Professional Documents

Culture Documents

Efficacy of Crab (Brachyura) Shell As Bioplastic: Ann Aubrey Polinar Dym Karyl Preagido Abijah Ruth Plantar

Uploaded by

J O0 ratings0% found this document useful (0 votes)

15 views23 pagesOriginal Title

Efficacy-of-Crab-Brachyura-shell-as (1)

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views23 pagesEfficacy of Crab (Brachyura) Shell As Bioplastic: Ann Aubrey Polinar Dym Karyl Preagido Abijah Ruth Plantar

Uploaded by

J OCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 23

EFFICACY OF CRAB

(BRACHYURA)

SHELL AS

BIOPLASTIC

ANN AUBREY POLINAR

DYM KARYL PREAGIDO

ABIJAH RUTH PLANTAR

STATEMENT OF THE PROBLEM

1. What are the characteristics of crab

shells as bioplastics in terms of:

Durability

Water resistance

Ho2: What is the significant difference in

conventional plastic and the crab shells

as bioplastics?

NULL HYPOTHESIS

Ho1: There is no characteristics of crab

shells as bioplastics in terms of :

Durability

Water resistance

Ho2: There is no significant difference in

conventional plastic and the crab shells

as bioplastics

SIGNIFICANCE OF THE STUDY

Crab Vendors – crab vendors will gain

pieces of information regarding the

effectiveness of chitin in crab shells as a

biodegradable plastic which can help in

reducing waste in the environment. In

such case, crab vendors could also help

lessen the chemical dangers and

problems in the society.

LGU Lala – the LGU Lala will be

informed about the benefits coming

from agricultural waste materials such

as crustacean shells to be used as an

alternative for a renewable substrate

and to be widely used and beneficial to

humankind for sustainable industry.

SCOPE

AND LIMITATIONS

This study focuses only on the

characteristics of crab shells as

bioplastics in terms of; a.) Durability

and b.) Water Resistance. It also targets

the effectiveness of crab shells as

biodegradable plastic. Moreover, it also

intends to determine the difference in

conventional plastic and crab shells as

biodegradable plastic.

CHAPTER III

Various methods was introduced by

the researchers accordingly, starting

from the collection of raw materials

needed in the experiment down to data

gathering, interpretation and analysis. A

conceptual framework of the flow of the

study is shown below.

Gathering of Materials

Preparation of Experimental Set-Ups

Production of Bioplastics

Testing the Samples Using UTM, WR and durability

Analyzing the Data Gathered

Interpreting the Results

GATHERING MATERIALS

The raw materials that were used in

this study were the Crab Shells

collected from the markets,

households, restaurants and/or

fishing sites. Water (distilled and tap)

was used as solvent. All other

reagents used includes: NaOH

(Sodium Hydroxide), HCl

(Hydrochloric Acid) and Sorbitol (as

plasticizer).

PREPARATION OF

EXPERIMENTAL SET-UPS

Crab shells are obtained from crab

was first washed with tap water

followed by distilled water to avoid

contamination. Before use, the crabs

were first dried under the heat of the

sun and then crushed into smaller

pieces called chitin flakes

After obtaining 10g of chitin flakes,

the flakes will be soaked with 150ml of

hydrochloric acid (HCl) to remove

excess minerals under vigorous

stirring and be left at room

temperature for 24hrs.

The demineralized shells were filtered

and deproteinized with 15g sodium

hydroxide (NaOH) to assist with the

deacetylation while the solution is being

boiled and stirred vigorously. After the

deacetylation process, the solution was

left at room temperature for another

24hrs. The sample obtained (which was

the chitosan) was then washed

thoroughly with deiones (distilled) water

until it reaches ph=7 (neutral).

PRODUCTION OF

BIOPLASTICS

Each experiment set-up of

extracted chitosan solution was

mixed with 9g of starch to improve its

plasticity and the sample was then

oven dried at various temperatures for

about 1 hour and stored at room

temperature.

The process was then repeated three

times with a variation ratio of A( 100g

chitosan: 150ml HCl: 15g NaOH: 80 °C),

B(80g chitosan: 300 HCl: 20g NaOH:

90°C) and C(50g chitosan: 450ml HCl:

30g NaOH: 100°C) D(100g chitosan: 50

ml H2O: 150ml HCl: 15g NaOH: 80 °C)

respectively.

TESTING THE SAMPLE USING UTM

(DURABILITY)

The sample was placed between (2)

fixtures (grip) to clamp the material and

weight (force or load) is applied to the

material gripped at one end while the

other end is fixed. As the weight

increases, the sample had gradually

increased its length (stretched) before it

breaks. The length of the stretched

sample was measured afterwards.

TESTING THE SAMPLE USING WATER

PERMEABILITY (RESISTANCE)

Water uptake was used to investigate the

permeability of the bioplastic by cutting

sample with size approximately 2x2 cm and

weighed (mass). The sample was placed on

a container with distilled water for 30

minutes. After immersion in water, the

sample was removed from the water and

weighed to measure the wet weighed. Water

uptake was calculated as follows:

Water uptake = [(wet weight-dry-

weight)/wet weight] x 100%

ANALYZING AND INTERPRETATION

OF DATA

After the testing method of the

samples, the data gathered was analyzed

using inferential statistics. The statistical

treatment that was used in analyzing the

data gathered are the ANOVA (F-test) to

address whether the means of the

samples are statistically different and T-

test to determine the comparison

between sample means/variation with the

samples of biodegradable plastic and

non- biodegradable plastic. This study

will use a significance level equal to 0.05.

The results will be interpreted and

discussed by the researchers.

You might also like

- Extraction Characterization and Applications of Chitosan From Fish Scales PDFDocument5 pagesExtraction Characterization and Applications of Chitosan From Fish Scales PDFUlfa AriefNo ratings yet

- 123Document6 pages123necboowatonNo ratings yet

- IOP Conference: Effect of Acid Concentration on Eel Fish Bone Gelatin CharacteristicsDocument8 pagesIOP Conference: Effect of Acid Concentration on Eel Fish Bone Gelatin Characteristicsermawati lestariNo ratings yet

- Thongchai2020 Article IntegrationOfCollagenIntoChitoDocument7 pagesThongchai2020 Article IntegrationOfCollagenIntoChitoNelson SouzaNo ratings yet

- Chuaychan 2016Document10 pagesChuaychan 2016hoangvipro99No ratings yet

- 2021 Oct 14 STT47 Paper p.664-670Document7 pages2021 Oct 14 STT47 Paper p.664-670Pheeraphong BunroekNo ratings yet

- Solids Determination MethodsDocument3 pagesSolids Determination MethodsrahoznawrozNo ratings yet

- Chapter 2Document5 pagesChapter 2AubreyNo ratings yet

- Articulo CientificoDocument7 pagesArticulo CientificoSalocinNo ratings yet

- Ce2356-Environmental Engineering Lab: Department of Civil EngineeringDocument50 pagesCe2356-Environmental Engineering Lab: Department of Civil Engineeringjss_devNo ratings yet

- 2 Microbial Paper PDFDocument4 pages2 Microbial Paper PDFShamsuddin BabuNo ratings yet

- Factors Affecting the Characteristics of Bioplastic from Seaweed Ulva lactucaDocument8 pagesFactors Affecting the Characteristics of Bioplastic from Seaweed Ulva lactucaYugi mutouNo ratings yet

- Valencia-Perez 2015 Con DOIDocument7 pagesValencia-Perez 2015 Con DOIImelevenNo ratings yet

- Suspended Solids AnalysisDocument16 pagesSuspended Solids AnalysisFaizYosh100% (2)

- CHITOSAN CRYOGEL SCAFFOLDSDocument14 pagesCHITOSAN CRYOGEL SCAFFOLDSApt Fitri RosdianaNo ratings yet

- 1983 Properties of Gamma Irradiated Sugarcane BagasseDocument5 pages1983 Properties of Gamma Irradiated Sugarcane BagassexsystemNo ratings yet

- New Process For Synthesizing Chitosan From Snail Shells: Journal of Physics: Conference SeriesDocument7 pagesNew Process For Synthesizing Chitosan From Snail Shells: Journal of Physics: Conference SeriesReemaNo ratings yet

- Seasonal Chitin Content in Jaffna CrabsDocument8 pagesSeasonal Chitin Content in Jaffna CrabsHanshiya RagaNo ratings yet

- Caracterisation Chitosan 1Document4 pagesCaracterisation Chitosan 1Ali SulaimanNo ratings yet

- A Comparison of Kombucha SCOBY Bacterial Cellulose Purification MethodsDocument7 pagesA Comparison of Kombucha SCOBY Bacterial Cellulose Purification MethodsRismaNo ratings yet

- Total Solid ReportDocument16 pagesTotal Solid ReportNurul Izzati Raihan RamziNo ratings yet

- .ZHOU Effect of Different Thawing Methods On The Quality of MackerelDocument11 pages.ZHOU Effect of Different Thawing Methods On The Quality of MackerelJuan Diego Espinoza AlvinesNo ratings yet

- Si 2015Document8 pagesSi 2015ThuNo ratings yet

- DownloadDocument12 pagesDownloadjhoanna grace nideaNo ratings yet

- Research Proposal Ni InjelDocument5 pagesResearch Proposal Ni InjelRhodail Andrew CastroNo ratings yet

- Atributos Sensoriales de Carpa Herbívora Con Quitosano Almacenados A 4°C-2017Document13 pagesAtributos Sensoriales de Carpa Herbívora Con Quitosano Almacenados A 4°C-2017Camilo Huertas CamposNo ratings yet

- Water Quality (Solid) Lab ReportDocument10 pagesWater Quality (Solid) Lab ReportYew ChunNo ratings yet

- Physico-Mechanical Properties of Chemically-Treated Bacterial Cellulose Membrane - George Et Al., 2005Document5 pagesPhysico-Mechanical Properties of Chemically-Treated Bacterial Cellulose Membrane - George Et Al., 2005Carinna SaldanaNo ratings yet

- Munir 2018Document8 pagesMunir 2018Jesús BarónNo ratings yet

- Physicochemical Properties of Gelatin From Jellyfish Rhopilema HispidumDocument6 pagesPhysicochemical Properties of Gelatin From Jellyfish Rhopilema HispidumAdrian Nur SalimNo ratings yet

- Biodegradable PlasticDocument24 pagesBiodegradable PlasticAin SoberanoNo ratings yet

- Science, Technology, Engineering, and Mathematics Ligao National High School - Senior High SchoolDocument10 pagesScience, Technology, Engineering, and Mathematics Ligao National High School - Senior High SchoolMaria Kyla Peñafiel TeodoroNo ratings yet

- 10.1021@jf3048884Document7 pages10.1021@jf3048884mizucheckNo ratings yet

- Physical and Antimicrobial Properties of Banana Flour and Chitosan BiodegradableDocument6 pagesPhysical and Antimicrobial Properties of Banana Flour and Chitosan BiodegradableLC7040861No ratings yet

- Structural Characterization of Cellulose ObtainedDocument5 pagesStructural Characterization of Cellulose ObtainedRezza MarcellaNo ratings yet

- Guidance On The Quantitative Analysis of PhytoplanDocument25 pagesGuidance On The Quantitative Analysis of PhytoplanRashif NaufalNo ratings yet

- Pullulan Hydrogel Wound Dressings with Antibacterial ReleaseDocument9 pagesPullulan Hydrogel Wound Dressings with Antibacterial ReleaseMehul KhimaniNo ratings yet

- Quality changes during frozen storage of blue shrimp (Litopenaeus stylirostris) with antioxidant, α-tocopherol, under different conditionsDocument7 pagesQuality changes during frozen storage of blue shrimp (Litopenaeus stylirostris) with antioxidant, α-tocopherol, under different conditionsRamzi SaeedNo ratings yet

- Study How Sugar Concentration and Temperature Affect Kiwifruit During Osmotic DryingDocument12 pagesStudy How Sugar Concentration and Temperature Affect Kiwifruit During Osmotic DryingGaganpreet Kaur Fashion DesigningNo ratings yet

- IB ESS INTERNAL ASSESTMENTexample 3Document18 pagesIB ESS INTERNAL ASSESTMENTexample 3Carla MinghettiNo ratings yet

- Bacteriocin Production by Lactic Acid Bacteria Encapsulated in Calcium Alginate BeadsDocument8 pagesBacteriocin Production by Lactic Acid Bacteria Encapsulated in Calcium Alginate BeadsangelicaaragonNo ratings yet

- Water Conservation in Canned Tuna (Pet Food) Plant in ThailandDocument10 pagesWater Conservation in Canned Tuna (Pet Food) Plant in ThailandAbhishek ChadagaNo ratings yet

- Production of Starch Based Bioplastic From Cassava Peel Reinforced With Microcrystalline Celllulose Avicel ph101 Using Sorbitol As PlasticizerDocument8 pagesProduction of Starch Based Bioplastic From Cassava Peel Reinforced With Microcrystalline Celllulose Avicel ph101 Using Sorbitol As PlasticizerShanaiah Charice GanasNo ratings yet

- Experiment On: Extrusion Cooking AIMDocument8 pagesExperiment On: Extrusion Cooking AIMShobikaNo ratings yet

- Osmotic Dehydration Combined With Microwave Drying of Tilapia Fillets The Impacts of Osmosis DehydraDocument10 pagesOsmotic Dehydration Combined With Microwave Drying of Tilapia Fillets The Impacts of Osmosis Dehydrafrancisco cadenaNo ratings yet

- Enzym ProteazaDocument16 pagesEnzym Proteazavithuat1No ratings yet

- 15.0 Experiment On Determination of Total Dissolved and Suspended Solids in WaterDocument15 pages15.0 Experiment On Determination of Total Dissolved and Suspended Solids in Waterhero100% (2)

- Biological Treatment of Paper Pulping Effluents by Using Fungal ReactorDocument7 pagesBiological Treatment of Paper Pulping Effluents by Using Fungal ReactorLuciaMarinaR.OrizaNo ratings yet

- Treatment of Synthetic TurbidDocument7 pagesTreatment of Synthetic TurbidNovitaaNo ratings yet

- Taro and Seagrapes RRLDocument5 pagesTaro and Seagrapes RRLMarianne Nathalie Sarmiento50% (2)

- 1 - Abalone Production System - Cultivation in RASDocument10 pages1 - Abalone Production System - Cultivation in RAStororoNo ratings yet

- Influence of Treatments in The Quality of Nile Tilapia (Oreochromis Niloticus) FilletsDocument8 pagesInfluence of Treatments in The Quality of Nile Tilapia (Oreochromis Niloticus) Filletsmarine2006No ratings yet

- Efecto de La Cubierta de Quitosano en La Calidad Postcosecha de Espárrago VerdeDocument6 pagesEfecto de La Cubierta de Quitosano en La Calidad Postcosecha de Espárrago VerdeTamiko MitzumaNo ratings yet

- Investigatory ProjectDocument15 pagesInvestigatory Projectak1740120No ratings yet

- 10 11648 J Ajpst 20200602 12Document7 pages10 11648 J Ajpst 20200602 12data.caindog.swuNo ratings yet

- Extraction of Banana PeelsDocument14 pagesExtraction of Banana PeelsFritz CarpenteroNo ratings yet

- 2017 Article 173Document8 pages2017 Article 173Qualidade FrilaboNo ratings yet

- Standard methods for the examination of water and sewageFrom EverandStandard methods for the examination of water and sewageNo ratings yet

- Plankton: A Guide to Their Ecology and Monitoring for Water QualityFrom EverandPlankton: A Guide to Their Ecology and Monitoring for Water QualityNo ratings yet

- Understanding Culture, Society and Politics: Quarter 1 - Module 2Document17 pagesUnderstanding Culture, Society and Politics: Quarter 1 - Module 2Yamaneehs De Guia100% (1)

- Understanding Culture, Society and Politics: Quarter 1 - Module 3Document18 pagesUnderstanding Culture, Society and Politics: Quarter 1 - Module 3mark turbanadaNo ratings yet

- Understanding Culture, Society and Politics: Quarter 1 - Module 4Document18 pagesUnderstanding Culture, Society and Politics: Quarter 1 - Module 4mark turbanada100% (2)

- Summer Class - InfatuationDocument4 pagesSummer Class - InfatuationJ ONo ratings yet

- The Effect of Visual Product Aesthetics On Consumers' Price SensitivityDocument7 pagesThe Effect of Visual Product Aesthetics On Consumers' Price SensitivityJ ONo ratings yet

- College of Natural Sciences and Mathematics Mathematics DepartmentDocument2 pagesCollege of Natural Sciences and Mathematics Mathematics DepartmentJ ONo ratings yet

- Forbidden Summer AttractionDocument4 pagesForbidden Summer AttractionJ ONo ratings yet

- What Is Mathematics? Where Is Mathematics?Document7 pagesWhat Is Mathematics? Where Is Mathematics?J ONo ratings yet

- AU440-36V-MH: DimensionsDocument2 pagesAU440-36V-MH: DimensionsJohnny FucahoriNo ratings yet

- Sarah Fahy CV College PDFDocument4 pagesSarah Fahy CV College PDFapi-487352339No ratings yet

- With Reference To Relief, Drainage and Economic Importance, Explain The Differences Between The Northern Mountains and Western MountainsDocument3 pagesWith Reference To Relief, Drainage and Economic Importance, Explain The Differences Between The Northern Mountains and Western Mountainshajra chatthaNo ratings yet

- Diagnosis and Management of Ulnar Nerve PalsyDocument20 pagesDiagnosis and Management of Ulnar Nerve PalsyamaliafarahNo ratings yet

- 2 Way 3 Way Piping DiagramDocument1 page2 Way 3 Way Piping DiagrammarrukhjNo ratings yet

- Nikon Nivo C Series Instruction ManualDocument65 pagesNikon Nivo C Series Instruction ManualBambang Deriyanto100% (1)

- Jadwal Oral Presentation Peserta FIT-VIIIDocument26 pagesJadwal Oral Presentation Peserta FIT-VIIIKlinik FellitaNo ratings yet

- Simplex 4100ES 5 Days Customer TrainingDocument1 pageSimplex 4100ES 5 Days Customer TrainingBrahmantyo HadiprasetyoNo ratings yet

- Codex CRD26Document9 pagesCodex CRD26arely svetlana gaspar badilloNo ratings yet

- RR No. 6-2015 PDFDocument5 pagesRR No. 6-2015 PDFErlene CompraNo ratings yet

- Aircraft Instruments and Avionics PDFDocument211 pagesAircraft Instruments and Avionics PDFairbuk doeing88% (8)

- Product Overview: NCV71208: Octal Solenoid Current Controller With N-FET PredriversDocument1 pageProduct Overview: NCV71208: Octal Solenoid Current Controller With N-FET PredriversDimitar PetrovNo ratings yet

- Odonata 35 PDFDocument40 pagesOdonata 35 PDFJose VelasquezNo ratings yet

- Vetotop Doc Technical Map en 3573Document4 pagesVetotop Doc Technical Map en 3573Rebel XNo ratings yet

- Innogy Invitation For Seminar PCODocument6 pagesInnogy Invitation For Seminar PCOTivorshio MacabodbodNo ratings yet

- Sedimentation Tank Design NptelDocument7 pagesSedimentation Tank Design NptelNayan HalderNo ratings yet

- Preserving Food Drying Fruits and VegetablesDocument12 pagesPreserving Food Drying Fruits and Vegetablespdxpharris100% (1)

- Hyperfunctional Voice DisordersDocument11 pagesHyperfunctional Voice DisordersJam PNo ratings yet

- Sorogon Medical Mission Group Hospital Operation RecordDocument3 pagesSorogon Medical Mission Group Hospital Operation RecordRoden BerdinNo ratings yet

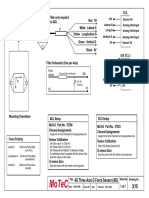

- Filter and wiring schematic for 3-axis ADL G-force sensorDocument1 pageFilter and wiring schematic for 3-axis ADL G-force sensorJuan Ramón Pérez LorenzoNo ratings yet

- A Study On Satisfaction Level of Employees With Special Reference Textile IndustryDocument12 pagesA Study On Satisfaction Level of Employees With Special Reference Textile Industrysai kiran bade100% (1)

- Group 3Document11 pagesGroup 3Sharp MIER TVNo ratings yet

- Technical Data Sheet PDFDocument2 pagesTechnical Data Sheet PDFLuis VilelaNo ratings yet

- Low Noise Pseudomorphic HEMT Technical DataDocument4 pagesLow Noise Pseudomorphic HEMT Technical Datahendpraz88No ratings yet

- 08 Ch-8 PDFDocument6 pages08 Ch-8 PDFMANJEET SINGHNo ratings yet

- The Strange ICA Stones of PeruDocument31 pagesThe Strange ICA Stones of PeruRoman Aleshkevich100% (1)

- Reactor & Impeller Design in Hydrogenation: GBHE Technical Bulletin CTB #79Document13 pagesReactor & Impeller Design in Hydrogenation: GBHE Technical Bulletin CTB #79manuNo ratings yet

- Brooks MT 3018Document16 pagesBrooks MT 3018Martin AndradeNo ratings yet

- Chapter 43 - Lead - 2015 - Handbook On The Toxicology of MetalsDocument57 pagesChapter 43 - Lead - 2015 - Handbook On The Toxicology of MetalsChanWingSanNo ratings yet

- Wörterbuch Der Humanbiologie - Dictionary of Human Biology - Deutsch - Englisch - Englisch - Deutsch. English - German - German - English (PDFDrive)Document1,002 pagesWörterbuch Der Humanbiologie - Dictionary of Human Biology - Deutsch - Englisch - Englisch - Deutsch. English - German - German - English (PDFDrive)MilaNo ratings yet