Professional Documents

Culture Documents

Test 1 - Concrete Mix Design Dishan

Uploaded by

Yasndra Abeygunewardhane0 ratings0% found this document useful (0 votes)

111 views20 pagesccc

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentccc

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

111 views20 pagesTest 1 - Concrete Mix Design Dishan

Uploaded by

Yasndra Abeygunewardhaneccc

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 20

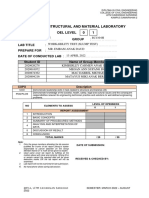

Concrete Mix Design – Test 1

Dr. Moussa Baalbaki

© 2015 Holcim Ltd

Example of Mix Design Calculation

• Conditions and Specification

Indoor concrete slab for an individual house

200 mm thick

No special exposure

Specified strength of 20 MPa at 28 days on cylinder

Slump of 175 mm

25 consecutive tests are available with a standard deviation of 3MPa

Sanstha cement with density 3.1

Siam City Cement (Lanka) Limited | All Rights Reserved. 2

Example of Mix Design Calculation

• Coarse Aggregate

Crushed particles

20 mm nominal maximum size

Specific gravity = 2.7

Dry-rodded bulk density = 1600 kg/m3

Absorption, abs = 0.5%

Moisture content, mc = 1.0%

Siam City Cement (Lanka) Limited | All Rights Reserved. 3

Example of Mix Design Calculation

• Fine Aggregate (Sand)

Natural sand

Specific gravity = 2.65

Fineness modulus, FM = 2.8

Absorption, abs = 1%

Moisture content, mc = 4%

Siam City Cement (Lanka) Limited | All Rights Reserved. 4

Example of Mix Design Calculation

• Admixtures

Water reducer

- Manufacturer recommends 3 ml per kg of cement for 7% water reduction

- Specific gravity = 1

Siam City Cement (Lanka) Limited | All Rights Reserved. 5

Example of Mix Design Calculation

1-

1- Strength

Strength • From this information calculate the concrete mix design

2-

2- W/C

W/C to meet the conditions and specification by following the

3-

3- Stone

Stone 12 steps of the Absolute Volume method

4-

4- Air

Air

5-

5- Slump

Slump

6-

6- Water

Water

7-

7- Cement

Cement

8-

8- Type

Type

9-

9- Admixture

Admixture

10-

10- Sand

Sand

11-

11- Moisture

Moisture

12-

12- Trials

Trials

Siam City Cement (Lanka) Limited | All Rights Reserved. 6

Strength requirements

1-

1- Strength

Strength

2-

2- W/C

W/C

f'c 20Mpa

3-

3- Stone

Stone Corrected due to Durability

f'c - MPa

4-

4- Air

Air No any special exposure Max. W/C -

5-

5- Slump

Slump 25 consecutive tests are

available with a standard

6-

6- Water

Water deviation of 3MPa Modification Factor 1.03

At leass 30 number of test

7-

7- Cement

Cement are needed but here we

8- have 25 test. Lets take SD=3 Standard deviation 3

8- Type

Type

20+ 1.03x3 =

9-

9- Admixture

Admixture f'cr 23.09MPa

10-

10- Sand

Sand

11-

11- Moisture

Moisture

12-

12- Trials

Trials

Siam City Cement (Lanka) Limited | All Rights Reserved. 7

Determining Water-Cement Ratio

1-

1- Strength

Strength

2-

2- W/C

W/C

3-

3- Stone

Stone

4-

4- Air

Air

5-

5- Slump

Slump

6-

6- Water

Water

W/C = 0.64

7-

7- Cement

Cement

8-

8- Type

Type

9-

9- Admixture

Admixture

10-

10- Sand

Sand

11-

11- Moisture

Moisture Non air entrained W/C 0.64

12-

12- Trials

Trials

Siam City Cement (Lanka) Limited | All Rights Reserved. 8

Coarse aggregate requirements

1-

1- Strength

Strength

2-

2- W/C

W/C

3-

3- Stone

Stone

Coarse Aggregate Max. Size 20mm

4-

4- Air

Air

FM of fine aggregate 2.8

5-

5- Slump

Slump

From interpolation Bulk volume factor 0.62

6-

6- Water

Water

Corrected bulk volume 0.68

7-

7- Cement

Cement factor

8-

8- Type

Type

0.62 X 1600

9-

9- Admixture

Admixture

Coarse Aggregate 992Kg

10-

10- Sand

Sand

Absorption 0.5%

11-

11- Moisture

Moisture

C/A (SSD) 992x1.005 kg

12-

12- Trials

Trials

997 kg

Siam City Cement (Lanka) Limited | All Rights Reserved. 9

Air Content

1-

1- Strength

Strength

2-

2- W/C

W/C

3-

3- Stone

Stone

4-

4- Air

Air

5-

5- Slump

Slump

6-

6- Water

Water

7-

7- Cement

Cement 1% air content

considering void of

8-

8- Type

Type concrete

9-

9- Admixture

Admixture

10-

10- Sand

Sand

11-

11- Moisture

Moisture

12-

12- Trials

Trials

Siam City Cement (Lanka) Limited | All Rights Reserved. 10

Air Content

1-

1- Strength

Strength

2-

2- W/C

W/C

3-

3- Stone

Stone

4-

4- Air

Air

5-

5- Slump

Slump

6-

6- Water

Water

7-

7- Cement

Cement

8-

8- Type

Type

9-

9- Admixture

Admixture

10-

10- Sand

Sand

11-

11- Moisture

Moisture

12-

12- Trials

Trials Slump is specified as a 175+- 25 mm

Siam City Cement (Lanka) Limited | All Rights Reserved. 11

Water content

1-

1- Strength

Strength

2-

2- W/C

W/C

3-

3- Stone

Stone

4-

4- Air

Air

5-

5- Slump

Slump

6-

6- Water

Water

7-

7- Cement

Cement

8-

8- Type

Type

9-

9- Admixture

Admixture

10-

10- Sand

Sand From interpolating Water Content 213kg

Manufacturer recommends 3 198.09kg

11-

11- Moisture

Moisture ml per kg of cement for 7%

12-

12- Trials

Trials water reduction Corrected Water Content 198kg

Siam City Cement (Lanka) Limited | All Rights Reserved. 12

Cement content

1-

1- Strength

Strength

2-

2- W/C

W/C

3-

3- Stone

Stone

4-

4- Air

Air

5-

5- Slump

Slump

6-

6- Water

Water 309.515625

7-

7- Cement

Cement

Cement Content 310kg

Min. cement for

8-

8- Type

Type durability aspect - kg

9-

9- Admixture

Admixture Min. cement for

workability 320kg 320

10-

10- Sand

Sand

11-

11- Moisture

Moisture

12-

12- Trials

Trials

Siam City Cement (Lanka) Limited | All Rights Reserved. 13

Cement Type

1-

1- Strength

Strength

2-

2- W/C

W/C

3-

3- Stone

Stone

4-

4- Air

Air

5-

5- Slump

Slump

6-

6- Water

Water

7-

7- Cement

Cement Sanstha cement with density 3.1

8-

8- Type

Type

9-

9- Admixture

Admixture

10-

10- Sand

Sand

11-

11- Moisture

Moisture

12-

12- Trials

Trials

Siam City Cement (Lanka) Limited | All Rights Reserved. 14

Admixtures

1-

1- Strength

Strength Water reducer

2-

2- W/C

W/C Manufacturer recommends 3 ml per

kg of cement for 7% water reduction

3-

3- Stone

Stone Specific gravity = 1

4-

4- Air

Air

5-

5- Slump

Slump cement content 320kg

6-

6- Water

Water

Initial water 213

7-

7- Cement

Cement

8-

8- Type

Type New Water 198 4.22%

9-

9- Admixture

Admixture

Admixture amount 0.96kg

10-

10- Sand

Sand

11-

11- Moisture

Moisture

12-

12- Trials

Trials

Siam City Cement (Lanka) Limited | All Rights Reserved. 15

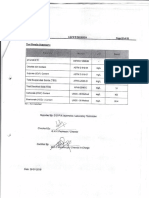

Sand content

1-

1- Strength

Strength Volume (1000

Material Mass (kg/m3) Density

2-

2- W/C

W/C liters)

3-

3- Stone

Stone

Cement 320 3100 103.2

4-

4- Air

Air

5-

5- Slump

Slump Water 198 1000 204

6-

6- Water

Water

Stone (SDD) 997 2700 369

7-

7- Cement

Cement

8-

8- Type

Type Air 1% 10

9-

9- Admixture

Admixture

10-

10- Sand

Sand Sand (SDD) 844 2650 318

11-

11- Moisture

Moisture

Water reducer 0.96 1000 0.96

12-

12- Trials

Trials

total 2360 1000

Siam City Cement (Lanka) Limited | All Rights Reserved. 16

Moisture corrections

1-

1- Strength

Strength Mass (kg/m3)

Moisture

2-

2- W/C

W/C Material Mass (kg/m3) – moist

corrections

conditions

3-

3- Stone

Stone

4-

4- Air

Air Cement 320 320

5-

5- Slump

Slump Water 198 -30 168

6-

6- Water

Water

7-

Stone (SDD) 997 +5 1002

7- Cement

Cement

8-

8- Type

Type Air 1% 1%

9-

9- Admixture

Admixture

Sand (SSD) 844 +25 869

10-

10- Sand

Sand

11-

11- Moisture

Moisture Water reducer 0.96 0.96

12-

12- Trials

Trials

total 2360 2360

Siam City Cement (Lanka) Limited | All Rights Reserved. 17

Trial batch for 25 liter (0.025 m3)

1-

1- Strength

Strength Mass (kg/m3) – Batch quantities

Conversion

2-

2- W/C

W/C Material moist for 50 L in moist

factor for 50 L

3- conditions conditions

3- Stone

Stone

4-

4- Air

Air Cement 320 0.05 16

5-

5- Slump

Slump

Water 174 0.05 8.7

6-

6- Water

Water

7-

7- Cement

Cement Stone 1002 0.05 50.1

8-

8- Type

Type

Air 1% 0.05

9-

9- Admixture

Admixture

10-

10- Sand

Sand Sand 869 0.05 42.7

11-

11- Moisture

Moisture Water reducer 0.96 0.05 0.048

12-

12- Trials

Trials

total 2360

Siam City Cement (Lanka) Limited | All Rights Reserved. 18

Concrete mixing preparation and testing

Preparation

• Determine humidity condition of sand and coarse aggregate

• Correct water with respect to saturated surface dry condition of aggregates

• Weight separately all concrete constituents for the define volume to be mixed

Mixing

1. Mix during 30 sec. sand + coarse aggregate + 90% of water (premix with AEA if any)

2. Add cement + (retarder or accelerator if any) and mix 3 min.

3. Stop 1 min

4. Add 10% remain water (premix with WR or HRWR if any) and mix 5 min

5. End

Fresh concrete testing

• Slump, temperature, unit weight and air content after 10 min (bring back to the mixer all concrete

used for the testing)

• Cover the pan mixer to avoid water evaporation

• Repeat fresh concrete testing after 30, 60,120,180 min (mix 1min before)

• Sample specimen needed for hardened concrete properties

Siam City Cement (Lanka) Limited | All Rights Reserved. 19

Trial batch

1-

1- Strength

Strength • Trial batch tested for:

2-

2- W/C

W/C Slump (mm)

3-

3- Stone

Stone Density or Unit weight (kg/m3)

4-

4- Air

Air Air content (%)

5-

5- Slump

Slump Strength (MPa)

6-

6- Water

Water

• Adjustments made in general on:

7-

7- Cement

Cement

8-

8- Type

Type

9-

9- Admixture

Admixture Water content Slump / density / air content

10-

10- Sand

Sand

Admixture doses

11-

11- Moisture

Moisture

Strength

12-

12- Trials

Trials Cement content

Siam City Cement (Lanka) Limited | All Rights Reserved. 20

You might also like

- Celebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985From EverandCelebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985No ratings yet

- MS-04 Nilagama and Ranwediyaawa Tunnel PortalDocument59 pagesMS-04 Nilagama and Ranwediyaawa Tunnel PortalAmila Priyadarshana DissanayakeNo ratings yet

- Water Cement Ratio (Gate60 Short Notes)Document4 pagesWater Cement Ratio (Gate60 Short Notes)akash rathodNo ratings yet

- Building Schedule of Rates GuideDocument7 pagesBuilding Schedule of Rates GuideDarshanaKuburegeNo ratings yet

- Marble Chips in ConcreteDocument6 pagesMarble Chips in ConcreteMidhun JosephNo ratings yet

- Soundness Test of Cement Using Autoclave MethodDocument3 pagesSoundness Test of Cement Using Autoclave MethodPritha DasNo ratings yet

- WorkedExamplestoBS8110 MinDocument49 pagesWorkedExamplestoBS8110 MinRwagatare civilcontractorsNo ratings yet

- Chapter 2 Design For ServiceabilityDocument29 pagesChapter 2 Design For ServiceabilityJoena Linda100% (1)

- Measure Concrete Consistency with Slump TestDocument5 pagesMeasure Concrete Consistency with Slump TestLove Rosiee100% (1)

- (LECT - 19,20) Prestressed Concrete Poles, Piles, SleepersDocument28 pages(LECT - 19,20) Prestressed Concrete Poles, Piles, SleepersSushil Mundel100% (1)

- Properties and Testing of Hardened ConcreteDocument17 pagesProperties and Testing of Hardened ConcreteKannan KandappanNo ratings yet

- ACC Cement Users GuideDocument51 pagesACC Cement Users GuideArijit dasguptaNo ratings yet

- Design Mix Calculation Grade 30NDocument6 pagesDesign Mix Calculation Grade 30NikhwanNo ratings yet

- Concrete Mix Design Beng 2021Document31 pagesConcrete Mix Design Beng 2021musinguzi robertNo ratings yet

- Split Tensile TestDocument5 pagesSplit Tensile Testarijitdey6No ratings yet

- Soil NailedDocument13 pagesSoil NailedBina QSNo ratings yet

- Experimental Study On Concrete (M30) by Partial Replacement of Fine Aggregate With Copper SlagDocument8 pagesExperimental Study On Concrete (M30) by Partial Replacement of Fine Aggregate With Copper SlagIAEME PublicationNo ratings yet

- Cofferdams: Civil Engineering Practice (CE-203)Document31 pagesCofferdams: Civil Engineering Practice (CE-203)Ali100% (1)

- Sand Cement Brick Containing Recycled PDFDocument7 pagesSand Cement Brick Containing Recycled PDFsyakirohNo ratings yet

- Concrete Information - Design of Concrete Pavement For City StreetsDocument8 pagesConcrete Information - Design of Concrete Pavement For City Streetsoscargon19100% (1)

- Plate Load Test: Principles and Case Histories of Deep Vibro TechniquesDocument25 pagesPlate Load Test: Principles and Case Histories of Deep Vibro TechniquesRifqi FirmansyahNo ratings yet

- Prefaricated Structures Unit IIIDocument53 pagesPrefaricated Structures Unit IIIvgshankar26100% (1)

- Concrete Mix Design Report PDFDocument32 pagesConcrete Mix Design Report PDFMohamed AhmedNo ratings yet

- A Study Report On Flexible Pavement Construction in VidishaDocument4 pagesA Study Report On Flexible Pavement Construction in VidishaIJRASETPublicationsNo ratings yet

- Study On Mechanism of Strength Distribution DevelopmentDocument19 pagesStudy On Mechanism of Strength Distribution DevelopmentnadirshahNo ratings yet

- Road Note No. 4 Method/DOE MethodDocument11 pagesRoad Note No. 4 Method/DOE MethodashoknrNo ratings yet

- Study On Strength and Durability Properties of Ternary Blended Hybrid FRCDocument9 pagesStudy On Strength and Durability Properties of Ternary Blended Hybrid FRCIAEME PublicationNo ratings yet

- REBOUND HAMMER TESTING FOR CONCRETE SURFACE HARDNESSDocument6 pagesREBOUND HAMMER TESTING FOR CONCRETE SURFACE HARDNESSFaizah Sophi100% (1)

- Transporting of ConcreteDocument5 pagesTransporting of ConcreteSreenath TalankiNo ratings yet

- Experimental Study On Concrete With Partial Replacement of Cement With Fly Ash & Coarse Aggregate by Ceramic TilesDocument7 pagesExperimental Study On Concrete With Partial Replacement of Cement With Fly Ash & Coarse Aggregate by Ceramic TilesIJSTENo ratings yet

- Final Year Project Chapter 2Document7 pagesFinal Year Project Chapter 2MohamadMuqhrisNo ratings yet

- Fly Ash As Binder in ConcreteDocument10 pagesFly Ash As Binder in ConcreteZuhair NadeemNo ratings yet

- Artificial Neural Network For Concrete Mix DesignDocument11 pagesArtificial Neural Network For Concrete Mix DesignUmer Farooq100% (1)

- Two Hinged Parabolic ArchDocument1 pageTwo Hinged Parabolic ArchJeya Lakhsmi0% (1)

- Windsor Probe and Quantab TestDocument28 pagesWindsor Probe and Quantab Testsabareesan09No ratings yet

- BS-1881-110 CONCRETE Making Test Cylinders From Fresh Con PDFDocument12 pagesBS-1881-110 CONCRETE Making Test Cylinders From Fresh Con PDFAshraf TomizehNo ratings yet

- Structure of Hydrated Cement PasteDocument11 pagesStructure of Hydrated Cement PasteAli Ismael100% (1)

- PHASE 1 PPT CRCTDDocument14 pagesPHASE 1 PPT CRCTDSudhira ShettyNo ratings yet

- Experimental Study On Concrete Using Copper Slag As Replacement Material of Fine Aggregate 2165 784X.1000156Document6 pagesExperimental Study On Concrete Using Copper Slag As Replacement Material of Fine Aggregate 2165 784X.1000156Siddhesh Kamat Mhamai100% (2)

- Concrete Slump Test ExplainedDocument16 pagesConcrete Slump Test ExplainedKushagra GoelNo ratings yet

- Making ways for better days with soil stabilizationDocument36 pagesMaking ways for better days with soil stabilizationJean MbuNo ratings yet

- Major Construction Equipment Used inDocument2 pagesMajor Construction Equipment Used inAnzsherinah Sebastian Gumiho100% (1)

- LABORATORY COMPACTION TEST ImmaDocument9 pagesLABORATORY COMPACTION TEST ImmaIsmail A IsmailNo ratings yet

- Brick Manufacturing Using Waste MaterialsDocument8 pagesBrick Manufacturing Using Waste MaterialsAnjana Kanwar RajawatNo ratings yet

- CBR Test Procedure Determination of California Bearing Ratio For Road Design PDFDocument5 pagesCBR Test Procedure Determination of California Bearing Ratio For Road Design PDFMohamed AdelNo ratings yet

- Development of High Strength Concrete From Recycled Aggregate Concrete.Document94 pagesDevelopment of High Strength Concrete From Recycled Aggregate Concrete.Micah GentleNo ratings yet

- Chapter 1B Mat FoundationsDocument17 pagesChapter 1B Mat Foundationsmohamed hassan adenNo ratings yet

- Concrete Technology Unit 4Document30 pagesConcrete Technology Unit 4sainathNo ratings yet

- Estimation and Costing PDFDocument51 pagesEstimation and Costing PDFPARVATHANENI SAI KRISHNANo ratings yet

- Structural Engineering NotesDocument5 pagesStructural Engineering NotesRishabh LalaNo ratings yet

- Thesis Presentation Edited&FinalDocument49 pagesThesis Presentation Edited&FinalJafar AhamadNo ratings yet

- GUIDELINES ON USE OF READY MIXED CONCRETE MIX DESIGNDocument14 pagesGUIDELINES ON USE OF READY MIXED CONCRETE MIX DESIGNRaju Shetty CjNo ratings yet

- Colombo Port City Causing Unimaginable Environmental HarmDocument6 pagesColombo Port City Causing Unimaginable Environmental HarmThavam RatnaNo ratings yet

- Report of AggregateDocument10 pagesReport of AggregateNisaAris50% (2)

- Workability Test (Slump Test) Lab ReportDocument10 pagesWorkability Test (Slump Test) Lab ReportMAC DARREL MICHAEL MAC DARREL MICHAELNo ratings yet

- CC Road Construction: Materials, Machinery and StepsDocument18 pagesCC Road Construction: Materials, Machinery and StepsJayesh GojiyaNo ratings yet

- Highway Lab Report 5Document14 pagesHighway Lab Report 5Abdallah AlhasanNo ratings yet

- Test 1 - Concrete Mix Design Yasendra AbeyDocument21 pagesTest 1 - Concrete Mix Design Yasendra AbeyYasndra AbeygunewardhaneNo ratings yet

- Approval Final Drawing 26.01.2021Document1 pageApproval Final Drawing 26.01.2021Yasndra AbeygunewardhaneNo ratings yet

- TV 20 2013 4 683 687Document5 pagesTV 20 2013 4 683 687mknhanoNo ratings yet

- Cement & Concrete Composites: Kung'u Githachuri, Mark G. AlexanderDocument7 pagesCement & Concrete Composites: Kung'u Githachuri, Mark G. AlexanderRamesh BabuNo ratings yet

- Test 1 - Concrete Mix Design Yasendra AbeyDocument21 pagesTest 1 - Concrete Mix Design Yasendra AbeyYasndra AbeygunewardhaneNo ratings yet

- Rebound Hammer Test - HT2102004 - 1Document1 pageRebound Hammer Test - HT2102004 - 1Yasndra AbeygunewardhaneNo ratings yet

- Comparison in Thermal Conductivity of Hollow Concrete Blocks Filled With Straw Bales & Tyre WasteDocument11 pagesComparison in Thermal Conductivity of Hollow Concrete Blocks Filled With Straw Bales & Tyre WasteYasndra AbeygunewardhaneNo ratings yet

- 35 16X11X5.2 ExtaraDocument29 pages35 16X11X5.2 ExtaraYasndra AbeygunewardhaneNo ratings yet

- TCLog 2021-03-10 12-40 A3 20210218EXTRADocument26 pagesTCLog 2021-03-10 12-40 A3 20210218EXTRAYasndra AbeygunewardhaneNo ratings yet

- Is 16415 Product ManualDocument17 pagesIs 16415 Product ManualKumar gsNo ratings yet

- INSEE Letter For Requesting SponsorshipsDocument3 pagesINSEE Letter For Requesting SponsorshipsYasndra AbeygunewardhaneNo ratings yet

- Simulation Report: Hydrating Concrete Block: Total Properties of Concrete Were Redefined by UserDocument29 pagesSimulation Report: Hydrating Concrete Block: Total Properties of Concrete Were Redefined by UserYasndra AbeygunewardhaneNo ratings yet

- TCLog 2021-03-10 12-40 A3 20210218EXTRADocument26 pagesTCLog 2021-03-10 12-40 A3 20210218EXTRAYasndra AbeygunewardhaneNo ratings yet

- Holcimheat Thermocal Report: Summary TableDocument7 pagesHolcimheat Thermocal Report: Summary TableYasndra AbeygunewardhaneNo ratings yet

- G 35 16X11X5.2 FR Slag, No IceDocument2 pagesG 35 16X11X5.2 FR Slag, No IceYasndra AbeygunewardhaneNo ratings yet

- 1.5X1.5X3 Mack FoilDocument5 pages1.5X1.5X3 Mack FoilYasndra AbeygunewardhaneNo ratings yet

- Test Methods For Evaluating Preventive Measures For Controlling Expansion Due To Alkali-SilcaDocument62 pagesTest Methods For Evaluating Preventive Measures For Controlling Expansion Due To Alkali-SilcaYasndra AbeygunewardhaneNo ratings yet

- Water 2Document1 pageWater 2Yasndra AbeygunewardhaneNo ratings yet

- Simulation Report: Hydrating Concrete Block: Total Properties of Concrete Were Redefined by UserDocument29 pagesSimulation Report: Hydrating Concrete Block: Total Properties of Concrete Were Redefined by UserYasndra AbeygunewardhaneNo ratings yet

- Mitigation of Alkali-Silica Reaction in Mortar WithDocument7 pagesMitigation of Alkali-Silica Reaction in Mortar WithYasndra AbeygunewardhaneNo ratings yet

- Water 3Document1 pageWater 3Yasndra AbeygunewardhaneNo ratings yet

- Test Methods For Self-Compacting Concrete (SCC) PDFDocument56 pagesTest Methods For Self-Compacting Concrete (SCC) PDFAdnan MujkanovicNo ratings yet

- Water 1Document1 pageWater 1Yasndra AbeygunewardhaneNo ratings yet

- Water 1Document1 pageWater 1Yasndra AbeygunewardhaneNo ratings yet

- Water 3Document1 pageWater 3Yasndra AbeygunewardhaneNo ratings yet

- INSEE I2i FlyerDocument2 pagesINSEE I2i FlyerYasndra AbeygunewardhaneNo ratings yet

- Glo Brochure Sikagard 555 W ElasticDocument4 pagesGlo Brochure Sikagard 555 W ElasticYasndra AbeygunewardhaneNo ratings yet

- Water 2Document1 pageWater 2Yasndra AbeygunewardhaneNo ratings yet

- INSEE I2i Flyer B PDFDocument2 pagesINSEE I2i Flyer B PDFYasndra AbeygunewardhaneNo ratings yet

- INSEE EXTRA Product DescriptionDocument2 pagesINSEE EXTRA Product DescriptionYasndra AbeygunewardhaneNo ratings yet

- 12.7 7 Wire Strand Proprieties VSLDocument1 page12.7 7 Wire Strand Proprieties VSLAbu BiduNo ratings yet

- Albafluid: CD LubricantDocument5 pagesAlbafluid: CD LubricantGokhan RamiNo ratings yet

- Saej402v002 PDFDocument8 pagesSaej402v002 PDFLuis LujanoNo ratings yet

- Finding An Alternative Binder For Asphalt Using Plastic-BitumenDocument11 pagesFinding An Alternative Binder For Asphalt Using Plastic-BitumenStephen BoachieNo ratings yet

- Low Density Polyethylene: DescriptionDocument2 pagesLow Density Polyethylene: DescriptionlyesNo ratings yet

- Chemicals Zetag DATA Powder Zetag 7645 - 0410Document2 pagesChemicals Zetag DATA Powder Zetag 7645 - 0410PromagEnviro.comNo ratings yet

- Khftxs BHGFFDocument72 pagesKhftxs BHGFFfarhan sdNo ratings yet

- International CatalogDocument16 pagesInternational CatalogDesmond KhorNo ratings yet

- General Ser Vice Ball Valves: GB SeriesDocument13 pagesGeneral Ser Vice Ball Valves: GB SeriesRyan DuhonNo ratings yet

- Mulligan, David - Cure Monitoring For Composites and Adhesives-Ismithers Rapra Publishing (2003!01!01)Document124 pagesMulligan, David - Cure Monitoring For Composites and Adhesives-Ismithers Rapra Publishing (2003!01!01)khan babaNo ratings yet

- Some Critical Issues For Injection MoldingDocument282 pagesSome Critical Issues For Injection MoldingJosé Ramírez100% (7)

- Chemistry3 96) PDocument43 pagesChemistry3 96) PShlok ParekhNo ratings yet

- Pin PingDocument13 pagesPin PingJéssica MaríaNo ratings yet

- Utility FogDocument33 pagesUtility Fogarjun c chandrathil50% (2)

- ASME B16.9 InterpretationsDocument13 pagesASME B16.9 InterpretationsamerNo ratings yet

- AISI 4140 - 42Cr4Mo2Document2 pagesAISI 4140 - 42Cr4Mo2rajbir_singh75% (4)

- HydrolysisH PDFDocument12 pagesHydrolysisH PDFEuwan Tyrone PriasNo ratings yet

- Crankset Standard: Crankset / Bottom Bracket Compatibility ChartDocument1 pageCrankset Standard: Crankset / Bottom Bracket Compatibility ChartGiovanny Gaona JimenezNo ratings yet

- CRT, Crte: Vertical, Multistage, Centrifugal Titanium PumpsDocument36 pagesCRT, Crte: Vertical, Multistage, Centrifugal Titanium Pumpsost lsblNo ratings yet

- FevicolDocument10 pagesFevicolashutoshkumar5549No ratings yet

- SDS - Chemrock 958aDocument1 pageSDS - Chemrock 958amangengueyNo ratings yet

- Importance and Methods of Enhancing MetalDocument56 pagesImportance and Methods of Enhancing MetalJoan F. Malig75% (20)

- Boiler Operation and Safety GuideDocument19 pagesBoiler Operation and Safety GuidemarlpatsNo ratings yet

- Comparison Study of Basalt Fiber and Steel Fiber As Additives To ConcreteDocument9 pagesComparison Study of Basalt Fiber and Steel Fiber As Additives To ConcreteIJRASETPublicationsNo ratings yet

- Lecture 1A.1: Introduction To Steel's Role in Construction in EuropeDocument64 pagesLecture 1A.1: Introduction To Steel's Role in Construction in Europealadinmf1No ratings yet

- PCI Zone6 Curved Spliced GirdersDocument20 pagesPCI Zone6 Curved Spliced GirdersRodrigo LameirasNo ratings yet

- Permanent FormworkDocument13 pagesPermanent FormworkjimmydomingojrNo ratings yet

- Experiment On Single PieceDocument3 pagesExperiment On Single PieceZatchBell100% (4)

- How Air Duct Cleaning Can Help Prevent: Dallas, TX CALL US: (972) 884-555Document6 pagesHow Air Duct Cleaning Can Help Prevent: Dallas, TX CALL US: (972) 884-555Infinity Air Duct ProNo ratings yet

- Power Generation Using Piezoelectric Materials: December 2018Document5 pagesPower Generation Using Piezoelectric Materials: December 2018High rated GabruNo ratings yet