Professional Documents

Culture Documents

Chapter 9 - Manufacturing Process: Direct Labor

Uploaded by

aaron manacap0 ratings0% found this document useful (0 votes)

10 views11 pagesOriginal Title

Chapter_9.pptx

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views11 pagesChapter 9 - Manufacturing Process: Direct Labor

Uploaded by

aaron manacapCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 11

Chapter 9 – Manufacturing Process

• What are the Primary Activities in the Conversion Process?

• Schedule production

• Obtain raw materials (internal transfer)

• Use labor and manufacturing resources to convert raw materials int

finished goods

• Store finished goods until sold (internal transfer)

S&A Exp

Raw Work Finished Cost of

In Goods Selling &

Purchases Materials Goods Admin Costs

Process Sold

Direct Labor Applied Man Overhead

Manufacturing Under / Over-

Overhead applied

Chapter 9 – Manufacturing Process

• Which of the Conversion Process Activities are Accounting Events?

• Obtain raw materials

– Increase work-in-process inventory

– Decrease direct materials inventory

• Use labor and overhead

– Increase work-in-process inventory

• Store finished goods

– Increase finished goods inventory

– Decrease work-in-process inventory

S&A Exp

Raw Work Finished Cost of

In Goods Selling &

Purchases Materials Goods Admin Costs

Process Sold

Direct Labor Applied Man Overhead

Manufacturing Under / Over-

Overhead applied

Chapter 9 – Manufacturing Process

• What is the basic flow of information in the conversion process?

• A customer places an order and production is scheduled.

• Direct materials are requisitioned and recorded.

• Labor is used and recorded

• A cost record is prepared and goods are manufactured.

• Goods are finished and recorded.

S&A Exp

Raw Work Finished Cost of

In Goods Selling &

Purchases Materials Goods Admin Costs

Process Sold

Direct Labor Applied Man Overhead

Manufacturing Under / Over-

Overhead applied

Chapter 9 – Manufacturing Process

• What is the purpose of the inventory accounts in a manufacturing company and

what types of activities cause the accounts to increase and decrease?

• Direct materials inventory—the cost of direct materials on hand; increases when

direct materials are purchased; decreases when direct materials are issued into

production

• Work-in-process inventory—the cost of products started, but not completed;

increases when direct materials and direct labor are used in production and when

manufacturing overhead is assigned to production; decreases when goods are

finished and transferred out (cost of goods manufactured)

• Finished goods inventory—the cost of products finished, but not sold; increases

when goods are finished and transferred in; decreases when goods are sold (cost of

goods sold)

S&A Exp

Raw Work Finished Cost of

In Goods Selling &

Purchases Materials Goods Admin Costs

Process Sold

Direct Labor Applied Man Overhead

Manufacturing Under / Over-

Overhead applied

Chapter 9 – Manufacturing Process

• Definitions

– Direct (Raw) Materials Cost

• Physically traceable items / costs to the final product

– Direct Labor Cost

• Costs of employees who actually manufacture the product

– Manufacturing Overhead Costs (Applied)

• Represents indirect (materials and labor) manufacturing costs

– Manufacturing Overhead Costs (Actual)

• The real amount MOH costs us (prob not going to = applied amt)

• Need to adjust in our COGS for accuracy

– Selling & Administrative Costs

• Represents other costs related to selling the item

S&A Exp

Raw Work Finished Cost of

In Goods Selling &

Purchases Materials Goods Admin Costs

Process Sold

Direct Labor Applied Man Overhead

Manufacturing Under / Over-

Overhead applied

Chapter 9 – Manufacturing Process

• Calculations

I’m headed

Beginning to WIP!!

Raw

Mat

+ Purchases of R.M.

Begin

= Cost of R.M. avail for use

- R.M. Issued into production

= Ending R.M. Inventory

Chapter 9 – Manufacturing Process

I’m headed

• Calculations to Finished

Goods!!

WIP

Beginning

+ Direct Mat Issued

+Direct Labor Used Begin

+ Applied Manu O.H.

= Cost of goods in Process

-Cost of goods manufactured

=Ending WIP Inventory

Chapter 9 – Manufacturing Process

• Calculations I’m headed

to COGS!!

Beginning Fin Goods Inv Finished

Goods

+Cost of Goods Manufactured

=Cost of Goods Avail for Sale Begin

-Cost of Goods Sold (COGS)

=Ending Fin Goods Inv

Chapter 9 – Manufacturing Process

• Calculations

COGS

Beginning COGS

+ Cost of Finished Goods Sold Begin

+ / - Man OH Under / Over Applied

=Total COGS For The Period

Chapter 9 – Overhead Application

• Overhead… Isn’t it a cost to the manufacturing (WIP)?

– Yes!!! So, how do we “get it into” WIP?

– Overhead occurs differently than DM and DL!

– DM / DL happen regularly… easy to match with WIP

– MOH happens sporadically

• Tough to match directly (that’s why it’s “indirect”) to WIP

• Must “Apply” it to WIP to match it up

• How do we Apply it?

– A “guess-timation” of the MOH costs

– What if we “Apply it” wrong? (which we will, not going to be dead on!)

– Have to adjust our COGS

» Overapplied (too much) needs to decrease COGS

» Underapplied (not enough) needs to increase COGS

• So… what do we do???

– How do we Journalize it?

Chapter 9 – Manufacturing Process

• Definitions

– Direct Materials Cost

• Physically traceable items / costs to the final product

– Direct Labor Cost

• Costs of employees who actually manufacture the product

– Manufacturing Overhead Costs

• Represents indirect (materials and labor) manufacturing costs

– Selling & Administrative Costs

• Represents other costs related to selling the item

You might also like

- Manufacturing Wastes Stream: Toyota Production System Lean Principles and ValuesFrom EverandManufacturing Wastes Stream: Toyota Production System Lean Principles and ValuesRating: 4.5 out of 5 stars4.5/5 (3)

- Understanding Costs For Management Decisions: Uaa - Acct 650 Seminar in Executive Uses of Accounting Dr. Fred BarbeeDocument92 pagesUnderstanding Costs For Management Decisions: Uaa - Acct 650 Seminar in Executive Uses of Accounting Dr. Fred BarbeeAhmed RazaNo ratings yet

- Systems Design: Job-Order Costing: Managerial Accounting Dr. Fred BarbeeDocument19 pagesSystems Design: Job-Order Costing: Managerial Accounting Dr. Fred BarbeeAbdirazak MohamedNo ratings yet

- Lecture 05Document19 pagesLecture 05Mahnoor AzizNo ratings yet

- Cost Terms, Concepts, and Classifications: Uaa - Acct 202 Principles of Managerial Accounting Dr. Fred BarbeeDocument41 pagesCost Terms, Concepts, and Classifications: Uaa - Acct 202 Principles of Managerial Accounting Dr. Fred Barbeekindergarten tutorialNo ratings yet

- Process Cost SystemsDocument48 pagesProcess Cost SystemssajdahwasNo ratings yet

- Chaitra B Chaitra C MDocument28 pagesChaitra B Chaitra C MChaitra MuralidharaNo ratings yet

- Chap004 7e EditedDocument47 pagesChap004 7e EditedfarahNo ratings yet

- What Is Cost AccountingDocument165 pagesWhat Is Cost AccountingUy SamuelNo ratings yet

- BIAYA: Konsep, Klasifikasi Dan PerilakuDocument38 pagesBIAYA: Konsep, Klasifikasi Dan PerilakuNetta MonicaNo ratings yet

- Chap004, Process CostingDocument17 pagesChap004, Process Costingrief1010No ratings yet

- 2 - Cost Terms Concepts and Classifications - EtudiantDocument38 pages2 - Cost Terms Concepts and Classifications - EtudiantheniosyoutubeNo ratings yet

- Chapter No.04 - Process Costing and Hybrid Product-Costing SystemsDocument39 pagesChapter No.04 - Process Costing and Hybrid Product-Costing SystemsWali NoorzadNo ratings yet

- Chapter 7.process Costing - For Students - Part1Document13 pagesChapter 7.process Costing - For Students - Part1DAN NGUYEN THENo ratings yet

- SPPTChap 004Document50 pagesSPPTChap 004QUANG NGUYỄN VINHNo ratings yet

- BIAYA: Konsep, Klasifikasi Dan PerilakuDocument44 pagesBIAYA: Konsep, Klasifikasi Dan PerilakuWijanarka DwilaksanaNo ratings yet

- Process Costing and Hybrid Product-Costing Systems: Mcgraw-Hill/IrwinDocument116 pagesProcess Costing and Hybrid Product-Costing Systems: Mcgraw-Hill/IrwinImran RafiqNo ratings yet

- Chapter 2Document31 pagesChapter 2Syeda SamiaNo ratings yet

- Basic Cost Management Concepts and Accounting For Mass Customization OperationsDocument89 pagesBasic Cost Management Concepts and Accounting For Mass Customization OperationsabeeraNo ratings yet

- Akb Bab4Document37 pagesAkb Bab4MulyaniNo ratings yet

- Hilton 11e Chap004 PPT-STUDocument42 pagesHilton 11e Chap004 PPT-STULạnh LùngNo ratings yet

- Ronald Hilton Chapter 3Document25 pagesRonald Hilton Chapter 3Difen L HaradiniNo ratings yet

- Garrison Lecture Chapter 2 - Cost ConceptsDocument80 pagesGarrison Lecture Chapter 2 - Cost Conceptsnahid mushtaqNo ratings yet

- 2020 Session 1 CM CompleteDocument31 pages2020 Session 1 CM CompleteAbhishek BaruaNo ratings yet

- BIAYA: Konsep, Klasifikasi Dan PerilakuDocument48 pagesBIAYA: Konsep, Klasifikasi Dan PerilakuAziz SugihartoNo ratings yet

- CH 4Document41 pagesCH 4nigoxiy168No ratings yet

- Process Costing - Chapter 4Document18 pagesProcess Costing - Chapter 4Asadullahil GalibNo ratings yet

- Basic Cost Management Concepts and Accounting For Mass Customization OperationsDocument25 pagesBasic Cost Management Concepts and Accounting For Mass Customization OperationsTalitha ApsariNo ratings yet

- Chapter 3Document40 pagesChapter 3Korubel Asegdew YimenuNo ratings yet

- Managerial Accounting Garrison Noreen Brewer Chapter 04Document76 pagesManagerial Accounting Garrison Noreen Brewer Chapter 041793 Taherul IslamNo ratings yet

- Process Costing and Hybrid Product-Costing SystemsDocument38 pagesProcess Costing and Hybrid Product-Costing SystemsZia UddinNo ratings yet

- Basic Cost Management Concepts and Accounting For Mass Customization OperationsDocument54 pagesBasic Cost Management Concepts and Accounting For Mass Customization OperationsAshesh DasNo ratings yet

- Systems Design: Process Costing: Mcgraw Hill/IrwinDocument15 pagesSystems Design: Process Costing: Mcgraw Hill/IrwinMarc Jim GregorioNo ratings yet

- Costs Terms, Concepts and Classifications: Chapter TwoDocument54 pagesCosts Terms, Concepts and Classifications: Chapter TwosanosyNo ratings yet

- Lec1 IntroDocument57 pagesLec1 Intronathan panNo ratings yet

- Lecture 02Document79 pagesLecture 02chiuchuiyingccyNo ratings yet

- CHP 5Document127 pagesCHP 5HumaNo ratings yet

- Group 1 - Managerial Accounting and Cost ConceptsDocument47 pagesGroup 1 - Managerial Accounting and Cost ConceptsJeejohn SodustaNo ratings yet

- Process Costing and Hybrid Product-Costing Systems: Mcgraw-Hill/IrwinDocument44 pagesProcess Costing and Hybrid Product-Costing Systems: Mcgraw-Hill/Irwinsunanda mNo ratings yet

- Basic Cost Management Concepts and Accounting For Mass Customization OperationsDocument52 pagesBasic Cost Management Concepts and Accounting For Mass Customization OperationsyosepjoltNo ratings yet

- Systems Design: Job-Order Costing: Uaa - Acct 202 Principles of Managerial Accounting Dr. Fred BarbeeDocument22 pagesSystems Design: Job-Order Costing: Uaa - Acct 202 Principles of Managerial Accounting Dr. Fred BarbeeOrnica BalesNo ratings yet

- Chapter 10 PPT Agm-1Document13 pagesChapter 10 PPT Agm-1Paulina DocenaNo ratings yet

- Chapter Two: Cost Terms, Concepts and ClassificationsDocument72 pagesChapter Two: Cost Terms, Concepts and ClassificationsYuvaraj SubramaniamNo ratings yet

- Cost Accounting: Basic Cost Concepts and Accounting For Mass Customization OperationsDocument44 pagesCost Accounting: Basic Cost Concepts and Accounting For Mass Customization OperationsSaciid Xaji AxmedNo ratings yet

- Process Cost Systems: Financial and Managerial Accounting 8th Edition Warren Reeve FessDocument46 pagesProcess Cost Systems: Financial and Managerial Accounting 8th Edition Warren Reeve FessRajanNo ratings yet

- Chap4 (E)Document47 pagesChap4 (E)Kiên Lê TrungNo ratings yet

- Process Cost Systems: AccountingDocument48 pagesProcess Cost Systems: Accountingmentari cahyaNo ratings yet

- Introduction To Managerial Accounting and Cost ConceptsDocument17 pagesIntroduction To Managerial Accounting and Cost ConceptsvanessaNo ratings yet

- Xcostcon Cost Accounting CycleDocument14 pagesXcostcon Cost Accounting Cycleabrylle opinianoNo ratings yet

- Module 2 Introduction To Cost Terms and ConceptsDocument52 pagesModule 2 Introduction To Cost Terms and ConceptsChesca AlonNo ratings yet

- Cost TutorialDocument26 pagesCost TutorialedrianclydeNo ratings yet

- Hilton Chapter 4 Prerecorded LectureDocument12 pagesHilton Chapter 4 Prerecorded Lecturesunq hccnNo ratings yet

- Process Costing and Hybrid Product-Costing SystemsDocument17 pagesProcess Costing and Hybrid Product-Costing SystemsWailNo ratings yet

- Basic Cost Management Concepts and Accounting For Mass Customization OperationsDocument52 pagesBasic Cost Management Concepts and Accounting For Mass Customization OperationsMicha MaaloulyNo ratings yet

- Basic Costing Principles and Manufacturing Concerns PresentationDocument16 pagesBasic Costing Principles and Manufacturing Concerns Presentationzinhlezwane2708No ratings yet

- Chapter 02Document17 pagesChapter 02Arshia EmamiNo ratings yet

- Lecture 06Document32 pagesLecture 06Mahnoor AzizNo ratings yet

- Dokumen - Tips Managerial Accounting Garrison Noreen Brewer Chapter 04Document76 pagesDokumen - Tips Managerial Accounting Garrison Noreen Brewer Chapter 04Arghya BiswasNo ratings yet

- Comparing Merchandising and ManufacturingDocument14 pagesComparing Merchandising and ManufacturingOna MaeNo ratings yet

- 01summary 2018PSNA Q22021Document18 pages01summary 2018PSNA Q22021Janine IgdalinoNo ratings yet

- CVP Analysis 2 3 PDF FreeDocument7 pagesCVP Analysis 2 3 PDF Freeaaron manacapNo ratings yet

- ReviewerDocument6 pagesReviewerSamuel FerolinoNo ratings yet

- Acctg 105 - PS 1 - Financial StatementsDocument8 pagesAcctg 105 - PS 1 - Financial Statementsaaron manacapNo ratings yet

- NotesDocument9 pagesNotesaaron manacapNo ratings yet

- Chapter 9 - Manufacturing Process: Direct LaborDocument11 pagesChapter 9 - Manufacturing Process: Direct Laboraaron manacapNo ratings yet

- Ch02 In-Class Problems - SolutionsDocument15 pagesCh02 In-Class Problems - SolutionsWalaa I. MatalqahNo ratings yet

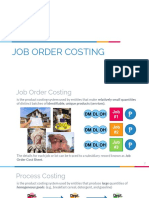

- Acctg201 JobOrderCostingLectureNotesDocument20 pagesAcctg201 JobOrderCostingLectureNotesaaron manacapNo ratings yet

- Ch02 In-Class Problems - SolutionsDocument15 pagesCh02 In-Class Problems - SolutionsWalaa I. MatalqahNo ratings yet

- Acctg201 JobOrderCostingDocument14 pagesAcctg201 JobOrderCostingaaron manacapNo ratings yet

- Cost of Goods Manufactured and Cost of Goods SoldDocument6 pagesCost of Goods Manufactured and Cost of Goods Soldaaron manacapNo ratings yet

- Acctg201 IntroductionDocument10 pagesAcctg201 Introductionaaron manacapNo ratings yet

- Acctg201 IntroductionLectureNotesDocument21 pagesAcctg201 IntroductionLectureNotesaaron manacapNo ratings yet

- Mathematical Logic: Mathematics FacultyDocument74 pagesMathematical Logic: Mathematics FacultyMarvin MarfaNo ratings yet

- CaseDocument7 pagesCaseaaron manacapNo ratings yet

- ObliCon ReviewerDocument6 pagesObliCon ReviewerrizrizNo ratings yet

- Periodic Method Illustrative ProblemDocument30 pagesPeriodic Method Illustrative ProblemRose Marie Hermosa100% (3)

- Law On Partnership and Corporation by Hector de LeonDocument113 pagesLaw On Partnership and Corporation by Hector de LeonShiela Marie Vics75% (12)

- UST Golden Notes 2011 ObliCon PDFDocument56 pagesUST Golden Notes 2011 ObliCon PDFEnnaid121100% (1)

- Systems Analysis and DesignDocument371 pagesSystems Analysis and DesignPaul John100% (5)

- 1 - EIS PM Definition RoleDocument11 pages1 - EIS PM Definition RoleMuhammad Amirullah SanadiNo ratings yet

- Foreign Vendor Assessment Program PDFDocument13 pagesForeign Vendor Assessment Program PDFAbdhel X-MetaNo ratings yet

- Effects of Warehousing Management On Organisational Performance: Case of Africa Global Logistics Rwanda LTDDocument11 pagesEffects of Warehousing Management On Organisational Performance: Case of Africa Global Logistics Rwanda LTDInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Anitha Project Print PDFDocument46 pagesAnitha Project Print PDFNaresh KumarNo ratings yet

- Human Resource ManagementDocument218 pagesHuman Resource ManagementJithin SajanNo ratings yet

- 2 Letter of Transmittal Correction 1Document6 pages2 Letter of Transmittal Correction 1Asif Rajian Khan AponNo ratings yet

- التجارة الالكترونية من منظور الادارة الاستراتيجيةفرص وتهديدات لصناعة التأمينDocument27 pagesالتجارة الالكترونية من منظور الادارة الاستراتيجيةفرص وتهديدات لصناعة التأمينIslam SiamNo ratings yet

- Assetivity Strategic Asset Management Plan TemplateDocument13 pagesAssetivity Strategic Asset Management Plan TemplateShashannk DoshiNo ratings yet

- Intro S4HANA Using Global Bike Data Sheet SD en v3.3Document2 pagesIntro S4HANA Using Global Bike Data Sheet SD en v3.3Big DripNo ratings yet

- Hitt Chapter 2Document18 pagesHitt Chapter 2Ami KallalNo ratings yet

- EY Unqork Collaboration Is Delivering Transformational ChangeDocument5 pagesEY Unqork Collaboration Is Delivering Transformational ChangeRch tvgyNo ratings yet

- Gold Plus SIP-final 2Document57 pagesGold Plus SIP-final 2Anubhav KumarNo ratings yet

- Demand Flow TechnologyDocument8 pagesDemand Flow TechnologySantiago AntonioNo ratings yet

- Evolution of Management TheoryDocument30 pagesEvolution of Management TheoryCristine BellenNo ratings yet

- To Study Business Development - Strategy of XYZ OrganizationDocument50 pagesTo Study Business Development - Strategy of XYZ OrganizationMyat Yamin KyawNo ratings yet

- Anki Updated ProjectDocument90 pagesAnki Updated ProjectPrints BindingsNo ratings yet

- Oracle E-Business Suite Controls Application Security Best Practices TOCDocument5 pagesOracle E-Business Suite Controls Application Security Best Practices TOCGreg LusinskiNo ratings yet

- EntreDocument11 pagesEntreKartik NaikNo ratings yet

- Chapter 01-05-NewDocument107 pagesChapter 01-05-NewNgọc QuyênNo ratings yet

- Role of Islamic Leadership in Value Based Corporate ManagementDocument297 pagesRole of Islamic Leadership in Value Based Corporate ManagementSakduddin ZamliNo ratings yet

- Credit DepartmentDocument6 pagesCredit DepartmentArnold BelangoyNo ratings yet

- Rudra CV 2023Document2 pagesRudra CV 2023sanjib paridaNo ratings yet

- 29.1 Types of Data (Metadata, Raw Data & Summary Data)Document3 pages29.1 Types of Data (Metadata, Raw Data & Summary Data)Diego Fernando GaliciaNo ratings yet

- Walmart - Market Leader StrategiesDocument4 pagesWalmart - Market Leader Strategiesmurtaza mannanNo ratings yet

- Sap MMDocument31 pagesSap MMTallha50% (2)

- IS - CH1 and CH2Document90 pagesIS - CH1 and CH2aruba akbarNo ratings yet

- Value EngineeringDocument45 pagesValue EngineeringRamonNo ratings yet

- Accounting - Introduction SummaryDocument2 pagesAccounting - Introduction SummaryWei HouNo ratings yet

- Managing Performance in Intermediate Care Services - A Balanced Scorecard ApproachDocument94 pagesManaging Performance in Intermediate Care Services - A Balanced Scorecard Approachfarazalam08No ratings yet