Professional Documents

Culture Documents

Orifice Meter & Barton Recorder

Uploaded by

Noor AliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Orifice Meter & Barton Recorder

Uploaded by

Noor AliCopyright:

Available Formats

Orifice meter

and

Barton recorder

by Wang Wenqi

Well Testing Company

GWDC

2013-5

2013 well testing training, Tarim, China

contents

Part 1: Preface(3-5)

Part 2: Orifice meter(6-31)

Part 3: Barton recorder(32-38)

Part 4: Orifice meter operation(39-46)

2013 well testing training, Tarim, China

Part 1:

Preface

2013 well testing training, Tarim, China

Gas measurement methods

• orifice meter ( 孔板流量计 )

• orifice well tester ( 垫圈流量计,又译锐孔测试器,国内又称低压放空测气

法)

• critical flowmeter ( 临界流速流量计 )

• choke nipple ( 节流油嘴 ), similar with critical flowmeter

• flow nozzle ( 喷嘴流量计,又译流量喷嘴 )

• Venturi tube ( 文丘里管 )

• Pitot tube ( 皮托管 )

• elbow meter ( 弯管流量计,又叫离心式流量计 )

• turbine flowmeter ( 涡轮流量计 )

• mass flowmeter ( 各种质量流量计 )

• positive displacement meter ( 容积式流量计 )

• liquid displacing in vertical separator ( 立式分离器排液测气法 )

• friction way ( 管线摩阻法 )

• obturation way ( 密闭测气法 )

…

2013 well testing training, Tarim, China

common methods

• orifice meter ( 孔板流量计 ) , most useful

• orifice well tester ( 垫圈流量计 )

• critical flowmeter ( 临界流速流量计 )

• choke nipple ( 节流油嘴 ), similar with critical

flowmeter

2013 well testing training, Tarim, China

Part 2:

orifice meter

2013 well testing training, Tarim, China

Varieties of orifice meter

• Daniel, common used

• North Star (→Nu Flo). Wespro & Porta-Test separators

• China National, SY standard

2013 well testing training, Tarim, China

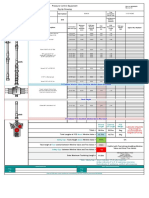

Daniel orifice meter

2013 well testing training, Tarim, China

North Star orifice meter

2013 well testing training, Tarim, China

installing

position

of

orifice

meter

2013 well testing training, Tarim, China

Daniel

orifice

meter

2013 well testing training, Tarim, China

Daniel orifice meter

and recorder

2013 well testing training, Tarim, China

carrier seal Orifice plate

Daniel

orifice

meter

2013 well testing training, Tarim, China

Orifice plate

API standard

The upstream edge of the orifice

plate bore shall be square and

sharp.

The orifice plate bore edge is

considered too dull for

accurate flow measurement if the

upstream edge reflects a beam of

light when viewed without

magnification or if the upstream

edge shows a beam of light when

checked with an orifice edge

gauge.

2013 well testing training, Tarim, China

Orifice plate

SY/T 6143

standard

The upstream edge of the orifice

plate bore shall be square and

sharp.

If d≥25mm, the upstream edge

can’t reflects a beam of light when

viewed without magnification;

if d < 25mm, need rk≤0.0004d,

otherwise, add a modificatory

factor bk in calculation formula.

2013 well testing training, Tarim, China

Two kinds of seal (holder)

rubber

Teflon: H2S

2013 well testing training, Tarim, China

Daniel orifice meter: dissected

2013 well testing training, Tarim, China

Daniel

orifice

meter:

structure

2013 well testing training, Tarim, China

USA: pressure taps

American Gas Association: Report No. 3,

Gas Processors Association: GPA 8185-00,

API: Manual of Petroleum Measurement Standards, Chapter 14.3

Three types of taps to take flowing pressure

• Flange taps( 法兰取压 ). Be used on all kinds of CNLC’s

separators

• Vena contracta taps( 缩流取压,理论取压 ). Used rarely

• Pipe taps. ( 管子取压 )

2013 well testing training, Tarim, China

The diameter of the pressure tap holes

shall be 3⁄8 inch for pipe with a

Flange Taps nominal diameter of 2 or 3 inches;

shall be 1⁄2 inch for pipe with a

API standard

nominal diameter of 4 inches or more.

2013 well testing training, Tarim, China

Flange Taps API standard

Flange taps are a pair of tap holes positioned as follows :

• The upstream tap center is located 1 inch upstream

of the nearest plate face.

• The downstream tap center is located 1 inch

downstream of the nearest plate face.

• The upstream and downstream taps must be in the

same radial position.

2013 well testing training, Tarim, China

Orifice Tapping Location

2013 well testing training, Tarim, China

Vena contracta taps & Pipe taps

Flange Taps

Vena contracta taps

Pipe Taps

2013 well testing training, Tarim, China

China: pressure taps

SY/T 6143 - 1996: standard orifice measurement methods for natural gas flow

Two types of taps to take flowing pressure

• 角接(角节?)取压: angular pitch taps

单独钻孔取压 : independent hole taps

环隙取压 : annular slot taps

• 法兰取压 Flange taps. Same with API standard

----------------------------------------------------------------------------------------------

-

Other types of taps used in non-SY standards:

• 缩流取压 Vena contracta taps. D—0.84D ~ 0.34D when d / D=0.l 一

0.8. Used in some homemade meter, but not mentioned in SY/T 6143

• 径距取压 D - D/2 taps. Used by some homemade meter, but not

mentioned in SY/T 6143

• 管子取压或管接取压 Pipe taps. ( 2.5 D — 8 D )

2013 well testing training, Tarim, China

Flange taps The diameter of the

pressure tap hole shall be

SY/T 6143 - 1996 smaller than 0.13D and

13mm

2013 well testing training, Tarim, China

Flange Taps SY/T 6143 - 1996

Flange taps are a pair of tap holes positioned as follows:

• The upstream tap center is located 1 inch upstream of the

nearest plate face.

• The downstream tap center is located 1 inch downstream

of the nearest plate face.

• The upstream and downstream taps must be in the same

radial position.

2013 well testing training, Tarim, China

角接取压

(单独钻孔取压和环隙取压)

SY/T 6143 - 1996

When diameter ratio (d/D)

β≤0.65, 0.005D≤a≤0.03D;

β > 0.65, 0.01D

≤a≤0.02D

2013 well testing training, Tarim, China

pressure taps for orifice meter( 孔板流量计取压方式一览表 )

D: meterrun ID, d: orifice size

American Gas Association:Report No.3, China petroleum

upstream some

取压方式 downstream hole center Gas Processors Association:GPA 8185-00, & gas industry CNLC

hole center homemade

pressure taps to orifice API:Manual of Petroleum Measurement Standards, standard: separators

to orifice meters

Chapter 14.3 SY/T 6143

单独钻孔取压

角接取

independent hole

压

taps?

angular 0.5 tap 0.5 tap ●

环隙取压:

pitch

annular slot

taps?

taps?

法兰取压

1 inch 1 inch ● ● ●

Flange taps

理论取压(缩流取压) 0.84 D~0.34 D

D ● ●

Vena contracta taps (when d/D=0.l~0.8)

径距取压

D 0.5 D ●

diameter distance taps

管接取压(管线取压、

2.5 D 8 D ●

管子取压)pipe taps

2013 well testing training, Tarim, China

目前取压方式有如下五种

1. 角接取压法:上下游侧取压孔中心至孔板前后端面的间距各等于取压孔径的一

半;如果用环室取压时等于环隙宽度的一半。

2. 法兰取压法:上下游取压孔中心至孔板前后后端面的间距均为 25.4±0.8mm 或

叫作“ 1 英寸法兰取压法”

3. 理论取压(缩流取压)法:上游的取压孔中心至孔板前端面距离等于管道内径,

下游的取压孔中心至孔板前端面的间距取决孔板孔径与管道内径比值 d / D ,

如 d / D 在 0.l 一 0.8 时取压孔位置分别在 0.84D ~ 0.34D 范围内变动。

4. 径距取压:上游取压孔中心至孔板前端面的间距为 D ,下游取压孔中心至孔

板前端面间距为 D/2 。

5. 管接取压法:上游取压孔中心至孔板前端面为 2.5D ,下游取压孔中心至孔板

后端面为 8D 。

—— 《 传感器与仪表论坛》

2013 well testing training, Tarim, China

straightening vanes

2013 well testing training, Tarim, China

straightening

vanes:

cross section

2013 well testing training, Tarim, China

Part 3:

Barton recorder

2013 well testing training, Tarim, China

Barton

recorder

2013 well testing training, Tarim, China

Daniel orifice meter

and recorder

2013 well testing training, Tarim, China

Barton

Recorder

with

Differential

Pressure

Unit

2013 well testing training, Tarim, China

Barton

Recorder

2013 well testing training, Tarim, China

Differential

Pressure

Unit

2013 well testing training, Tarim, China

Differential Pressure Unit

2013 well testing training, Tarim, China

Part 4:

Orifice meter operation

2013 well testing training, Tarim, China

Steps to Install a Selected Orifice Plate

2013 well testing training, Tarim, China

Daniel

orifice

meter:

structure

2013 well testing training, Tarim, China

Install a selected orifice plate

14 Open Barton manifold valves to equalize the pressure across the Barton.

15 Install a orifice plate to gas meter, follow the below steps (suppose the carrier is

in upper chamber):

15.1 Make sure the sliding door is closed.

15.2 Make sure the equalizer valve is closed.

15.3 Open the bleeder valve to relieve pressure in upper chamber.

15.4 Lubricate with Daniels grease to make a seal between top valve and valve strip.

15.5 Loose the bar screws and draw off the clamping bar.

15.6 Rotate the upper shaft (counter clockwise) to lift up (or free) sealing bar and

gasket.

15.7 Remove clamping bar, sealing bar and gasket.

15.8 Rotate the plate carrier completely out. Take out plate.

15.9 Install a new plate correctly in holder.

15.10 Install the plate holder correctly in the carrier.

15.11 Place the carrier evenly into upper chamber and engage with upper shaft and

pinions.

15.12 Rotate the plate carrier down with the upper shaft (clockwise) until carrier is

just below where the sealing bar and gasket will sit.

2013 well testing training, Tarim, China

Install a selected orifice plate (continued)

15.13 Inspect the gasket and make sure it is in good shape, replace after every third

operation.

15.14 Replace the gasket, sealing bar and clamping bar.

15.15 Tighten down the clamping bar screws in a staggered pattern.

15.16 Make sure the bleeder valve is closed.

15.17 Open the equalizer valve to allow pressure into the top chamber.

15.18 Open the slide valve gate.

15.19 Rotate the upper shaft to move the carrier down and engage the bottom shaft.

15.20 Rotate the lower shaft to move the plate carrier completely down into the

meter run.

15.21 Close the sliding door.

15.22 Close the equalizer valve.

15.22 Open the bleeder valve to relieve pressure in the top chamber.

15.24 Lubricate if necessary.

15.25 After the pressure is relieved, close the bleeder valve.

16 Close the Barton manifold valves and observe differential pressure point on

recorder range of 30%-70%.

2013 well testing training, Tarim, China

Note

Before changing choke bean at choke manifold,

ensure lift orifice plate and by pass separator. After

the flow is stable, pass it to separator and make

sure the suitable orifice.

2013 well testing training, Tarim, China

Steps to change orifice plate

14 Open Barton manifold valves to equalize the pressure across the Barton.

15 Install a selected orifice plate to gas meter, follow the below steps:

15.1 Close the bleeder valve.

15.2 Open the equalizer valve to allow pressure into the upper chamber.

15.3 Rotate the lower shaft to move the plate carrier up and engage the up shaft.

15.4 Rotate the upper shaft to move the carrier up to the upper chamber.

15.5 Close the sliding door.

15.6 Close the equalizer valve.

Following steps are same with above 15.3--15.24

…

16 Close the Barton manifold valves and observe differential pressure point on

recorder range

2013 well testing training, Tarim, China

2013 well testing training, Tarim, China

You might also like

- Hydrocarbon Fluid Inclusions in Petroliferous BasinsFrom EverandHydrocarbon Fluid Inclusions in Petroliferous BasinsNo ratings yet

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsFrom EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsNo ratings yet

- Production Logging and Its Implementation: A Technical ReviewDocument10 pagesProduction Logging and Its Implementation: A Technical ReviewghufranNo ratings yet

- 6 MandrelsDocument17 pages6 MandrelsEduardoWireNo ratings yet

- Abrassive Perforating Via Coiled Tubing RevisitedDocument4 pagesAbrassive Perforating Via Coiled Tubing RevisitedRachel PanjaitanNo ratings yet

- Well Intervention CoilHose A4Document2 pagesWell Intervention CoilHose A4William EvansNo ratings yet

- Tubing Cutter Radial Cutting TorchDocument2 pagesTubing Cutter Radial Cutting Torcharvandi_mahryNo ratings yet

- Coiled Tubing Surface Equipment PPTDocument75 pagesCoiled Tubing Surface Equipment PPTBolsec14No ratings yet

- Wl&fe Unit-4Document40 pagesWl&fe Unit-4Paul AjithNo ratings yet

- Landing Horizontal WellsDocument25 pagesLanding Horizontal Wellssmithyry2014No ratings yet

- 11 SSFC PDFDocument50 pages11 SSFC PDFChaib MaamarNo ratings yet

- PLT-presntation - PDFDocument60 pagesPLT-presntation - PDFEdi Agurto CarrascoNo ratings yet

- COMPLETION DESIGN OVERVIEWDocument22 pagesCOMPLETION DESIGN OVERVIEWAbiodun AkalaNo ratings yet

- Break Out and Laying Down BhaDocument3 pagesBreak Out and Laying Down BhakhurramNo ratings yet

- RPO identification code and data gathering instrumentationDocument1 pageRPO identification code and data gathering instrumentationsnnsnnsnnNo ratings yet

- .Sand Vac - Well VacCleanoutSystems PDFDocument2 pages.Sand Vac - Well VacCleanoutSystems PDFjoseperozo45No ratings yet

- Wellbore Integrity Restoration Services Brochure PDFDocument8 pagesWellbore Integrity Restoration Services Brochure PDFDavid LuhetoNo ratings yet

- PPE I PR 005Document11 pagesPPE I PR 005MahanderOadNo ratings yet

- Case Hole PDFDocument11 pagesCase Hole PDFyazidNo ratings yet

- Wireline (Rev.15.8.12)Document5 pagesWireline (Rev.15.8.12)hNo ratings yet

- Acid-Tunneling Technique Shows Success in Stimulating Carbonate ReservoirsDocument3 pagesAcid-Tunneling Technique Shows Success in Stimulating Carbonate ReservoirsFisher YohannesNo ratings yet

- SLK-PR-06.00 Procedure For Tubing PuncherDocument3 pagesSLK-PR-06.00 Procedure For Tubing PuncherDonald TchiroueNo ratings yet

- XLOT Recommended PracticeDocument5 pagesXLOT Recommended PracticerashidbashirliveNo ratings yet

- Model E Hydraulic Setting ToolDocument1 pageModel E Hydraulic Setting ToolrezaNo ratings yet

- Slick Line Rig UpDocument1 pageSlick Line Rig UpWookie VanNo ratings yet

- SPE-108284-Sucker RodDocument14 pagesSPE-108284-Sucker RodRuben ChirinosNo ratings yet

- Vdocuments - MX MCR Training ManualDocument71 pagesVdocuments - MX MCR Training ManualLina Marcela Monares ToroNo ratings yet

- Asphaltenes & Wax Deposition in Production System & Remedial MeasuresDocument43 pagesAsphaltenes & Wax Deposition in Production System & Remedial MeasuresБатырхан ИзбасарNo ratings yet

- Presentasi Coiled Tubing - Virnando Batu AraDocument20 pagesPresentasi Coiled Tubing - Virnando Batu AraVirnando NainggolanNo ratings yet

- Basic Coiled Tubing Course Part 1Document105 pagesBasic Coiled Tubing Course Part 1Es BahNo ratings yet

- Brochure - NCS Multistage-Unlimited-Pin-point Fracturing - CompressedDocument8 pagesBrochure - NCS Multistage-Unlimited-Pin-point Fracturing - CompressedNightNo ratings yet

- Fs2 Isolation Barrier ValveDocument12 pagesFs2 Isolation Barrier Valvehamed66652No ratings yet

- Slickline Service Tools Part 1Document8 pagesSlickline Service Tools Part 1William EvansNo ratings yet

- U6 - Economic Optimization of Unconventional ReservoirsDocument92 pagesU6 - Economic Optimization of Unconventional ReservoirsWoodoo OodoowNo ratings yet

- Pressure Operated Tester Valve POTVDocument1 pagePressure Operated Tester Valve POTVJeff GanglNo ratings yet

- Log ResponsesDocument1 pageLog ResponsesHamza Lahbiben0% (1)

- Saudi Aramco Running and Setting Procedures ManualDocument14 pagesSaudi Aramco Running and Setting Procedures ManualMahrouz MadoNo ratings yet

- Well Control in CTD OperationsDocument6 pagesWell Control in CTD OperationsAdel Ahmed AlkhaligyNo ratings yet

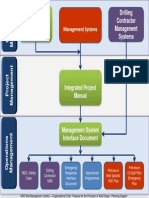

- IPM Flow Chart TempDocument1 pageIPM Flow Chart TempAnonymous U5t9NYzhLWNo ratings yet

- Wellbook PsDocument1 pageWellbook PsjrtnNo ratings yet

- Section 04 - Hole Cleaning PDFDocument41 pagesSection 04 - Hole Cleaning PDFayhamNo ratings yet

- Wellhead and Gate Valve BrochureDocument6 pagesWellhead and Gate Valve BrochureananNo ratings yet

- Production Logging Fundamentals 1667457005Document53 pagesProduction Logging Fundamentals 1667457005macNo ratings yet

- Slickline AcceleratorsDocument1 pageSlickline Acceleratorsasset_kulmagambetovNo ratings yet

- Standard Winche PDFDocument38 pagesStandard Winche PDFChristian Leandro Villarraga GonzalezNo ratings yet

- BasicsDocument170 pagesBasicshoiNo ratings yet

- Alaska Drilling and Wells Recommended Practice: CTD Drilling FluidDocument4 pagesAlaska Drilling and Wells Recommended Practice: CTD Drilling FluidAdel Ahmed AlkhaligyNo ratings yet

- Manual Upct-HDocument131 pagesManual Upct-HJose Antonio Acosta100% (1)

- Slickline Service ToolsDocument2 pagesSlickline Service ToolsAhmed GharbiNo ratings yet

- Formation Pressure Evaluation: Acquisition and InterpretationDocument12 pagesFormation Pressure Evaluation: Acquisition and InterpretationAlejandroMendozaNo ratings yet

- Schlumberger Wireline Tool RatingsDocument4 pagesSchlumberger Wireline Tool RatingsWaleed Barakat MariaNo ratings yet

- Enerjet Spare Part Selection V1.1: General Tool StringDocument1 pageEnerjet Spare Part Selection V1.1: General Tool StringJose Antonio AcostaNo ratings yet

- Gtops CMTD 5669583 02Document10 pagesGtops CMTD 5669583 02Wualdir Martin Vivas ChungaNo ratings yet

- 37 Coiled TubingDocument45 pages37 Coiled TubingBrahim LetaiefNo ratings yet

- Fill Only The Yellow Cells !: Pump Rate Pump RateDocument3 pagesFill Only The Yellow Cells !: Pump Rate Pump RateCristian BarbuceanuNo ratings yet

- Completion Fluid Selection for Minimum Formation DamageDocument45 pagesCompletion Fluid Selection for Minimum Formation DamageWaled Fekry100% (2)

- (I) SLP22 ct09-LMDocument36 pages(I) SLP22 ct09-LMMohammed Anis FortasNo ratings yet

- 4 - in and 5-In. Posiset Thru-Tubing Plug (1 - In. Od) : Description FeaturesDocument1 page4 - in and 5-In. Posiset Thru-Tubing Plug (1 - In. Od) : Description Featureshamed1725No ratings yet

- Completion ComponentsDocument28 pagesCompletion ComponentsnabiNo ratings yet

- Paper Scale OnepetroDocument15 pagesPaper Scale OnepetroRani JuliariniNo ratings yet

- Paper PDFDocument7 pagesPaper PDFadeel rafiqNo ratings yet

- Artificial Transmission Line Dec 16Document33 pagesArtificial Transmission Line Dec 16Arindam SenNo ratings yet

- College Physics, 9th Ed.-188-200Document13 pagesCollege Physics, 9th Ed.-188-200Dave ImmanuelNo ratings yet

- ISE ProjectDocument5 pagesISE ProjectChaithanya MohanNo ratings yet

- gg1 Engineer S Controls Classic TrainsDocument1 pagegg1 Engineer S Controls Classic Trainsbaron mNo ratings yet

- TE50 Service ManualDocument133 pagesTE50 Service ManualJeferson SilvaNo ratings yet

- Oil & Gas Accounting 1Document78 pagesOil & Gas Accounting 1jm100% (2)

- Nobels Ab1 Switcher PDFDocument1 pageNobels Ab1 Switcher PDFChristian BrasselNo ratings yet

- T100 Series See-Thru Sight Glass Level GageDocument1 pageT100 Series See-Thru Sight Glass Level Gageadewunmi olufemiNo ratings yet

- 151 SFT3023 Test 1 QuestionDocument6 pages151 SFT3023 Test 1 QuestionNur RynahNo ratings yet

- Biological Nutrient RemovalDocument42 pagesBiological Nutrient RemovalGökhan TurhanNo ratings yet

- Ansi C29 6Document16 pagesAnsi C29 6AlbertoNo ratings yet

- Calculate Power FactorDocument2 pagesCalculate Power FactorbhadreshNo ratings yet

- Vardhman Textiles Limited Outlook of global textile industry: An Indian perspectiveDocument85 pagesVardhman Textiles Limited Outlook of global textile industry: An Indian perspectiveKrishna PatelNo ratings yet

- President SpeechDocument14 pagesPresident SpeechManish JaiswalNo ratings yet

- Joint (Up To 72.5kV)Document4 pagesJoint (Up To 72.5kV)des1982No ratings yet

- Pulley SystemDocument9 pagesPulley Systemvaithsr0% (1)

- Electrical Transmission Tower Types and Design - Electrical4U PDFDocument9 pagesElectrical Transmission Tower Types and Design - Electrical4U PDFJack PNo ratings yet

- Wind Turbines by UJJWAL NAUTIYALDocument14 pagesWind Turbines by UJJWAL NAUTIYALUjjwal NautiyalNo ratings yet

- Propulsion GeneralitesDocument2 pagesPropulsion GeneralitesChemss EddinneNo ratings yet

- CSTRDocument8 pagesCSTRAathira SNo ratings yet

- Analisa Setting Over Current Relay (Ocr) Dan Ground Fault Relay (GFR) Pada Trafo 60 MVA Di GIS 150 KV SimpangDocument8 pagesAnalisa Setting Over Current Relay (Ocr) Dan Ground Fault Relay (GFR) Pada Trafo 60 MVA Di GIS 150 KV Simpangmuhammad ikramNo ratings yet

- Introduction To Life 1Document73 pagesIntroduction To Life 1Franzienne ImadoNo ratings yet

- SPC-0804.02-20.04 Rev D2 General Welding and NDE Requirements For Pressure VesselDocument15 pagesSPC-0804.02-20.04 Rev D2 General Welding and NDE Requirements For Pressure VesselPadmanabhan VenkateshNo ratings yet

- Published On JanuaryDocument4 pagesPublished On Januaryavmurugan87No ratings yet

- 3 - Technical Engine DataDocument90 pages3 - Technical Engine Datatruong100% (1)

- Introduction To MEMS Lecture 4Document12 pagesIntroduction To MEMS Lecture 4Vaibhav ChaudharyNo ratings yet

- Conversion Factor-Qatar PetroleumDocument4 pagesConversion Factor-Qatar PetroleumrohanNo ratings yet

- GCP-HARP-1004 - College of Magics PDFDocument127 pagesGCP-HARP-1004 - College of Magics PDFMartin Gualdarrama50% (2)

- Optimal Management of Hydropower Production: Case of Memve'ele Hydropower Reservoir PolicyDocument33 pagesOptimal Management of Hydropower Production: Case of Memve'ele Hydropower Reservoir PolicyAJ JawileouNo ratings yet