Condition Based Maintenance

Ritwik.A

�Introduction

Condition monitoring (or, colloquially, CM) is the

process of monitoring a parameter of condition in

machinery (vibration, temperature etc.), in order to

identify a significant change which is indicative of a

developing fault.

It is a major component of predictive maintenance.

The use of condition monitoring allows maintenance to be

scheduled, or other actions to be taken to prevent

consequential damages and avoid its consequences.

� Condition monitoring has a unique benefit in that

conditions that would shorten normal lifespan can be

addressed before they develop into a major failure.

Condition monitoring techniques are normally used on

rotating equipment, auxiliary systems and other

machinery (compressors, pumps, electric motors, internal

combustion engines, presses), while

periodic inspection using non-destructive testing (NDT)

techniques and fit for service (FFS) evaluation are used

for static plant equipment such as steam

boilers, piping and heat exchangers.

� Often visual inspections are considered to form an underlying component

of condition monitoring, however this is only true if the inspection results

can be measured or critiqued against a documented set of guidelines.

For these inspections to be considered condition monitoring, the results

and the conditions at the time of observation must be collated to allow for

comparative analysis against the previous and future measurements.

The act of simply visually inspecting a section of pipework for the

presence of cracks or leaks cannot be considered condition monitoring

unless quantifiable parameters exist to support the inspection and a

relative comparison is made against previous inspections.

An act performed in isolation to previous inspections is considered a

Condition Assessment, Condition Monitoring activities require that

analysis is made comparative to previous data and reports the trending of

that comparison.

� For larger, more critical machines where safety

implications, production interruptions (so-called

"downtime"), replacement parts, and other costs of failure

can be appreciable (determined by the criticality index), a

permanent monitoring system is typically employed rather

than relying on periodic handheld data collection.

However, the diagnostic methods and tools available from

either approach are generally the same.

Recently on-line condition monitoring systems have

been applied to heavy process industries such as pulp,

paper, mining, petrochemical and power generation.

� Rotating equipment is an industry umbrella term that

includes gearboxes, reciprocating and centrifugal

machinery.

The most commonly used method for rotating machines

is vibration analysis.

�Types of Condition Monitoring

Subjective Condition Monitoring: Here the monitoring

personnel use their perception of senses and judgment to note

any change of the condition. The guidelines or hints where to

book for leakage, bearing play etc. posture or figures illustrating

different conditions of components may also be helpful.

Aided Subjective or condition monitoring with simple

gadgets: Here the monitoring personnel are simple gadgets to

add their ability to perceive conditions better.

Objective condition monitoring: Different instruments and

facilities are used for obtaining data giving direct measure of the

parametric condition of the components even while the machine

is working.

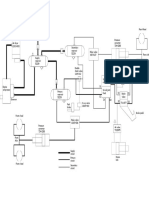

�CM process flow

�Advantages of Condition Monitoring

Improved availability of equipment

Minimized breakdown costs

Improved morality of the operating personal and safety.

Improved reliability

Improved planning

�Disadvantages

Gives only marginal benefits

Increased running cost

Sometimes difficult to organize

�Vibration Monitoring

Measurements can be taken on machine bearing casings

with accelerometers (seismic or piezo-electric transducers) to

measure the casing vibrations, and on the vast majority of

critical machines, with eddy-current transducers that directly

observe the rotating shafts to measure the radial (and axial)

displacement of the shaft.

The level of vibration can be compared with historical baseline

values such as former start ups and shutdowns, and in some

cases established standards such as load changes, to assess the

severity.

Machinery and parts OEM also define vibration limits based on

the machine design or of the internal parts, e.g. fault frequencies

of bearings.

� One commonly employed technique to interpret vibration

signal is to examine the individual frequencies present in

the signal.

These frequencies correspond to certain mechanical

components (for example, the various pieces that make up

a rolling-element bearing) or certain malfunctions (such as

shaft unbalance or misalignment).

By examining these frequencies and their harmonics, the

CM specialist can often identify the location and type of

problem, and sometimes the root cause as well.

� For example, high vibration at the frequency corresponding to the

speed of rotation is most often due to residual imbalance and is

corrected by balancing the machine.

A degrading rolling-element bearing, on the other hand, will

usually exhibit vibration signals at specific frequencies increasing

in intensity as it wears.

Special analysis instruments can detect this wear weeks or even

months before failure, giving ample warning to schedule

replacement before a failure which could cause a much longer

down-time.

Beside all sensors and data analysis it is important to keep in

mind that more than 80% of all complex mechanical equipment

fail accidentally and without any relation to their life-cycle period

� Most vibration analysis instruments today utilize a Fast

Fourier Transform (FFT) which is a special case of the

generalized Discrete Fourier Transform and converts the

vibration signal from its time domain representation to its

equivalent frequency domain representation.

However, frequency analysis (sometimes called Spectral

Analysis or Vibration Signature Analysis) is only one aspect

of interpreting the information contained in a vibration signal.

Frequency analysis tends to be most useful on machines that

employ rolling element bearings and whose main failure

modes tend to be the degradation of those bearings, which

typically exhibit an increase in characteristic frequencies

associated with the bearing geometries and constructions.

� Depending on the type of machine, its typical malfunctions, the

bearing types employed, rotational speeds, and other factors, the

CM specialist may use additional diagnostic tools, such as

examination of the time domain signal, the phase relationship

between vibration components and a timing mark on the machine

shaft (often known as a keyphasor), historical trends of vibration

levels, the shape of vibration, and numerous other aspects of the

signal along with other information from the process such as load,

bearing temperatures, flow rates, valve positions and pressures to

provide an accurate diagnosis.

This is particularly true of machines that use fluid bearings rather

than rolling-element bearings. To enable them to look at this data

in a more simplified form vibration analysts or machinery

diagnostic engineers have adopted a number of mathematical plots

to show machine problems and running characteristics, these plots

include the bode plot, the waterfall plot, the polar plot and the

orbit time base plot amongst others.

� Handheld data collectors and analyzers are now

commonplace on non-critical or balance of plant machines

on which permanent on-line vibration instrumentation

cannot be economically justified.

The technician can collect data samples from a number of

machines, then download the data into a computer where

the analyst (and sometimes artificial intelligence) can

examine the data for changes indicative of malfunctions

and impending failures

�Temperature monitoring

Slight temperature variations across a surface can be

discovered with visual inspection and non-destructive

testing with thermography.

Heat is indicative of failing components, especially

degrading electrical contacts and terminations.

Thermography can also be successfully applied to high-

speed bearings, fluid couplings, conveyor rollers, and

storage tank internal build-up

�Pistol Thermometer

Ideal as a professional tool for maintenance professionals,

the non-contact, pistol grip thermometer enables the

capture of a simultaneous, time stamped digital

photographic images as a temperature reading is taken.

The logged results and images from upto 100 locations

can be uploaded via a USB connections to a PC.

Thus the temperatures can be stored, presented graphically

on screen for improved documentation

�Temperature Crayons and Tapes

Temperature monitoring by feel of hand or by simple

measuring items / instruments, like thermometers,

temperature crayons and tapes etc is an age old practice of

finding out defects in components.

The subjecture of temperature monitoring is touching the

motor etc, and assessing.

Also temperature stickers are the most common and cost

effectives.

�Thermo – diodes & thermo – transistors

a) Thermo-diodes

It is a widely use method for measuring temperature. When the

temperature of doped semiconductors changes, the mobility of their

charge carriers changes and this effects the sate at which electrons

and holes can diffuse across a P.N.Junetion. The difference in voltage

and current through the junction is a function fo the temperature.

b) Thermo Transistors

in thermo-transistor the voltage across the junction between the base

and the emitter depends on the temperature. A common method is the

use of two transistor with different collector currents to find the

difference in the base emitter voltage between item. The difference is

the measure of temperature. It can be combined with circuit

components on a single chip to give a temperature sensor.

�Leakage monitoring

Leakage is unintended discharge or oozing of fluids and gases from mechanical

components, occurring because of,

Increase in clearance or ear out or

Exesion of parts like value seats, poppets and spools etc or ⦁ Damage of seals and packing or

⦁ Incorrect selection / filting of seals and components or ⦁ Other reasons Leakage are both

external or internal external leakage are relatively easy to detect as some fluid or gases flow

out of leaking components. Internal leakages are little difficult to detect as the leakage fluid /

gas goes back to reserroir directly or through esting pipelines and is normally not seen

following outside. For detecting fluid leakages of underground pipelines, on crude method is

that the area around the leakage gets wet and the fluid starts coming / oozing out from any

soft location. Few sensors are connected at some distance for timely indication of leakages

for very long times. In some cases, pressure drops are also indicated by leakages. Leak

testing methods can be classified according to the pressure and fluid (gas or liquid) in the

system. The commonly used leak testing methods are ⦁ Acoustic ⦁ Bubble testing ⦁ Flow

detection ⦁ Specific gas detectors ⦁ Quantity loss determination etc Direct sensing in gas

system at pressure is done by acoustic method, bubble method or flow detection. Specific gas

detectors like sulphur hexafluoside, halogen, thermal conductively, mass spectrometer

(helium) leak detector etc. are also used to detect and quantify the leaks for the components at

pressure or at vacuum.

��Performance monitoring

Performance monitoring is a less well-known condition

monitoring technique.

It can be applied to rotating machinery such as pumps and

turbines, as well as stationary items such as boilers and heat

exchangers.

Measurements are required of physical quantities:

temperature, pressure, flow, speed, displacement, according

to the plant item.

Absolute accuracy is rarely necessary, but repeatable data is

needed. Calibrated test instruments are usually needed, but

some success has been achieved in plant with DCS

(Distributed Control Systems).

� Performance analysis is often closely related to energy

efficiency, and therefore has long been applied in steam

power generation plants.

In some cases, it is possible to calculate the optimum time

for overhaul to restore degraded performance.

�Model-based voltage and current systems

(MBVI systems)

This is a technique that makes use of the information

available from the current and voltage signals across all

three phases simultaneously.

Model-based systems are able to identify many of the

same phenomena also seen by more conventional

techniques, covering electrical, mechanical, and

operational areas.

Model-based systems work on the lines and measure both

current and voltage while the motor is in operation and

then automatically creates a mathematical model of the

relationship between current and voltage.

� By applying this model to the measured voltage, a

modelled current is calculated and this is compared with

the actual measured current.

Deviations between the measured current and the

modelled current represent imperfections in the motor and

driven equipment system, which can be analysed using a

combination of Park’s vector to simplify the three-phase

currents into two orthogonal phases (D&Q), Fourier

analysis to give a power spectral density plot, and

algorithmic assessment of the resulting spectrum to

identify specific faults or failure modes.

� These systems are designed for permanent installation as a

condition monitoring solution rather than as a short-term

diagnostic measurement device, and their outputs can be

integrated into normal plant systems.

Being permanently connected, historic trends are

automatically captured.