Professional Documents

Culture Documents

RCA - Amine Foaming

Uploaded by

Boussebha Noureddine0 ratings0% found this document useful (0 votes)

12 views1 pageCopyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views1 pageRCA - Amine Foaming

Uploaded by

Boussebha NoureddineCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 1

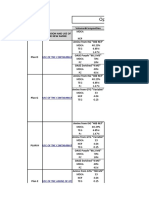

Foaming

Triggering factors Stabilising factors

Hydrocarbon Solids Other Hydraulics Free antifoam Presence of F

D E

contamination A contamination B Organics? C Stabilising agent

Operating level D1 Excessive injection

Free cellulose

Turndown D2 Poor antifoam design

B1 C1 or selection Viscosity of Amine

R/grade cond. inside A1 Charcoal particles Treatment product of

absorber cellulose or cartridge filters Gas blown into liq. D3

B2 Poor anti-foam mixing

Corrosion product

(iron sulphide/carbonate C2 Pump mini flow D4

Op. temp (approach)/P Residual wash/steam fluids Filtering/Skimming reqts.

B3

Other degradation product

Phase envelope

C3

Internal leak/ X-contamination

Particles present in

A2 B4 (e.g heat exchanger, lube/hot oil)

Free HC in inlet original Amine

stream C4 Amine strength

In-situ precipitates B5 Hoses

Dew point control C5 Amine oxidation

Particles c/over from u/s Salt of Glycolic/Acid

Mist, Other? units B6 Amine temperature

Emulsifier from C6

Carry-over Cellulose particle B7 (MX-1931) antifoam

residue

BTX A3 BTX C7

Particles introduce thru

tools (hoses, pumps) B8 C8

Wells (ODZ-13?)

well interventions fluids

You might also like

- Lip Mud CC-FR-21-006-K12Document2 pagesLip Mud CC-FR-21-006-K12Emilio HipolaNo ratings yet

- Inz 2K Polyaspartics Topcoat White GuideDocument2 pagesInz 2K Polyaspartics Topcoat White GuideOswaldo Manuel Ramirez Marin100% (1)

- Defect Identification Reference For Steel Sheet Metals PDFDocument82 pagesDefect Identification Reference For Steel Sheet Metals PDFNOOB GAMENo ratings yet

- Trico Bond EpDocument2 pagesTrico Bond EpBrandon TrocNo ratings yet

- Chemical Additives Oil and GasDocument18 pagesChemical Additives Oil and GasWilson WanNo ratings yet

- Moisturizing Daily Care With UV Protection, SPF 10: Ciba Specialty ChemicalsDocument2 pagesMoisturizing Daily Care With UV Protection, SPF 10: Ciba Specialty ChemicalsYulis AdrianaNo ratings yet

- Additives ReferenceDocument19 pagesAdditives ReferenceWilson Wan100% (1)

- Chemical Compatibility Results From Cole-Parmer IndiaDocument2 pagesChemical Compatibility Results From Cole-Parmer Indiapraval84No ratings yet

- Aplicación de Válvulas Macho en La PPIDocument26 pagesAplicación de Válvulas Macho en La PPIPablo Santa CruzNo ratings yet

- 2c Polyaspartic Anticorrosion CoatingsDocument2 pages2c Polyaspartic Anticorrosion CoatingsmajidhajnasrNo ratings yet

- Product Catalogue FujiDocument11 pagesProduct Catalogue FujiMotaz AL-THAHERNo ratings yet

- Technical Information Chemical Compatibility: Inspired by ChallengeDocument16 pagesTechnical Information Chemical Compatibility: Inspired by Challengeyrdna nawaiteosNo ratings yet

- DI Water Compatibility Chart - Greg ReynekeDocument5 pagesDI Water Compatibility Chart - Greg ReynekeneivaprojetosNo ratings yet

- LF 200 F Bulletin 2015 NDocument2 pagesLF 200 F Bulletin 2015 NAlexander Franco CastrillonNo ratings yet

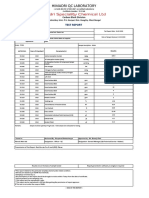

- Special Sample OF 14-2020Document1 pageSpecial Sample OF 14-2020PLASTIC LAB CBDNo ratings yet

- LT1I 8G GREASE CLASSIFICATION SlideshowDocument3 pagesLT1I 8G GREASE CLASSIFICATION SlideshowkevinNo ratings yet

- Drilling fluid product reference table section 16Document34 pagesDrilling fluid product reference table section 16Ejaz ul Haq kakarNo ratings yet

- BNT 2Document3 pagesBNT 2ahetesham marufNo ratings yet

- Technical Specification: Submersible Pump B 2066, 60 HZDocument8 pagesTechnical Specification: Submersible Pump B 2066, 60 HZSebastian Amézaga ZegarraNo ratings yet

- Limpiador y Abrillantador para Interiores de AutosDocument1 pageLimpiador y Abrillantador para Interiores de AutosJuly CapilloNo ratings yet

- LeadAcidBatterymanufacturingProcess ModelDocument1 pageLeadAcidBatterymanufacturingProcess ModelOtuzuma BakerNo ratings yet

- Coperion ZSK RangeDocument6 pagesCoperion ZSK RangeXuân Giang NguyễnNo ratings yet

- Hitec 523f PdsDocument2 pagesHitec 523f PdsPiaoNo ratings yet

- Hq153en Balinit-Dlc SeriesDocument4 pagesHq153en Balinit-Dlc SeriesJoão TarelhoNo ratings yet

- Block Diagram Nitric AcidDocument4 pagesBlock Diagram Nitric AcidBatrisyia AtikahNo ratings yet

- Eni Lamium 11C Is A Highly RefinedDocument2 pagesEni Lamium 11C Is A Highly RefinedSou MadaNo ratings yet

- V TypeDocument3 pagesV Typemikael8118No ratings yet

- Castrol Product Training: It'S More Than Just Oil. It'S Liquid EngineeringDocument106 pagesCastrol Product Training: It'S More Than Just Oil. It'S Liquid EngineeringFerry Marketing SekafuNo ratings yet

- Technical Specification: Submersible Pump B 2066, 50 HZDocument8 pagesTechnical Specification: Submersible Pump B 2066, 50 HZSebastian Amézaga ZegarraNo ratings yet

- Ultimeg Guidetoselection PDFDocument4 pagesUltimeg Guidetoselection PDFArif dwi prasetyoNo ratings yet

- Literature Preempt Material CompatibilityDocument2 pagesLiterature Preempt Material CompatibilityNatalia AlmaguerNo ratings yet

- Aniline PFDDocument1 pageAniline PFDkeyur11090% (1)

- Fish Bone - Skip Plating Ishikawa Poly PuneDocument3 pagesFish Bone - Skip Plating Ishikawa Poly Puneshivakumar ctNo ratings yet

- LF200 TDSDocument3 pagesLF200 TDSRobert SkibaNo ratings yet

- Corrosion Data: Rating ExplanationDocument12 pagesCorrosion Data: Rating ExplanationErick Emma SánchezNo ratings yet

- 10A Schottky Barrier Rectifier Features: PowerdiDocument3 pages10A Schottky Barrier Rectifier Features: PowerdiDiego De La FuenteNo ratings yet

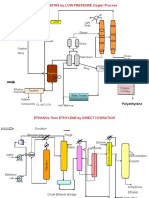

- POLY-OLEFINS by LOW PRESSURE Ziegler Process: Aluminum Alkyl Drier Light Ends DiluentDocument3 pagesPOLY-OLEFINS by LOW PRESSURE Ziegler Process: Aluminum Alkyl Drier Light Ends Diluentessakkiraj.mNo ratings yet

- OxoneDocument2 pagesOxoneSha Hriyar HNo ratings yet

- Steposol MET-10U: Technical InformationDocument3 pagesSteposol MET-10U: Technical Informationpkh29No ratings yet

- Chromate-Free Exterior Coil Coating Primer - HALOX 650 - 2Document1 pageChromate-Free Exterior Coil Coating Primer - HALOX 650 - 2Yousef LotfyNo ratings yet

- Sands and Sandstones Matrix Permeability: Flow Chart To Select Non-Damaging Horizontal Drill-In FluidDocument9 pagesSands and Sandstones Matrix Permeability: Flow Chart To Select Non-Damaging Horizontal Drill-In FluidaliNo ratings yet

- 06_SAFE OPERATIONDocument7 pages06_SAFE OPERATIONferdinanNo ratings yet

- Chevron product loading sequence chartDocument1 pageChevron product loading sequence chartMartin Andrew TugadeNo ratings yet

- Pages From DRY POWDER EXTINGUIHSERS UL LISTED - PDF - Adobe Acrobat Pro ExtendedDocument1 pagePages From DRY POWDER EXTINGUIHSERS UL LISTED - PDF - Adobe Acrobat Pro ExtendedAmeen Hamed AlwseyNo ratings yet

- Compound Selection Guide for Chemical ResistanceDocument6 pagesCompound Selection Guide for Chemical ResistanceRolando DoderoNo ratings yet

- ISO TITLEDocument4 pagesISO TITLEOswaldo Manuel Ramirez Marin100% (2)

- Inz 2-Polyaspartics Clear Floor Coating - 036 (Zero VOC)Document2 pagesInz 2-Polyaspartics Clear Floor Coating - 036 (Zero VOC)Vaittianathan MahavapillaiNo ratings yet

- CRC SL3640Document1 pageCRC SL3640AGSMotoVlog 06No ratings yet

- Miscellaneous ColaMine AlkanolamidesDocument1 pageMiscellaneous ColaMine AlkanolamidesmndmattNo ratings yet

- 27 2721 01 A Hair OilDocument2 pages27 2721 01 A Hair OilRahul mishraNo ratings yet

- Tannery Industry 2Document7 pagesTannery Industry 2kavya1811No ratings yet

- Tannery Industry 2Document7 pagesTannery Industry 2kavya1811No ratings yet

- AGENA Oil & Gas CatalogDocument1 pageAGENA Oil & Gas CatalogJose Luiz AlvesNo ratings yet

- Heat Exchangers: Corrosion ResistantDocument16 pagesHeat Exchangers: Corrosion ResistantIsaac IglesiasNo ratings yet

- PROCFLOWCHART (Sindo)Document1 pagePROCFLOWCHART (Sindo)Tony CeNo ratings yet

- Dow Corning 983Document3 pagesDow Corning 983antoineNo ratings yet

- 50at Fliter Catalog and User ManualDocument8 pages50at Fliter Catalog and User ManualGustavo CardenasNo ratings yet

- SolvonPB TDS ResourcesDocument2 pagesSolvonPB TDS ResourcesSelvakumar NatarajanNo ratings yet

- Raffinage des corps gras: objectifs, procédés d'élimination des contaminantsDocument14 pagesRaffinage des corps gras: objectifs, procédés d'élimination des contaminantsBoussebha NoureddineNo ratings yet

- Raffinage des corps gras: objectifs, procédés d'élimination des contaminantsDocument14 pagesRaffinage des corps gras: objectifs, procédés d'élimination des contaminantsmguisseNo ratings yet

- 03 Imec Apm PaperDocument5 pages03 Imec Apm PaperSandeep KumarNo ratings yet

- CPF Overall Start-Up and Mercury De-Sorption Operation: GTG-EXP-000-EXP-PRO-0010Document19 pagesCPF Overall Start-Up and Mercury De-Sorption Operation: GTG-EXP-000-EXP-PRO-0010Boussebha NoureddineNo ratings yet

- Operating Risk Assessment: Use of The Contaminated Amine From Isg With Oase Enriched and PurpleDocument6 pagesOperating Risk Assessment: Use of The Contaminated Amine From Isg With Oase Enriched and PurpleBoussebha NoureddineNo ratings yet

- Key personnel and contacts at CTADocument4 pagesKey personnel and contacts at CTABoussebha NoureddineNo ratings yet

- Streamlined Document for Hydrocarbon Processing PlantDocument19 pagesStreamlined Document for Hydrocarbon Processing PlantBoussebha NoureddineNo ratings yet

- GTG-EXP-000-EXP-PRO-0010 - Desorption Procedure Rev 01Document19 pagesGTG-EXP-000-EXP-PRO-0010 - Desorption Procedure Rev 01Boussebha NoureddineNo ratings yet

- Operating Risk Assessment: Use of The Contaminated Amine From Isg With Oase Enriched and PurpleDocument6 pagesOperating Risk Assessment: Use of The Contaminated Amine From Isg With Oase Enriched and PurpleBoussebha NoureddineNo ratings yet

- Carbon Bed Change Out Procedure 1Document2 pagesCarbon Bed Change Out Procedure 1Boussebha NoureddineNo ratings yet

- Risks DO's & DON'Ts: Inhibits Without Permission - Mechanical DamageDocument9 pagesRisks DO's & DON'Ts: Inhibits Without Permission - Mechanical DamageBoussebha NoureddineNo ratings yet

- Labcir - Marwa - FinalDocument119 pagesLabcir - Marwa - FinalMashavia AhmadNo ratings yet

- ES Model Question Paper With Solution KeyDocument10 pagesES Model Question Paper With Solution Keyvidhya_bineeshNo ratings yet

- React Rich Text EditorDocument3 pagesReact Rich Text Editordhirendrapratapsingh398No ratings yet

- Tata Steel-MDP SessionDocument69 pagesTata Steel-MDP Sessionsasharma82No ratings yet

- African in The Modern WorldDocument18 pagesAfrican in The Modern WorldSally AnkomaahNo ratings yet

- Ejc-M13 - FN953205Document203 pagesEjc-M13 - FN953205JoséNo ratings yet

- Eddy Current Testing Exam Questions Assignment2Document1 pageEddy Current Testing Exam Questions Assignment2Narotam Kumar GupteshwarNo ratings yet

- Linkstar RCST Installation Guide: Version DDocument56 pagesLinkstar RCST Installation Guide: Version Djorge_chavez01No ratings yet

- Radiographic Examination Procedure For Asme CodeDocument33 pagesRadiographic Examination Procedure For Asme CodeEdAlmNo ratings yet

- Exercise 1: Chọn đáp án đúng:: Buổi 9: Động từ khuyết thiếu (Modal verb)Document6 pagesExercise 1: Chọn đáp án đúng:: Buổi 9: Động từ khuyết thiếu (Modal verb)Huyền HồNo ratings yet

- T e 2552674 Percy Polls Peculiar Plants Fiction Year 5 Reading Comprehension - Ver - 5Document20 pagesT e 2552674 Percy Polls Peculiar Plants Fiction Year 5 Reading Comprehension - Ver - 5mariam osamaNo ratings yet

- dgx670 Es Om b0Document116 pagesdgx670 Es Om b0rafael enrique cely rodriguezNo ratings yet

- Gripper of FTV Invisio Panels For Horizontal FacadeDocument16 pagesGripper of FTV Invisio Panels For Horizontal FacadefghfNo ratings yet

- 3152-4 Data SheetDocument2 pages3152-4 Data SheetPhuongNguyenDinhNo ratings yet

- Sustainability - Research PaperDocument18 pagesSustainability - Research PapermrigssNo ratings yet

- B1 UDO Trace LogDocument14 pagesB1 UDO Trace LogCh M KashifNo ratings yet

- Gen Z WhitepaperDocument13 pagesGen Z Whitepaperjurgute2000No ratings yet

- 3ms Squence 3 (Summary)Document3 pages3ms Squence 3 (Summary)toumi khadidjaNo ratings yet

- E-Way BillDocument1 pageE-Way BillShriyans DaftariNo ratings yet

- Aling Presing ChichacornDocument2 pagesAling Presing ChichacornMhel Joshua Bautista HermitanioNo ratings yet

- Quickguide Students For CopyrightsDocument2 pagesQuickguide Students For Copyrightslordvorldomort100% (1)

- At GN4Document1 pageAt GN4jazzvivekNo ratings yet

- Philippine Christian University Graduate School of Business and Management Integrated Syllabi ModuleDocument5 pagesPhilippine Christian University Graduate School of Business and Management Integrated Syllabi ModuleRoselle Anne Luna GuatatoNo ratings yet

- Studentwise Final Placement DetailsLast 3 YearsDocument18 pagesStudentwise Final Placement DetailsLast 3 YearsAmitNo ratings yet

- Som-Ii Uqb 2019-20Document23 pagesSom-Ii Uqb 2019-20VENKATESH METHRINo ratings yet

- Micro800 4-Channel and 8-Channel Analog Voltage/Current Input and Output ModulesDocument12 pagesMicro800 4-Channel and 8-Channel Analog Voltage/Current Input and Output ModulesSyarifudin WahidNo ratings yet

- ISO 9000 Standards Guide Quality Systems InternationallyDocument12 pagesISO 9000 Standards Guide Quality Systems InternationallyArslan Saleem0% (1)

- Pharmacy Perspective on Improving Patient SafetyDocument44 pagesPharmacy Perspective on Improving Patient SafetydicodrNo ratings yet

- Filed & Entered: SBN 143271 SBN 165797 SBN 259014Document8 pagesFiled & Entered: SBN 143271 SBN 165797 SBN 259014Chapter 11 DocketsNo ratings yet

- Report-Teaching English Ministery of EduDocument21 pagesReport-Teaching English Ministery of EduSohrab KhanNo ratings yet