Professional Documents

Culture Documents

PPT-CH 5

Uploaded by

chemical todi0 ratings0% found this document useful (0 votes)

22 views24 pagesOriginal Title

PPT-Ch 5

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

22 views24 pagesPPT-CH 5

Uploaded by

chemical todiCopyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 24

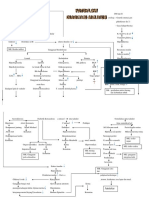

PROBLEM WELL ANALYSIS

Depending on the economics of a

particular situation, a problem well may

be related within specific limits to low oil

or gas production, high GOR, high water

cut, or mechanical problems.

Limited Producing Rate

Limited Producing rate may be a result of

1. Low reservoir permeability

2. Low reservoir pressure for depth

3. Formation damage

4. Well bore or tubing plugging

5. High viscosity oil

6. Excessive back pressure on formation

7. Inadequate artificial lift

8. Mechanical problems

Water Production Problems in oil or

gas wells

Water Problems may result from:

1. Natural water drive or waterflood aggravated by

fingering or coning.

2. Extraneous sources including casing leaks or

primary cement failure.

3. Fracturing or acidizing into adjacent water zones.

Water encroachment is normal in a water

drive reservoir. Three water – oil

contacts may usually be defined in oil

wells:

• Original water–oil contact : Depth below

which no oil is found.

• Producing water–oil contact : Depth

below which no producible oil is found.

This depth rises with oil production in a

water drive reservoir.

• Completion water–oil contact : Depth

below which first water production

appears. This depth rises with production

in a water drive reservoir or in a water

flood

Water encroachment is complicated by

stratified or layered permeability. Fingering,

illustrated in Fig.6.1 is differential water

encroachment through the more permeable

zones. Because fluids will move faster through

zones of high permeability, these zones will

usually watered out first.

Early water breakthrough may not cause

abandonment, but a large volume of

water is often produced before oil or gas

is depleted from the remaining zones.

Fig. 6.1: Irregular water encroachment in heterogeneous reservoir

can result in early water breakthrough.

“Fingering” of water, defined as

upstructure water movement in the more

permeable zones of a multi zone

completion, is rate sensitive. Premature

fingering may be reduced by reducing

total fluid production rates.

“Water coning” in oil or gas well is

defined as vertical movement of water

across bedding planes in producing

formation. Fig.6.2 illustrates coning in an

oil reservoir. Coning for more than a few

feet is relatively rare in most unfractured

sandstone reservoirs.

Fig. 6.2: Coning of water

Water or gas coning will not cross barriers to

vertical permeability unless these barriers are

broken by natural or induced fractures.

Elimination of a cone usually requires reduced

production rates. Recompletion or repair may

alleviate the problem if water is coning through

a cement channel or through vertical fractures.

Removal of Wax Deposits

Paraffin deposits vary greatly from one

reservoir to another, and differences have

even been noted in wells in the same

reservoir.

The most common methods of removing

paraffin from wells are:

1. Mechanical

2. Solvents

3. Heat

4. Dispersion

Mechanical removal of Wax

Scrapers and cutters are used extensively

to remove paraffin from tubing. These

techniques are relatively economical and

usually result in minimal formation

damage.

Scraping can cause perforation plugging

if it is necessary to circulate scraped

paraffin down the tubing and out of the

casing. If frequent cleanout is required,

mechanical cleaning becomes more

costly, especially when the value of lost

production is added to the cleanout costs.

Solvent removal of wax

The use of solvents are relatively common,

but care must be observed in solvent

selection. Chlorinated hydrocarbon like

carbon tetrachloride can have adverse effect

on refinery catalyst.

Carbon disulfide has been called the

universal paraffin solvent. But it is

expensive, extremely flammable and toxic.

Certain water soluble organic compounds

which decomposes to form carbon disulfide

are mixed with water and introduced into the

tubing or annulus and fall to the bottom of

the hole.

These aqueous solutions are somewhat

safer to handle than carbon disulfide.

Condensate, Kerosene and diesel oil are

commonly used to dissolve paraffin in

wells in which the asphaltene content of

the deposits is very low.

Aromatic chemical such as toluene and

xylene are excellent solvents for

asphaltene as well as paraffin deposits.

Care should be taken as toluene and

xylene has low flash point.

The use of heat for removal of wax

Hot oiling is one of the most popular methods of

paraffin removal. Paraffin is both dissolved and

melted by the hot oil

Crude or other oil is heated to a temperature

significantly greater than that of the formation. Hot

oil is normally pumped down the casing and up the

tubing

Hot oiling can cause permeability damage if

melted wax enters the formation, particularly

in wells having a reservoir temperature of less

than 160 0F.

Hot water is sometimes used to clean wells

completed in low temperature reservoirs.

Any application of heat to remove paraffin

should be carried out before large deposits

have accumulated.

Removal of wax with dispersants

Water soluble dispersants can be used to

remove paraffin deposits.

Halliburton’s Parasperse, a water soluble

dispersant, is used in 2% to 10% chemical

concentrations, depending on the amount of

paraffin to be removed. It does not dissolve

paraffin but disperses paraffin particles to be

circulated from the well.

You might also like

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- DESALTERSDocument48 pagesDESALTERSPRET1971100% (1)

- Oil & Gas SeperationDocument34 pagesOil & Gas Seperationassatpute100% (2)

- Chevron Water in OilDocument2 pagesChevron Water in OilVannex MensidorNo ratings yet

- Oil and Gas Artificial Fluid Lifting TechniquesFrom EverandOil and Gas Artificial Fluid Lifting TechniquesRating: 5 out of 5 stars5/5 (1)

- Oilfield Processing Volume Two Crude Oil Manning Part 1Document221 pagesOilfield Processing Volume Two Crude Oil Manning Part 1rohl55100% (2)

- Removing Contaminants From Crude Oil - AthlonDocument5 pagesRemoving Contaminants From Crude Oil - AthlonIrene CarrilloNo ratings yet

- Hydrocarbon Production Engineering: Presented By: Manish Kumar (18PE10006)Document14 pagesHydrocarbon Production Engineering: Presented By: Manish Kumar (18PE10006)Manish KumarNo ratings yet

- Produced Water TreatmentDocument53 pagesProduced Water TreatmentMahathir Che Ap83% (6)

- Water Contamiination of Steam TurbineDocument6 pagesWater Contamiination of Steam TurbineIlham Surya HadiNo ratings yet

- 03 04 Petroleum Waste Water Desalter Case StudyDocument6 pages03 04 Petroleum Waste Water Desalter Case StudyivandavidmtNo ratings yet

- Desalting Crude OilDocument13 pagesDesalting Crude Oilpardise4000No ratings yet

- Chapter 4-Crude Oil DesaltingDocument19 pagesChapter 4-Crude Oil DesaltingYasir Khan100% (3)

- Degassing & DehydrationDocument15 pagesDegassing & Dehydrationabdelwahab alneamahNo ratings yet

- Wax RemediationDocument3 pagesWax RemediationDonna GrayNo ratings yet

- Channel Flow Behind CasingDocument2 pagesChannel Flow Behind Casingحسين رامي كريم A 12No ratings yet

- Lecture 04Document16 pagesLecture 04Touseef IsmailNo ratings yet

- Question 21 We Are Observing Fouling of Our Feedeffluent Exchangers That Has Impacted Heat Transfer and Restricted Feed What Are Potential Contributing Causes and How Can We MitigateDocument10 pagesQuestion 21 We Are Observing Fouling of Our Feedeffluent Exchangers That Has Impacted Heat Transfer and Restricted Feed What Are Potential Contributing Causes and How Can We MitigateQwERTyNo ratings yet

- Petro Unit 2-IDocument77 pagesPetro Unit 2-INawal AgarwalNo ratings yet

- Q'Max Technical Bulletin #6 Viscosity Modification in Oil MudsDocument6 pagesQ'Max Technical Bulletin #6 Viscosity Modification in Oil MudsAnonymous JMuM0E5YONo ratings yet

- Crude Oil TreatmentDocument27 pagesCrude Oil TreatmentmahmoudNo ratings yet

- The Effective Way of Separating WaterDocument38 pagesThe Effective Way of Separating WaterIrshad Muhammad100% (4)

- Types FDFDocument2 pagesTypes FDFaymen telliNo ratings yet

- Hotwell and Oil in Boiler WaterDocument5 pagesHotwell and Oil in Boiler WaterAbrham DubeNo ratings yet

- Oil/Water Separation Design & ApplicationDocument6 pagesOil/Water Separation Design & ApplicationSushil RajakNo ratings yet

- PetroleumDocument15 pagesPetroleumstephen mwendwaNo ratings yet

- Crude Oil DesaltingDocument14 pagesCrude Oil DesaltingDucViking100% (1)

- Crude Oil Processing On Offshore Facilities PDFDocument14 pagesCrude Oil Processing On Offshore Facilities PDFmohit4821No ratings yet

- Drilling Fluid EssayDocument5 pagesDrilling Fluid EssayAyman MikailNo ratings yet

- Desalting Heavy Crude Oils - The Venezuelan ExperienceDocument10 pagesDesalting Heavy Crude Oils - The Venezuelan ExperienceDomingoAPerazaS100% (1)

- Petroleum Refining Processes1Document73 pagesPetroleum Refining Processes1Arun DasNo ratings yet

- ABSTRACTDocument7 pagesABSTRACTRawda SeragNo ratings yet

- 06 - Ows & SweageDocument5 pages06 - Ows & SweageAisha Zaheer100% (1)

- Challenges During Operation and Shutdown of Waxy Crude PipelinesDocument13 pagesChallenges During Operation and Shutdown of Waxy Crude PipelinesJesseNo ratings yet

- Drilling Mud Fluid: Kurdistan Region Government - Iraq Erbil Polytechnic University Department of PetroleumDocument9 pagesDrilling Mud Fluid: Kurdistan Region Government - Iraq Erbil Polytechnic University Department of PetroleumabdulqadirNo ratings yet

- Lec.1 Desalting ProcessDocument30 pagesLec.1 Desalting ProcessAhmed RedaNo ratings yet

- Desalting Heavy Canadian Crudes PDFDocument5 pagesDesalting Heavy Canadian Crudes PDFAnonymous 2TfNdCgNo ratings yet

- Surface FacilitiesDocument20 pagesSurface Facilitiesheriku_mulyaNo ratings yet

- 2.1.6.1 Potencial Operating ProblemsDocument7 pages2.1.6.1 Potencial Operating ProblemsCarlosNo ratings yet

- Unit-4 Flow Assurance & MitigationDocument71 pagesUnit-4 Flow Assurance & MitigationHet PatelNo ratings yet

- Carryover in BoilerDocument2 pagesCarryover in Boilershan877No ratings yet

- SWS Paper FinalA4Document17 pagesSWS Paper FinalA4faisalmuradNo ratings yet

- Treatment of Oil Special ProblemsDocument34 pagesTreatment of Oil Special ProblemsUdeme JohnNo ratings yet

- Crude Oil DesaltingDocument5 pagesCrude Oil DesaltingAhmed Mohamed Khalil0% (1)

- Oil TreatDocument3 pagesOil TreatfarhanNo ratings yet

- Lecture 02A - DesaltingDocument30 pagesLecture 02A - DesaltingJorge Enciso AcuñaNo ratings yet

- Flow Assurance - AOEDocument19 pagesFlow Assurance - AOEAmeya SaneNo ratings yet

- Well Problems and Solutions, Well Problem, SolutionsDocument16 pagesWell Problems and Solutions, Well Problem, SolutionsParesh AgarwalNo ratings yet

- Section 2. Evaporators: 2.1 2 2.2 Scale Deposition 2 2.3 Scale Prevention 4 2.4 Approvals 5 2.5 Evaporator Layouts 5Document6 pagesSection 2. Evaporators: 2.1 2 2.2 Scale Deposition 2 2.3 Scale Prevention 4 2.4 Approvals 5 2.5 Evaporator Layouts 5Rohith UnniNo ratings yet

- Workover FluiddsDocument19 pagesWorkover FluiddsNIRAJ DUBEYNo ratings yet

- Pre-Treatment Infinity GroupDocument28 pagesPre-Treatment Infinity Groupsherifelbayoumy266No ratings yet

- CHAPTER 6 Separation & ProcessingDocument72 pagesCHAPTER 6 Separation & Processingfaitholiks841No ratings yet

- Oil Base MudDocument25 pagesOil Base MudWasif KarimNo ratings yet

- Flow AssuranceDocument124 pagesFlow AssuranceJezz100% (2)

- UntitledDocument7 pagesUntitledAjay NishadNo ratings yet

- EmulsionsDocument14 pagesEmulsionsPaolo CavaioniNo ratings yet

- CHE10406, Crude Oil DesaltingDocument1 pageCHE10406, Crude Oil DesaltingMechanicalNo ratings yet

- Environmental Pollution Control Engineering (Che1815Pe21)Document8 pagesEnvironmental Pollution Control Engineering (Che1815Pe21)chemical todiNo ratings yet

- Environmental Pollution Control Engineering (Che1815Pe21)Document5 pagesEnvironmental Pollution Control Engineering (Che1815Pe21)chemical todiNo ratings yet

- New Doc 2020-03-23 11.59.30 PDFDocument1 pageNew Doc 2020-03-23 11.59.30 PDFchemical todiNo ratings yet

- Environmental Pollution Control Engineering (Che1815Pe21)Document6 pagesEnvironmental Pollution Control Engineering (Che1815Pe21)chemical todiNo ratings yet

- New Doc 2020-03-25 13.21.50 PDFDocument3 pagesNew Doc 2020-03-25 13.21.50 PDFchemical todiNo ratings yet

- Environmental Pollution Control Engineering (Che1815Pe21)Document11 pagesEnvironmental Pollution Control Engineering (Che1815Pe21)chemical todiNo ratings yet

- EPCE 5 (Sedimentation)Document7 pagesEPCE 5 (Sedimentation)chemical todiNo ratings yet

- Environmental Pollution Control Engineering (Che1815Pe21)Document13 pagesEnvironmental Pollution Control Engineering (Che1815Pe21)chemical todiNo ratings yet

- New Doc 2020-03-21 20.34.21Document9 pagesNew Doc 2020-03-21 20.34.21chemical todiNo ratings yet

- Heat Transfer Operation Marks - 20 Class Test - I Date - /2018Document1 pageHeat Transfer Operation Marks - 20 Class Test - I Date - /2018chemical todiNo ratings yet

- New Doc 2020-03-21 21.46.20Document3 pagesNew Doc 2020-03-21 21.46.20chemical todiNo ratings yet

- Regulations On The Discharge of in Dustrial Polutants in Water, Thres Hold LimitDocument6 pagesRegulations On The Discharge of in Dustrial Polutants in Water, Thres Hold Limitchemical todiNo ratings yet

- Heat Transfer Operation Marks - 20 Class Test - Iii DATE - 24/05/2018Document1 pageHeat Transfer Operation Marks - 20 Class Test - Iii DATE - 24/05/2018chemical todiNo ratings yet

- Summer Internship/Vocational Training Report: - Mr. Bardan LamaDocument40 pagesSummer Internship/Vocational Training Report: - Mr. Bardan Lamachemical todiNo ratings yet

- Steam Education PowerPoint TemplatesDocument48 pagesSteam Education PowerPoint TemplatesRobi IlhamNo ratings yet

- Environmental Pollution Control Engineering (Che1815Pe21)Document8 pagesEnvironmental Pollution Control Engineering (Che1815Pe21)chemical todiNo ratings yet

- Fundamentals of Well Stimulation TechniqueDocument58 pagesFundamentals of Well Stimulation Techniquechemical todiNo ratings yet

- PPT-CH 3Document64 pagesPPT-CH 3chemical todiNo ratings yet

- Chemical Engineering Job Interview QuestionsDocument5 pagesChemical Engineering Job Interview Questionschemical todi0% (1)

- Assignment 2 (Archit Todi 17 - 274)Document15 pagesAssignment 2 (Archit Todi 17 - 274)chemical todiNo ratings yet

- PED Assignment 17 - 274Document13 pagesPED Assignment 17 - 274chemical todiNo ratings yet

- PPT-CH 7Document19 pagesPPT-CH 7chemical todiNo ratings yet

- Geologic Considerations in Production OperationsDocument72 pagesGeologic Considerations in Production Operationschemical todiNo ratings yet

- Calculation Sheet For Pump Hydraulic (Fps Unit)Document1 pageCalculation Sheet For Pump Hydraulic (Fps Unit)chemical todiNo ratings yet

- P E C L 2: Rocess Ngineering Ourse - EctureDocument10 pagesP E C L 2: Rocess Ngineering Ourse - Ecturechemical todiNo ratings yet

- P E C L 7: Rocess Ngineering Ourse - EctureDocument8 pagesP E C L 7: Rocess Ngineering Ourse - Ecturechemical todiNo ratings yet

- Flow-Induced Vibration (FIV) AnalysisDocument3 pagesFlow-Induced Vibration (FIV) Analysischemical todiNo ratings yet

- Crisis Management - Meaning, Need and Its FeaturesDocument16 pagesCrisis Management - Meaning, Need and Its Featureschemical todi100% (1)

- P E C L 3: Rocess Ngineering Ourse - EctureDocument6 pagesP E C L 3: Rocess Ngineering Ourse - Ecturechemical todiNo ratings yet

- Project DesertsDocument17 pagesProject Desertssuja_sriniNo ratings yet

- My Project PresentationDocument12 pagesMy Project Presentationkarunasand15No ratings yet

- ALPS 2327 Chemistry Assignment Paper PDFDocument11 pagesALPS 2327 Chemistry Assignment Paper PDFAyushNo ratings yet

- Zoology Practical 4Document13 pagesZoology Practical 4Asraful IslamNo ratings yet

- Immulite Homocysteine 2000Document30 pagesImmulite Homocysteine 2000Symbolin MusenkoNo ratings yet

- Case Study NCP ActualDocument3 pagesCase Study NCP Actualdhamy florNo ratings yet

- Patoflow DMDocument2 pagesPatoflow DMAngel da CostaNo ratings yet

- New Approaches To Cryopreservation of Cells, Tissues, and OrgansDocument19 pagesNew Approaches To Cryopreservation of Cells, Tissues, and OrgansLaura CursaruNo ratings yet

- Oil Palm Fractions Derivatives Web PDFDocument6 pagesOil Palm Fractions Derivatives Web PDFIan RidzuanNo ratings yet

- Lesson Plan Personality DisorderDocument7 pagesLesson Plan Personality DisorderRaj MeghwalNo ratings yet

- Buy Lizol Floor Cleaner 5000 ML Online - GeMDocument4 pagesBuy Lizol Floor Cleaner 5000 ML Online - GeMHimanshu ShuklaNo ratings yet

- Directory of Acredited Medical Testing LaboratoriesDocument93 pagesDirectory of Acredited Medical Testing LaboratoriesCALIDAD METROMEDICA E.UNo ratings yet

- Answer Key EXAM DRILL 2 - Community Health Nursing Nursing Practice Ii - CHN and Care of The Mother and ChildDocument24 pagesAnswer Key EXAM DRILL 2 - Community Health Nursing Nursing Practice Ii - CHN and Care of The Mother and Childbetiful83% (6)

- Antiemetics - AMBOSSDocument4 pagesAntiemetics - AMBOSSOpio IsaacNo ratings yet

- Research 101Document14 pagesResearch 101Ace Ryu SmithNo ratings yet

- Grade 12 - Biology Resource BookDocument245 pagesGrade 12 - Biology Resource BookMali100% (6)

- Science 10 Q3 - M2Document14 pagesScience 10 Q3 - M2Avha CortesNo ratings yet

- Retention and Relapse in OrthodonticsDocument48 pagesRetention and Relapse in OrthodonticsSurabhi roy33% (3)

- SM - Business PoliciesDocument46 pagesSM - Business PoliciesPrithvi AcharyaNo ratings yet

- International Journal of Trend in Scientific Research and Development (IJTSRD)Document4 pagesInternational Journal of Trend in Scientific Research and Development (IJTSRD)Editor IJTSRDNo ratings yet

- Aaos PDFDocument4 pagesAaos PDFWisnu CahyoNo ratings yet

- The Thermal ConductivityDocument6 pagesThe Thermal ConductivityLuc LeNo ratings yet

- JSLHR Author InstructionsDocument14 pagesJSLHR Author InstructionsChanyanit CharoenpholNo ratings yet

- Boq Floor Tiling WorksDocument1 pageBoq Floor Tiling WorksISAAC KIPSEREM0% (2)

- UntitledDocument41 pagesUntitledDion AdalaNo ratings yet

- Application of Statistical MethodsDocument5 pagesApplication of Statistical Methodsradquinineza0% (1)

- Service ProgramDocument47 pagesService ProgramHuseyn aliyevNo ratings yet

- FCA Problems RevisedDocument12 pagesFCA Problems RevisedRomelle Jane M. VelascoNo ratings yet

- Fleming Trio-E Promotional SheetDocument2 pagesFleming Trio-E Promotional SheetRed BarnNo ratings yet

- Cable Test Bridge KMK 7Document2 pagesCable Test Bridge KMK 7zaki3speedNo ratings yet