Professional Documents

Culture Documents

Where To Check The LFL Before Hot Work ?: Did You Know?

Uploaded by

Abdullah Anar0 ratings0% found this document useful (0 votes)

37 views1 pageBeacon Process Safety Alert - August 2020-English

Original Title

202008BeasconEnglish

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentBeacon Process Safety Alert - August 2020-English

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

37 views1 pageWhere To Check The LFL Before Hot Work ?: Did You Know?

Uploaded by

Abdullah AnarBeacon Process Safety Alert - August 2020-English

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 1

This issue sponsored by

Messages for Manufacturing Personnel aiche.org/ccps www.iomosaic.com

www.aiche.org/ccps/process-safety-beacon

Where to Check the LFL Before Hot Work ? August 2020

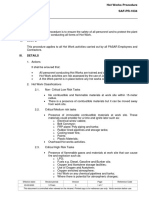

35ft (10.7m) radius*

all the way down to

Did You Know?

Location of planned the ground, all

• Sparks from flame-cutting, welding and grinding can

hot work around the tank and

1 even below grade bounce a long way. That is why most permits call for

2 removing combustible materials and testing for flammable

gases within 35ft (10.7m)

6 • Gravity can pull sparks and hot particles down to the

ground – and even down into pits and sumps. Monitor

7 LFL under where elevated hot work is performed

• Most flammable vapors are heavier than air, so they tend

to accumulate in low spaces, including sewers and sumps.

8 9 • Even lighter flammable vapors can linger in places with

3 4 poor ventilation – like inside pipes, vessels, or

containment walls.

5 • Contractors and Maintenance Workers don’t know your

process. They don’t know all the places to look for

Locations to be checked for LFL before & during hot work flammable vapors.

• Conditions can change while hot work is being performed.

There have been many fires and explosions in

Process operations, upsets, or even weather conditions can

our industry over the years due to ignition

introduce flammable materials near where hot work is

during spark-producing Hot Work. The May

being performed.

2020 Beacon covered the fatal consequences

from one such event. One element of preparing

for Hot Work is to check for – and prevent – the What Can You Do?

presence of combustible materials and/or

flammable vapors “within 35 ft (10.7m)”. • Check every opening and sump within the 35ft (10.7m)

zone or “bell” or the distance specified by your company.

(* The recommended distances from both US OSHA

and the National Fire Protection Assoc.(NFPA)). • Some companies require retests LFL frequently to manage

changing conditions. Monitor the affected area to maintain

Many companies check for flammable vapors at

a safe condition.

all places where the sparks from the hot work

could be expected to bounce. The diagram • Use your knowledge of the process area to think of places

shows some locations to be checked. LFL gas where flammable vapors or combustible liquids and solids

detector readings need to check around the could exist

location of the hot work itself, as well as every • Use the “wands” or sample tubes that come with your gas

place around and below where the hot particles detectors to check inside spaces

could bounce. This includes using a probe (or

sampling hose) to check inside open process • Use Welding blankets and other protections to stop sparks

pipes or inside sumps and process drains such and particles getting to places where they shouldn’t. BUT

as points 5-9. DON’T COUNT ON THESE ALONE!

Test in ALL the places where flammable vapors could be ignited !

©

AIChE 2020. All rights reserved. Reproduction for non-commercial, educational purposes is encouraged. However, reproduction for any commercial

purpose without express written consent of AIChE is strictly prohibited. Contact us at ccps_beacon@aiche.org or 646-495-1371.

You might also like

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Where To Check The LFL Before Hot Work?: Did You Know?Document1 pageWhere To Check The LFL Before Hot Work?: Did You Know?Krunal BapodaraNo ratings yet

- Hot Works ProcedureDocument7 pagesHot Works Proceduresafetyassistant23No ratings yet

- FCX-HS06 Hot Work PolicyDocument2 pagesFCX-HS06 Hot Work Policyberry trisnamuktiNo ratings yet

- Hip - Qatif Aramco - FinalDocument10 pagesHip - Qatif Aramco - FinalDarius DsouzaNo ratings yet

- Hot Work Safety Training (1122)Document15 pagesHot Work Safety Training (1122)Rosano D. Manamtam100% (1)

- ART - F5 - PWR - A - Coal Power Article-Guidelines For Handling PRB CoalDocument7 pagesART - F5 - PWR - A - Coal Power Article-Guidelines For Handling PRB CoalMohammed ZabiNo ratings yet

- Job Safety Analysis Worksheet (JSA)Document4 pagesJob Safety Analysis Worksheet (JSA)Kyle Garagara-MogolNo ratings yet

- 5 Mins - Gas Detection - enDocument1 page5 Mins - Gas Detection - en孔超No ratings yet

- Welding and Other Hotwork Presentation PPDocument72 pagesWelding and Other Hotwork Presentation PPharis88abdulNo ratings yet

- Awning Install JhaDocument2 pagesAwning Install JhafatimahNo ratings yet

- Carz Explosion Isolation FlapDocument2 pagesCarz Explosion Isolation Flappios.helectorNo ratings yet

- SOG F5 PWR Silo Fire FightingDocument9 pagesSOG F5 PWR Silo Fire FightingGothandaraman Muthu ManickamNo ratings yet

- Site Safety Supervisor PresentationDocument9 pagesSite Safety Supervisor Presentationabdos salamNo ratings yet

- Test NotesDocument6 pagesTest NotesharikrishnaNo ratings yet

- Preh W CheckDocument2 pagesPreh W CheckMd UsamaNo ratings yet

- Paul Webber Induction Furnance SafetyDocument38 pagesPaul Webber Induction Furnance SafetyPSS PrasadNo ratings yet

- 28 HotworkDocument5 pages28 HotworkMohammed MinhajNo ratings yet

- Work Permit SystemDocument57 pagesWork Permit SystemAdelson AntunesNo ratings yet

- Hot Work Activity RemindersDocument24 pagesHot Work Activity RemindersKristine Danielle RamirezNo ratings yet

- WSHC Flash Fire Due To Static DischargesDocument4 pagesWSHC Flash Fire Due To Static DischargesGoogool YNo ratings yet

- Application Story: FLIR Cameras Enable Timely Detection and Localization of Self-Combusting CoalsDocument4 pagesApplication Story: FLIR Cameras Enable Timely Detection and Localization of Self-Combusting Coals熙槃No ratings yet

- HSE Alert-42 Safety While Welding Cutting & Grinding 17.06.13Document1 pageHSE Alert-42 Safety While Welding Cutting & Grinding 17.06.13ajeet kumar singhNo ratings yet

- How To Handle Hot SpotDocument6 pagesHow To Handle Hot SpotMustafa Ramadan100% (4)

- Building and Life Safety Issues For Tents: Fact SheetDocument2 pagesBuilding and Life Safety Issues For Tents: Fact SheetAhmedBadrNo ratings yet

- HOT Job ChecklistDocument1 pageHOT Job ChecklistAyoun Ul HaqueNo ratings yet

- IEPL-Weekly Safety Information Bulletin Issue 27: Safety During Hot WorkDocument3 pagesIEPL-Weekly Safety Information Bulletin Issue 27: Safety During Hot Workkirandevi1981No ratings yet

- Potential Health & Safety Hazards: 1. 1.1. To Provide Safe Work Procedures and Guidelines On Brazing OperationsDocument8 pagesPotential Health & Safety Hazards: 1. 1.1. To Provide Safe Work Procedures and Guidelines On Brazing OperationssbjamdadeNo ratings yet

- ATEX AwarenessDocument46 pagesATEX AwarenessariftaskeenadvocateNo ratings yet

- Hot WorkDocument20 pagesHot WorkmarceloNo ratings yet

- Foundry Health and Safety: Hot Working of MetalsDocument14 pagesFoundry Health and Safety: Hot Working of MetalsHaseeb KazmiNo ratings yet

- Oil and Gas Well Drilling and Servicing Etool - General Safety and Health - Hot Work - Occupational Safety and Health AdministrationDocument4 pagesOil and Gas Well Drilling and Servicing Etool - General Safety and Health - Hot Work - Occupational Safety and Health AdministrationIne Nurista100% (1)

- Jsa HotDocument11 pagesJsa HotsagarauceNo ratings yet

- Hot WorkDocument5 pagesHot WorkjhoniNo ratings yet

- High Temperature Ultrasonic TestingDocument3 pagesHigh Temperature Ultrasonic TestingCarlos Bustamante100% (1)

- Ground FlareDocument8 pagesGround FlareIdham ArifNo ratings yet

- CAT-08 Hot Work and Safe Work-EnglishDocument23 pagesCAT-08 Hot Work and Safe Work-EnglishDanNo ratings yet

- Hot Work Safety GuideDocument8 pagesHot Work Safety Guidecic engineeringNo ratings yet

- Hot Work Safety GuideDocument7 pagesHot Work Safety Guideafifmahfud09No ratings yet

- Molasse Tank Safety DesignDocument10 pagesMolasse Tank Safety DesignChristian BarNo ratings yet

- Hot Work Guidelines EnglishDocument5 pagesHot Work Guidelines EnglishJan KubišNo ratings yet

- Learning From IncidentsDocument60 pagesLearning From IncidentsMario CoronelNo ratings yet

- Process Interruptions: A Threat To Process Safety: Did You ?Document1 pageProcess Interruptions: A Threat To Process Safety: Did You ?Abdullah AnarNo ratings yet

- Hot Work PermitDocument1 pageHot Work PermitMo AboukhzamNo ratings yet

- VSX-C301: Audio/Video Multi-Channel ReceiverDocument44 pagesVSX-C301: Audio/Video Multi-Channel ReceiverRon WoodNo ratings yet

- 4 Hot Work Fire WatchDocument34 pages4 Hot Work Fire Watchjefferson oronsayeNo ratings yet

- Hazardous MaterialsDocument35 pagesHazardous MaterialsKhalid Mohammed SaudNo ratings yet

- Welding & Hotwork Safety-JackieDocument43 pagesWelding & Hotwork Safety-JackieSalve Ignacio100% (1)

- 4 Hot Work Fire WatchDocument34 pages4 Hot Work Fire WatchBhakti SagarNo ratings yet

- PR RFR P07 27 v1-0 How To Ensure Safety For Cyclone Lining WorkDocument6 pagesPR RFR P07 27 v1-0 How To Ensure Safety For Cyclone Lining WorkJuan Nacimba NacimbaNo ratings yet

- Atex (Atmosphere Explosive) and Fuel Polishing SystemsDocument3 pagesAtex (Atmosphere Explosive) and Fuel Polishing SystemsMuhammad Fadhil BudimanNo ratings yet

- 1 HotworkDocument1 page1 Hotworkchariot1729No ratings yet

- Mechanical Demolish JhaDocument2 pagesMechanical Demolish JhafatimahNo ratings yet

- Lincoln Electric 625 OIPMDocument34 pagesLincoln Electric 625 OIPMSARET respaldoNo ratings yet

- 2014 Jan RWW 873 Fire Resistant 01 PDFDocument1 page2014 Jan RWW 873 Fire Resistant 01 PDFJp DroguettNo ratings yet

- Welding & Hotwork Safety-JackieDocument43 pagesWelding & Hotwork Safety-JackieNinia GannabanNo ratings yet

- Conventional Fire Detectors: Listed FM ApprovedDocument2 pagesConventional Fire Detectors: Listed FM ApprovedosayiNo ratings yet

- 3.05A - Onsite Emergency Plan - Rev 10 - 2013Document47 pages3.05A - Onsite Emergency Plan - Rev 10 - 2013Vaibhav Vithoba NaikNo ratings yet

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- EI 1550 Handbook On Equipment Used For The Maintenance and Delivery of Clean Aviation FuelDocument125 pagesEI 1550 Handbook On Equipment Used For The Maintenance and Delivery of Clean Aviation FuelAbdullah AnarNo ratings yet

- 202003beaconenglish PDFDocument1 page202003beaconenglish PDFAbdullah AnarNo ratings yet

- Hazardous Chemicals Hidden in Plain Sight: Image HereDocument1 pageHazardous Chemicals Hidden in Plain Sight: Image HereAbdullah AnarNo ratings yet

- Process Interruptions: A Threat To Process Safety: Did You ?Document1 pageProcess Interruptions: A Threat To Process Safety: Did You ?Abdullah AnarNo ratings yet

- A Hidden Chain of Hazards: What Can You Do? What Happened?Document1 pageA Hidden Chain of Hazards: What Can You Do? What Happened?Abdullah AnarNo ratings yet

- Firefighters' Clothing and Equipment Performance, Protection, and ComfortDocument372 pagesFirefighters' Clothing and Equipment Performance, Protection, and ComfortAbdullah AnarNo ratings yet

- Marine ProcedureDocument31 pagesMarine ProcedureAbdullah Anar100% (2)

- HSE Visual Standards Manual Rev 00 (Template)Document16 pagesHSE Visual Standards Manual Rev 00 (Template)Abdullah AnarNo ratings yet

- Health, Safety and Environmental Management System (HSE MS)Document68 pagesHealth, Safety and Environmental Management System (HSE MS)Abdullah Anar100% (1)

- HSE New Hire OrientationDocument118 pagesHSE New Hire OrientationAbdullah AnarNo ratings yet

- Kyocera Fs-1020d Service ManualDocument109 pagesKyocera Fs-1020d Service ManualvonBoomslangNo ratings yet

- Prestressed Transfer Plate Design and ConstructionDocument16 pagesPrestressed Transfer Plate Design and Constructiona96lhf0% (1)

- IC A25 Basic ManualDocument24 pagesIC A25 Basic ManualMiguel López AguayoNo ratings yet

- History of Microsoft OfficeDocument2 pagesHistory of Microsoft OfficeRichie BlasabasNo ratings yet

- IEEE Guide For Selection of Valve-Regulated Lead-Acid (VRLA) Batteries For Stationary ApplicationsDocument27 pagesIEEE Guide For Selection of Valve-Regulated Lead-Acid (VRLA) Batteries For Stationary ApplicationsDino Dino DinoNo ratings yet

- Development AgreementDocument17 pagesDevelopment AgreementSridhara babu. N - ಶ್ರೀಧರ ಬಾಬು. ಎನ್67% (3)

- For The Professional: Smart Irrigation SolutionsDocument56 pagesFor The Professional: Smart Irrigation SolutionsWafiq EidNo ratings yet

- RCA Study - Wilbur Smith Traffic & Revenue Forecasts - 012712Document103 pagesRCA Study - Wilbur Smith Traffic & Revenue Forecasts - 012712Terry MaynardNo ratings yet

- Artificial Intelligence in Food Industry: Submitted To: Sir Anwar Submitted By: Gul E Kainat 15-ARID-4939Document32 pagesArtificial Intelligence in Food Industry: Submitted To: Sir Anwar Submitted By: Gul E Kainat 15-ARID-4939Lubna KhanNo ratings yet

- List of Cases For Quiz No 4 With DigestDocument11 pagesList of Cases For Quiz No 4 With DigestDawn JessaNo ratings yet

- Introduction of KUT650 Ultrasonic Flaw Detector - HongTuoDocument3 pagesIntroduction of KUT650 Ultrasonic Flaw Detector - HongTuolovaldes62No ratings yet

- Modelling of Electrical Transformers in Dynamic RegimesDocument8 pagesModelling of Electrical Transformers in Dynamic RegimesFatmir JashariNo ratings yet

- Kaigah HPP - Executive SummaryDocument27 pagesKaigah HPP - Executive SummaryAli Nawaz Khan100% (1)

- Resume SparkDocument4 pagesResume SparkleninbabusNo ratings yet

- Chapter 1Document10 pagesChapter 1Jean Salaveria CenasNo ratings yet

- GC 70 UlDocument2 pagesGC 70 UlAnonymous VNu3ODGavNo ratings yet

- 64 LawDocument2 pages64 LawJay TiwariNo ratings yet

- MAYNARD R. PERALTA, Petitioner, v. CIVIL SERVICE COMMISSION, Respondent. SyllabusDocument5 pagesMAYNARD R. PERALTA, Petitioner, v. CIVIL SERVICE COMMISSION, Respondent. SyllabusGhee MoralesNo ratings yet

- Direct Shear Test ResultDocument7 pagesDirect Shear Test ResultDeepak Kr GuptaNo ratings yet

- FM PDFDocument1 pageFM PDFnes2130No ratings yet

- Bach, Well Tempered ClavierDocument3 pagesBach, Well Tempered ClavierLucas BauerNo ratings yet

- Template 2 PIA Report Part 2 Appendix ADocument14 pagesTemplate 2 PIA Report Part 2 Appendix AJhong100% (1)

- 2020 Wheat Brochure PM V8Document12 pages2020 Wheat Brochure PM V8TefeNo ratings yet

- Blood Bank Management SystemDocument4 pagesBlood Bank Management SystemIJARSCT JournalNo ratings yet

- Red Hat JBoss Enterprise Application Platform-7.1-Introduction To JBoss EAP-es-ESDocument12 pagesRed Hat JBoss Enterprise Application Platform-7.1-Introduction To JBoss EAP-es-ESYesidRaadRomeroNo ratings yet

- Protect - MNS Motor Management INSUM: Technical InformationDocument53 pagesProtect - MNS Motor Management INSUM: Technical InformationAbhijith Sreevalsam100% (1)

- Television and Video EngineeringDocument42 pagesTelevision and Video EngineeringGanesh ChandrasekaranNo ratings yet

- Final B.O.Q For Lecture and Laboratory BlockDocument128 pagesFinal B.O.Q For Lecture and Laboratory BlockkanabuevansNo ratings yet

- 2019 Sitaca - v. - Palomares - Jr.20210424 12 rsvs2dDocument10 pages2019 Sitaca - v. - Palomares - Jr.20210424 12 rsvs2dchan.aNo ratings yet

- CLX6260FD Service ManualDocument159 pagesCLX6260FD Service ManualAndres Lopez ArandaNo ratings yet