Professional Documents

Culture Documents

5S English

Uploaded by

priyankaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5S English

Uploaded by

priyankaCopyright:

Available Formats

TRAINING ON 5S

A Journey Towards Excellence 1

Aren’t you frustrated in your workplace?

Oh, this position

Where is that makes me tired !

document ?

I cannot find it !

Oh, time is not

I cannot remember enough to complete

what/how to next… this work!

Why we cannot

Why I am making

communicate

mistakes again

properly?

and again

A Journey Towards Excellence 2

Thinking negatively in inside box and give-up

A Journey Towards Excellence 3

Work together

and do something

with big positive

attitude?

A Journey Towards Excellence 4

You need tools !

Even you are

positive

thinker,

you still need

something to

make your

ideas realistic

A Journey Towards Excellence 5

•There are useful tools

5S

approaches

A Journey Towards Excellence 6

What is 5S ?

It is for improvement of working environment

5S is a philosophy and a way of organizing and managing the

workspace and workflow with the intent to improve efficiency by

eliminating waste, improving flow and reducing process

unreasonableness.

A Journey Towards Excellence 7

5S activities are to create good working environment

through reduction of “Muri”, “Mura”, and “Muda”

What is 5S ? It help to have a basis of strong management of

workplace

What is “Muri”, “Mura”, and “Muda”?

• Muri : overburden, unreasonableness or absurdity

• Mura : unevenness or inconsistency, primarily with physical

matter and the human spiritual condition

• Muda : activity which is wasteful or doesn’t add value

A Journey Towards Excellence 8

Japanese English

5S in S-1 Seiri Sort

Japanese/English

5S is literally five S-2 Seiton Set

abbreviations of

Japanese terms S-3 Seiso Shine

with 5 initials of S.

S-4 Seiketsu Standardize

S-5 Sitsuke Sustain

A Journey Towards Excellence 9

What 5S can do?

Teamwork improvement through everyone’s participation

Identify Abnormalities

Identify wastes and reduce the wastes

A Journey Towards Excellence 10

The 7 wastes

Overproduction

Over processing

Inventory

Rework Waiting

Transportation Motion

A Journey Towards Excellence 11

•5S BENIFITS

Improve productivities

Improve safety

A Journey Towards Excellence 12

If no 5S

activities…

.

A Journey Towards Excellence 13

Details of 5S approach

5S: Sort-Set-Shine-Standardize-Sustain

S1:

Sort

S5: S2:

Sustain Set

S4:

S3:

Standardiz

Shine

e

A Journey Towards Excellence 14

S1: Sorting activities

Equipment, material, tools files, furniture etc. can be

categorized based on the frequency of use!

Equipment,

materials

tools etc. in your

workplace May need it

Items only used occasionally

are in this category

Not need it

Need it

Items not used in current work

process are in this category

Items often use are in this category

A Journey Towards Excellence 15

Examples of

“Sorting”

• Place “Red tag” for categorization

of items to identify unnecessary

items

• Move unnecessary items( broken

tools, obsolete jigs and fixtures,

scrap and excess raw material etc.)

to central stored area

• Free up valuable floor space

(Space utilization)

• Finding abnormality of equipment

and tools (Out of order, missing

parts etc.)

A Journey Towards Excellence 16

S2: Setting activities

Think not only “beatification.

Need to consider workflow and

arrange items

• Needed items

• Items often use

(with current

work process)

Arrange them properly based on

Have consensus among Use 5S tools for proper

“Can see, Can take-out, Can

co-workers on where and Organization of items

return” Philosophy

how to organize necessary such as

items • Labeling

• Color coding

• Numbering

• Zoning etc.

A Journey Towards Excellence 17

Example of

“Setting” activities

• Labeling , numbering, zoning for

clear identification of storage

areas to keep necessary items

• Set necessary items matching

with workflow to minimize

unnecessary movement and

transportation time

A Journey Towards Excellence 18

S3: Shining activities

• Clean floor, windows and walls.

• Clean and Maintain office automation

machines, medical equipment and

tools, office furniture

• Develop and follow regular cleaning

and Maintenance schedule

A Journey Towards Excellence 19

Example of

“Shining” activities

• Daily sweeping and mopping of

floor, bathroom, corridor etc.

• Regular cleaning and

maintenance of equipment and

tools

• Periodical check for changes in

equipment and the service area

such as: leaks, vibration,

misalignment, breakage etc.

• IPC activities such as hand

hygiene, waste segregation are

also part of shine

A Journey Towards Excellence 20

S4: Standardizing activities

S1

S2

S3

Develop mechanism to standardize Standardization will lead equalization of activities

S1-S3 implementation for continuation = “Production leveling and smoothing”

Standardization is useful for;

• Easy implementation of S1 to S3 activities

• Equalization process output

• Everyone’s participation

A Journey Towards Excellence 21

Example of

“Standardize”

activities

• Work instructions, Standard

Operating Procedures (SOPs)

• Checklist development and

regular usage for SOPs

• Mechanism and format

development for ordering

supplies, reporting etc

• Color coding for waste

segregation

• Standardized common symbols

A Journey Towards Excellence 22

S5: Sustainability activities

People get bored if no changes.

Need to develop a mechanism to

make staff exited and motivated

Further Improvement

Prevent fallback

Improvement

Measure improvement with proper

periodical monitoring

A Journey Towards Excellence 23

Example of

“Sustain” activities

• Regular progress reporting

• Refresher training

• Periodical evaluation of 5S

activities with proper advices for

continuation and further

improvements

• Appreciation, recognition and

awarding on good 5S activities

• Reminder using 5S corner, new

letters, good practice sheet etc.

A Journey Towards Excellence 24

5S Conceptual Framework

SORT

SUSTAIN STANDARDIZE SET

SHINE

A Journey Towards Excellence 25

Visible results enhance the generation of more and new

ideas

The workplace gets cleaned up and better organized

5S is Office operations become easier and safer

becoming

popular for Results are visible to everyone - insiders and outsiders

seven solid People are naturally disciplined

reasons People take pride in their clean and organized workplace

As a result, the company’s good image generates more better

A Journey Towards Excellence 26

Target of 5S

Targets of Five-S include:

Zero changeovers leading to product/ service diversification

Zero defects leading to higher quality

Zero waste leading to lower cost

Zero delays leading to on time delivery

Zero injuries promoting safety

Zero breakdowns bringing better maintenance

A Journey Towards Excellence 27

Remember

5S implementation can improve both working environment and the service content.

• Benefits on WEI (Weekly Economics Index) will be better realized as you go along the training.

Go systematically to implement S1-S5:

• Sort necessary & unnecessary items;

• Arrange items according to workflow;

• Make workplace and tools shining (daily cleaning);

• Standardize “sort-set-shine” process; and

• Workers acquire positive attitude to sustain & improve quality of health services.

Effectiveness of 5S in improving health care services content:

• Complement to machine and instruments safety efforts.

• Minimizes chances of breakdown, and maintaining through proper sorting (files, records) and appropriate

labeling (spare parts, instruments), as well as use of checksheets to avoid skip of planned maintenance (such

as cleaning and lubricating).

• Contribute to better continuum of care.

• Use of defined checksheets ensure correct linkages to needed maintenance.

A Journey Towards Excellence 28

Example of

5S activities

A Journey Towards Excellence 29

A Journey Towards Excellence 30

A Journey Towards Excellence 31

A Journey Towards Excellence 32

THANK

YOU

A Journey Towards Excellence 33

You might also like

- The Brex Boys' Uncomfortable ReckoningDocument10 pagesThe Brex Boys' Uncomfortable ReckoningejmottaNo ratings yet

- 5S Visual WorkplaceDocument19 pages5S Visual WorkplaceAda Munoz100% (3)

- 5S Principles and ApplicationDocument168 pages5S Principles and ApplicationLuzviminda Rustia Capili MoralesNo ratings yet

- 5S PPT PrinciplesDocument53 pages5S PPT PrinciplesSampath MalaarachchiNo ratings yet

- 5S - Final PPDocument71 pages5S - Final PPSiti Sara Rahim100% (1)

- Tcodes Used For SAP Plant MaintenanceDocument2 pagesTcodes Used For SAP Plant MaintenancepalhotaNo ratings yet

- Aren't You Frustrated in Your Workplace?Document52 pagesAren't You Frustrated in Your Workplace?Noman SiddiqueNo ratings yet

- 5S PrincipleDocument53 pages5S PrincipleAmir M. VillasNo ratings yet

- 5 SDocument32 pages5 SWilson Agustin100% (1)

- The Intentional Leader: A Practical Guide to Leadership Essentials New EditionFrom EverandThe Intentional Leader: A Practical Guide to Leadership Essentials New EditionNo ratings yet

- Owner'S Manual For Chain Hoist: English Original InstructionsDocument114 pagesOwner'S Manual For Chain Hoist: English Original InstructionsPePe RodasNo ratings yet

- 5S, The Foundation For Lean System: Characteristics of World ClassDocument46 pages5S, The Foundation For Lean System: Characteristics of World ClassKaito100% (1)

- Apply 5S ProceduresDocument54 pagesApply 5S Proceduresbirhanu morkaNo ratings yet

- 5s Basic TrainingDocument28 pages5s Basic TrainingKvt VivekanandanNo ratings yet

- Welcomes All The Participants To The: Continuous Training & Development ProgramDocument47 pagesWelcomes All The Participants To The: Continuous Training & Development Programselvarangam govindarajanNo ratings yet

- 5 S ProgramDocument118 pages5 S ProgramNatarajan RajNo ratings yet

- Css 11 Ncii Quarter 3 Module 4 Maintain Hand ToolsDocument16 pagesCss 11 Ncii Quarter 3 Module 4 Maintain Hand ToolsR TECHNo ratings yet

- 5S Principles, TOT, JICADocument40 pages5S Principles, TOT, JICAAmit Kumar Singh100% (1)

- Introduction To 5S ModuleDocument167 pagesIntroduction To 5S ModuleJoshua Su Chun AnnNo ratings yet

- 5's Training 2022Document39 pages5's Training 2022Teresa PunzalanNo ratings yet

- 5 SDocument22 pages5 SAnkita RajNo ratings yet

- Guide 5SDocument33 pagesGuide 5SGUILLERMO VAZQUEZNo ratings yet

- 5S - Kaizen - TQM ApproachDocument32 pages5S - Kaizen - TQM ApproachAmit Kumar SinghNo ratings yet

- What Is 5S Principle?: 5S Training of Trainers For Training Institutions Training Material No. 13Document53 pagesWhat Is 5S Principle?: 5S Training of Trainers For Training Institutions Training Material No. 13indresh kumarNo ratings yet

- Case Materials Tanzania 08 01Document52 pagesCase Materials Tanzania 08 01testing eiplNo ratings yet

- What Is 5S Principle?: 5S Training of Trainers For Training Institutions Training Material No. 13Document53 pagesWhat Is 5S Principle?: 5S Training of Trainers For Training Institutions Training Material No. 13kajal0% (1)

- What Is 5S Principle?Document44 pagesWhat Is 5S Principle?EDWIN POBLETENo ratings yet

- 5S Training Material For Trainer's Training For Training OthersDocument53 pages5S Training Material For Trainer's Training For Training Othersgemah.prodNo ratings yet

- 5 S PrinciplesDocument53 pages5 S Principles720721206028 MADHESH DNo ratings yet

- What Is 5S Principle?Document53 pagesWhat Is 5S Principle?sandipNo ratings yet

- Principale of 5SDocument53 pagesPrincipale of 5SJerem DhuiNo ratings yet

- What Is 5 S ?: Mozzan Razzaq 19-NTU-TE-0069 M. Umar Qayyum 19-NTU-TE-0131Document76 pagesWhat Is 5 S ?: Mozzan Razzaq 19-NTU-TE-0069 M. Umar Qayyum 19-NTU-TE-0131aqsa imranNo ratings yet

- What Is 5S Principle?Document56 pagesWhat Is 5S Principle?Aldrin De jesusNo ratings yet

- 5s PresentationDocument37 pages5s PresentationMudassarNo ratings yet

- Five S and QC Tools IntroductionDocument72 pagesFive S and QC Tools IntroductionV PNo ratings yet

- Case Materials Tanzania 08 01Document26 pagesCase Materials Tanzania 08 01kiruthikamadheswaran2805No ratings yet

- Fdocuments - in - 5s Basic Training 1Document114 pagesFdocuments - in - 5s Basic Training 1solomon tadeseNo ratings yet

- 5S Basic Training: Whatis5Sandwhydowewanttodoit?Document15 pages5S Basic Training: Whatis5Sandwhydowewanttodoit?priya66jNo ratings yet

- 5S TrainingDocument30 pages5S TrainingMacky SebastianNo ratings yet

- 5S and Workplace Productivity CLADocument48 pages5S and Workplace Productivity CLASteben MeuerteNo ratings yet

- 5s MethodologicalDocument69 pages5s MethodologicalHoàng Thị NguyênNo ratings yet

- DLP 2. 5s (5s)Document9 pagesDLP 2. 5s (5s)markjijaywalkNo ratings yet

- 5s Lesson PlanDocument9 pages5s Lesson PlanmarkjijaywalkNo ratings yet

- 5s Module EmployeesDocument61 pages5s Module EmployeesAracelli Fye BernardinoNo ratings yet

- What Is 5S Principle?: Training On HousekeepingDocument56 pagesWhat Is 5S Principle?: Training On HousekeepingALOKE GANGULYNo ratings yet

- Cot2 - Practice Occupational Health and Safety ProceduresDocument37 pagesCot2 - Practice Occupational Health and Safety ProceduresFerdinand R. AlbertoNo ratings yet

- How To Begin Lean 5S Your WorkspaceDocument1 pageHow To Begin Lean 5S Your WorkspacemugenthararaoNo ratings yet

- Five S Training Module Rev FDocument70 pagesFive S Training Module Rev FPrathap NatarajaNo ratings yet

- Module 5 - Basic PQ ToolsDocument136 pagesModule 5 - Basic PQ Toolsdhir.ankurNo ratings yet

- 5S Housekeeping: A Discipline For ProductivityDocument25 pages5S Housekeeping: A Discipline For ProductivityCarlos HernandezNo ratings yet

- 5S Methodology: "The Secret To Japanese Success"Document19 pages5S Methodology: "The Secret To Japanese Success"Hasna JaafarNo ratings yet

- Housekeeping & 5 "S" Faculty-S.SukumarDocument26 pagesHousekeeping & 5 "S" Faculty-S.SukumarPERATCHI SELVANNo ratings yet

- 5S in The WorkplaceDocument16 pages5S in The WorkplaceChor DayanNo ratings yet

- CHAPTER 3 - QM in HospitalityDocument34 pagesCHAPTER 3 - QM in Hospitalitynndt05092003No ratings yet

- 4C Consulting Private LimitedDocument21 pages4C Consulting Private LimitedAjay KaushikNo ratings yet

- Principles of Work Environment ImprovementDocument24 pagesPrinciples of Work Environment ImprovementFerdinand R. AlbertoNo ratings yet

- Employability Skills - Quality Tools Theory 2.5.65 Purpose of House Keeping and PracticeDocument1 pageEmployability Skills - Quality Tools Theory 2.5.65 Purpose of House Keeping and PracticeSAVITA MAURYANo ratings yet

- Housekeeping and 5sDocument26 pagesHousekeeping and 5svbvis25No ratings yet

- 5S Basic Training: Whatis5Sandwhydowewanttodoit?Document15 pages5S Basic Training: Whatis5Sandwhydowewanttodoit?arvindrathodNo ratings yet

- 5S Approaches.1Document22 pages5S Approaches.1Amit Kumar SinghNo ratings yet

- Masonry 9 Q4 WEEK 1&2Document7 pagesMasonry 9 Q4 WEEK 1&2Marjohn ElentorioNo ratings yet

- Uniform System of Accounts For The LodgingDocument6 pagesUniform System of Accounts For The LodgingRasika Sameera SampathNo ratings yet

- Hands On ManagementDocument2 pagesHands On ManagementaliciaNo ratings yet

- TJMaxx Customer SupportDocument2 pagesTJMaxx Customer SupportMary LouiseNo ratings yet

- Sample - Management Review MeetingDocument9 pagesSample - Management Review MeetingClaire TanNo ratings yet

- Kuala Lumpur: Answer Sheets: GBHDHFH: 23525: ABMC2054 Cost & Management Accounting IDocument30 pagesKuala Lumpur: Answer Sheets: GBHDHFH: 23525: ABMC2054 Cost & Management Accounting IJUN XIANG NGNo ratings yet

- Prof Sales ReviewerDocument6 pagesProf Sales ReviewerAlthea MoveNo ratings yet

- BST PQMS2Document10 pagesBST PQMS2jaiNo ratings yet

- Module 5 Intacc SoluDocument13 pagesModule 5 Intacc SoluMiks EnriquezNo ratings yet

- Lecture 2 (CHP 2)Document46 pagesLecture 2 (CHP 2)ralturkNo ratings yet

- Understanding The IEPF (Investor Education and Protection Fund) Process in IndiaDocument3 pagesUnderstanding The IEPF (Investor Education and Protection Fund) Process in India15986No ratings yet

- Freight Forwarding Practice and ProcedureDocument50 pagesFreight Forwarding Practice and Procedurezama zamazuluNo ratings yet

- Corporate Governance Ch-5Document22 pagesCorporate Governance Ch-5Diana SaidNo ratings yet

- Fa Aug 2020Document4 pagesFa Aug 2020Ieymarh Fatimah100% (1)

- BA Midterm Exam 2023 Fall 231Document3 pagesBA Midterm Exam 2023 Fall 231Hương NguyễnNo ratings yet

- A Summer Internship Project Report: "Job Costing"Document17 pagesA Summer Internship Project Report: "Job Costing"Kshirsagar AbhijeetNo ratings yet

- Operations and Production Management: Toc Msc. Małgorzata Zalewska-TraczykDocument86 pagesOperations and Production Management: Toc Msc. Małgorzata Zalewska-TraczykAjay MsdNo ratings yet

- DMLF Newsletter Issue 1Document6 pagesDMLF Newsletter Issue 1Dagnachew Tesfaye AbetewNo ratings yet

- 2020 Management Paper by Talvir SInghDocument202 pages2020 Management Paper by Talvir SInghSheetala HegdeNo ratings yet

- GSO Citizen Charter 2021Document3 pagesGSO Citizen Charter 2021Sairel Daing MohammadNo ratings yet

- Huifung: I'm Shopping For..Document5 pagesHuifung: I'm Shopping For..krsnaNo ratings yet

- Oyo Summer Internship ReportDocument31 pagesOyo Summer Internship ReportJayasree S RNo ratings yet

- Jeremy Company ProfileDocument7 pagesJeremy Company ProfileJe'remy EpanNo ratings yet

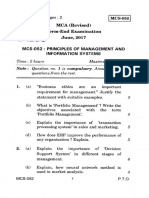

- MCS-052 MCA (Revised) Term-End Examination June, 2017: Principles of Management and Information SystemsDocument2 pagesMCS-052 MCA (Revised) Term-End Examination June, 2017: Principles of Management and Information SystemsOm Prakash MishraNo ratings yet

- AFSIC Marketing Brochure 2023Document17 pagesAFSIC Marketing Brochure 2023Memory Shonge RutsitoNo ratings yet

- Bulletlist - The Marketing ProcessDocument4 pagesBulletlist - The Marketing ProcessSs ArNo ratings yet

- Ins200 - T2 - Risk ManagementDocument39 pagesIns200 - T2 - Risk ManagementNurul SyazwaniNo ratings yet