Professional Documents

Culture Documents

1-2 Industrial Process Design

1-2 Industrial Process Design

Uploaded by

Patricia HOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1-2 Industrial Process Design

1-2 Industrial Process Design

Uploaded by

Patricia HCopyright:

Available Formats

Industrial Process

Design

© 2012 G.P. Towler / UOP. For educational use in conjunction with

Towler & Sinnott Chemical Engineering Design only. Do not copy

Chemical Engineering Design

1. Design Work Process

Determine Set Design

Customer Needs Specifications

Build Performance

Models

Generate Design

R&D if Needed

Concepts

Predict Fitness

For Service

Evaluate Economics

& Select Design

Customer

Approval

Detailed Design & Procurement

Begin Operation

Equipment Selection & Construction

Common to all design problems in all industries

© 2012 G.P. Towler / UOP. For educational use in conjunction with

Towler & Sinnott Chemical Engineering Design only. Do not copy

Chemical Engineering Design

How do companies implement this

design process?

© 2012 G.P. Towler / UOP. For educational use in conjunction with

Towler & Sinnott Chemical Engineering Design only. Do not copy

Chemical Engineering Design

2. The Design Team

Project Business

Sponsor Input

Project

Manager

Process Technical Control

Cost Engineer Consultants

Engineer(s) Specialists Engineer

R&D Mechanical Civil

Contractors

Specialists Engineer(s) Engineers

© 2012 G.P. Towler / UOP. For educational use in conjunction with

Towler & Sinnott Chemical Engineering Design only. Do not copy

Chemical Engineering Design

Specialization and Outsourcing

Operating Companies

Technology Vendors

• Own plants

• Own patents

• Produce chemicals

• Sell catalysts, enzymes,

• High sales revenue equipment, licenses

• Margins & return on assets • Sales volume low

(ROA) vary by sector

• Margins, ROA usually high

Engineering & Construction Companies

• Experienced project managers

• Highly competitive & cost effective

• Medium sales volume, low margins

© 2012 G.P. Towler / UOP. For educational use in conjunction with

Towler & Sinnott Chemical Engineering Design only. Do not copy

Chemical Engineering Design

Company Performance by Sector

Company Symbol Market Cap Revenue Profit Margin ROA

($ billion) ($ billion) % %

ExxonMobil XOM 472.5 365.5 10.8 18.1

Valero Energy VLO 40.55 91.8 5.9 15.1

Dow DOW 42.7 49.1 7.6 7.6

DuPont DD 47.3 27.4 13.5 10.1

Pfizer PFE 179.5 48.4 40 16.9

Merck MRK 107.9 22.6 19.6 10.7

Shaw Group SGR 3.8 4.8 1.1 NA

Fluor FLR 9.8 14.1 1.9 5.1

Notes:

• Data from www.CNN.money.com as of 7.2.07

• Oil industry is usually not so profitable as during 2005-2007

• Technology companies are usually smaller, and are often subsidiaries or

privately held. Financial data are often not publicly available.

© 2012 G.P. Towler / UOP. For educational use in conjunction with

Towler & Sinnott Chemical Engineering Design only. Do not copy

Chemical Engineering Design

Long ago (<1980s) most projects were done “in

house”

Operating

Company Project Business

Sponsor Input

Project

Manager

Process Technical Control

Cost Engineer Consultants

Engineer(s) Specialists Engineer

R&D Mechanical Civil

Contractors

Specialists Engineer(s) Engineers

E&C

Technology Company

Vendor

© 2012 G.P. Towler / UOP. For educational use in conjunction with

Towler & Sinnott Chemical Engineering Design only. Do not copy

Chemical Engineering Design

Nowadays

(For most companies, most sectors)

Project Business

Operating Sponsor Input

Company

Project

Manager

Process Technical Control

Cost Engineer Consultants

Engineer(s) Specialists Engineer

R&D Mechanical Civil

Contractors

Specialists Engineer(s) Engineers

Technology E&C

Vendor Company

© 2012 G.P. Towler / UOP. For educational use in conjunction with

Towler & Sinnott Chemical Engineering Design only. Do not copy

Chemical Engineering Design

Implications

• Most major projects involve several companies working

together

• “OpCo” might itself be a joint venture between several

companies

• The companies might all be based in different regions of

the world

• Teamwork, technology transfer and effective

communications have high impact and value

• Good project management is more important than ever

© 2012 G.P. Towler / UOP. For educational use in conjunction with

Towler & Sinnott Chemical Engineering Design only. Do not copy

Chemical Engineering Design

3. The Project Plan

ID Task Name

Project must be delivered:

M-1 M1 M2 M3 M4 M5 M6 M7 M8 M9 M10 M11 M12 M13 M14 M15 M16 M17 M18 M19 M20 M21 M22 M23

1 Project KO Meeting 3/31

2 Process Commercialization 74 days

3 Verify Operating Conditions

4 Process Design - Flowsheet

• On-time

5 Verify Full Design Criteria

6 Process Design/Optimization

7 Cold Flow Modeling 206 days

8 Design Sparger

9 Approve Sparger Design 7/15

10 Construction of Wedge

11

12

13

PP design/construction/shakedown

Cold Flow Testing

Catalyst Scale-up 150 days

• On-budget

14 Catalyst Scale-up

15 Demonstration Plant 251 days

• OpCo usually writes

16 Commercialization Team Formed 1/12

17 Demo Plant Design Basis

18 Process Engineering

19 PFD Review 2/22

20

21

22

Basic Engineering

P&ID review 5/18 incentives into the E&C

Detailed Engineering

23

24

25

Layout Review

Procurement

8/31

contract to ensure that

Fabrication

26

27

Delivery & Installation

Begin Run 12/28 this happens

© 2012 G.P. Towler / UOP. For educational use in conjunction with

Towler & Sinnott Chemical Engineering Design only. Do not copy

Chemical Engineering Design

Design Work Process

Determine Set Design

Customer Needs Specifications

Build Performance

Models

These steps Generate Design

have to R&D if Needed

Concepts

come first Predict Fitness

For Service

Evaluate Economics

& Select Design

Customer

Approval

Detailed Design & Procurement

Begin Operation

Equipment Selection & Construction

This also needs time This takes time

© 2012 G.P. Towler / UOP. For educational use in conjunction with

Towler & Sinnott Chemical Engineering Design only. Do not copy

Chemical Engineering Design

The Project Plan

• Is developed & implemented by

the project manager

ID Task Name M-1 M1 M2 M3 M4 M5 M6 M7 M8 M9 M10 M11 M12 M13 M14 M15 M16 M17 M18 M19 M20 M21 M22 M23

1 Project KO Mee ting 3/31

• Sets deadlines for completion

2 Process Commercialization 74 days

3 Verify Operating Conditions

4 Process Design - Flowsheet

of activities & intermediate

5 Verify Full Design Criteria

6 Process Design/Optimization

7 Cold Flow Modeling 206 days

deliverables

8 Design Sparger

9 Approve Sparger Design 7/15

10 Constru ction of Wedge

11 PP design/construction/shakedown

12 Cold Flow Testing

13 Catalyst Scale-up 150 days

• Allows scheduling of

14 Catalyst Scale-up

15 Demons tration Plant 251 days

16 Commercialization Team Formed 1/12

subordinate or dependent tasks

17 Demo Plant Design Basis

18 Process Engineering

19 PFD Review 2/22

20 Basic Engineering

21 P&ID re view 5/18

22 Detailed Eng ineering

• Allows estimation of the

23 Layout Review 8/31

24 Procurement

25 Fabrication

required manpower resources

26 Delivery & Installation

27 Begin Run 12/28

at each stage of the project

• Determines the procurement

schedule & gives an estimate of

when cash outlays are

expected

© 2012 G.P. Towler / UOP. For educational use in conjunction with

Towler & Sinnott Chemical Engineering Design only. Do not copy

Chemical Engineering Design

Example: 11-Week Plan for a Process Design Project

© 2012 G.P. Towler / UOP. For educational use in conjunction with

Towler & Sinnott Chemical Engineering Design only. Do not copy

Chemical Engineering Design

What’s In a Project Plan?

List of tasks

© 2012 G.P. Towler / UOP. For educational use in conjunction with

Towler & Sinnott Chemical Engineering Design only. Do not copy

Chemical Engineering Design

What’s In a Project Plan?

Durations, start

and end dates

© 2012 G.P. Towler / UOP. For educational use in conjunction with

Towler & Sinnott Chemical Engineering Design only. Do not copy

Chemical Engineering Design

What’s In a Project Plan?

Predecessor

tasks

© 2012 G.P. Towler / UOP. For educational use in conjunction with

Towler & Sinnott Chemical Engineering Design only. Do not copy

Chemical Engineering Design

What’s In a Project Plan?

Resource

allocations

© 2012 G.P. Towler / UOP. For educational use in conjunction with

Towler & Sinnott Chemical Engineering Design only. Do not copy

Chemical Engineering Design

What’s In a Project Plan?

Gantt

chart

© 2012 G.P. Towler / UOP. For educational use in conjunction with

Towler & Sinnott Chemical Engineering Design only. Do not copy

Chemical Engineering Design

Example: 11-Week Plan for a Process Design Project

© 2012 G.P. Towler / UOP. For educational use in conjunction with

Towler & Sinnott Chemical Engineering Design only. Do not copy

Chemical Engineering Design

Tools for Project Planning

• Specialized software for larger projects

– MS Project

– SureTrak

– Primavera Project Planner

– Enterprise PM

– Cobra

• Small project plans & Gantt charts can be drawn in spreadsheets

or using cheap software (<$100)

– AceProject (free on-line)

– TurboProject

– Project Vision

– Quick Gantt

© 2012 G.P. Towler / UOP. For educational use in conjunction with

Towler & Sinnott Chemical Engineering Design only. Do not copy

Chemical Engineering Design

4. The Design Basis

Determine Set Design

Customer Needs Specifications

Build Performance

Models

Generate Design

R&D if Needed

Concepts Predict Fitness

For Service

Evaluate Economics

& Select Design

Customer

Approval

Detailed Design & Procurement

Begin Operation

Equipment Selection & Construction

We need to know:

• What are we designing? How much of it do we want?

• Where will it be built? What are the boundary conditions?

© 2012 G.P. Towler / UOP. For educational use in conjunction with

Towler & Sinnott Chemical Engineering Design only. Do not copy

Chemical Engineering Design

Process Design Basis

Project Name

• Documentation of design

Company Name Project Number Sheet 1

Address REV DATE BY APVD REV DATE BY APVD

DESIGN BASIS

assumptions and boundary conditions

Form XXXXX-YY-ZZ

1 General Information

Owners Name

Process Unit Name

Plant Location

Correspondance Contacts

Address

is very important

Telephone / Fax

E-mail

• For new process plants, most

2 Measurement System

English Metric

3 Equipment Numbering System

companies use some sort of design

Equipment will be identified by alphabetic AC Air cooler G Grinder, mill R Reactor

prefix as defined here, followed by three- B Boiler H Heater (fired or electric) SP Sample point

digit serial number unless otherwise C Compressor, blower, fan J Ejector, jet, turboexpander T Storage tank

indicated CT Cooling tower M Mixer V Vessel (including columns)

D Dryer ME Miscellaneous equipment

First digit - process section E Exchanger P Pump

basis form or questionnaire to serve

Second & third digits - equipment count F Filter, classifier PRV Pressure relief valve

4 Primary Products

Product Name

as a record of the design basis

Product Grade

MSDS Form Number

Production Rate

Tons per year

Tons per day

Other units

• This record is also essential in

Product Purity (wt%)

Product shipment mode

Additional Specifications

5 Primary Raw Materials

(Attach additional sheets if needed)

handing off information between the

operating company, technology

Feedstock name

Feedstock grade

MSDS form number

Feedstock availability

Tons per year

suppliers and contractors

Tons per day

Other units

Feedstock price ($/lb)

(Default: open market price)

Known feedstock impurities Name ppmw Name ppmw Name ppmw Name ppmw

• There’s a template online at:

booksite.Elsevier.com/Towler

Additional specifications

6 Site Information

Low ambient temperature (F)

High ambient temperature (F)

Hight ambient relative humidity (%)

Site elevation (ft)

Maximum wind loading (mph)

Other site design requirements

© 2012 G.P. Towler / UOP. For educational use in conjunction with

Towler & Sinnott Chemical Engineering Design only. Do not copy

Chemical Engineering Design

What’s in the Design Basis?

Project Name

Company Name Project Number Sheet 1

Address REV DATE BY APVD REV DATE BY APVD

DESIGN BASIS

Form XXXXX-YY-ZZ

1 General Information

Owners Name

Process Unit Name

Plant Location

Correspondance Contacts

Address

Telephone / Fax

E-mail

2 Measurement System

English Metric

Project Name

3 Equipment Numbering System

Equipment will be identified by alphabetic AC Air cooler G Grinder, mill R Reactor

prefix as defined here, followed by three- B Boiler H Heater (fired or electric) SP Sample point

digit serial number unless otherwise C Compressor, blower, fan J Ejector, jet, turboexpander T Storage tank

indicated CT Cooling tower M Mixer V Vessel (including columns)

D Dryer ME Miscellaneous equipment

First digit - process section E Exchanger P Pump

Second & third digits - equipment count F Filter, classifier PRV Pressure relief valve

Project Number Sheet 1

4 Primary Products

Product Name

Product Grade

MSDS Form Number

Production Rate

Tons per year

Tons per day

REV DATE BY APVD REV DATE BY APVD

Other units

Product Purity (wt%)

Product shipment mode

Additional Specifications

5 Primary Raw Materials

(Attach additional sheets if needed)

Feedstock name

Feedstock grade

MSDS form number

Feedstock availability

Tons per year

Tons per day

Other units

Feedstock price ($/lb)

(Default: open market price)

Known feedstock impurities Name ppmw Name ppmw Name ppmw Name ppmw

Additional specifications

6 Site Information

Low ambient temperature (F)

High ambient temperature (F)

Hight ambient relative humidity (%)

Site elevation (ft)

Maximum wind loading (mph)

Other site design requirements

Project information and revision tabs

• To allow retrieval of documentation

• To ensure that revisions are properly documented and make sure that the

engineers aren’t working from the wrong version

• To document review and approval of the design basis

© 2012 G.P. Towler / UOP. For educational use in conjunction with

Towler & Sinnott Chemical Engineering Design only. Do not copy

Chemical Engineering Design

What’s in the Design Basis?

Project Name

Company Name Project Number Sheet 1

Address REV DATE BY APVD REV DATE BY APVD

DESIGN BASIS

Form XXXXX-YY-ZZ

1 General Information

Owners Name

Process Unit Name

Plant Location

Correspondance Contacts

Address

Telephone / Fax

E-mail

2 Measurement System

English Metric

3 Equipment Numbering System

Equipment will be identified by alphabetic AC Air cooler G Grinder, mill R Reactor

prefix as defined here, followed by three- B Boiler H Heater (fired or electric) SP Sample point

digit serial number unless otherwise C Compressor, blower, fan J Ejector, jet, turboexpander T Storage tank

indicated CT Cooling tower M Mixer V Vessel (including columns)

D Dryer ME Miscellaneous equipment

First digit - process section E Exchanger P Pump

Second & third digits - equipment count F Filter, classifier PRV Pressure relief valve

4 Primary Products

Product Name

Product Grade

MSDS Form Number

Production Rate

Tons per year

Tons per day

Other units

Product Purity (wt%)

Product shipment mode

1 General Information

Additional Specifications

5 Primary Raw Materials

(Attach additional sheets if needed)

Owners Name

Feedstock name

Feedstock grade

MSDS form number

Feedstock availability

Tons per year

Tons per day

Other units

Process Unit Name

Feedstock price ($/lb)

(Default: open market price)

Known feedstock impurities Name ppmw Name ppmw Name ppmw Name ppmw

Plant Location

Correspondance Contacts

Additional specifications

6 Site Information Address

Low ambient temperature (F)

High ambient temperature (F)

Hight ambient relative humidity (%)

Site elevation (ft)

Maximum wind loading (mph)

Telephone / Fax

Other site design requirements

Contact information

• Company name

• Process unit name

• Who to contact & where to reach them

© 2012 G.P. Towler / UOP. For educational use in conjunction with

Towler & Sinnott Chemical Engineering Design only. Do not copy

Chemical Engineering Design

What’s in the Design Basis?

Project Name

Company Name Project Number Sheet 1

Address REV DATE BY APVD REV DATE BY APVD

DESIGN BASIS

Form XXXXX-YY-ZZ

1 General Information

Owners Name

Process Unit Name

Plant Location

Correspondance Contacts

Address

Telephone / Fax

E-mail

2 Measurement System

English Metric

3 Equipment Numbering System

Equipment will be identified by alphabetic AC Air cooler G Grinder, mill R Reactor

prefix as defined here, followed by three- B Boiler H Heater (fired or electric) SP Sample point

digit serial number unless otherwise C Compressor, blower, fan J Ejector, jet, turboexpander T Storage tank

indicated CT Cooling tower M Mixer V Vessel (including columns)

D Dryer ME Miscellaneous equipment

First digit - process section E Exchanger P Pump

Second & third digits - equipment count F Filter, classifier PRV Pressure relief valve

4 Primary Products

Product Name

Product Grade

2 Measurement System

MSDS Form Number

Production Rate

Tons per year

Tons per day

Other units

Product Purity (wt%)

Product shipment mode

Additional Specifications

English Metric

5 Primary Raw Materials

(Attach additional sheets if needed)

Feedstock name

Feedstock grade

MSDS form number

3 Equipment Numbering System

Feedstock availability

Tons per year

Tons per day

Other units

Feedstock price ($/lb)

(Default: open market price)

Known feedstock impurities Name ppmw Name ppmw Name ppmw Name ppmw

Equipment will be identified by alphabetic AC Air cooler G Grinder, mill R Reactor

prefix as defined here, followed by three- B Boiler H Heater (fired or electric) SP Sample point

Additional specifications

6 Site Information

Low ambient temperature (F)

High ambient temperature (F)

Hight ambient relative humidity (%)

digit serial number unless otherwise C Compressor, blower, fan J Ejector, jet, turboexpander T Storage tank

indicated CT Cooling tower M Mixer V Vessel (including columns)

Site elevation (ft)

Maximum wind loading (mph)

Other site design requirements

D Dryer ME Miscellaneous equipment

First digit - process section E Exchanger P Pump

Second & third digits - equipment count F Filter, classifier PRV Pressure relief valve

Conventions followed

• Units of measurement

– Customer specific and may also depend on location

– Design engineers have to be able to work with both metric and English units

• Equipment labeling convention

• Sometimes other conventions and codes, e.g. design codes

© 2012 G.P. Towler / UOP. For educational use in conjunction with

Towler & Sinnott Chemical Engineering Design only. Do not copy

Chemical Engineering Design

What’s in the Design Basis?

Company Name

Address

Project Name

Project Number

REV DATE BY APVD REV

Sheet

DATE BY

1

APVD

Product Name

Product Grade

DESIGN BASIS

Form XXXXX-YY-ZZ

1 General Information

MSDS Form Number

Owners Name

Process Unit Name

Plant Location

Correspondance Contacts

Address

Telephone / Fax

E-mail

2 Measurement System

3 Equipment Numbering System

Equipment will be identified by alphabetic

English

AC Air cooler

Metric

G Grinder, mill R Reactor

Production Rate

Tons per year

prefix as defined here, followed by three- B Boiler H Heater (fired or electric) SP Sample point

digit serial number unless otherwise C Compressor, blower, fan J Ejector, jet, turboexpander T Storage tank

indicated CT Cooling tower M Mixer V Vessel (including columns)

D Dryer ME Miscellaneous equipment

First digit - process section E Exchanger P Pump

Second & third digits - equipment count F Filter, classifier PRV Pressure relief valve

Tons per day

4 Primary Products

Product Name

Product Grade

MSDS Form Number

Other units

Production Rate

Tons per year

Tons per day

Other units

Product Purity (wt%)

Product shipment mode

Additional Specifications

5 Primary Raw Materials

(Attach additional sheets if needed)

Feedstock name

Feedstock grade

MSDS form number

Feedstock availability

Tons per year

Tons per day

Other units

Feedstock price ($/lb)

(Default: open market price)

Known feedstock impurities Name ppmw Name ppmw Name ppmw Name ppmw

Product Purity (wt%)

Additional specifications

Product shipment mode

6 Site Information

Low ambient temperature (F)

High ambient temperature (F)

Hight ambient relative humidity (%)

Site elevation (ft)

Additional Specifications

Maximum wind loading (mph)

Other site design requirements

Product information for primary products

• Product grades desired

• Safety data sheet reference number

• Production rate, purity, shipment details

© 2012 G.P. Towler / UOP. For educational use in conjunction with

Towler & Sinnott Chemical Engineering Design only. Do not copy

Chemical Engineering Design

What’s in the Design Basis?

Feedstock name

Company Name

Project Name

Project Number Sheet 1

Feedstock grade

MSDS form number

Address REV DATE BY APVD REV DATE BY APVD

DESIGN BASIS

Form XXXXX-YY-ZZ

1 General Information

Owners Name

Process Unit Name

Feedstock availability

Plant Location

Correspondance Contacts

Address

Telephone / Fax

E-mail

2 Measurement System

English Metric

Tons per year

Tons per day

3 Equipment Numbering System

Equipment will be identified by alphabetic AC Air cooler G Grinder, mill R Reactor

prefix as defined here, followed by three- B Boiler H Heater (fired or electric) SP Sample point

digit serial number unless otherwise C Compressor, blower, fan J Ejector, jet, turboexpander T Storage tank

indicated CT Cooling tower M Mixer V Vessel (including columns)

Other units

D Dryer ME Miscellaneous equipment

First digit - process section E Exchanger P Pump

Second & third digits - equipment count F Filter, classifier PRV Pressure relief valve

4 Primary Products

Product Name

Product Grade

MSDS Form Number

Production Rate

Tons per year

Tons per day

Other units

Product Purity (wt%)

Product shipment mode

Additional Specifications

5 Primary Raw Materials

(Attach additional sheets if needed)

Feedstock name

Feedstock price ($/lb)

(Default: open market price)

Feedstock grade

MSDS form number

Feedstock availability

Tons per year

Tons per day

Other units

Feedstock price ($/lb)

(Default: open market price)

Known feedstock impurities Name ppmw Name ppmw Name ppmw Name ppmw

Known feedstock impurities Name ppmw

Additional specifications

6 Site Information

Low ambient temperature (F)

High ambient temperature (F)

Hight ambient relative humidity (%)

Site elevation (ft)

Maximum wind loading (mph)

Other site design requirements

Information for primary raw materials Additional specifications

• Feedstock grades

• Safety information

• Availability and pricing

• Feed impurities and their concentrations

© 2012 G.P. Towler / UOP. For educational use in conjunction with

Towler & Sinnott Chemical Engineering Design only. Do not copy

Chemical Engineering Design

What’s in the Design Basis?

Project Name

Company Name Project Number Sheet 1

Address REV DATE BY APVD REV DATE BY APVD

DESIGN BASIS

Form XXXXX-YY-ZZ

Low ambient temperature (F)

1 General Information

Owners Name

Process Unit Name

Plant Location

High ambient temperature (F)

Correspondance Contacts

Address

Telephone / Fax

Hight ambient relative humidity (%)

2 Measurement System

English Metric

3 Equipment Numbering System

Equipment will be identified by alphabetic AC Air cooler G Grinder, mill R Reactor

Site elevation (ft)

prefix as defined here, followed by three- B Boiler H Heater (fired or electric) SP Sample point

digit serial number unless otherwise C Compressor, blower, fan J Ejector, jet, turboexpander T Storage tank

indicated CT Cooling tower M Mixer V Vessel (including columns)

D Dryer ME Miscellaneous equipment

First digit - process section E Exchanger P Pump

Second & third digits - equipment count F Filter, classifier PRV Pressure relief valve

4 Primary Products

Product Name

Product Grade

MSDS Form Number

Production Rate

Tons per year

Maximum wind loading (mph)

Other site design requirements

Tons per day

Other units

Product Purity (wt%)

Product shipment mode

Additional Specifications

5 Primary Raw Materials

(Attach additional sheets if needed)

Feedstock name

Feedstock grade

MSDS form number

Feedstock availability

Tons per year

Tons per day

Other units

Feedstock price ($/lb)

(Default: open market price)

Known feedstock impurities Name ppmw Name ppmw Name ppmw Name ppmw

Additional specifications

6 Site Information

Low ambient temperature (F)

High ambient temperature (F)

Hight ambient relative humidity (%)

Site elevation (ft)

Maximum wind loading (mph)

Other site design requirements

Site information

• Ambient conditions needed for design of insulation, air coolers, etc.

• Special conditions such as wind loads, hurricane and earthquake

conditions that are needed for mechanical and civil engineering

design

© 2012 G.P. Towler / UOP. For educational use in conjunction with

Towler & Sinnott Chemical Engineering Design only. Do not copy

Chemical Engineering Design

What’s in the Design Basis?

Project Name

Company Name Project Number Sheet 2

Address REV DATE BY APVD REV DATE BY APVD

Form XXXXX-YY-ZZ

DESIGN BASIS

Sheet 2 of the Design Basis has

utility information

7 Utility Information

Fuel Gas

Gas source or operation mode Nat Gas

Supply header temperature (F)

Supply header pressure (psia)

Net calorific value (BTU/lb)

Marginal availability (lb/h)

Marginal fuel cost ($/MMBTU)

• Fuel gases

Sulfur content (wppm)

Nitrogen content (wppm)

Chlorine content (wppm)

Gas composition (vol%)

H2O

O2

N2

CO

CO2

H2S

• Fuel oils

H2

CH4

C2H4

C2H6

C3H6

C3H8

C4H8

iC4H10

nC4H10

• Steam levels

C5H10

C5+

Fuel Oil

Fuel source or operation mode #2 Heating Oil

Supply header temperature (F)

Supply headder pressure (psia)

Net calorific value (BTU/lb)

Marginal availability (lb/h)

• Coolants

Marginal fuel cost ($/MMBTU)

Fuel viscosity at F

Fuel viscosity at F

Flash point (F)

Pour point (F)

Sulfur content (wppm)

Nitrogen content (wppm)

Ash content (wt %)

Steam

• Process water

Steam header classification VHP HP MP LP

Operating pressure (psia)

Operating temperature (F)

Mechanical design pressure (psia)

Mechanical design temperature (F)

Marginal availability (lb/h)

Marginal cost ($/Mlb)

Coolants

• Electricity

Coolant classification Cooling Tower Water Once-Through Water Chilled Water

Operating pressure (psia)

Supply temperature (F)

Maximum return temperature (F)

Marginal availability (lb/h)

Marginal cost ($)

Marginal cost units

Process Water Feeds

Water feed stream Raw Water Process Water Boiler Feed Water Condensate

• Process Air

Supply pressure (psia)

Supply temperature (F)

Marginal availability (lb/h)

Marginal cost ($/1000 gal)

Total dissolved solids (wt%)

Hardness as CaCO3 (ppmw)

Chloride as Cl (ppmw)

Metallurgy

Conditions, availability, price, etc.

Electric power

Power range (kW)

Voltage (V)

Phase

Frequency (Hz)

Marginal availability (kW)

Marginal cost ($/kWh)

Plant air streams

Air stream Plant Air Instrument Air Plant Nitrogen

Header pressure (psia)

Header temperature (F)

Moisture (ppmw)

Marginal availability (lb/h)

Marginal cost ($/Mscf)

© 2012 G.P. Towler / UOP. For educational use in conjunction with

Towler & Sinnott Chemical Engineering Design only. Do not copy

Chemical Engineering Design

5. Design Practices: Codes & Standards

• Methods and rules for designing processes and equipment are given in

design codes of practice

• Codes are set by national or international industry panels (e.g., ISO, ASME, API, ISA)

• Codes are reviewed and reissued frequently

• Codes specify practices for design, construction, testing and operation of equipment and processes, that are

expected to lead to a safe design, based on the experience of the code committee

• Design in accordance with code is usually required by the company or by law

• Standard sizes for piping & equipment, compositions, etc. are given in

standards

• Tubing dimensions, valve sizes, exchanger layouts, screw threads, wire gauges, screens, …

• The two terms tend to be used interchangeably

• Always consult the current (latest) edition of the code. Always make

sure that the codes and standards used comply with local legal

requirements.

• Examples will be given throughout the course

© 2012 G.P. Towler / UOP. For educational use in conjunction with

Towler & Sinnott Chemical Engineering Design only. Do not copy

Chemical Engineering Design

5. Design Practices: Design Factors

(Design Margins)

• Equipment is usually sized for greater than the

design throughput

– Allows for uncertainty in the design method and data

– Leaves some room for expanding output

– Ensures the plant can run at design capacity

• Companies usually have a policy on design

margins

– Typically size equipment for 110% of design basis

– Be careful to add design margin only once!

© 2012 G.P. Towler / UOP. For educational use in conjunction with

Towler & Sinnott Chemical Engineering Design only. Do not copy

Chemical Engineering Design

6. Design Documentation

Determine Set Design

Customer Needs Specifications

Build Performance

Models

Generate Design

R&D if Needed

Concepts Predict Fitness

For Service

Evaluate Economics

& Select Design

Customer

Approval

Detailed Design & Procurement

Begin Operation

Equipment Selection & Construction

Design information must be clearly documented to enable:

• Fair comparison between competing design alternatives

• Transfer of information to E&C company for detailed design

• Development of plant manuals

© 2012 G.P. Towler / UOP. For educational use in conjunction with

Towler & Sinnott Chemical Engineering Design only. Do not copy

Chemical Engineering Design

Design Documentation

The design documentation for a process usually includes a minimum of:

1. The design basis

2. A written description of the process

3. A process flow diagram

4. At least one mass & energy balance

5. Product specifications and properties

6. A list of major plant equipment

7. Equipment specification sheets

8. A piping and instrumentation diagram

9. A cost estimate

10.HS&E information (e.g., HAZAN, HAZOP, MSDS forms)

Additional information such as techno-economic analysis, market information,

analysis of competing technologies or alternative design options may also be

included if within the scope of the project

© 2012 G.P. Towler / UOP. For educational use in conjunction with

Towler & Sinnott Chemical Engineering Design only. Do not copy

Chemical Engineering Design

Design Documentation

1. The design basis

2. A written description of the process • The PFD or flowsheet

3. Process flow diagram identifies all the

4. At least one mass & energy balance equipment items and

5. Product specifications and properties process streams

6. A list of major plant equipment

7. Equipment specification sheets

• Usually broken into

8. A piping and instrumentation diagram

9. A cost estimate several separate sheets,

10.HS&E information defining plant sections

• By convention, feeds

enter at left, products exit

right

• Usually also indicates

stream temperature &

pressure

XYZ Co.

© 2012 G.P. Towler / UOP. For educational use in conjunction with

Towler & Sinnott Chemical Engineering Design only. Do not copy

Chemical Engineering Design

Design Documentation

1. The design basis

2. A written description of the process • Mass & energy balances

3. Process flow diagram are usually given for each

4. At least one mass & energy balance design case (e.g.,

5. Product specifications and properties SOR/EOR, different

6. A list of major plant equipment

feeds, winter /summer,

7. Equipment specification sheets

8. A piping and instrumentation diagram etc.)

9. A cost estimate

10.HS&E information • Usually mass flow, mole

flow, wt% and mole% are

given for every

component in every

stream

• Often summarized as a

table at the bottom of the

PFD

1 2 3 4 5 6 7 8 9 10 11 12

25C 25C 25C 25C 25C 25C 25C 25C 25C 25C 25C 25C

120 kPa 121 kPa 122 kPa 123 kPa 124 kPa 125 kPa 126 kPa 127 kPa 128 kPa 129 kPa 130 kPa 131 kPa

kg/h kmol/h wt% mol% kg/h kmol/h wt% mol% kg/h kmol/h wt% mol% kg/h kmol/h wt% mol% kg/h kmol/h wt% mol% kg/h kmol/h wt% mol% kg/h kmol/h wt% mol% kg/h kmol/h wt% mol% kg/h kmol/h wt% mol% kg/h kmol/h wt% mol% kg/h kmol/h wt% mol% kg/h kmol/h wt% mol%

Hydrogen

Helium

Lithium

Beryllium

Boron

XYZ Co.

Nitrogen

Carbon

Nitrogen

Oxygen

Fluorine

Neon

T otal

© 2012 G.P. Towler / UOP. For educational use in conjunction with

Towler & Sinnott Chemical Engineering Design only. Do not copy

Chemical Engineering Design

Design Documentation

1. The design basis

2. A written description of the process

3. Process flow diagram

4. At least one mass & energy balance 1

5. Product specifications and properties 25C

120 kPa

6. A list of major plant equipment kg/h kmol/h wt% mol%

Hydrogen

7. Equipment specification sheets Methane

8. A piping and instrumentation diagram Ethane

Ethylene

9. A cost estimate Propane

10.HS&E information Propylene

Butanes

n-butylene

i-butylene

Water

Carbon dioxide

Total

1 2 3 4 5 6 7 8 9 10 11 12

25C 25C 25C 25C 25C 25C 25C 25C 25C 25C 25C 25C

120 kPa 121 kPa 122 kPa 123 kPa 124 kPa 125 kPa 126 kPa 127 kPa 128 kPa 129 kPa 130 kPa 131 kPa

kg/h kmol/h wt% mol% kg/h kmol/h wt% mol% kg/h kmol/h wt% mol% kg/h kmol/h wt% mol% kg/h kmol/h wt% mol% kg/h kmol/h wt% mol% kg/h kmol/h wt% mol% kg/h kmol/h wt% mol% kg/h kmol/h wt% mol% kg/h kmol/h wt% mol% kg/h kmol/h wt% mol% kg/h kmol/h wt% mol%

Hydrogen

Helium

Lithium

Beryllium

Boron

Nitrogen

Carbon

Nitrogen

XYZ Co.

Oxygen

Fluorine

Neon

Total

© 2012 G.P. Towler / UOP. For educational use in conjunction with

Towler & Sinnott Chemical Engineering Design only. Do not copy

Chemical Engineering Design

Design Documentation

• Defines equipment names

1. The design basis

2. A written description of the process

3. Process flow diagram • Indicates which equipment is

4. At least one mass & energy balance “spared”

5. Product specifications and

properties

6. A list of major plant • Often used to summarize

equipment equipment costs and serve as

7. Equipment specification sheets

8. A piping and instrumentation a starting point for the capital

diagram cost estimate

9. A cost estimate

10. HS&E information No. of Capa city Capacity Equipment Cost pe r

Plant Section La bel Equipment Na me Type Metallurgy Ite ms Mea sure Ca pacity Units Measure Ca pa city Units Ite m (k$)

Air cooler Area m2

Boiler Steam rate kg/h

Column Diameter m No. of trays

Compressor Flow m3/s Power kW

Cooling tower Flow m3/h

Dryer Evap duty kg/h

Ejector Gas flow kg/h

Exchanger Area m2

Heater (fired) Duty MW

Air cooler

Mixer Drive power kW

Air cooler

Motor Power kW

Air cooler

Pump Flow litre/min Power kW

Air cooler

Tank Volume m3

Air cooler

Vessel Volume m3

© 2012 G.P. Towler / UOP. For educational use in conjunction with

Towler & Sinnott Chemical Engineering Design only. Do not copy

Chemical Engineering Design

Design Documentation

Project Name

Company Name Project Number Sheet 1 of 1

Address REV DATE BY APVD REV DATE BY APVD

SHELL & TUBE HEAT EXCHANGER

1. The design basis

Form XXXXX-YY-ZZ

Owner's Name

Plant Location Units English Metric

Case Description

Equipment label Equipm ent name

Plant section

2. A written description of the process

Process service

Design code TEMA Exchanger type

Shells per unit Series Parallel

Surface per unit ft2 Surface per shell ft2

DATA PER UNIT

3. Process flow diagram Stream No.

Fluid

IN

SHELL SIDE

OUT IN

TUBE SIDE

OUT

4. At least one mass & energy balance

Total fluid flow lb/h

Total vapor flow lb/h

Total liquid flow lb/h

Total steam flow lb/h

Fluid vaporized / condensed lb/h

Density lb/cu ft

5. Product specifications and

Dynamic viscosity lbm/ft.s

Specific heat capacity Btu/lb.F

Thermal conductivity Btu.ft/h.ft2.F

Latent heat Btu/lb

properties

Normal temperature ºF

Max temperature ºF

Min temperature ºF

Pressure psia

Pressure drop allowed psi

6. A list of major plant equipment

Pressure drop calculated psi

Flow velocity ft/s

Number of passes

Film transfer coefficient Btu/h.ft2.F

Fouling coefficient Btu/h.ft2.F

7. Equipment specification

Heat duty Btu/h

FT factor

Effective mean temperature difference ºF

Minimum surface required ft2

sheets

CONSTRUCTION & MATERIALS PER SHELL

Tubes

Material

Count Pitch in Square Triangular Welded

Length ft O.D. in Wall thickness in

8. A piping and instrumentation

Design pressure at max temp psia Test pressure psia Max external pressure psia

Number of tubes blanked

Shell

diagram

Material

Length ft I.D. in Wall thickness in

Design pressure at max temp psia Test pressure psia Min internal pressure psia

Baffle material Baffle type Baffle pitch in

Tubesheet material Tubesheet thickness in

Bonnet material Bonnet type

9. A cost estimate Branches

Shell side inlet

Tube side inlet

in N.B.

in N.B.

Shell side outlet

Tube side outlet

in N.B.

in N.B.

10. HS&E information

NOTES

1.

2.

3.

4.

5.

• Give detailed design information (stream properties, dimensions) for each

major piece of equipment

• Occasionally include mechanical drawings if the equipment is not standard

• Sometimes substituted with vendor specification sheets for sourced items

© 2012 G.P. Towler / UOP. For educational use in conjunction with

Towler & Sinnott Chemical Engineering Design only. Do not copy

Chemical Engineering Design

What’s in a Spec Sheet? Project Name

Company Name Project Number Sheet 1 of 1

• Project info & rev tab

Address REV DATE BY APVD REV DATE BY APVD

SHELL & TUBE HEAT EXCHANGER

Form XXXXX-YY-ZZ

Owner's Name

Plant Location Units English Metric

Case Description

Equipme nt la bel Equipme nt na me

• Equipment service and

Plant section

Process service

Design code TEMA Exchanger type

Shells per unit Series Parallel

Surface per unit ft2 Surface per shell ft2

summary information DATA PER UNIT

IN

SHELL SIDE

OUT IN

TUBE SIDE

OUT

Stream No.

Fluid

Total fluid flow lb/h

Total vapor flow lb/h

• Stream data needed

Total liquid flow lb/h

Total steam flow lb/h

Fluid vaporized / condensed lb/h

Density lb/cu ft

Dynamic viscosity lbm/ft.s

for design Specific heat capacity

Thermal conductivity

Latent heat

Normal temperature

Btu/lb.F

Btu.ft/h.ft2.F

Btu/lb

ºF

Max temperature ºF

Min temperature ºF

Pressure psia

Pressure drop allowed psi

• Calculated design

Pressure drop calculated psi

Flow velocity ft/s

Number of passes

information for the

Film transfer coefficient Btu/h.ft2.F

Fouling coefficient Btu/h.ft2.F

Heat duty Btu/h

FT factor

Effective mean temperature difference ºF

equipment

Minimum surface required ft2

CONSTRUCTION & MATERIALS PER SHELL

Tubes

Material

Count Pitch in Square Triangular Welded

Length ft O.D. in Wall thickness in

• Dimensions and

Design pressure at max temp psia Test pressure psia Max external pressure psia

Number of tubes blanked

Shell

Material

construction details

Length ft I.D. in Wall thickness in

Design pressure at max temp psia Test pressure psia Min internal pressure psia

Baffle material Baffle type Baffle pitch in

Tubesheet material Tubesheet thickness in

Bonnet material Bonnet type

Branches

Shell side inlet in N.B. Shell side outlet in N.B.

• Notes

Tube side inlet in N.B. Tube side outlet in N.B.

NOTES

1.

2.

3.

4.

5.

© 2012 G.P. Towler / UOP. For educational use in conjunction with

Towler & Sinnott Chemical Engineering Design only. Do not copy

Chemical Engineering Design

Standard Templates

• Typical templates for spec sheets and calc

sheets are available at:

booksite.Elsevier.com/Towler

• These can be customized for your design

projects

© 2007 G.P. Towler / UOP. For educational use in conjunction with

Sinnott & Towler Chemical Engineering Design only. Do not copy

Chemical Engineering Design

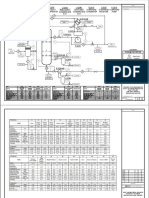

Design Documentation

1. The design basis • The P&ID is more detailed

2. A written description of the process

3. Process flow diagram than the PFD and almost

4. At least one mass & energy balance always runs to several

5. Product specifications and properties sheets

6. A list of major plant equipment

7. Equipment specification sheets • It shows all the plant

8. A piping and instrumentation diagram instruments, control

9. A cost estimate

10.HS&E information systems, control logic and

shutdown systems

• It also shows pipe sizes

and metallurgy (but not

pipe layout)

• The P&ID is critical for

performing design safety

XYZ Co.

reviews

© 2012 G.P. Towler / UOP. For educational use in conjunction with

Towler & Sinnott Chemical Engineering Design only. Do not copy

Chemical Engineering Design

Design Documentation

1. The design basis • Variable costs of production

2. A written description of the process

3. Process flow diagram – Raw materials

4. At least one mass & energy balance – Utilities

5. Product specifications and properties – Consumables

6. A list of major plant equipment – Packaging & shipping

7. Equipment specification sheets

8. A piping and instrumentation diagram

• Fixed costs of production

9. A cost estimate

– Wages

10.HS&E information

– Taxes

– Maintenance

– Overheads

• Capital costs

– Working capital

– Installed capital cost

– Royalty costs

– Annual capital charge

© 2012 G.P. Towler / UOP. For educational use in conjunction with

Towler & Sinnott Chemical Engineering Design only. Do not copy

Chemical Engineering Design

Design Documentation

• Information on materials safety is

1. The design basis

2. A written description of the process

required for hazard analysis,

3. Process flow diagram detailed design

4. At least one mass & energy balance

5. Product specifications and

properties • Material Safety Data Sheets

6. A list of major plant equipment (MSDSs) must be provided to

7. Equipment specification sheets

8. A piping and instrumentation employees and customers by law

diagram in the U.S.A. (OSHA Hazard

9. A cost estimate

Communication Standard 29 CFR

10.HS&E information

Part 1910.1200)

• Information also needs to be

collected to begin applying for

emissions permits

• The type of information needed

and level of detail varies locally

© 2012 G.P. Towler / UOP. For educational use in conjunction with

Towler & Sinnott Chemical Engineering Design only. Do not copy

Chemical Engineering Design

Conclusion: What Makes a Process

Design in Industry

1. Design work process

2. Design team

3. Project plan

4. Design basis

5. Standard design procedures &

practices

6. Design documentation

© 2012 G.P. Towler / UOP. For educational use in conjunction with

Towler & Sinnott Chemical Engineering Design only. Do not copy

Chemical Engineering Design

Questions ?

© 2012 G.P. Towler / UOP. For educational use in conjunction with

Towler & Sinnott Chemical Engineering Design only. Do not copy

Chemical Engineering Design

You might also like

- Continental GTSIO 520 Operating ManualDocument48 pagesContinental GTSIO 520 Operating Manualprivateaerospace100% (2)

- AspenHYSYSRefiningV7 3 OpsDocument478 pagesAspenHYSYSRefiningV7 3 OpsAnonymous w46Y2Qf84No ratings yet

- 1275630GTDocument236 pages1275630GTLeobardo Genaro Roque NájeraNo ratings yet

- BS En3-7Document56 pagesBS En3-7Sumanta Bhaya83% (6)

- Towler - Chemical - Engineering - Design - MS Powerpoint PDFDocument13 pagesTowler - Chemical - Engineering - Design - MS Powerpoint PDFhananurdinaaaNo ratings yet

- Licuacion de Gas NaturalDocument41 pagesLicuacion de Gas NaturalYoselin M. EspinozaNo ratings yet

- Sloleya DistillationtraysasmechanicalequipmentDocument62 pagesSloleya Distillationtraysasmechanicalequipmentmsn1981No ratings yet

- Vapor Phase Pressure Drop MethodsDocument32 pagesVapor Phase Pressure Drop MethodsjamestppNo ratings yet

- How Can The UniSim® Design Air Cooler - Xchanger Suite Xace® Link Be UsedDocument5 pagesHow Can The UniSim® Design Air Cooler - Xchanger Suite Xace® Link Be UsedDionie Wilson Diestro100% (1)

- Singapore - Selective H2S Absorption Webinar - Bryan Research and EngineeringDocument8 pagesSingapore - Selective H2S Absorption Webinar - Bryan Research and EngineeringEslam ShiblNo ratings yet

- 1000444Document5 pages1000444Semih ÖzsağıroğluNo ratings yet

- Modeling and Rating Propane Refrigeration SlidesDocument15 pagesModeling and Rating Propane Refrigeration SlidesEslam ShiblNo ratings yet

- Repsol - Use of Simulation For HDS UnitDocument16 pagesRepsol - Use of Simulation For HDS UnitHoracio RodriguezNo ratings yet

- Process Duty Specification For 01-Pk-051 Vacuum System: Ejectors CapacityDocument5 pagesProcess Duty Specification For 01-Pk-051 Vacuum System: Ejectors CapacityvasudhaNo ratings yet

- Stepwise Simulation of Vacuum Transfer2Document7 pagesStepwise Simulation of Vacuum Transfer2Hadis ShojaeiNo ratings yet

- JPT 2017-NoviembreDocument84 pagesJPT 2017-Noviembreabraham dominguezNo ratings yet

- 20 - Optimising FCC Operation - UOPDocument24 pages20 - Optimising FCC Operation - UOPVirgo LeezdevilNo ratings yet

- 05 - 2 Heat Balance - Practice Problem - InstructorDocument31 pages05 - 2 Heat Balance - Practice Problem - Instructorsawitri diah ayu komala100% (2)

- UOP Course DescriptionDocument2 pagesUOP Course DescriptionVictor Esteban CondorNo ratings yet

- The Star Process by Uhde: Industrial SolutionsDocument24 pagesThe Star Process by Uhde: Industrial SolutionsAjaykumarNo ratings yet

- FCC Propylene Production Tech PaperDocument8 pagesFCC Propylene Production Tech PaperMaría Belén JaureguiNo ratings yet

- Introduction To Uop: Jim Mcgehee Development Specialist, Heavy OilsDocument22 pagesIntroduction To Uop: Jim Mcgehee Development Specialist, Heavy OilsAnkush Bhandari100% (1)

- Pressure Drop Calculation Equations For Piping and PipelineDocument6 pagesPressure Drop Calculation Equations For Piping and PipelineHsein WangNo ratings yet

- AspenTech Course Catalog FY23 PDFDocument24 pagesAspenTech Course Catalog FY23 PDFvlananloNo ratings yet

- Guide Line To Vendor Regarding Tube Layout PreparationDocument4 pagesGuide Line To Vendor Regarding Tube Layout PreparationSalman AkramNo ratings yet

- The Hot Bypass Pressure Control Rev. Agosto 2018Document12 pagesThe Hot Bypass Pressure Control Rev. Agosto 2018luiz.henriqueNo ratings yet

- Ogjournal20201005 DL PDFDocument68 pagesOgjournal20201005 DL PDFMarcelo SchaderNo ratings yet

- MdeaDocument2 pagesMdeaVera MarsellaNo ratings yet

- Carbon Monoxide - Syngas Pipeline Systems - Reformated Jan 12Document82 pagesCarbon Monoxide - Syngas Pipeline Systems - Reformated Jan 12JC PinoNo ratings yet

- Heat Exchangers Designing For Super-Critical Fluid ServiceDocument6 pagesHeat Exchangers Designing For Super-Critical Fluid ServiceHsein WangNo ratings yet

- (510-C-002) PDS For Absorber I - R0Document14 pages(510-C-002) PDS For Absorber I - R0idilfitriNo ratings yet

- Introduction To VR HCR by GS Caltex Corporation PDFDocument26 pagesIntroduction To VR HCR by GS Caltex Corporation PDFRey100% (2)

- Aiche + Chemical Engineering:: Today, Tomorrow & Leading The FutureDocument339 pagesAiche + Chemical Engineering:: Today, Tomorrow & Leading The FutureShah Wali UllahNo ratings yet

- Heat Transfer Equipment 2. Boiling and CondensingDocument20 pagesHeat Transfer Equipment 2. Boiling and CondensingRicardo Franco ArboledaNo ratings yet

- 01 - Introduction To Refinery Energy Management NOTE PAGESDocument15 pages01 - Introduction To Refinery Energy Management NOTE PAGESAhmed ElhadyNo ratings yet

- BTX From FCC PDFDocument7 pagesBTX From FCC PDFjosealvaroNo ratings yet

- 1019 DPP Ele Dts 003 SDV Data SheetDocument2 pages1019 DPP Ele Dts 003 SDV Data SheetJoseNo ratings yet

- BHEF Section B - HandoutDocument23 pagesBHEF Section B - HandoutadrianstydNo ratings yet

- SAES-E-004 02-18-2018 FinalDocument35 pagesSAES-E-004 02-18-2018 Finalsaleem naheedNo ratings yet

- Final Project Report: Uop, LLCDocument165 pagesFinal Project Report: Uop, LLCSiddharth KishanNo ratings yet

- Prico Process PDFDocument13 pagesPrico Process PDFcorkynhoNo ratings yet

- PFD Unit 2000 - ReferenceDocument2 pagesPFD Unit 2000 - ReferenceAgravante JakeNo ratings yet

- Haward Technology Middle East Point Enginee Technology Middle East 77 Pe120Document203 pagesHaward Technology Middle East Point Enginee Technology Middle East 77 Pe120alexverde3No ratings yet

- 3 3 MR Robert PardemannDocument47 pages3 3 MR Robert Pardemannhoremheb1No ratings yet

- PDS For Hot Flash Column - R0Document6 pagesPDS For Hot Flash Column - R0idilfitriNo ratings yet

- Hydraulic Decoking System: Nnovation Efficiency QualityDocument8 pagesHydraulic Decoking System: Nnovation Efficiency QualitykennymagallanesNo ratings yet

- PHD Thesis Naveen BhutaniDocument252 pagesPHD Thesis Naveen BhutaniSagar SrinivasNo ratings yet

- 05020-250-090-MDS-116-01-01 Rev.2 (090TK-001,002) DCU FEED TANKSDocument5 pages05020-250-090-MDS-116-01-01 Rev.2 (090TK-001,002) DCU FEED TANKSSelim SelimNo ratings yet

- A. Radically Different Formulation and Solution of The Single-Stage Flash ProblemDocument14 pagesA. Radically Different Formulation and Solution of The Single-Stage Flash ProblemPrantik DasNo ratings yet

- 05 - Sulzer - Separator InternalsDocument53 pages05 - Sulzer - Separator InternalsVicente RegulezNo ratings yet

- 09-05-Sulzer-Key To Success in Ethylene Plant-VFDocument23 pages09-05-Sulzer-Key To Success in Ethylene Plant-VFnktiah1207No ratings yet

- Process EngineerDocument3 pagesProcess EngineerJowy DeaunaNo ratings yet

- PDS For Prewash Flash Column - R0Document8 pagesPDS For Prewash Flash Column - R0idilfitriNo ratings yet

- Vapour Compression For Propane-Propylene SplittersDocument3 pagesVapour Compression For Propane-Propylene SplittersJohnNo ratings yet

- N-0900-P-02-01 - PGH 2nd Stage Reactor (R-0902)Document11 pagesN-0900-P-02-01 - PGH 2nd Stage Reactor (R-0902)Darrel Espino AranasNo ratings yet

- 2018 UOP Course ScheduleDocument2 pages2018 UOP Course SchedulePRATEEK KUMAR DASNo ratings yet

- Industrial: Western European Energy Conservation Technologies For EvaporatorsDocument33 pagesIndustrial: Western European Energy Conservation Technologies For EvaporatorsPhoe ChitNo ratings yet

- Industrial Process DesignDocument36 pagesIndustrial Process DesignAldo Reda Muñoz NavarroNo ratings yet

- Chapter 1Document72 pagesChapter 1Thanhthung DinhNo ratings yet

- Chapter 1 - enDocument44 pagesChapter 1 - enhuynhphuong699No ratings yet

- Product Training Nov 2019: Automotive & Design Level 1Document31 pagesProduct Training Nov 2019: Automotive & Design Level 1Nhũ Ép Kim KurzNo ratings yet

- Presented By, Mohamed Rafeek (Senior Engineer, Flowserve, France)Document22 pagesPresented By, Mohamed Rafeek (Senior Engineer, Flowserve, France)rafeekmekgceNo ratings yet

- Operating Manual: Air Conditioner Wall Mounted TypeDocument10 pagesOperating Manual: Air Conditioner Wall Mounted TypejohnincanadaNo ratings yet

- Lightning Protection SystemDocument2 pagesLightning Protection SystemIra Jane LosañezNo ratings yet

- Andt Thank AlgerieDocument28 pagesAndt Thank AlgerieChristian BarNo ratings yet

- Ba Markiv UsaDocument20 pagesBa Markiv UsaThaiminh VoNo ratings yet

- Sag Tension Sample CalculationDocument9 pagesSag Tension Sample CalculationKC ColinNo ratings yet

- IIT KHARAGPUR, PG Brochure 2019Document54 pagesIIT KHARAGPUR, PG Brochure 2019SATYAM RAWATNo ratings yet

- Photo TransistorDocument43 pagesPhoto TransistorSyed muhammad zaidi100% (12)

- BrochureDocument2 pagesBrochureshwyfrecyclingNo ratings yet

- Service Details Man BW PDFDocument7 pagesService Details Man BW PDFTapas ChaudhuriNo ratings yet

- Produçao de Briquetes A Partir Da Casca Do Fruto de Licuri (Syagrus Coronata) e Palha de Cana-de-AçúcarDocument9 pagesProduçao de Briquetes A Partir Da Casca Do Fruto de Licuri (Syagrus Coronata) e Palha de Cana-de-AçúcarRenan Guilherme de Oliveira GuihNo ratings yet

- Archibald Page Citation Aug 2020Document2 pagesArchibald Page Citation Aug 2020David NashNo ratings yet

- TurboCare Engineered Solution For Turbine & Generator Repair (Litgeringen)Document51 pagesTurboCare Engineered Solution For Turbine & Generator Repair (Litgeringen)Dzulqcaefliey TsuelaymhaenNo ratings yet

- Suspension System Presentation by Prashant MathurDocument20 pagesSuspension System Presentation by Prashant MathurPrashant MathurNo ratings yet

- Asia Pacific 2011: "Keeping It Simple - Back To Basics in Safety"Document2 pagesAsia Pacific 2011: "Keeping It Simple - Back To Basics in Safety"sugiyantoNo ratings yet

- Top Links July 2018Document79 pagesTop Links July 2018Andrew Richard ThompsonNo ratings yet

- 3735-WIN2000 HIAS Air Pipe Heads With Closing Device 2018a - 19062018 WebDocument2 pages3735-WIN2000 HIAS Air Pipe Heads With Closing Device 2018a - 19062018 WebOleg EnaNo ratings yet

- CTXS07 FTXS09 12 Operation ManualDocument42 pagesCTXS07 FTXS09 12 Operation ManualMojeeb HassanzadaNo ratings yet

- SiLENSe 5.1 ReleaseNotesDocument10 pagesSiLENSe 5.1 ReleaseNotesPawan KumarNo ratings yet

- ME2135E Fluid Mechanics II Tutorial 2Document2 pagesME2135E Fluid Mechanics II Tutorial 2Law Zhan HongNo ratings yet

- Boom Hydraulic System CAT 330Document17 pagesBoom Hydraulic System CAT 330hectorNo ratings yet

- Characteristic Curve Diodes and LedsDocument22 pagesCharacteristic Curve Diodes and LedsRyanMehaslNo ratings yet

- Foldable Added Bus Step: Presented byDocument56 pagesFoldable Added Bus Step: Presented byIsabelita PavettNo ratings yet

- High Energy Rate Forming ProcessDocument8 pagesHigh Energy Rate Forming Processjasonmani90No ratings yet

- Berge Bulk Application FormDocument6 pagesBerge Bulk Application FormMehmet Ergean100% (3)

- THD-20140903 Control ValveDocument28 pagesTHD-20140903 Control ValveMario GuzmanNo ratings yet

- SAGIM ELY - MP8-Technical-SpecificationsDocument21 pagesSAGIM ELY - MP8-Technical-SpecificationsEduardo TamargoNo ratings yet

- 250 To 5000 Watts PWM DC - AC 220V Power Inverter - Nonstop-Free Electronic Circuits Project Diagram and SchematicsDocument11 pages250 To 5000 Watts PWM DC - AC 220V Power Inverter - Nonstop-Free Electronic Circuits Project Diagram and SchematicsPankaj D Patel100% (1)