Professional Documents

Culture Documents

Poster Template

Uploaded by

Endurance BillyOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Poster Template

Uploaded by

Endurance BillyCopyright:

Available Formats

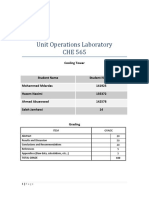

Title: Rotary Evaporator (Rotavap) Effects of Pressure on Boiling Point

Student: Lukmo Billy

Munster Technological University, Cork

Objective Results Discussion

The practical use of a Rotavap Table 1 presents the following info: The 3 graphs shows that the rate of pressure increases as the temperature

nnn

aims to give an understanding of Pressure Absolute Pressure Temperature of increases. This is due to the temperature being close to the boiling point of

the relationship between pressure Gauge (bar) Pressure (bar) (mmHg) vapour (ºC) water. From the experiment, an observation can be made where the water

and temperature in the following -0.25 0.75 562.5 85 started to evaporate at a temperature of 80ºC. This is proven since at 80ºC,

liquids: tap water and deionized there are a few water droplets present at the wall of the condenser and the

-0.45 0.55 412.5 80

increase in temperature and the increase in temperature caused the volume

water. -0.65 0.35 262.5 73

of condensate to increase and gather at the receiving flask. Besides, at the

-0.85 0.15 112.5 50 end of the experiment the water has evaporated which left only the water

-0.95 0.05 37.5 30 pulp at the evaporation flask. The volume of it is

Table 2 presents the following info:

Absolute Pressure Boiling Point (ºC) Boiling Point (ºC) Boiling Point % Error

Pressure (bar) (mmHg) Experimental from Antoine (ºC)

Equation from Steam

Tables

0.75 562.5 85 91.81 91.7 7.48%

0.55 412.5 80 83.8 83.6 4.31 %

0.35 262.5 73 72.8 72.6 0.55 %

0.15 112.5 50 54.05 53.9 7.24 %

0.05 37.5 30 32.9 32.75 8.39 %

Schematics

Conclusion

The result for this experiment is shown that when the temperature

Table 3 presents the following info increases, the higher the rate of pressure becomes. The objective for

Sample` Temp(°C) Conductivity (µS/min) this experiment was achieved as the rate of pressure of the tap

water and deionized water is affected by the temperature which

Tap Water 25 Reading 1 Reading 2 Reading 3

have been manipulated.

510 500 510 The main benefits of a Rotavap/vacuum distillation are low boiling

DI 25 0.07 0.1 0.1 points, fast evaporation of solvent, fewer operations and it supresses

Condensate 25 0.2 0.3 0.25 bumping.

References

• Perry’s Chemical Engineers’ Handbook.

Elementary Principles of Chemical Processes”, R. M. Felder and R.W.

Figure.1 presents a labelled diagram of a Rotavap Characterisation results Rousseau, 2005, John Wiley and Sons, USA.

You might also like

- Working Guide to Petroleum and Natural Gas Production EngineeringFrom EverandWorking Guide to Petroleum and Natural Gas Production EngineeringRating: 5 out of 5 stars5/5 (2)

- Gaballo - Exp2 - Simple Distillation and Determination of An Unknown SampleDocument10 pagesGaballo - Exp2 - Simple Distillation and Determination of An Unknown SampleJULIANA MARIE GABALLONo ratings yet

- Results and Discussion: Experiment No.2Document5 pagesResults and Discussion: Experiment No.2zidrick benjaminNo ratings yet

- Batch Distillation: Camila Carvajal Paula Gutiérrez Sojo Karen RomeroDocument12 pagesBatch Distillation: Camila Carvajal Paula Gutiérrez Sojo Karen RomeroCamila CarvajalNo ratings yet

- Experiment No. 5Document5 pagesExperiment No. 5Fareeha SaeedNo ratings yet

- Mechanical Lab: Investigation of The Effect of Air Velocity On The Cooling Tower PerformanceDocument7 pagesMechanical Lab: Investigation of The Effect of Air Velocity On The Cooling Tower PerformanceMasoud doskiNo ratings yet

- Physical Chemistry 2 Laboratory Experiment No. 2 - Steam DistillationDocument10 pagesPhysical Chemistry 2 Laboratory Experiment No. 2 - Steam DistillationAmiel Clark CabotajeNo ratings yet

- Science and Cooking BOOKDocument131 pagesScience and Cooking BOOKAldana AldanaNo ratings yet

- 1961 - Hydrogenating Cottonseed Oil at Relatively High Pressure WisniakDocument6 pages1961 - Hydrogenating Cottonseed Oil at Relatively High Pressure WisniakDavid Flores MolinaNo ratings yet

- Project On Effect of Addition of Different Solutes On The Elevation of Boiling Point of Solvent .Document11 pagesProject On Effect of Addition of Different Solutes On The Elevation of Boiling Point of Solvent .aryan guleriaNo ratings yet

- CHE246 - Technical Lab Report On Rotary PDFDocument5 pagesCHE246 - Technical Lab Report On Rotary PDFanujaNo ratings yet

- Balmerexp 2Document11 pagesBalmerexp 2applejuice85No ratings yet

- Refinery Workbook ExerciseDocument54 pagesRefinery Workbook ExerciseHarshit SharmaNo ratings yet

- World's Largest Science, Technology & Medicine Open Access Book PublisherDocument9 pagesWorld's Largest Science, Technology & Medicine Open Access Book PublisherWilder GanozaNo ratings yet

- Bergmann 1991Document10 pagesBergmann 1991Alexandru-Adrian BrateiNo ratings yet

- 4.1 Simple and Fractional DistillationDocument2 pages4.1 Simple and Fractional Distillationmayra perezNo ratings yet

- Process Lab Report 4Document3 pagesProcess Lab Report 4Sourav SutradharNo ratings yet

- Sakshi Jain - C - February - 20 PDFDocument10 pagesSakshi Jain - C - February - 20 PDFSakshi JainNo ratings yet

- Vapor Liquid Equilibrium Ethanol WaterDocument13 pagesVapor Liquid Equilibrium Ethanol Waterhao GamesNo ratings yet

- Sep LabDocument17 pagesSep LabnakeyahxoNo ratings yet

- Laboratory Report Experiment 5 CHM476Document14 pagesLaboratory Report Experiment 5 CHM476Hazwan HamimNo ratings yet

- GatelaJP Week10 Reynolds-NumbersDocument8 pagesGatelaJP Week10 Reynolds-NumbersPatrick GatelaNo ratings yet

- Lab Report Reaction (Temperature)Document8 pagesLab Report Reaction (Temperature)najihahNo ratings yet

- Lab Report 2Document9 pagesLab Report 2Magloire Kekeli Segla100% (1)

- Experiment 4 - Simple and Fractional DistillationDocument9 pagesExperiment 4 - Simple and Fractional DistillationrosaNo ratings yet

- Lab 05Document6 pagesLab 05Areeba NaqviNo ratings yet

- Chemistry Investigatory Project Elevation in Boiling PointDocument5 pagesChemistry Investigatory Project Elevation in Boiling PointVasant GavaliNo ratings yet

- Abstraction LossesDocument33 pagesAbstraction LossesAnnabeth ChaseNo ratings yet

- Chem Lab Report 7 (Autorecovered)Document10 pagesChem Lab Report 7 (Autorecovered)Na'im SuhaimiNo ratings yet

- Process Notes: Final ProjectDocument8 pagesProcess Notes: Final ProjectCluisantony Jayco DizeNo ratings yet

- Experiment 4Document12 pagesExperiment 4Doğukan Aybars ÖztürkNo ratings yet

- Experiment 2Document7 pagesExperiment 2EDWIN SIMBARASHE MASUNUNGURENo ratings yet

- Experiment Lloyd Chem 1Document4 pagesExperiment Lloyd Chem 1Jan Norence FrancelizoNo ratings yet

- 117 Labreport #2Document21 pages117 Labreport #2Glaize Anne Gamelong100% (1)

- Standard Calibration Curve: PrincipleDocument3 pagesStandard Calibration Curve: PrincipleNeelam MalikNo ratings yet

- Investigatory Project Chem 12thDocument13 pagesInvestigatory Project Chem 12thRaviNo ratings yet

- 2nd Sem Chemistry ManualDocument19 pages2nd Sem Chemistry ManualOliver Ryan FernandesNo ratings yet

- Petrochemicals & Petroleum Refining Technology - Exp5Document11 pagesPetrochemicals & Petroleum Refining Technology - Exp5Farihah EyfaNo ratings yet

- Ex.3-Heat of NeutralizationDocument10 pagesEx.3-Heat of Neutralizationalia2003skNo ratings yet

- 2014 Continuous Distillation Group 28 251114 Edited 2.0Document48 pages2014 Continuous Distillation Group 28 251114 Edited 2.0Arati VeraNo ratings yet

- Phys Chem Exp 6Document11 pagesPhys Chem Exp 6Cucu AlbertNo ratings yet

- Energy BalanceDocument12 pagesEnergy BalanceZain Ul AbedinNo ratings yet

- USP Chapter 645 ConductivityDocument4 pagesUSP Chapter 645 ConductivitySulistiaNo ratings yet

- Chem 343 Experiment 3 Lab ReportDocument7 pagesChem 343 Experiment 3 Lab ReportAddison GasserNo ratings yet

- Solar Water HeatingDocument12 pagesSolar Water Heatingchrisss220No ratings yet

- Basic Service Training: Cooling Circuit R600a and R134aDocument64 pagesBasic Service Training: Cooling Circuit R600a and R134aKyaw San OoNo ratings yet

- Lab 5 - Group 5Document12 pagesLab 5 - Group 5LAU POEY YEE STUDENTNo ratings yet

- Venturi Meter: by Vincent El Ghoubaira, Mohamad Abou Daher and Nazih HarbDocument20 pagesVenturi Meter: by Vincent El Ghoubaira, Mohamad Abou Daher and Nazih HarbMohamad Abou DaherNo ratings yet

- Che244 Exp 1Document6 pagesChe244 Exp 1NABILA AFIEQAH NASRUDINNo ratings yet

- Troubleshooting Design Project: Production of Ethanol Via The Vapor-Phase Hydration of Ethylene BackgroundDocument18 pagesTroubleshooting Design Project: Production of Ethanol Via The Vapor-Phase Hydration of Ethylene BackgroundMary Grace VelitarioNo ratings yet

- S-Chem011La-Inorganic and Organic Chemistry Laboratory Module 3: Copper ReactionDocument11 pagesS-Chem011La-Inorganic and Organic Chemistry Laboratory Module 3: Copper ReactionAvrick GoNo ratings yet

- Report Distillation ColumnDocument20 pagesReport Distillation ColumnAzam Najmi33% (3)

- Experiment No.1: Experiment Name: Change in Flow RateDocument9 pagesExperiment No.1: Experiment Name: Change in Flow Ratewrya hussainNo ratings yet

- Cooling Tower ReportDocument9 pagesCooling Tower ReportMohammad MdardasNo ratings yet

- SOP For Analysis of WaterDocument9 pagesSOP For Analysis of WaterGencay ErginNo ratings yet

- Reid Vapor Pressure BCDocument9 pagesReid Vapor Pressure BCMinh Trần LêNo ratings yet

- CH 2Document63 pagesCH 2Arbanah Muhammad82% (11)

- Mechanical Design of ReactorDocument12 pagesMechanical Design of ReactorDanialRemeNo ratings yet

- Huayi - Compressor - GLY12NRb - R134a - 115 - 60Document5 pagesHuayi - Compressor - GLY12NRb - R134a - 115 - 60bgomez1986No ratings yet

- O'Donnell-Gareth MECH6012 Summer 20-21 (Format For Students)Document22 pagesO'Donnell-Gareth MECH6012 Summer 20-21 (Format For Students)Endurance BillyNo ratings yet

- O'Donnell-Gareth MECH6012 Summer 20-21 (Format For Students)Document22 pagesO'Donnell-Gareth MECH6012 Summer 20-21 (Format For Students)Endurance BillyNo ratings yet

- O'Donnell-Gareth MECH6012 Summer 20-21 (Format For Students)Document22 pagesO'Donnell-Gareth MECH6012 Summer 20-21 (Format For Students)Endurance BillyNo ratings yet

- Cooling Tower Practical Overview 2021 Part 2Document14 pagesCooling Tower Practical Overview 2021 Part 2Endurance BillyNo ratings yet

- Reynolds Number OverviewDocument10 pagesReynolds Number OverviewEndurance BillyNo ratings yet

- Practical Rotavap OverviewDocument14 pagesPractical Rotavap OverviewEndurance BillyNo ratings yet

- Pattanaik 2019Document26 pagesPattanaik 2019Ankush KumarNo ratings yet

- Grammar Subject For Elementary - 5th Grade - Coordinating Conjunctions by SlidesgoDocument56 pagesGrammar Subject For Elementary - 5th Grade - Coordinating Conjunctions by SlidesgoAr NitaNo ratings yet

- Javier Auyero, Debora Alejandra Swistun - Flammable - Environmental Suffering in An Argentine Shantytown (2009)Document201 pagesJavier Auyero, Debora Alejandra Swistun - Flammable - Environmental Suffering in An Argentine Shantytown (2009)Laura BejaranoNo ratings yet

- Nursing Philosophy PaperDocument6 pagesNursing Philosophy PaperDanielle AalderinkNo ratings yet

- Practical Research 2: Quarter 1 - Module 2: Importance of Quantitative Research Across FieldsDocument16 pagesPractical Research 2: Quarter 1 - Module 2: Importance of Quantitative Research Across FieldsDivina Grace Rodriguez - LibreaNo ratings yet

- Electrician PDFDocument53 pagesElectrician PDFAbujaid KahnNo ratings yet

- Magnetic Reduction-To-The-Pole at Low Latitudes: Observations and ConsiderationsDocument11 pagesMagnetic Reduction-To-The-Pole at Low Latitudes: Observations and ConsiderationscarlosNo ratings yet

- Astm D2196-10Document5 pagesAstm D2196-10Bryan de BarrosNo ratings yet

- Engineering Data On Valve Selection Sizing and Location CSA Air Valves PDFDocument27 pagesEngineering Data On Valve Selection Sizing and Location CSA Air Valves PDFtruss85No ratings yet

- Truth About Reptilian Alien RacesDocument12 pagesTruth About Reptilian Alien RacesSuripeddi Koundinya60% (5)

- Drum Brakes RT: According To DIN 15435Document1 pageDrum Brakes RT: According To DIN 15435LukaNo ratings yet

- Energy From Biomass: Laboratory TrainingDocument11 pagesEnergy From Biomass: Laboratory TrainingPNo ratings yet

- Bozic Niksa 2018 Chardak Ni Na Zemlji Ni Na Nebu PrikazDocument1 pageBozic Niksa 2018 Chardak Ni Na Zemlji Ni Na Nebu PrikazSanja LoncarNo ratings yet

- Stewart - Design of Piled Bridge Abutments On Soft Clay For Loading FromDocument9 pagesStewart - Design of Piled Bridge Abutments On Soft Clay For Loading FromMarcelaMarquesNo ratings yet

- 1577078761Document54 pages1577078761Jyotishman SharmaNo ratings yet

- MODULE 2 The Nature of The Human PersonDocument8 pagesMODULE 2 The Nature of The Human PersonMary Grace Lobina ColamboNo ratings yet

- Defrino SummaryDocument1 pageDefrino SummaryAlma JavierNo ratings yet

- Reformation of Moral Philosophy and Its Foundation in Seerah of The Prophet MuhammadDocument15 pagesReformation of Moral Philosophy and Its Foundation in Seerah of The Prophet MuhammadMuhammad Idrees LashariNo ratings yet

- The Psychology of Human SexualityDocument26 pagesThe Psychology of Human SexualityHailie JadeNo ratings yet

- METAMORPHISM Earth and Life Science Week 4Document22 pagesMETAMORPHISM Earth and Life Science Week 4Jessicalyn LabitoriaNo ratings yet

- Science 7Document4 pagesScience 7April Rose Alforque MagbanuaNo ratings yet

- Bon SL Zoom Slit Lamp User and Service ManualDocument20 pagesBon SL Zoom Slit Lamp User and Service ManualRoberto FalconeNo ratings yet

- (Solved) QUESTION ONE Brick by Brick (BBB) Is A BuildingDocument6 pages(Solved) QUESTION ONE Brick by Brick (BBB) Is A BuildingBELONG TO VIRGIN MARYNo ratings yet

- EN22307194-Ranathunga R.A.S.S-Tensile Testing of Metals.Document16 pagesEN22307194-Ranathunga R.A.S.S-Tensile Testing of Metals.Nipun DinushaNo ratings yet

- B. Tech Scheme - 2016 Batch PDFDocument8 pagesB. Tech Scheme - 2016 Batch PDFAlex HalesNo ratings yet

- Abaqus Automatic Stabilization When and How To Use ItDocument8 pagesAbaqus Automatic Stabilization When and How To Use ItBingkuai bigNo ratings yet

- BSBLDR523 Lead and Manage Effective Workplace Relationships Assessment BookletDocument21 pagesBSBLDR523 Lead and Manage Effective Workplace Relationships Assessment BookletJeremiah Noromor Ronquillo100% (1)

- Clinical Profile and Visual Outcome of Ocular Injuries in Tertiary Care Rural HospitalDocument8 pagesClinical Profile and Visual Outcome of Ocular Injuries in Tertiary Care Rural HospitalIJAR JOURNALNo ratings yet

- Daylight Factor - Wikipedia, The Free EncyclopediaDocument2 pagesDaylight Factor - Wikipedia, The Free EncyclopediadasaNo ratings yet

- Atomic StructureDocument28 pagesAtomic StructureIsrael PopeNo ratings yet