Professional Documents

Culture Documents

XSIGHT - TIP 2021 - XST KL - Malaysia 8 June 2021

Uploaded by

Rozi OthmanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

XSIGHT - TIP 2021 - XST KL - Malaysia 8 June 2021

Uploaded by

Rozi OthmanCopyright:

Available Formats

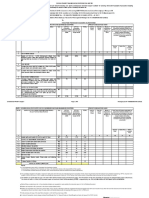

PS ES D M

XST KL

Offshore

XSIGHT TECHNOLOGY INNOVATION PLAN 2021 Division

XST KL9 – Integration of Floating PV to power Hydrogen Electrolyser System installed in a

de-commissioned WHP or CPP

Option A – Containerised solution: Option B – Stick-built solution:

PEM technology AEM technology

4 sets of 2.5MW H2 Electrolyser package i.e. 480 strings of 25kW H2 Electrolyser modules i.e.

10MW total 12MW total

Max. 2000 Nm3/hr production Max. 2500 Nm3/hr production

Power gen. req’t 18MW, require 2 nos. of FPVs Power gen. req’t 21MW, require 2 nos. of FPVs

TARGET

Schedule: Developing a typical configuration that can be used in

Phase 1 – Definition of layout and electrical configurations. different offshore scenarios in terms of equipment

Phase 2 – Existing asset adequacy checks. layout, power consumption and utility configuration.

DECARBONIZATION

Phase 1 completed Phase 2 completed

H2 Electrolyser FPV electrical Export pipeline Typical configuration for

Platform weight

Feb-2021 equipment layout interface Apr-2021 adequacy check

adequacy & FA Jul-2021 offshore H2 production in

configuration configuration check lieu of de-commissioning

Floating PV Park Existing CPP/WHP

1

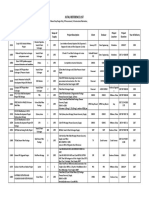

ES D M

XST KL

PS

XST Chennai

XSIGHT TECHNOLOGY INNOVATION PLAN 2021

XST KL6 / CHN 6 – AI for Intelligent P&ID

AI APPLICATIONS

Non-Parametric (exp.

The deployment of AI with parametric ML (logic) and non-parametric Parametric (exp. Fuzzy

Artificial Neural

ML(mapping) application into Intelligent P&ID with the following Expert System)

Network)

targets:

TARGET

minimize time and improve productivity

1. Identify FROM & TO from P&ID and relative coordinate in the 2D (approx. up to 50% improvement in

DIGITALIZATION, DATA & SMART

plot plan productivity costs/times)

2. Identify vertical coordinate

3. Identify piping branches/intersections

4. To produce Piping MTO (pipe length & elbow) Activities breakdown:

Phase 1 – Engineering & Design.

Phase 1 completed Phase 2 completed Phase 2 – AI Software Development

SCHEDULE Phase 3 – Testing & validation complete

End

Plan/Design/ Specificatio Building Jun Model Oct Dec

Feb Testing & validation

data n datasets & e training & & 202 202

202 Assessment

collection/anal preparation logic 202 refinement 1 1

1

ysis 1

You might also like

- Keyboard Lessons in Western StyleDocument34 pagesKeyboard Lessons in Western StyleSreejith Kris80% (5)

- Macworld - April 2024 USADocument120 pagesMacworld - April 2024 USAsoufortniteNo ratings yet

- 402-91-EL-LIS-00003 Rev B - SignedDocument14 pages402-91-EL-LIS-00003 Rev B - SignedKrishnan KrishNo ratings yet

- Sap BPC Business Blueprint DocumentDocument12 pagesSap BPC Business Blueprint DocumentgeneNo ratings yet

- Electrical Load List Rev00Document4 pagesElectrical Load List Rev00epe civilNo ratings yet

- 220 /400 KV Power SS Volume IIDocument735 pages220 /400 KV Power SS Volume IItanujaayer100% (1)

- BPS For 132kV Copper CableDocument8 pagesBPS For 132kV Copper CableHaldar UttamNo ratings yet

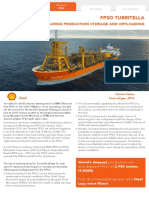

- Factsheet TurritellaDocument2 pagesFactsheet TurritellaJeganeswaranNo ratings yet

- Electric Machines Considering Power ElectronicsDocument68 pagesElectric Machines Considering Power ElectronicsAnkit DalalNo ratings yet

- Wavence UBT Trial - Zain KSA - ED04 - 20181004Document18 pagesWavence UBT Trial - Zain KSA - ED04 - 20181004محمود عثمان100% (2)

- HELP-SIMULATOR gOLDRATTDocument9 pagesHELP-SIMULATOR gOLDRATTjose floresNo ratings yet

- Chapter 3 Random Variables and Probability DistributionsDocument20 pagesChapter 3 Random Variables and Probability Distributions佳俐No ratings yet

- Pmu Bayan Lepas Splliting Bus Bar 275/132kV TNBT 867/2006: TransDocument7 pagesPmu Bayan Lepas Splliting Bus Bar 275/132kV TNBT 867/2006: Transbadhur zaman hajaNo ratings yet

- ATT-TELCO-812-000-159-AOtX Methods and ProceduresDocument252 pagesATT-TELCO-812-000-159-AOtX Methods and ProceduresDurga RaoNo ratings yet

- BRKSPG 2204Document84 pagesBRKSPG 2204Hafedh EsseyehNo ratings yet

- Electrostatic Precipitator Failure Analysis Using FMEA Method On Steam Turbine Electricity Generation (PLTU Banten 2 - Indonesia)Document3 pagesElectrostatic Precipitator Failure Analysis Using FMEA Method On Steam Turbine Electricity Generation (PLTU Banten 2 - Indonesia)Калин ТодоровNo ratings yet

- CLIC Meeting 062020 v2Document18 pagesCLIC Meeting 062020 v2sultan1786No ratings yet

- PFC Price List 15 Sept 2013 EpcosDocument24 pagesPFC Price List 15 Sept 2013 EpcosAnonymous SDeSP1100% (1)

- 49 - EE449T - Electric Power in ShipsDocument3 pages49 - EE449T - Electric Power in ShipsAlaa M El-adlNo ratings yet

- Description: for TALAL TAHER consultants ةظوفحم خسنلا قوقح عيمج رهاطلا للاط / سدنهملا بتكملDocument22 pagesDescription: for TALAL TAHER consultants ةظوفحم خسنلا قوقح عيمج رهاطلا للاط / سدنهملا بتكملvin ssNo ratings yet

- Chip-Based Quantum Communications: ReviewsDocument8 pagesChip-Based Quantum Communications: ReviewsJorgeNo ratings yet

- Mid-Infrared Quantum Cascade Lasers: Yu Yao, Anthony J. Hoffman and Claire F. GmachlDocument8 pagesMid-Infrared Quantum Cascade Lasers: Yu Yao, Anthony J. Hoffman and Claire F. GmachlAndreiNo ratings yet

- Vol Iii BiddingDocument30 pagesVol Iii Biddingmarab12No ratings yet

- Biniss ExcellenceDocument74 pagesBiniss Excellenceforum5 4caNo ratings yet

- JVL Industrial Ethernet Expansion Modules For MAC MotorsDocument8 pagesJVL Industrial Ethernet Expansion Modules For MAC MotorsElectromateNo ratings yet

- Design of High Gain Folded-Cascode Operational Amplifier Using 1.25 Um CMOSDocument9 pagesDesign of High Gain Folded-Cascode Operational Amplifier Using 1.25 Um CMOSHassan El-kholyNo ratings yet

- Wide-Area Monitoring and Control For Electric Power Systems: Mats Larsson, Corporate Research ABB SwitzerlandDocument22 pagesWide-Area Monitoring and Control For Electric Power Systems: Mats Larsson, Corporate Research ABB SwitzerlandkhalidNo ratings yet

- An 8-Bit 120-MS/s Interleaved CMOS Pipeline ADC Based On MOS Parametric AmplificationDocument5 pagesAn 8-Bit 120-MS/s Interleaved CMOS Pipeline ADC Based On MOS Parametric Amplificationjulio perezNo ratings yet

- Home Services Solutions Domains Insights Careers Company: Dayanand Shambhu Signoff SemiconductorsDocument12 pagesHome Services Solutions Domains Insights Careers Company: Dayanand Shambhu Signoff Semiconductorsgudala praveenNo ratings yet

- Adaptive Control Signal Parameters in LTE Technology With MIMODocument14 pagesAdaptive Control Signal Parameters in LTE Technology With MIMOSumanth JoglekarNo ratings yet

- Jutal Reference List: NotesDocument3 pagesJutal Reference List: Notesreign226No ratings yet

- Icx Cmos e 2004Document3 pagesIcx Cmos e 2004HilalzkNo ratings yet

- A Carrierless Amplitude Phase CAP Modulation FormaDocument11 pagesA Carrierless Amplitude Phase CAP Modulation FormaMalik Adil FarooqNo ratings yet

- Session 03 PDFDocument40 pagesSession 03 PDFusman murtazaNo ratings yet

- M V Current TransformersDocument9 pagesM V Current TransformersAhmed ElshnshoryNo ratings yet

- Journal Jpe 14-2 1420244966Document11 pagesJournal Jpe 14-2 1420244966Hua Hidari YangNo ratings yet

- Nu3-Ktrg: 1e/TG 4E/ "Document1 pageNu3-Ktrg: 1e/TG 4E/ "Raju ReddyNo ratings yet

- Final Project - 201535TJ505 - LAKSHMIKANTHA REDDYDocument57 pagesFinal Project - 201535TJ505 - LAKSHMIKANTHA REDDYShar MohdNo ratings yet

- White Paper To Mok - FINAL-1Document26 pagesWhite Paper To Mok - FINAL-1William Mook67% (3)

- Terma Space Power System A4 v9 CleanedDocument6 pagesTerma Space Power System A4 v9 CleanedAndres TellariniNo ratings yet

- A HighDensity, High 10 KV Silicon Carbide (Speed SiC) MOSFET Power ModuleDocument73 pagesA HighDensity, High 10 KV Silicon Carbide (Speed SiC) MOSFET Power Moduleu.s.routNo ratings yet

- Profile: Employment HistoryDocument5 pagesProfile: Employment HistoryMoin- ud-dinNo ratings yet

- Mid Sem 2022-2023Document17 pagesMid Sem 2022-2023Mehul GuptaNo ratings yet

- A High-Speed Low Power Multi-ModulusDocument7 pagesA High-Speed Low Power Multi-ModulusIssam FathallahNo ratings yet

- Short Circuit Tested Substation Busbars & Fittings 11kV - 500kV To 63ka / 1 SecondDocument15 pagesShort Circuit Tested Substation Busbars & Fittings 11kV - 500kV To 63ka / 1 Secondpisang123456No ratings yet

- The Growing Ecosystem For Egan Fet Power Conversion: PrologueDocument6 pagesThe Growing Ecosystem For Egan Fet Power Conversion: PrologueoszemNo ratings yet

- Kim Lighting EKG Gen. 2 Series Brochure 1985Document18 pagesKim Lighting EKG Gen. 2 Series Brochure 1985Alan MastersNo ratings yet

- Guideline PepDocument29 pagesGuideline PepJaafar DahlanNo ratings yet

- Architecture and DSP Implementation of A DVB-S2 BaDocument9 pagesArchitecture and DSP Implementation of A DVB-S2 Bakuang.fanNo ratings yet

- Optimizing Satellite Communications Using Doubletalk Carrier-In-Carrier cdm-625 Advanced Satellite ModemDocument21 pagesOptimizing Satellite Communications Using Doubletalk Carrier-In-Carrier cdm-625 Advanced Satellite ModemhamzaNo ratings yet

- Datasheet NCP81109Document28 pagesDatasheet NCP81109zigmund zigmundNo ratings yet

- Location: Project: Date:: Bus Directly Connected Load Total Bus LoadDocument6 pagesLocation: Project: Date:: Bus Directly Connected Load Total Bus LoadAngfika Septianto WijayaNo ratings yet

- YS2-03-C10017-TL-BOQ-Z-001 Rev. 0 (BoQ CP)Document10 pagesYS2-03-C10017-TL-BOQ-Z-001 Rev. 0 (BoQ CP)Gajendra PatilNo ratings yet

- Vol III PDFDocument9 pagesVol III PDFmarab12No ratings yet

- Datasheet of Analyser - Pe-V0-415-673-A203 R02Document44 pagesDatasheet of Analyser - Pe-V0-415-673-A203 R02ankushbahaleNo ratings yet

- SC452 Dual Phase Single Chip IMVP 6 VcorDocument37 pagesSC452 Dual Phase Single Chip IMVP 6 VcorspotNo ratings yet

- CNFET Based Voltage Differencing Transconductance Amplifier: IOP Conference Series: Materials Science and EngineeringDocument8 pagesCNFET Based Voltage Differencing Transconductance Amplifier: IOP Conference Series: Materials Science and EngineeringMohd YasirNo ratings yet

- Sample Doc FATP Complete V - 1.6 EID MW Indosat ProjectDocument33 pagesSample Doc FATP Complete V - 1.6 EID MW Indosat ProjectMuh ramli RamliNo ratings yet

- Sugandh Uldc Scada OverviewDocument18 pagesSugandh Uldc Scada OverviewRatilal M JadavNo ratings yet

- PFC Product Profile (India)Document88 pagesPFC Product Profile (India)Anonymous SDeSP1No ratings yet

- Eclipse Design & Material, Inc.: A Systems Solution Technology CompanyDocument28 pagesEclipse Design & Material, Inc.: A Systems Solution Technology Companysabregold19993394100% (2)

- CEPLDocument18 pagesCEPLSudhanshu BaranwalNo ratings yet

- Token Ring Technology ReportFrom EverandToken Ring Technology ReportNo ratings yet

- StarLAN Technology ReportFrom EverandStarLAN Technology ReportRating: 3 out of 5 stars3/5 (1)

- Highly Integrated Gate Drivers for Si and GaN Power TransistorsFrom EverandHighly Integrated Gate Drivers for Si and GaN Power TransistorsNo ratings yet

- Design of An Employee Management System: (A Case Study of National Iron Ore Mining Company, Itakpe)Document10 pagesDesign of An Employee Management System: (A Case Study of National Iron Ore Mining Company, Itakpe)MilkessaAddunyaaKanaaNo ratings yet

- OpenText RightFax 10.6 Administrative Utilities GuideDocument56 pagesOpenText RightFax 10.6 Administrative Utilities GuideAshwani Yadav100% (1)

- Jisamar - Application of Oriented Fast and Rotated Brief (Orb) and Bruteforce Hamming in Library Opencv For Classification of PlantsDocument9 pagesJisamar - Application of Oriented Fast and Rotated Brief (Orb) and Bruteforce Hamming in Library Opencv For Classification of PlantsVerdi YasinNo ratings yet

- TAPCON® 240-LV: Operating Instructions BA 223/03Document24 pagesTAPCON® 240-LV: Operating Instructions BA 223/03joseNo ratings yet

- Question Bank - Unit IIIDocument2 pagesQuestion Bank - Unit IIIMoses DianNo ratings yet

- Default Password ListDocument77 pagesDefault Password ListSahirNo ratings yet

- Introduction To EDDCDocument10 pagesIntroduction To EDDCDjebali MouradNo ratings yet

- STM 32 L 552 RCDocument340 pagesSTM 32 L 552 RCManish K MuraliNo ratings yet

- Database Cheat SheetDocument4 pagesDatabase Cheat SheetJoseph CraigNo ratings yet

- Steel-Concrete Composite Bridges: Design, Life Cycle Assessment, Maintenance, and Decision-MakingDocument14 pagesSteel-Concrete Composite Bridges: Design, Life Cycle Assessment, Maintenance, and Decision-MakingNicholas FeatherstonNo ratings yet

- Europass 2FA Tutorial - ENDocument18 pagesEuropass 2FA Tutorial - ENbaljit singhNo ratings yet

- Service Manual Belinea - 101750 - 101751 - Art - No - 111732 - 111733 - SMDocument58 pagesService Manual Belinea - 101750 - 101751 - Art - No - 111732 - 111733 - SMyekukuNo ratings yet

- 2019 12 20 - LogDocument244 pages2019 12 20 - LogAikalazizi ZizieaircondNo ratings yet

- Deliverable D7.4 Exploitation and Techno-Economic ModelDocument55 pagesDeliverable D7.4 Exploitation and Techno-Economic ModelgkoutNo ratings yet

- Brookins A. The Temple of Django Database Performance 2020Document159 pagesBrookins A. The Temple of Django Database Performance 2020Vítor SilvaNo ratings yet

- Quốc Gia Khởi NghiệpDocument87 pagesQuốc Gia Khởi NghiệpPhan LongNo ratings yet

- 1.3 HCF and LCMDocument38 pages1.3 HCF and LCMS K TAnNo ratings yet

- Numerical Ability Worksheet 27Document3 pagesNumerical Ability Worksheet 27Areum YuNo ratings yet

- Item 1.7 Cable Utp CAT 6 Legrant-LG-032755Document3 pagesItem 1.7 Cable Utp CAT 6 Legrant-LG-032755antonio villafañaNo ratings yet

- Tools For Weather ForecastingDocument2 pagesTools For Weather ForecastingGatik YadavNo ratings yet

- Deep TurnaroundDocument14 pagesDeep TurnaroundHusain RagibNo ratings yet

- Draft TIC 3.0 Vol. 1 Program GuidebookDocument26 pagesDraft TIC 3.0 Vol. 1 Program GuidebookJulio Cesar BalderramaNo ratings yet

- Red Hat System Administration IDocument5 pagesRed Hat System Administration Ijeetendra_kumar2008No ratings yet

- God of War 3 PC CD Keygen Generator Direct Download For PC - RarDocument3 pagesGod of War 3 PC CD Keygen Generator Direct Download For PC - Rarjack sparrowNo ratings yet

- Elevi Admisi Cex Etapa IiDocument5 pagesElevi Admisi Cex Etapa IimarianoNo ratings yet