Professional Documents

Culture Documents

Establishing a Model Flow Cell

Uploaded by

AnkurOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Establishing a Model Flow Cell

Uploaded by

AnkurCopyright:

Available Formats

Establishing a Model

Flow Cell

One-piece flow, standard work, 5S, pull systems

TRIDENT BUSINESS SYSTEM

One-piece Flow

Event

Prep, Execution, Outputs

TRIDENT BUSINESS SYSTEM

Prep for a one-piece flow cell event

• Use Value Stream Analysis to plan your cells

• Value Stream Analysis defines cell boundaries:

ONE BY LOWEST

ONE COST

• Define for the cell:

Who are the customers? 1-Piece

Flow

Standard

Work

What are the outputs?

Pull

Who are the suppliers? 5-S

Systems

What are the inputs?

What are the triggers? DEFECT- ON

FREE DEMAND

Establish Takt time based on historical demand and forecast

TRIDENT BUSINESS SYSTEM

Execution of a one piece flow cell event

• Safety first • "Charger" (Water Spider) work

• Don't allow unsafe conditions – Support work done on the "outside“ of the cell

• Make jobs easy to do (ergonomic) – Material handling, parts support, information

• Prevent unsafe acts (make them impossible) transfer, etc.

• Managed with standard work

• Quality

– Takt time, work sequence and standard WIP

• Every part is a good part

– Standard documentation posted

• Build prevention into product and process

– Production control boards

• Right-sized equipment One-piece Flow

• No faster than the cell's target Takt time

• 1/10th the "typical" capital cost

• Runs autonomously (load-load) DONE 4 3

Natural

Groups in

• Operator works on the inside of the cell each cell

– No isolated people in "birdcages" IN

– Value-adding work done on the "inside" 1 2

– U-shaped counter-clockwise layouts best

TRIDENT BUSINESS SYSTEM

Outputs of a one-piece flow cell event

• Remember that a cell has…

1-ITEM STD.

• 1-piece flow FLOW WORK

• Standard work BASIC

5-S

PULL

SYS.

• 5-S

• Pull systems

VISUAL MANAGEMENT

• Establishing the cell layout is the first step

• Standard work is next (during the same event)

• Follow up with good basic 5-S (make it very visual)

• Create pull systems for cell customers and

suppliers

• Manage the cell ("all or nothing" in first 3

weeks!!!)

TRIDENT BUSINESS SYSTEM

Prep for a standard work event…

• Charter the event

• Define the scope of the event

• Define the one that flows

• Define the historical demand (last 3 months) and forecast

demand

• Calculate the current Takt Time (TT)

• Calculate the current Cycle Time (CT)

• What is a 30% improvement in productivity?

• Document the areas top 5 quality issues

TRIDENT BUSINESS SYSTEM

Executing a standard work event

• Day 1 – tool training, charter review, baseline data review, observation of

area and time observation studies, waste identification, Takt Time/Cycle

Time bar chart creation, start to analyze problems and brainstorm

solutions

• Day 2 – documentation of current state standard work and waste

identification, selection of waste to be eliminated, brainstormed

improvements analyzed and prioritized

• Day 3 – design of physical cell layout for one-piece flow and pull

production, create new work sequence with waste eliminated, try-storm

and troubleshoot the changes

• Day 4 – implement one-piece flow and pull production, document the

new standard work, train the operators, post the standard work

documents and create the production control board

• Day 5 – report out

TRIDENT BUSINESS SYSTEM

Outputs of a standard work event

TRIDENT BUSINESS SYSTEM

5 S – Visual

Management

Part of Flow Cell Development

TRIDENT BUSINESS SYSTEM

5S: The Foundation of Visual

Management

• Sort - Eliminate what is not needed

• Set - A place for everything and everything in its place

• Shine - Cleaning and looking for ways to keep it clean

• Standardize - Systemize the maintenance of the first 3 S’s

• Sustain - Stick to the rules. Show real progress. Spread

the rules to other areas of the facility.

TRIDENT BUSINESS SYSTEM

Pull System Event

Prep, Execution, Outputs

TRIDENT BUSINESS SYSTEM

Prep for a pull system event

• Define scope of event

• Define the goal

• How much is 50% of the inventory ($)

• Which units are in? Out?

• What are the high runners (80/20)?

FOR… BEST: VISUAL

• Which will be replenished / sequenced? "ITEMS OUT" (pulled by customers) BETTER: CONTAINER

• What is quantity to make? "ITEMS IN" (pulled from suppliers)

CONSUMABLES (pulled from suppliers)

3: TRIGGER

(what, where to / from,

GOOD: CARDS

• Trigger quantity when, how many)

1: UPSTREAM 2: DOWNSTREAM

• Do the boundaries “feel” right? ITEMS

READY

4: FLOW

ITEMS

BEING USED

• Right units

• Right trigger quantities THINK 80/20

REPLENISH… 80% OF THE UNIT VOLUME COMES FROM 20% OF THE ITEMS

STORE IN

RESERVED

• Challenging stretch goal PLACES

SEQUENCE… 20% OF THE UNIT VOLUME COMES FROM 80% OF THE ITEMS STORE IN

• Document demand history and mix? FIFO LANES

• Cost R.I. EVENT GOALS: REDUCE INVENTORY $ BY 50%

• Volume

• Package sizes

• Document current on-time delivery

• Number of missed / late deliveries; missed

milestones

• Identify an overstock area

TRIDENT BUSINESS SYSTEM

Executing a pull system event

• Observe the process directly

• Review your observations, material usage, and cost

• Choose the lot size and containers (smaller is better)

• Design the pull system

• Upstream ready items

• Downstream in-use items

• Establish the pull trigger

• Best: Visual

• Better: Container

• Good: Cards

• Isolate the “extra” parts somewhere else (upstream)

• Create the triggers and fill the pull system with items

• Implement cell performance board

• To track issues and resolution

• Repeat observation and measurements

• Document the inventory reduction ($)

TRIDENT BUSINESS SYSTEM

Outputs of a pull system event

Pull system rules are implemented and managed

visually

• Rule One: downstream process withdraws only necessary items

from the upstream process and at the required point in time

• Rule Two: upstream process replenishes only the items in the

quantities withdrawn by the downstream process

• Rule Three: defective items are never transported to the

downstream process

• Rule Four: the pull system is the only system for replenishment

• Rule Five: the size of the Pull System has been minimized.

• Rule Six: the actual quantity of items contained in a container, bin,

box, pallet or in-box must be equal to the quantity written on the

Pull Signal trigger

TRIDENT BUSINESS SYSTEM

Elements of a flow cell

1-ITEM STD.

FLOW WORK

BASIC PULL

5-S SYS.

VISUAL MANAGEMENT

TRIDENT BUSINESS SYSTEM

You might also like

- Lean Systems: Arron O. EnriquezDocument39 pagesLean Systems: Arron O. EnriquezRonan AmbrocioNo ratings yet

- Value Streams: Fundamentals of Manufacturing Excellence ProgramDocument30 pagesValue Streams: Fundamentals of Manufacturing Excellence ProgramTuan AnhNo ratings yet

- Operations Management: Course Instructor: Mansoor QureshiDocument37 pagesOperations Management: Course Instructor: Mansoor QureshiZUBAIR KHALIDNo ratings yet

- Session V, Two RevolutionsDocument27 pagesSession V, Two RevolutionsrehanroxNo ratings yet

- Lecture 5Document7 pagesLecture 5SanchuNo ratings yet

- Lecture 27-28 Jit & Lean SystemsDocument59 pagesLecture 27-28 Jit & Lean Systemsmanali VaidyaNo ratings yet

- Implement Lean Cell DesignDocument30 pagesImplement Lean Cell DesignbmyertekinNo ratings yet

- Indonesia Factory Implements Smart Sewing SystemDocument18 pagesIndonesia Factory Implements Smart Sewing Systemsivanesan rajamanickamNo ratings yet

- Toyota Inventory ManagementDocument26 pagesToyota Inventory ManagementWWZNo ratings yet

- Automotive Industry Cluster TPM Training Material Kobetsu Kaizen Step 0 - 1Document42 pagesAutomotive Industry Cluster TPM Training Material Kobetsu Kaizen Step 0 - 1raghavendrarh6464No ratings yet

- Project Case - Smart SewingDocument18 pagesProject Case - Smart SewingRksNo ratings yet

- TroubleshootingDocument39 pagesTroubleshootingTrí NguyễnNo ratings yet

- 08 - IE3120 JIT 2015 HandoutDocument44 pages08 - IE3120 JIT 2015 HandoutGabrielNo ratings yet

- Om m10 Jit Lean HandoutDocument24 pagesOm m10 Jit Lean HandoutChandan SainiNo ratings yet

- Lean Manufacturing Just-In-TimeDocument26 pagesLean Manufacturing Just-In-TimeHirdesh KumarNo ratings yet

- Lean Manufacturing Just-In-TimeDocument26 pagesLean Manufacturing Just-In-TimeNARENDER SINGHNo ratings yet

- Lecture 14-1 Cellular ManufacturingDocument20 pagesLecture 14-1 Cellular Manufacturingsaliba.project2020No ratings yet

- Value Stream MappingDocument54 pagesValue Stream MappingQuynh Chau TranNo ratings yet

- JITfinalDocument40 pagesJITfinalRatnesh Kumar RaiNo ratings yet

- 6 - Just-In-time and Lean ThinkingDocument59 pages6 - Just-In-time and Lean ThinkingSahil KandhariNo ratings yet

- Lean Ops & JITDocument37 pagesLean Ops & JITPrince ZiaNo ratings yet

- Just-In-time (Jit) Production SystemDocument21 pagesJust-In-time (Jit) Production SystemMBA...KID100% (4)

- VSM PDFDocument52 pagesVSM PDFChip ChopNo ratings yet

- 4.GSI 2022 - The Automobile Industry_BDocument36 pages4.GSI 2022 - The Automobile Industry_Bw4kprtrn9vNo ratings yet

- Toyota Production System & Dual Kanban System: Irfan Kazi & Naresh SDocument25 pagesToyota Production System & Dual Kanban System: Irfan Kazi & Naresh SLabiz Saroni ZidaNo ratings yet

- What Is Lean Manufacturing?Document33 pagesWhat Is Lean Manufacturing?Kriti SinghNo ratings yet

- An OverviewDocument37 pagesAn OverviewRahmat UllahNo ratings yet

- Manufacturing System BETP 3814Document32 pagesManufacturing System BETP 3814Mariani SinagaNo ratings yet

- Smed 2 Operator Training - Julian KalacDocument27 pagesSmed 2 Operator Training - Julian KalacJulian KalacNo ratings yet

- T4.lean Manufacturing TechniquesDocument81 pagesT4.lean Manufacturing TechniquesAl AidenNo ratings yet

- Contemporary Issues and The Impact of Technology On Management AccountingDocument30 pagesContemporary Issues and The Impact of Technology On Management Accountingaiman afiqNo ratings yet

- Just-in-Time and Lean SystemsDocument27 pagesJust-in-Time and Lean SystemsIrfan Ahmad AwanNo ratings yet

- History of Lean ManufacturingDocument29 pagesHistory of Lean Manufacturingsunilkhairnar38No ratings yet

- Lean Manufacturing and It's Implementation in Automotive IndustryDocument48 pagesLean Manufacturing and It's Implementation in Automotive IndustryshenoyniteshNo ratings yet

- Toyota Lean ManufacturingDocument62 pagesToyota Lean ManufacturingVicente Manuel Angulo GutiérrezNo ratings yet

- Process Selection and Facility Layout: Learning ObjectivesDocument25 pagesProcess Selection and Facility Layout: Learning ObjectivesWinter NaiNo ratings yet

- 0.3. Manufacturing SystemsDocument30 pages0.3. Manufacturing SystemsAkhilesh VarmaNo ratings yet

- Value Stream Mapping & Management - VSMM: Chee HongDocument9 pagesValue Stream Mapping & Management - VSMM: Chee Hongyogesh sharmaNo ratings yet

- Poka-Yoke Lean StrategyDocument82 pagesPoka-Yoke Lean Strategypablo7890100% (1)

- Value Stream Mapping: Bill Paolucci Ipfw March 17, 2009Document73 pagesValue Stream Mapping: Bill Paolucci Ipfw March 17, 2009AkNo ratings yet

- Vs M PresentationDocument73 pagesVs M PresentationMaiNo ratings yet

- Lean 2012Document25 pagesLean 2012AlexandruNo ratings yet

- JITDocument31 pagesJITmanojbhatia1220No ratings yet

- LEAN SCM Hidden FactoryDocument33 pagesLEAN SCM Hidden FactoryJulian KalacNo ratings yet

- Backlog ManagementDocument28 pagesBacklog ManagementMaximo SupportNo ratings yet

- DAY2Document30 pagesDAY2AKSHAY NANGIANo ratings yet

- IDM Basic Training IntroductionDocument33 pagesIDM Basic Training IntroductionThomas DuNo ratings yet

- Lean Manufacturing and It's Implementation in Automotive IndustryDocument48 pagesLean Manufacturing and It's Implementation in Automotive IndustryshenoyniteshNo ratings yet

- The Lean Enterprise: Lean Foundations Continuous Improvement TrainingDocument28 pagesThe Lean Enterprise: Lean Foundations Continuous Improvement TrainingPablo Riquelme GonzálezNo ratings yet

- ATCO Make To Stock (MTS) Business FlowDocument36 pagesATCO Make To Stock (MTS) Business FlowSharif AshaNo ratings yet

- Chapter Two Lean Production SystemDocument31 pagesChapter Two Lean Production SystemIslam Abdou AbbasNo ratings yet

- JIT & LeanDocument90 pagesJIT & LeanPedro Augusto Ribeiro MartinsNo ratings yet

- Lean ProductionDocument31 pagesLean ProductionAshish Chatrath100% (2)

- TPM 5S TrainingDocument69 pagesTPM 5S Trainingruchikaporwal2018No ratings yet

- 1) Slide - Deck - BBA-S1Document47 pages1) Slide - Deck - BBA-S1ChristopherNo ratings yet

- Fundamental Simulation Concepts (Chapter 2)Document46 pagesFundamental Simulation Concepts (Chapter 2)Yến Oanh Nguyễn LêNo ratings yet

- MOS TESTING TITLESDocument76 pagesMOS TESTING TITLESIndri YensiNo ratings yet

- Operation Management Class NotesDocument16 pagesOperation Management Class NotesMónica DuránNo ratings yet

- Creating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowFrom EverandCreating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowRating: 4 out of 5 stars4/5 (1)

- IT Success!: Towards a New Model for Information TechnologyFrom EverandIT Success!: Towards a New Model for Information TechnologyRating: 3 out of 5 stars3/5 (1)

- Mabsap/p Jun-Xio.: Bria ActonDocument8 pagesMabsap/p Jun-Xio.: Bria ActonAnkurNo ratings yet

- Merton Truck CompanyDocument7 pagesMerton Truck CompanySiddhantNo ratings yet

- User Input %age Weightage Calculated Values Uers Has To PutDocument8 pagesUser Input %age Weightage Calculated Values Uers Has To PutAnkurNo ratings yet

- Manish - GSCM ENT - ASSIGN - 2Document3 pagesManish - GSCM ENT - ASSIGN - 2AnkurNo ratings yet

- THE GOAL MounikaPanthala 1806012Document5 pagesTHE GOAL MounikaPanthala 1806012AnkurNo ratings yet

- JH - Hta & SocDocument31 pagesJH - Hta & SocAnkurNo ratings yet

- Case 1 Xiaomi Final Group 10Document7 pagesCase 1 Xiaomi Final Group 10AnkurNo ratings yet

- Fundamentals of LEAN ManufacturingDocument111 pagesFundamentals of LEAN ManufacturingAnkur50% (2)

- Baby Shower GameDocument1 pageBaby Shower GameAnkurNo ratings yet

- AviralBhatnagar CATPreparationDocument77 pagesAviralBhatnagar CATPreparationJasmine SahooNo ratings yet

- ZerodhaTD PDFDocument21 pagesZerodhaTD PDFRitesh RK MeshramNo ratings yet

- 600 Forms Editing! 2Document570 pages600 Forms Editing! 2widodo dp96% (24)

- Press Release NITIE PlacementsDocument13 pagesPress Release NITIE PlacementsscienceplexNo ratings yet

- 42,0410,0192Document212 pages42,0410,0192René López Victoria EscobarNo ratings yet

- Battery StorageDocument46 pagesBattery StorageKishore MuluguNo ratings yet

- Data Sheet - Ozone Generator Water SystemDocument3 pagesData Sheet - Ozone Generator Water SystemleeNo ratings yet

- Huawei CloudEngine S5731-H Series Switches BrochureDocument13 pagesHuawei CloudEngine S5731-H Series Switches BrochureMurillo SilvaNo ratings yet

- Vas 5052 Vehicle Diagnostic Tool ManualDocument32 pagesVas 5052 Vehicle Diagnostic Tool Manualautool100% (2)

- Katalog Defro - en 01 - 2022Document36 pagesKatalog Defro - en 01 - 2022Octavian MrejeruNo ratings yet

- Boolean Searching LessonDocument14 pagesBoolean Searching LessonPradeep Dhar100% (1)

- Cat OptoNCDT en UsDocument40 pagesCat OptoNCDT en UsDaniel FredianiNo ratings yet

- Entes CatalogueDocument154 pagesEntes CatalogueShvan NajeebNo ratings yet

- Key Plan:: North True NorthDocument1 pageKey Plan:: North True Northraj vaddiNo ratings yet

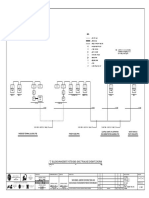

- Building Management System (BMS) Basic Trunkline Schematic Diagram 2Document3 pagesBuilding Management System (BMS) Basic Trunkline Schematic Diagram 2Anonymous NcB95G6XwNo ratings yet

- A Corona Ring Is A Conducting Ring Mounted On The End of or RadiallyDocument6 pagesA Corona Ring Is A Conducting Ring Mounted On The End of or RadiallygopalNo ratings yet

- Vocalist Live 4 - Owner's Manual (English)Document38 pagesVocalist Live 4 - Owner's Manual (English)Zeca VieiraNo ratings yet

- Fashion Tech ParkDocument5 pagesFashion Tech ParkMohamed ArzathNo ratings yet

- Pelton Turbine Operation and DesignDocument22 pagesPelton Turbine Operation and DesignManuel CaipoNo ratings yet

- Replacement AlgoDocument13 pagesReplacement AlgoTejaswi SuryaNo ratings yet

- Garmin G5: Electronic Flight Instrument Part 23 AML STC Installation ManualDocument202 pagesGarmin G5: Electronic Flight Instrument Part 23 AML STC Installation ManuallocoboeingNo ratings yet

- RFID Reader Using ArduinoDocument4 pagesRFID Reader Using ArduinoInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- SAP License DefinitionsDocument1 pageSAP License DefinitionsshubendubarweNo ratings yet

- Directional Driller X CVDocument2 pagesDirectional Driller X CVMino MinoNo ratings yet

- History of Suspension SystesmDocument6 pagesHistory of Suspension Systesmmangutkar_amit67% (3)

- Good job definition and synonyms from Macmillan DictionaryDocument1 pageGood job definition and synonyms from Macmillan DictionarykrishnaNo ratings yet

- Question Paper 2 PDFDocument4 pagesQuestion Paper 2 PDFfotickNo ratings yet

- Week 3 L4 (Design Thinking)Document16 pagesWeek 3 L4 (Design Thinking)buy inviteeNo ratings yet

- Empowerment Technologies Q3 M13Document16 pagesEmpowerment Technologies Q3 M13Joanne Marielle Veloria100% (1)

- Q Series Patient Monitor Service Manual: Guangdong Biolight Meditch Co,.LtdDocument60 pagesQ Series Patient Monitor Service Manual: Guangdong Biolight Meditch Co,.LtdJuan CastroNo ratings yet

- Using The Intel® License Manager For Flexlm : All Rights Reserved Issued in U.S.A. Document Number: 251879-005Document14 pagesUsing The Intel® License Manager For Flexlm : All Rights Reserved Issued in U.S.A. Document Number: 251879-005gingaNo ratings yet

- The Contribution of Electronic Marketing in The Increment of Grape Sales in Dodoma A Study of Bihawana and Mpunguzi VillageDocument5 pagesThe Contribution of Electronic Marketing in The Increment of Grape Sales in Dodoma A Study of Bihawana and Mpunguzi VillageInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- DVR QT 560 SeriesDocument4 pagesDVR QT 560 SeriesmarcosgarnicaNo ratings yet

- Siemens SMSCP FAQ + InformationDocument3 pagesSiemens SMSCP FAQ + Informationobaidur_rehman_3No ratings yet