaft.

PSIT Mechanical Department 6

Due to this the rotational

motion of input shaft is

converted into sliding

motion of links which is

then converted to

rotational motion of

output shaft.

PSIT Mechanical Department 7

Fig: Section view of the rotating pins

PSIT Mechanical Department 8

MACHINE DESIGN

The general steps to be followed in the designing of the

machine are as followed.

Preparation of the statement of the problem indicating

the purpose of the machine.

Selection of mechanism to be used.

Selection of the material.

Determining the size of component drawing.

Preparation of component drawing.

Manufacturing and assembling the machine.

Testing of the machine for functioning

PSIT Mechanical Department 9

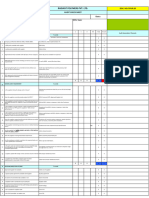

MATERIALS USED

PSIT Mechanical Department 10

MANUFACTURING OF PARTS

Primary shaping: Preliminary shaping of

machine components.

Machining Process: Final shape of machine

components on lathe.

Surface finishing: polishing, lapping, filing.

Joining: Arc welding

Special operation: Lubrication, adjustment

PSIT Mechanical Department 11

APPLICATIONS

It can be used as an extension for a socket wrench.

The mechanism is used for multiple spindle drilling operation

called “Gang Drilling”

Also used for angular drilling between 0 to 90 degree position.

Lubrication pump for C.N.C lathe machines.

Air blower for electronic and computer machine

The EL-BOW mechanism is used for movement of periscope

in submarines, In the year 1685 for the famous London tower

clock.

Driving for all kind of four faced tower clocks.

This mechanism is very useful for reaching a drive at a clumsy

location

PSIT Mechanical Department 12

GEARED V/S GEARLESS

TRANSMISSION

PSIT Mechanical Department 13

PSIT Mechanical Department 14

PSIT Mechanical Department 15

ADVANTAGES

Complete freedom of interchangeability.

More efficient than gear.

Power could be transferred to any desired angle.

Ease of manufacturing.

Misalignment of shafts can be tolerated to some

extent.

Simpler cooling system.

Low cost of manufacturing.

Portability of parts

PSIT Mechanical Department 16

LIMITATIONS

Does not work at very low starting torque.

Improper hole drilling could pose much problem.

Sudden load would cause mechanism breakdown.

Links are to be replaced after certain cycle time.

Speed ratio is always content 1:1

PSIT Mechanical Department 17

FUTURE SCOPES

Torque bearing capacity can be improved.

Flexible bent links can be used.

Has a bright future in automation and robotics.

Can be used in automobile industry in near

future

PSIT Mechanical Department 18

CONCLUSION

The model works correctly as per the

design.

With the help of this system, we can

efficiently reduce the cost in power

transmission.

Further advancement in this technology

can be made.

PSIT Mechanical Department 19

REFERENCES

[1] Prof R. Somraj, B. Sailesh , “DESIGN AND FABRICATION

OF GEARLESS POWER TRANSMISSION FOR SKEW

SHAFTS”, International Research Journal of Engineering and

Technology (IRJET) , Volume: 04 Issue: 04 | Apr -2017

[2] Neeraj Patil , Jayesh Gaikwad , Mayur Patil , Chandrakant

Sonawane , Shital Patel, “Gearless Transmission Mechanism and

its Applications” International Journal of Innovative Research in

Science, Engineering and Technology, Vol. 6, Issue 3, March 2017

[3] Ashish Kumar, Puneet Pawar, Sagar Rana, Shishir Bist,

“Multi-Angular Gearless Drive” International Journal of Scientific

& Engineering Research, Volume 6, Issue 7, July-2015

[4] Solanki Nehal Pramesh, Patel Harshil K, Singh Montu,

Rajwani Avesh, “DESIGN AND ANALYSIS OF GEARLESS

TRANSMISSION THROUGH ELBOW MECHANISM”

International Journal of Scientific Research in Engineering

(IJSRE) Vol. 1 (3), March 2017

PSIT Mechanical Department 20

THANK YOU

PSIT Mechanical Department 21

You might also like

- Gearless Angular Transmission Project Report 1Document25 pagesGearless Angular Transmission Project Report 1सारंग।एस बीकेएमNo ratings yet

- Gearless Transmission Research PaperDocument10 pagesGearless Transmission Research PaperresonancebansalNo ratings yet

- Gearless Transmission Using Elbow MechanismDocument32 pagesGearless Transmission Using Elbow Mechanismsanoop joseNo ratings yet

- Elbow MechanismDocument61 pagesElbow MechanismSourav Kotgund100% (2)

- Gearless Transmission Project ReportDocument32 pagesGearless Transmission Project ReportHarish Kumar73% (22)

- Gearless Power Transmission MohitDocument21 pagesGearless Power Transmission MohitJitender Kumar Yadav100% (1)

- Gearless Power Transmission Project ReportDocument37 pagesGearless Power Transmission Project ReportErole Technologies Pvt ltd Homemade EngineerNo ratings yet

- Motorized Screw JackDocument19 pagesMotorized Screw JackPushpendra Kumar33% (3)

- Scramjet ReportDocument25 pagesScramjet ReportKRITHIKA T 2228617100% (1)

- Gearless Power Transmission MohitDocument21 pagesGearless Power Transmission MohitJitender Kumar YadavNo ratings yet

- Pneumatic Controlled Ramming HolderDocument50 pagesPneumatic Controlled Ramming Holderraghul92No ratings yet

- Automatic Screw Jack Project ReportDocument12 pagesAutomatic Screw Jack Project ReportKaran Bansal67% (3)

- Fabrication of Magnetic Suspension SystemDocument46 pagesFabrication of Magnetic Suspension SystemNationalinstituteDsnr100% (1)

- Design and Fabrication of Pedal Drilling MachineDocument8 pagesDesign and Fabrication of Pedal Drilling MachineAMAL BNo ratings yet

- Design and Fabrication of Multipurpose Agriculture Aided VehicleDocument13 pagesDesign and Fabrication of Multipurpose Agriculture Aided VehicleSHARATHKUMAR MNo ratings yet

- Box Shifting MechanismDocument21 pagesBox Shifting MechanismNishant Chauhan67% (9)

- Automobile Lab ManualDocument35 pagesAutomobile Lab ManualKeshav AsopaNo ratings yet

- Box Transport Mechanism ProjectDocument65 pagesBox Transport Mechanism ProjectAli S79% (43)

- Power Generation Through Suspension SystemDocument12 pagesPower Generation Through Suspension SystemRaja Sahu100% (2)

- Gearless Transmission - 2Document42 pagesGearless Transmission - 2Tanvi KhuranaNo ratings yet

- 3 Design and Analysis of Gearless TransmissionDocument68 pages3 Design and Analysis of Gearless TransmissionRåjêßh M Ińtü100% (2)

- Rotational Motion Transmission SystemsDocument21 pagesRotational Motion Transmission Systemslolu pandey100% (2)

- Cam and Follower MechanismDocument44 pagesCam and Follower MechanismAkshay100% (1)

- Project Report On Analysis of Propeller ShaftDocument24 pagesProject Report On Analysis of Propeller ShaftGurpreet Singh50% (8)

- Project ReportDocument38 pagesProject ReportBablu Kumar100% (1)

- Project Report PDFDocument39 pagesProject Report PDFTejas Inamdar67% (3)

- Report of Pneumatic Punchng Machine 100%Document50 pagesReport of Pneumatic Punchng Machine 100%Roger Anton64% (14)

- Motorized Smart Turning MechanismDocument16 pagesMotorized Smart Turning MechanismSUMEET SINGH50% (2)

- Automatic Pneumatic HammerDocument3 pagesAutomatic Pneumatic HammerIyappan40% (5)

- Power Generating Shock Absorber Seminar FinalDocument28 pagesPower Generating Shock Absorber Seminar FinalMoh'd Safvan67% (6)

- Design and Fabrication of an Oldham Coupling MechanismDocument20 pagesDesign and Fabrication of an Oldham Coupling MechanismSidharth MalohtraNo ratings yet

- Quick lifting jack guideDocument36 pagesQuick lifting jack guideRoyalAryans76% (17)

- Button Operated Electromagnetic Gear ChangerDocument64 pagesButton Operated Electromagnetic Gear ChangermkkfakesNo ratings yet

- Retrofit Regenerative Shock Absorber ProjectDocument24 pagesRetrofit Regenerative Shock Absorber ProjectTheVagabond Harshal33% (3)

- Button Operated Gear Shifting Mechanism For Two WheelerDocument23 pagesButton Operated Gear Shifting Mechanism For Two WheelerAlex Salvin75% (8)

- Flexible 360 Drill For Easy DrillingDocument15 pagesFlexible 360 Drill For Easy DrillingAnkit Vishwakarma67% (3)

- Gearless TransmissionDocument48 pagesGearless TransmissionIpaseta Dhara88% (8)

- Go Kart Chassis Design and AnalysisDocument73 pagesGo Kart Chassis Design and AnalysisMedariTrinadh100% (3)

- Ashu Project PPT Mid-2Document17 pagesAshu Project PPT Mid-218E3457 Mukundini67% (3)

- Improve efficiency of semi-automatic box wrapping machinesDocument31 pagesImprove efficiency of semi-automatic box wrapping machinesVaibhav50% (2)

- Drilling Machine ReportDocument38 pagesDrilling Machine ReportPraveen Mathias79% (14)

- Eight link Bottle shifting conveyor mechanismDocument59 pagesEight link Bottle shifting conveyor mechanismJeevan Landge PatilNo ratings yet

- Air Brake System Using Exhaust Gas Final ReportDocument68 pagesAir Brake System Using Exhaust Gas Final ReportErole Technologies Pvt ltd Homemade Engineer100% (2)

- Rice Planter Project ReportDocument46 pagesRice Planter Project ReportErole Technologies Pvt ltd Homemade Engineer100% (1)

- Gearless TransmissionDocument51 pagesGearless TransmissionSid Max83% (6)

- Mini Conveyor Using Geneva MechanismDocument11 pagesMini Conveyor Using Geneva MechanismJilly Arasu86% (7)

- Box Transport MechanismDocument24 pagesBox Transport MechanismInzi Gardezi82% (39)

- Magnetic Repulsion Piston EngineDocument29 pagesMagnetic Repulsion Piston EngineMilad Hakkim67% (3)

- Aircraft hydraulic system seminar reportDocument37 pagesAircraft hydraulic system seminar reportpriya007893878% (18)

- Paper Cutting MachineDocument12 pagesPaper Cutting MachineRaaz Jayasawal73% (15)

- A Project Report Gearless Power TransmissionDocument29 pagesA Project Report Gearless Power Transmissiondon131188No ratings yet

- Shu TrsDocument4 pagesShu Trsshubham kumarNo ratings yet

- Multipurpose Mechanical Machine Project ReportDocument41 pagesMultipurpose Mechanical Machine Project ReportAbhishek Sharma78% (9)

- Gearless TransmissionDocument67 pagesGearless TransmissionPSNo ratings yet

- Exam No 5344Document70 pagesExam No 5344sanket bhosaleNo ratings yet

- Ball Traction Drive - FinalDocument46 pagesBall Traction Drive - FinalTejas Shete0% (1)

- Finite Element Analysis of High-Speed Motorized Spindle Based OnDocument10 pagesFinite Element Analysis of High-Speed Motorized Spindle Based Onsunil481No ratings yet

- Design and Analysis of Differential GearboxDocument49 pagesDesign and Analysis of Differential GearboxLakshmiprasad Kadari50% (4)

- Kumaraguru College of TechnologyDocument12 pagesKumaraguru College of TechnologyKumaran RNo ratings yet

- Rediant-Supplier Audit Check Sheet RevisedDocument8 pagesRediant-Supplier Audit Check Sheet RevisedRohit TripathiNo ratings yet

- User Manual: Opening Using The Opening Code Generally StructureDocument1 pageUser Manual: Opening Using The Opening Code Generally StructurePetre LeahNo ratings yet

- BS 7884-1997 Specification For Copper and Copper-Cadmium Stranded Conductors For Overhead Electric Traction and Power Transmission SystemsDocument16 pagesBS 7884-1997 Specification For Copper and Copper-Cadmium Stranded Conductors For Overhead Electric Traction and Power Transmission SystemsThanh DangNo ratings yet

- Guidance Note On WeldingDocument102 pagesGuidance Note On WeldingVishal SharmaNo ratings yet

- Flowserve Durco CatalogDocument36 pagesFlowserve Durco CatalogbryandownNo ratings yet

- Bme (A) Group 8Document27 pagesBme (A) Group 8Tanay PrasadNo ratings yet

- 2017 GRND BND Part 3Document91 pages2017 GRND BND Part 3Zyan MonterdeNo ratings yet

- Documentatie Imprimanta M940Document22 pagesDocumentatie Imprimanta M940Florin StanciulescuNo ratings yet

- Gas Metal Arc Welding and Flux-Cored Arc Welding: Instructional/Task AnalysisDocument6 pagesGas Metal Arc Welding and Flux-Cored Arc Welding: Instructional/Task Analysisgowtham_venkat_4No ratings yet

- 6.ZXSDR B8200 (V4.1) Commissioning Guide 109pDocument109 pages6.ZXSDR B8200 (V4.1) Commissioning Guide 109pRamiz Rzaoglu100% (1)

- Lesson 1 - Position and Position Lines Learning OutcomesDocument23 pagesLesson 1 - Position and Position Lines Learning OutcomesMico SantosNo ratings yet

- Kinetic Modeling of The Hydrolysis of Acetic Anhydride at Higher Temperatures Using Adiabatic Batch Reactor (Thermos-Flask)Document8 pagesKinetic Modeling of The Hydrolysis of Acetic Anhydride at Higher Temperatures Using Adiabatic Batch Reactor (Thermos-Flask)Angie FiorellaNo ratings yet

- AOU - MEP Preferable Vendors' list-RevA PDFDocument55 pagesAOU - MEP Preferable Vendors' list-RevA PDFahmedNo ratings yet

- Backup PolicyDocument2 pagesBackup Policybedorlehacker100% (1)

- Skoog Chapter 22 JawabanDocument11 pagesSkoog Chapter 22 JawabanmarisaaaNo ratings yet

- 250 - C30R, U Operation and Maintenance: Export ControlledDocument8 pages250 - C30R, U Operation and Maintenance: Export ControlledturboshaftNo ratings yet

- Geothermal Basics - Power Plant CostsDocument2 pagesGeothermal Basics - Power Plant Costssudhir_921995600No ratings yet

- Kamstrup Multical 602 - Installation and User GuideDocument28 pagesKamstrup Multical 602 - Installation and User GuideMarco RamosNo ratings yet

- 40 DensityandSpecificHeat Sp12Document11 pages40 DensityandSpecificHeat Sp12fernandoribeiromocNo ratings yet

- Hager Wiring Accessories Catalogue 1120Document64 pagesHager Wiring Accessories Catalogue 1120lizukyNo ratings yet

- IQSK Issue 29 3Document27 pagesIQSK Issue 29 3Rustono R100% (3)

- Lecture (05) Boolean Algebra and Logic Gates: By: Dr. Ahmed ElshafeeDocument12 pagesLecture (05) Boolean Algebra and Logic Gates: By: Dr. Ahmed ElshafeevenkateshNo ratings yet

- Created by Ankur Sharma, Gurudayal Srivastava, Vikram Singh, Sanket TamhaneDocument7 pagesCreated by Ankur Sharma, Gurudayal Srivastava, Vikram Singh, Sanket TamhaneSankash Sood100% (2)

- Workboat Handover ChecklistDocument3 pagesWorkboat Handover ChecklistKunal Singh50% (2)

- Solomon Nigatu 0859/16 2. Getawa Melese ..... .0427/16Document32 pagesSolomon Nigatu 0859/16 2. Getawa Melese ..... .0427/16عبدالقادر مكونن سعيدNo ratings yet

- STK 630Document8 pagesSTK 630Paulo VictorNo ratings yet

- DTR Leaflet 02 R5Document2 pagesDTR Leaflet 02 R5Razzi HamzahNo ratings yet

- Delivery BedDocument137 pagesDelivery BedAdil LatifNo ratings yet

- HUADA LW Decanter CentrifugesDocument5 pagesHUADA LW Decanter CentrifugesАндрей МанышкинNo ratings yet

- Calculating The Size of A Server Room Air Conditioner OpenxtraDocument89 pagesCalculating The Size of A Server Room Air Conditioner Openxtraeric_engelbrechtNo ratings yet