0% found this document useful (0 votes)

239 views14 pagesBHA Design Principles for Drilling

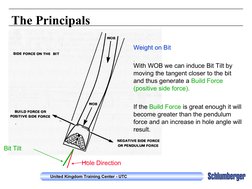

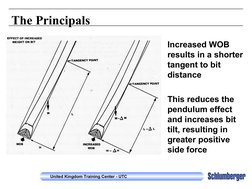

The document discusses objectives and principles of rotary bottom hole assembly (BHA) design. The objectives include describing the minimum number of BHA changes needed for different well profiles and explaining the effects of drill collar stiffness, under-gauge stabilizers, and changing drilling parameters. The principles section describes forces acting on the bit, including pendulum and build forces, and how weight on bit, drill collar stiffness, stabilizer placement, and hole conditions impact BHA behavior. Frequent surveying is advised when using measurement-while-drilling tools.

Uploaded by

Omid ShahbaziCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

239 views14 pagesBHA Design Principles for Drilling

The document discusses objectives and principles of rotary bottom hole assembly (BHA) design. The objectives include describing the minimum number of BHA changes needed for different well profiles and explaining the effects of drill collar stiffness, under-gauge stabilizers, and changing drilling parameters. The principles section describes forces acting on the bit, including pendulum and build forces, and how weight on bit, drill collar stiffness, stabilizer placement, and hole conditions impact BHA behavior. Frequent surveying is advised when using measurement-while-drilling tools.

Uploaded by

Omid ShahbaziCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd

- Introduction: Introduces the training module on Rotary Bottom Hole Assembly Design, highlighting its relevance and application in drilling operations.

- Objectives: Lists the objectives of the module, outlining what participants should achieve by the end of the training.

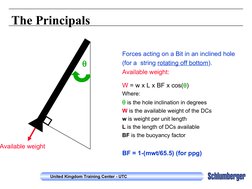

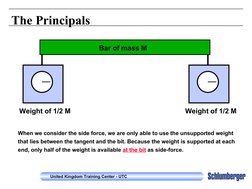

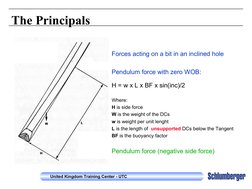

- The Principals: Details the fundamental principles underlying rotary bottom hole assembly design, including mechanical forces and their effects on equipment.

- Drill Collar Stiffness: Explains the concept of drill collar stiffness and its impact on drilling operations, with mathematical demonstrations.

- Stabilizer Effects: Analyzes the effects of stabilizers within the drill setup, focusing on their positioning relative to the bit.