Professional Documents

Culture Documents

Casting: Dept. of Mech & Mfg. Engg

Uploaded by

omkardashetwarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Casting: Dept. of Mech & Mfg. Engg

Uploaded by

omkardashetwarCopyright:

Available Formats

Casting

Dept. of Mech & Mfg. Engg.

1

Dept. of Mech & Mfg. Engg.

2

CASTING

It is the process of producing metallic parts by

pouring a molten metal in to the mould and

allowing the metal to solidify.

Dept. of Mech & Mfg. Engg.

3

Pattern materials

-Any material which will retain exact outline of the design

for required number of molds

Dept. of Mech & Mfg. Engg.

4

Dept. of Mech & Mfg. Engg.

5

Pattern materials

• Wood – easy to work & readily available

– can be cut in to required shapes

– used when small number of castings

• Metal - do not change their shape when subjected to

moist condition

– used when small number of castings

• Plastics – do not absorb moisture, smooth

– can be withdrawn from the mold easily,

without damaging the mold

• Plaster – High compressive strength

Dept. of Mech & Mfg. Engg.

6

Process of mold making

1. Preparation of drag

2. Preparing Cope

3. Reassemble the cope and drag

Dept. of Mech & Mfg. Engg.

7

Properties of a molding sand

• Porosity (permeability)

– Sand must be porous to allow the gases/ moisture present

with in the molds to be removed freely when molten metal is

poured

• Adhesiveness

– sand particles must be capable of adhering to sides of

molding boxes

• Cohesiveness / Strength

– Ability of sand particles to stick together

– Should be sufficient to permit the mold to be formed to the desired

shape even after the hot metal is poured in the mold

• Refractoriness

– Molding sands with a poor refractoriness may burn on to the

casting

– Measured by sinter point of sand

Dept. of Mech & Mfg. Engg.

8

Properties of a molding sand

• Collapsibility

– Mold made out of sand to collapse as the molten metal gets

solidified in it

• Flowability

– Ability of the sand to behave like a fluid so that, when rammed

sand will flow to all portions of a mold and around the pattern and

take up the required shape

– It increases as clay & water content increase

– High flowability is required of a molding sand of uniform density

– To obtain good impression of the pattern in the mold.

Dept. of Mech & Mfg. Engg.

9

Molding sand classification

They can be classified as:

1. Natural molding sand (Green sand)

- Taken from river beds & contain major amount of clay

- easily available at low cost

2. Synthetic sand

- contain little or no binder (clay)

- strength & bonding property can be easily controlled

- more expensive than natural sand

3. Special sand

- ideal in getting special characteristics..

Dept. of Mech & Mfg. Engg.

10

Sand preparation

• Very few natural sands have all the qualities

required by a molding sand

• It is mixed with other sands which possess the

required characteristics

• Sufficient moisture must be added to the sand

• Sand must be properly conditioned before use

Dept. of Mech & Mfg. Engg.

11

Green sand mold

Dept. of Mech & Mfg. Engg.

12

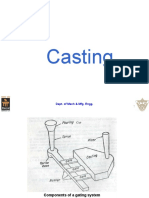

Green sand mold Drag

Pattern

Molding board

FIRST OPERATION

Vents

Weight Lifter

Riser pin Sprue pin Pouring basin

Cope

Riser

Parting Parting

line line Runner

Gate

Core

SECOND OPERATIONDept. of Mech & Mfg. Engg.

COMPLETE MOLD 13

Scooping

• It is the process of making a cavity in the sand mould

without using a pattern.

• Instead it makes use of casting hand tools like shovel,

rammer etc.

Dept. of Mech & Mfg. Engg.

14

Types of patterns

-Single piece pattern

-Split pattern

-Match plate pattern

-Cope & Drag pattern

-Loose-piece pattern

-Skeleton pattern

-Gated pattern

Dept. of Mech & Mfg. Engg.

15

Types of patterns

Dowel

pins

b) Split pattern

One piece pattern Loose piece pattern

Dept. of Mech & Mfg. Engg.

16

Match Plate pattern Gated pattern

Cope plate

Sand

Drag plate

Cope & Drag pattern

Gated pattern

Dept. of Mech & Mfg. Engg.

17

Single piece pattern

• Made from one piece & does not contain loose pieces

• Inexpensive & are of simplest type

Split pattern

• Most widely used pattern for intricate castings

• Here the pattern is split in to 2 parts so that one part is in

the cope & other is in the drag

• Two halves of the pattern is aligned properly by using

dowel pins

Dept. of Mech & Mfg. Engg.

18

Cope and Drag pattern

• Similar to split patterns

• The cope & drag halves of the pattern along with the

gating

and risering systems

• But they are attached separately to the metal or wooden

plate along with alignment pins

Match plate pattern

• An extension of cope and drag pattern

• Here the cope & drag patterns along with the gating &

risering are mounted on a single matching or metal plate

on either side

Dept. of Mech & Mfg. Engg.

19

Loose piece pattern

• Used when contour of the part is such that withdrawing

the

pattern from the mold is not possible

• Obstructing part is held as a loose piece

Skeleton pattern

• Made of strips of wood for preparing final pattern

by pouring the sand around the pattern and packing it

Dept. of Mech & Mfg. Engg.

20

Pattern Allowances

1. Shrinkage allowance

2. Machining or Finishing allowance

3. Draft or Taper allowance

4. Camber or distortion allowance

5. Shake or Rapping allowance

6. Mould wall movement allowance

Dept. of Mech & Mfg. Engg.

21

Pattern Allowances

1. Shrinkage allowance

• Most of the metals used in casting contract during

cooling from pouring temperature to room temperature

• Provided to compensate for solid contraction by

providing adequate allowances in the pattern

• Amount of contraction varies with different metals

Dept. of Mech & Mfg. Engg.

22

Pattern Allowances

2. Machining allowance

• Given on the surface of the pattern by increasing the metal

thickness there to compensate for loss of metal due to

machining on these surfaces

• Depends mainly upon method of machining to be employed

• Given in addition to the shrinkage allowance

Dept. of Mech & Mfg. Engg.

23

Pattern Allowances

3. Draft or Taper allowance

• Given slight taper on the vertical surfaces of the pattern

parallel to the direction of withdrawal from the mould

• Provided on both internal & external surfaces

• For easy withdrawal of pattern from the mould

Dept. of Mech & Mfg. Engg.

24

Pattern Allowances

4. Rapping allowance

• Negative allowance to be provided in the pattern

• When pattern is withdrawn from the mould by striking over

it from side to side, size of the cavity increases

• To compensate this rapping allowance is provided

Dept. of Mech & Mfg. Engg.

25

Pattern Allowances

5. Distortion allowance

• Castings having irregular shape, will not have uniform

contraction during their cooling

• Results in distortion of the castings

Remedy:

An opposite distortion is provided in the pattern

Dept. of Mech & Mfg. Engg.

26

Pattern Allowances

6. Mould wall movement allowance

• Mould wall movement takes place because of excessive

heat and pressure applied by the molten metal on the surface

layer of the sand

• Affects the size of the casting

Remedy:

• Provide proper allowance in the pattern

• Controlling the density & temperature of molten metal

• Controlling the composition of the molding sand

Dept. of Mech & Mfg. Engg.

27

Defects in casting

• Blowholes

– Smooth round holes appearing in the form group of small

holes below the surface of casting

– Due to entrapped bubble of gases

• Scabs

– Projection on the casting that occur when a portion of the

mould lifts and metal flows

• Drop

– Occurs when upper surface of the mold cracks and pieces

of sand falls in to the molten metal

• Shrinkage cavity

– Void created in the casting mainly due to uncontrolled

solidification of the metal

Dept. of Mech & Mfg. Engg.

28

• Internal air pocket

– It appears as small holes inside the casting, due to rapid pouring

of molten metal in to the mold

• Shifts

– An external defect caused due to core misplacement or

mismatching of top and bottom parts of the casting

• Fin

– A thin projection of the metal

– Caused due to incorrect assembling of molds or cores

• Swell

– Enlargement of metal cavity by metal pressure

– This is caused by improper ramming

• Warpage

– Unintentional and undesirable deformation in a casting that

occurs during solidification

Dept. of Mech & Mfg. Engg.

29

Back

General Casting Defects

Dept. of Mech & Mfg. Engg.

30

Back

Dept. of Mech & Mfg. Engg.

31

You might also like

- Document GDocument30 pagesDocument GWLLM100% (2)

- Soundarya Lahari Translation in EnglishDocument50 pagesSoundarya Lahari Translation in EnglishRanganatha Gowda100% (1)

- Aircraft StructureDocument11 pagesAircraft StructureVagesh VagesNo ratings yet

- Casting IntroDocument94 pagesCasting IntroJith ViswaNo ratings yet

- Casting & ForgingDocument42 pagesCasting & ForgingMrinal100% (1)

- DimensionsDocument103 pagesDimensionslaurariton100% (1)

- 2b-CASTING PROCESSESDocument42 pages2b-CASTING PROCESSESIzzat IkramNo ratings yet

- Metal CastingDocument89 pagesMetal CastingazeemdcetNo ratings yet

- The Church Fathers and HeresiesDocument79 pagesThe Church Fathers and Heresieskim minervaNo ratings yet

- Manfff 2Document110 pagesManfff 2Robel FikaduNo ratings yet

- Learn Critical Aspects of Pattern and Mould Making in FoundryFrom EverandLearn Critical Aspects of Pattern and Mould Making in FoundryNo ratings yet

- Dschool Bootleg Deck 2018 Final SM+Document90 pagesDschool Bootleg Deck 2018 Final SM+Tiago Lacerda100% (1)

- Manpower EstimationDocument28 pagesManpower EstimationRakesh Ranjan100% (2)

- MT-1 Full NotesDocument56 pagesMT-1 Full NotesM.Saravana Kumar..M.ENo ratings yet

- Buehler's Guide To Sample PreparationDocument74 pagesBuehler's Guide To Sample PreparationGowtham GanesanNo ratings yet

- Manufacturing Technology (MEC - 205) : Unit - 1 Introduction To Manufacturing and Metal CastingDocument74 pagesManufacturing Technology (MEC - 205) : Unit - 1 Introduction To Manufacturing and Metal CastingShridhar SavatNo ratings yet

- Lecture2casting 160411082846Document190 pagesLecture2casting 160411082846IgnatiusAbbyNo ratings yet

- 1 Sand Casting ProcessDocument50 pages1 Sand Casting ProcessMuhammad Ishaq100% (1)

- Foundary or CastingDocument88 pagesFoundary or CastingThulasi RamNo ratings yet

- Foundry LabDocument50 pagesFoundry Labanon-76437486% (21)

- M - I U - 1 C P: Anufacturing Processes NIT Asting RocessesDocument246 pagesM - I U - 1 C P: Anufacturing Processes NIT Asting RocessesMahesh SalotagiNo ratings yet

- CastingDocument74 pagesCastingParth Maldhure100% (1)

- Singapore Management University A Case Study 2020Document12 pagesSingapore Management University A Case Study 2020omkardashetwarNo ratings yet

- Dyneema Vs SteelDocument5 pagesDyneema Vs SteelSaurabh KumarNo ratings yet

- 3 PDFDocument199 pages3 PDFsanku surya sai charanNo ratings yet

- Start Up Slug Catcher and Train 1Document43 pagesStart Up Slug Catcher and Train 1Larbi HammounNo ratings yet

- Casting: Dept. of Mech & Mfg. EnggDocument21 pagesCasting: Dept. of Mech & Mfg. EnggomkardashetwarNo ratings yet

- Casting: Dept. of Mech & Mfg. EnggDocument48 pagesCasting: Dept. of Mech & Mfg. EnggomkardashetwarNo ratings yet

- Casting: Dept. of Mech & Mfg. EnggDocument21 pagesCasting: Dept. of Mech & Mfg. EnggomkardashetwarNo ratings yet

- 08 Casting - ForgingDocument35 pages08 Casting - ForgingomkardashetwarNo ratings yet

- MP - Unit I-1 PDFDocument51 pagesMP - Unit I-1 PDFGuest 128No ratings yet

- SBP 3Document34 pagesSBP 340 Sai VenkatNo ratings yet

- Unit-1 (1) MPDocument189 pagesUnit-1 (1) MPVishvas SinghhNo ratings yet

- CASTING (Compatibility Mode) PDFDocument42 pagesCASTING (Compatibility Mode) PDFnitesh_n2840No ratings yet

- Assignment IDocument23 pagesAssignment I016 ARUNACHALAM S R MNo ratings yet

- 11 (1) 1Document24 pages11 (1) 1অর্ঘ্য রায়No ratings yet

- Ch02 2022SEPT - Metal Casting 00Document62 pagesCh02 2022SEPT - Metal Casting 00Harith Farhan rozlanNo ratings yet

- Introduction To Metal Casting: by Prof. Keyur Parmar G.I.T.S, PrantijDocument72 pagesIntroduction To Metal Casting: by Prof. Keyur Parmar G.I.T.S, PrantijtraceminiNo ratings yet

- Lecture 7Document24 pagesLecture 7Anshul RajNo ratings yet

- 2.casting and Powder MetallurgyDocument11 pages2.casting and Powder MetallurgyVisan NaiduNo ratings yet

- Assignment IDocument23 pagesAssignment I016 ARUNACHALAM S R MNo ratings yet

- ME 3393 - Manufacturing ProcessesDocument24 pagesME 3393 - Manufacturing ProcessesSupervisor Dr.M.MahendraBoopathiNo ratings yet

- Engg. Practice - Foundry Part IIDocument22 pagesEngg. Practice - Foundry Part IIVbgsd DasNo ratings yet

- CastingDocument67 pagesCastingailjutzfbttqkoogcdNo ratings yet

- BMP (Class 02-Class 04) CastingDocument43 pagesBMP (Class 02-Class 04) CastingAsesh PramanikNo ratings yet

- 1 Hareesha N G Dept Aero Engg, DSCE, BloreDocument47 pages1 Hareesha N G Dept Aero Engg, DSCE, Bloremahammad kamaluddeenNo ratings yet

- Manpro Combined (Casting Welding)Document400 pagesManpro Combined (Casting Welding)dhruv rohillaNo ratings yet

- Sand CastingDocument9 pagesSand CastingShivaram Subbaraya VelumaniNo ratings yet

- MT MLMDocument17 pagesMT MLMSundara MoorthyNo ratings yet

- INTRODUCTION To MANUFACTURING PROCESS PART-2 (2) .PpsDocument47 pagesINTRODUCTION To MANUFACTURING PROCESS PART-2 (2) .Ppsmahammad kamaluddeenNo ratings yet

- Me 333 - CastingDocument30 pagesMe 333 - CastingFarhan HasinNo ratings yet

- 7 Casting TechnologyDocument15 pages7 Casting Technologyksvinyk7193No ratings yet

- Ws5-Metal CastingDocument20 pagesWs5-Metal CastingEsala PereraNo ratings yet

- Module II 12.04.21 Class 1Document19 pagesModule II 12.04.21 Class 1NikhithaNo ratings yet

- ME6302 MFT FullDocument227 pagesME6302 MFT FullmonaNo ratings yet

- Familiarization With Metal Casting I: Module Name: ME2024 Semester: 3Document13 pagesFamiliarization With Metal Casting I: Module Name: ME2024 Semester: 3Awishka EashanNo ratings yet

- Pattern Types and AllowancesDocument16 pagesPattern Types and AllowancesShanti Kiran ZNo ratings yet

- Metal CastingDocument23 pagesMetal CastingIntan Nurhaslinda100% (1)

- CHAPTER 11 Metal Casting ProcessDocument47 pagesCHAPTER 11 Metal Casting Processabd altwierNo ratings yet

- Lecture 2 - Various Casting Techniques (Actual)Document58 pagesLecture 2 - Various Casting Techniques (Actual)Harsh ShahNo ratings yet

- Cast 2Document77 pagesCast 2yash guptaNo ratings yet

- Casting 1Document43 pagesCasting 129011988No ratings yet

- Casting: Conventional Methods Unconventional MethodsDocument13 pagesCasting: Conventional Methods Unconventional Methodsarun t nNo ratings yet

- Casting Process IDocument31 pagesCasting Process IArpit JainNo ratings yet

- Metal Casting Processes: Rizwan M. Gul NWFP UetDocument80 pagesMetal Casting Processes: Rizwan M. Gul NWFP Uetirum,No ratings yet

- ME 203 Manufacturing Technology: V. ThulasikanthDocument77 pagesME 203 Manufacturing Technology: V. ThulasikanthRaghav satijaNo ratings yet

- Manufacturing Technology-I: Subject: Class: 4 Sem B.Tech-Mech A'Document170 pagesManufacturing Technology-I: Subject: Class: 4 Sem B.Tech-Mech A'Ram ArvindNo ratings yet

- Unit 6 w10 Djj3213 (Metal Processing Casting)Document44 pagesUnit 6 w10 Djj3213 (Metal Processing Casting)Syfull musicNo ratings yet

- 2015 Control AwardsDocument2 pages2015 Control AwardsomkardashetwarNo ratings yet

- Mbamission PreviewDocument21 pagesMbamission PreviewUtkarsh ANo ratings yet

- IIM Shilong Final Placement Report 2018-20 - May20 PDFDocument11 pagesIIM Shilong Final Placement Report 2018-20 - May20 PDFkartikeya pandeyNo ratings yet

- CV BuildingDocument3 pagesCV BuildingomkardashetwarNo ratings yet

- IPM Social Placements BrochureDocument20 pagesIPM Social Placements BrochureomkardashetwarNo ratings yet

- STTP BrochureDocument2 pagesSTTP BrochureomkardashetwarNo ratings yet

- Hi Tron Two Days IoT Internet of Things Professional Training BrochureDocument18 pagesHi Tron Two Days IoT Internet of Things Professional Training BrochureomkardashetwarNo ratings yet

- IOT Wireless Lighting AbstractDocument2 pagesIOT Wireless Lighting AbstractomkardashetwarNo ratings yet

- Are You B-School Ready?: Operations Case Study WebinarDocument16 pagesAre You B-School Ready?: Operations Case Study WebinaromkardashetwarNo ratings yet

- Information Brochure - MBA-CET 2020 - FinalloDocument23 pagesInformation Brochure - MBA-CET 2020 - FinalloAahaanaNo ratings yet

- PGP Help TextDocument3 pagesPGP Help TextNithya RajaramNo ratings yet

- IIM Shillong Placement Brochure 2017 18Document38 pagesIIM Shillong Placement Brochure 2017 18omkardashetwarNo ratings yet

- Syllbus For Online MHT CET 2019 DT 14-11-2018 1Document1 pageSyllbus For Online MHT CET 2019 DT 14-11-2018 1Jainam SavlaNo ratings yet

- MBA Admissions 2019Document42 pagesMBA Admissions 2019omkardashetwarNo ratings yet

- FileHandler PDFDocument21 pagesFileHandler PDFTysonNo ratings yet

- PGDM Admission Brochure 2019 21 ChennaiDocument28 pagesPGDM Admission Brochure 2019 21 ChennaiomkardashetwarNo ratings yet

- Goa Institute of Management: Placement Report 2018-2019Document7 pagesGoa Institute of Management: Placement Report 2018-2019omkardashetwarNo ratings yet

- Hand Out Admission 2020Document9 pagesHand Out Admission 2020ROHIT RANJANNo ratings yet

- Indian Institute of Management Bangalore Declaration by Parent/GuardianDocument2 pagesIndian Institute of Management Bangalore Declaration by Parent/GuardianBipin Bansal AgarwalNo ratings yet

- FMS Form-Filling Guidelines IMSDocument5 pagesFMS Form-Filling Guidelines IMSomkardashetwarNo ratings yet

- CMAT Solved Sample Paper PDFDocument14 pagesCMAT Solved Sample Paper PDFVikas SinghNo ratings yet

- Net List File FormatDocument4 pagesNet List File FormatRajeev RanjanNo ratings yet

- A Focus On User Outcomes Summary - Ba3b0c6dDocument2 pagesA Focus On User Outcomes Summary - Ba3b0c6dDiego Ignacio Pavez OlaveNo ratings yet

- Circuit Board Design TipsDocument3 pagesCircuit Board Design TipsEric Tran100% (1)

- Goa Institute of Management: Placement Report 2018-2019Document7 pagesGoa Institute of Management: Placement Report 2018-2019omkardashetwarNo ratings yet

- Great Lakes Information Brochure PDFDocument20 pagesGreat Lakes Information Brochure PDFVibhor SharmaNo ratings yet

- Company Law 19-7-2019Document786 pagesCompany Law 19-7-2019Anjali GuptaNo ratings yet

- K-90-1900 FM-200 AgentDocument1 pageK-90-1900 FM-200 AgentPutra LangitNo ratings yet

- 2414 2416 Installation ProcedureDocument4 pages2414 2416 Installation ProcedureJames BondNo ratings yet

- 7 AcousticsDocument23 pages7 AcousticsSummer Yeoreumie100% (1)

- Infertility NotesDocument41 pagesInfertility NotesPrasadNo ratings yet

- Application of Numerical MethodsDocument7 pagesApplication of Numerical MethodsMd Saidur Rahman Kohinoor100% (1)

- Nuclear Energy Today PDFDocument112 pagesNuclear Energy Today PDFDaniel Bogdan DincaNo ratings yet

- GDPDocument6 pagesGDPBenedetta NardiNo ratings yet

- A Green Chemistry Approach To Mercury ControlDocument7 pagesA Green Chemistry Approach To Mercury ControlDennis Daniel Condori EspilcoNo ratings yet

- Mic Fright and Camera PanicDocument5 pagesMic Fright and Camera PanicNica Arizapa100% (1)

- Relative Clauses - Revisión Del IntentoDocument4 pagesRelative Clauses - Revisión Del IntentoYordy Rodolfo Delgado RosarioNo ratings yet

- 9 Cartesian System of CoordinatesDocument15 pages9 Cartesian System of Coordinatesaustinfru7No ratings yet

- Nutritional and Antinutritional Composition of Fermented Foods Developed by Using Dehydrated Curry LeavesDocument8 pagesNutritional and Antinutritional Composition of Fermented Foods Developed by Using Dehydrated Curry LeavesManu BhatiaNo ratings yet

- Reviewer 3RD Exam FinalDocument14 pagesReviewer 3RD Exam FinalReane Romblon GerozagaNo ratings yet

- Gerus Air Driven Hydraulic PumpDocument7 pagesGerus Air Driven Hydraulic Pumpmahmoudayoub173No ratings yet

- PHontDawg Vol.2 2007Document8 pagesPHontDawg Vol.2 2007Tanczos AndrasNo ratings yet

- Essay Test 2021 (Practice Test)Document3 pagesEssay Test 2021 (Practice Test)Philani HadebeNo ratings yet

- Orallichenplanus 170929075918Document40 pagesOrallichenplanus 170929075918Aymen MouradNo ratings yet

- Weapon Type Code Range L M H Traits Category: Wong Rong Jing (Order #7811643)Document1 pageWeapon Type Code Range L M H Traits Category: Wong Rong Jing (Order #7811643)John SmithNo ratings yet

- 1822 B.E Cse Batchno 154Document53 pages1822 B.E Cse Batchno 154maniuyyala65No ratings yet

- Affiliated Institutions Anna University, Chennai Regulations - 2009 Curriculum Ii To Iv Semesters (Full Time) M.E. Applied ElectronicsDocument21 pagesAffiliated Institutions Anna University, Chennai Regulations - 2009 Curriculum Ii To Iv Semesters (Full Time) M.E. Applied ElectronicsRamya VNo ratings yet

- BS en 480-6-2005Document5 pagesBS en 480-6-2005Abey Vettoor0% (1)

- Echo SounderDocument2 pagesEcho SounderDimas AnggaNo ratings yet