Professional Documents

Culture Documents

Pore & Porosity

Uploaded by

loknath0 ratings0% found this document useful (0 votes)

17 views1 pageKaizen for Pore & Porosity

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentKaizen for Pore & Porosity

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views1 pagePore & Porosity

Uploaded by

loknathKaizen for Pore & Porosity

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 1

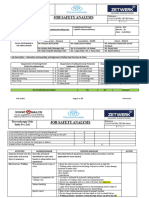

COPPER KAIZEN – SHEET

(Pl highlight whichever is

Productivity Quality Cost Delivery Safety Morale

applicable)

1. KAIZEN Title : 6.Before : Sl. No. (For BE use):

To implement correct Weld Width & Leg Logged By : Komara

Length and to improve welding process for Loknathadam

equipment availability and reliability.

2. Problem statement: Department : Asset Optimization

1. Insufficient Weld Width and Leg Length MM/ YY : 08 / 21

observed at welding areas.

2. Affects the job quality, strength and visual Implemented By : Komara

appearance of the finished welding. 7. After: Loknathadam

3. Frequent breakdowns. Department : Asset Optimization

3. Root cause identification : why, why

1. Low/high hand speeds and low/high

welding currents. MM/ YY : 08 / 21

2. Improper electrode angles and faulty

electrodes. 9. Actions to hold the gains :

4. Root cause : NIL

Welder unawareness about the job.

5. Solution : 8. Result Benefit : 10. How many places this KAIZEN can be

1. Use a sufficient wide joint preparation. 1. Time Save for Rework & Inspection. deployed horizontally : NA

2. Correct welding parameters like current and

hand travel speed. 2. Reduction of reject ratio and

You might also like

- Weld Width & Leg LengthDocument1 pageWeld Width & Leg LengthloknathNo ratings yet

- Course of Study Shielded Metal Arc Welder (H-024-1) Module 14: 1G Plate Smaw ProcessDocument5 pagesCourse of Study Shielded Metal Arc Welder (H-024-1) Module 14: 1G Plate Smaw Processmuhammad qasimNo ratings yet

- Wire Bonding Quality IssuesDocument21 pagesWire Bonding Quality Issueslst204No ratings yet

- Analysis of Hard Chromium Coating Defects and Its Prevention MethodsDocument6 pagesAnalysis of Hard Chromium Coating Defects and Its Prevention MethodsMULYADINo ratings yet

- Network Design Criterion Propagandism (0718)Document7 pagesNetwork Design Criterion Propagandism (0718)Ejaz AhmadNo ratings yet

- Shot Peening Process ControlDocument3 pagesShot Peening Process Controlkayasimge595No ratings yet

- Kaizen Idea Sheet: CountermeasureDocument1 pageKaizen Idea Sheet: CountermeasurerahulNo ratings yet

- 1 Annaling TestDocument2 pages1 Annaling TestProduction TortekNo ratings yet

- Single Span Composite Precast Beam and Deck Bridge Design ManualDocument26 pagesSingle Span Composite Precast Beam and Deck Bridge Design Manualani4576100% (1)

- Underground Cable Fault DetectorDocument21 pagesUnderground Cable Fault DetectorgiriNo ratings yet

- Spec Al ConductorDocument5 pagesSpec Al Conductorknow dworlNo ratings yet

- Data Sheet: Elcometer 124 Thickness GaugeDocument3 pagesData Sheet: Elcometer 124 Thickness GaugeMohamed NouzerNo ratings yet

- Elcometer 124 Thickness Gauge Product Data SheetDocument2 pagesElcometer 124 Thickness Gauge Product Data SheetMohamedNo ratings yet

- DOE Approach For Improving Wire Bonding QualityDocument5 pagesDOE Approach For Improving Wire Bonding QualityAsachan rujeephisitNo ratings yet

- TRA For Fabrication, Cutting, Grinding and WeldingDocument3 pagesTRA For Fabrication, Cutting, Grinding and WeldingSaif Ali100% (1)

- Quality Factors in Single-Defect Photonic-Crystal Lasers With Asymmetric Cladding LayersDocument6 pagesQuality Factors in Single-Defect Photonic-Crystal Lasers With Asymmetric Cladding LayersM Usman RiazNo ratings yet

- Development of Electron Optical Capabilities For Manufacturing of Large Components by Electron Beam WeldingDocument10 pagesDevelopment of Electron Optical Capabilities For Manufacturing of Large Components by Electron Beam WeldingafabNo ratings yet

- Neugroschl 2017Document31 pagesNeugroschl 2017Ujjwal SinghNo ratings yet

- Introduction To Tooling Solutions: TE Connectivity. The Leader in Crimp QualityDocument17 pagesIntroduction To Tooling Solutions: TE Connectivity. The Leader in Crimp QualitydamirNo ratings yet

- CIGRE-216 Assessment Midspan Joints TransmissionDocument10 pagesCIGRE-216 Assessment Midspan Joints TransmissionAdrian PramantaNo ratings yet

- CT, CVT and LA Gyanendra Sharma NPTI DelhiDocument75 pagesCT, CVT and LA Gyanendra Sharma NPTI DelhiNPTINo ratings yet

- Advanced Manufacturing To Enable The Next Generation of Nuclear PlantsDocument39 pagesAdvanced Manufacturing To Enable The Next Generation of Nuclear PlantsAníbal DI LUCHNo ratings yet

- SMAW 9 Week 4 Information SheetDocument3 pagesSMAW 9 Week 4 Information SheetCrauxz de TraxNo ratings yet

- Inspection Report - Electrical WorkDocument9 pagesInspection Report - Electrical Workpremkumarance_999016No ratings yet

- Machines CEP PRESENTATIONDocument19 pagesMachines CEP PRESENTATIONlaksh rathiNo ratings yet

- Effects of Geometry of A Local Thin Area Defect On Remaining Strength andDocument12 pagesEffects of Geometry of A Local Thin Area Defect On Remaining Strength andadityamunthe93No ratings yet

- Strain Gauge Midterm PresentationDocument19 pagesStrain Gauge Midterm PresentationMerek HennellyNo ratings yet

- Tds Oetc 400kv Cab SsDocument23 pagesTds Oetc 400kv Cab SsantaryamisinghNo ratings yet

- JS 01 Report Saiful 1925915 PDFDocument9 pagesJS 01 Report Saiful 1925915 PDFnoralizan azizNo ratings yet

- SEIP For 080-AC-002: GeneralDocument6 pagesSEIP For 080-AC-002: GeneralThinh NguyenNo ratings yet

- Standard Test Method For Vickers Indentation Hardness of Advanced CeramicsDocument8 pagesStandard Test Method For Vickers Indentation Hardness of Advanced CeramicsJosué Licona MármolNo ratings yet

- Port 5Document18 pagesPort 5gbsubbuNo ratings yet

- AMCRPS - AS 500 Design & Execution ManualDocument64 pagesAMCRPS - AS 500 Design & Execution Manualphilou6259No ratings yet

- MS For Public Address System InstallationDocument9 pagesMS For Public Address System Installationanver.yusifNo ratings yet

- Ut PittingDocument7 pagesUt PittingmmNo ratings yet

- Kaizen FormatdDocument2 pagesKaizen Formatdsubbu0815No ratings yet

- State Board of Technical Education &training: Transformer Testing and RepairingDocument32 pagesState Board of Technical Education &training: Transformer Testing and RepairingHima BinduNo ratings yet

- JS 01 Report Danial Hakimi 1925901Document5 pagesJS 01 Report Danial Hakimi 1925901noralizan azizNo ratings yet

- Aec VS MilspecDocument28 pagesAec VS MilspecJeremy ChiangNo ratings yet

- Achieving A Successful ENIG Finished PCB Under Revision A of IPC 4552 SMTAI 2017 PaperDocument10 pagesAchieving A Successful ENIG Finished PCB Under Revision A of IPC 4552 SMTAI 2017 Papercsyan1No ratings yet

- Crimping Terminals: The Importance of Using The Right ToolDocument8 pagesCrimping Terminals: The Importance of Using The Right ToolMauricio PalaciosNo ratings yet

- Race - File System: Features of FKG RaceDocument3 pagesRace - File System: Features of FKG RaceVimi GeorgeNo ratings yet

- Advanced Fatigue Analysis of Offshore Jacket Tubular Joints: Sesam - 50 Years of SuccessDocument49 pagesAdvanced Fatigue Analysis of Offshore Jacket Tubular Joints: Sesam - 50 Years of SuccessMuraliNo ratings yet

- Radiation Effects and COTS Parts in SmallSatsDocument12 pagesRadiation Effects and COTS Parts in SmallSatstomek_zawistowskiNo ratings yet

- 10.2478 - MSP 2022 0030Document15 pages10.2478 - MSP 2022 0030Alagar SamyNo ratings yet

- Hitachi AirisII 0.3T ReportDocument29 pagesHitachi AirisII 0.3T Reportmhamad aboalezNo ratings yet

- JSA-Fabrication, AssemblyDocument19 pagesJSA-Fabrication, AssemblyAshfaq Husain AnsariNo ratings yet

- Modeling A To Z - v2Document9 pagesModeling A To Z - v2Benny PoNo ratings yet

- Completion Report: Solar DWS System in Lower Kurram (FXKI 006)Document12 pagesCompletion Report: Solar DWS System in Lower Kurram (FXKI 006)JawadNo ratings yet

- Surface Integrity Analysis of Nitinol-60 Shape Memory Alloy in WEDMDocument13 pagesSurface Integrity Analysis of Nitinol-60 Shape Memory Alloy in WEDMAbdul FaheemNo ratings yet

- Pradipta Haris 2021 J. Phys. - Conf. Ser. 1899 012085Document9 pagesPradipta Haris 2021 J. Phys. - Conf. Ser. 1899 012085tomo tomoNo ratings yet

- Multiplexed Networks for Embedded Systems: CAN, LIN, FlexRay, Safe-by-Wire...From EverandMultiplexed Networks for Embedded Systems: CAN, LIN, FlexRay, Safe-by-Wire...No ratings yet

- Hot Work TRA Workshop NightDocument3 pagesHot Work TRA Workshop Nightmarvin100% (1)

- ZTT Et Expressway AAAC Conductor 21-Xj00486Document4 pagesZTT Et Expressway AAAC Conductor 21-Xj00486HarisNo ratings yet

- Week 37 Quality ReportDocument3 pagesWeek 37 Quality ReportQMSNo ratings yet

- CSWIP 3.1 Multiple Choice Paper 3 - Exams - CSWIP - The Welding Inspecions CommunityDocument7 pagesCSWIP 3.1 Multiple Choice Paper 3 - Exams - CSWIP - The Welding Inspecions CommunityĐặng SơnNo ratings yet

- 33 KV CT Straton Make 400Document5 pages33 KV CT Straton Make 400Anand SharmaNo ratings yet

- Lean Six Sigma Implementation in Cable HarnessDocument8 pagesLean Six Sigma Implementation in Cable HarnessAhmad Bin Ismail KhanNo ratings yet

- Token Ring Technology ReportFrom EverandToken Ring Technology ReportNo ratings yet