Professional Documents

Culture Documents

Tools TRG Module ACT Advance Cluster

Uploaded by

SANKUSIOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tools TRG Module ACT Advance Cluster

Uploaded by

SANKUSICopyright:

Available Formats

7 QC tools

Property of ACT ( ACMA Centre for Slide No. 1

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Seven QC Tools

Scatter Diagram

Stratification

Histogram

Graph and Control Chart

Cause and Effect Diagram

Pareto Diagram

Check Sheet

Property of ACT ( ACMA Centre for Slide No. 2

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

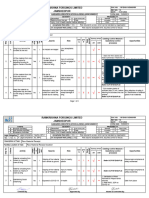

Sl.No Tools Function

Check Sheet / To Collect the data in a simple manner and to

1

Data Sheet prevent omitting the checks

To pick up the important few problems from

2 Pareto Daigram

the trivial many.

Cause and Effect To reorganise the factors (causes) which are

3

Diagram influencing the problem

Presentation of data in a pictorial form for

Graph and Control

4 better understanding and see if the process

Chart

is under stable conditions.

To see the distribution pattern compared

5 Histogram

against the standard values.

To segregate data according to contributing

6 Stratification

sources.(Suppliers,machines,operators etc)

7 Scatter Diagram To see relation between two sets of data

Property of ACT ( ACMA Centre for Slide No. 3

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Check Sheet

Solder Bath Temperature

Checked by : Raised by :

Take reading of temperature nearest to degree.

Time Temp (0C) Time Temp (0C)

0800 60 1300 61

0900 62 1400 58

1000 59 1500 63

1100 58 1600 63

1200 59 1700 59

Note : Power failure from 12.00 to 12.15 Hours

Property of ACT ( ACMA Centre for Slide No. 4

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

What is Check Sheet ?

A Check sheet is a paper form on which item to be

checked have been printed already so that data can be

collected easily and concisely. Its main purposes are

two-fold :

1) To make data-gathering easy ;

2) To arrange data automatically so that they can be

used easily later on

Two Types of Data :

1. Measurement data or Variable data.

2. Attribute data.

Property of ACT ( ACMA Centre for Slide No. 5

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Check sheets are of following types :

a) Check sheet for production process distribution.

b) Defective item check sheet.

c) Defect location check sheet.

d) Defect cause check sheet.

Property of ACT ( ACMA Centre for Slide No. 6

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Check Sheet for Production Process Distribution:

Checks

Deviation F

5 10 15 requency

-10 20

-9

Specification -8

-7

-6

-5 1

-4 2

-3 4

-2 6

-1 9

8.300 0 11

1 8

2 7

3 3

4 2

5 1

6 1

7

Specification 8

9

10

Total 55

Property of ACT ( ACMA Centre for Slide No. 7

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Defective Item Check Sheet:

Product :

Date :

Manufacturing stage: Final inspection

Section :

Type of defect: Scar,incomplete

Inspector’s name :

crack,misshapen.

Lot no :

Total no.inspected : 1525

Order no :

Remarks : All items inspected.

Type Checks Subtotal

Surface scars IIII IIII IIII II 17

Cracks IIII IIII I 11

Incomplete IIII IIII IIII IIII IIII I 26

Mishappen III 3

Others IIII 5

Total : 62

Total rejects 42

Property of ACT ( ACMA Centre for Slide No. 8

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Defect Location Check Sheet

A B C D

1 4

2 3 1

A 1

B 12 15 2

C 10 11

3

D 1

From the location matrix it is

4

clear that most of the blow holes

are occupied in the segment B2,B3,C2 & C3.

Defect Location Matrix For Blowholes (50 Defective Components)

Property of ACT ( ACMA Centre for Slide No. 9

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Defect Cause Check Sheet.

Mon Tue Wed Thu Fri Sat

Equipment Operator

AM PM AM PM AM PM AM PM AM PM AM PM

oo ox ooo oo xxxx oo

x xxx xx

1

ooo xx oo xx

A

2 oo xxx

1 oo xx

B

2 xx oo

o Damage x Blowhole Poor finish Crack Others

Property of ACT ( ACMA Centre for Slide No. 10

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Points to remembered while making check sheets

Easy to use and understand.

Information should be true and accurate.

Decide objective by involving all the members.

Use 5W and 1H principle.

Who will collect the data ?

When will the data be collected ?

Where will the data be collected ?

How will data be collected ?

Check sheets should be displayed on visible area.

Property of ACT ( ACMA Centre for Slide No. 11

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Benefits of Check Sheets

Data Collection have the following benefits :

• Right decision can be made.

• Errors due to subjective feeling or personal bias are avoided.

• Agreement on decisions necessary rather than different or

subjective opinion.

• Measurement understandable to all.

• Assessments of magnitude of improvements.

• Discovery of causes affecting quality and productivity .

Property of ACT ( ACMA Centre for Slide No. 12

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Pareto Diagram

250 100

100

96.75

91.53

200 85.28 80

156

150 60

105

100 50.98 40

50 20

20 16

9

0 0

Cold oil shot Damage Chip off Bad app

shut

Types of Defects

Property of ACT ( ACMA Centre for Slide No. 13

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

What is Pareto Diagram ?

Pareto diagrams are presentation technique used to

show facts and they help us to separate the “vital few”.

Pareto diagram was first thought out by an Italian economist,

Pareto (1848 - 1923), when he used it as a method for national

income analysis to show that a large proportion of the wealth

was centered around a small minority of people.

After that, an American Quality Control Authority, Mr.Juran used

it in the field of Quality Control.

Property of ACT ( ACMA Centre for Slide No. 14

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Steps to make the pareto diagrams :

1) Decide what problems are to be investigated and how to collect the

data.

2) Design a data tally sheet listing the items,with space to record their

totals.

3) Fill out the tally sheet and calculate the totals (Example-1)

4) Make the pareto diagram data sheet listing the items, their individual

totals,cumulative totals,percentages of overall total, and cumulative

percentages (Example-2)

Property of ACT ( ACMA Centre for Slide No. 15

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Steps to make the pareto diagrams (contd.) :

1) Draw two vertical axes and a horizontal axis.

2) Construct a bar diagram.

3) Draw the cumulative curve (Pareto curve).

4) Write any necessary items on the diagram.

a) Items concerning the diagram.

b) Items concerning the data.

5) Arrange the items in the order of quantity,and fill out the data sheet.

Property of ACT ( ACMA Centre for Slide No. 16

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Data Tally Sheet - Example -1

Type of Defect Tally Total

Crack IIII IIII 10

Scratch IIII IIII IIII IIII …………. IIII II 42

Stain IIII I 6

Strain IIII IIII IIII IIII I I I .I

……………………… IIII 104

Gap IIII 4

Pinhole IIII IIII IIII IIII 20

Others IIII IIII IIII 14

Total 200

Property of ACT ( ACMA Centre for Slide No. 17

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Data Sheet for Pareto Diagram - Example - 2

Type of Number of Cumulative Percentage of Cumulative

Defect Defect Total Overall Total Percentage

Strain 104 104 52 52

Scratch 42 146 21 73

Pinhole 20 166 10 83

Crack 10 176 5 88

Stain 6 182 3 91

Gap 4 186 2 93

Others 14 200 7 100

Total 200 - 100 -

Property of ACT ( ACMA Centre for Slide No. 18

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Parteo Diagram by Defective Items:

100

200 April 1 - June 30 93 100

88 91

180 83 90

160 80

73

140 70

120

52 60

100 50

80 104 40

60 30

42

40 20

20

20 10 6 4 14 10

0 0

D B F A C E Others

A :Crack, B: Scratch, C: Stain, D: Strain, E: Gap, F: Pinhole.

(Number of Units Investigated : 5,000)

Property of ACT ( ACMA Centre for Slide No. 19

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Cause and Effect Diagram

Man Machine

Characteristics

Material Method

Property of ACT ( ACMA Centre for Slide No. 20

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

What is Cause and Effect Diagram ?

Any defect in a component, a product or service could be

due to one or more causes.To find out the relationship between

the causes and effect, a diagram is drawn systematically by

mapping out all the probable causes influencing the effect.

Cause

This is and effect

called diagram

a “Cause andwas introduced

Effect by “Dr.K.Ishikawa”.

Diagram”

He used it in Kawasaki Iron Works in 1943.

Since final diagram looks like a fish bone it is also called as

Fish Bone Diagram.

Property of ACT ( ACMA Centre for Slide No. 21

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Format of a Cause and Effect Diagram

Main Cause Main Cause Level 2

A Cause

Level 3

Cause Level 1

Cause

Characteristics

Main Cause Main Cause

Above diagram depicts the basic format of Cause and Effect diagram.

There is a hierarchical relationship of the effect to the main causes and

their subsequent relationship to the sub-causes.

Property of ACT ( ACMA Centre for Slide No. 22

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Procedure for Making Cause-and-effect Diagrams

for Identifying Causes:

1) Determine the quality characteristics.

2) Choose one quality characteristics and write it on the right-

hand side of a sheet of paper, draw in the backbone form

left to right, and enclose the characteristic in a square. Next,

write the primary causes which affect the quality characteristics

as big bones also enclosed by squares.

Property of ACT ( ACMA Centre for Slide No. 23

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Procedure for Making Cause-and-effect Diagrams

for Identifying Causes – (contd):

3) Write the causes (Secondary causes) which affect the big

bones (primary causes) as medium-sized bones and write the

causes (tertiary causes) which affect the medium-sized bones

as small bones.

4) Assign an importance to each factor and mark the particularly

important factor that seem to have a significant effect on the

quality characteristics.

5) Record any necessary information.

Property of ACT ( ACMA Centre for Slide No. 24

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Example of Cause-and-Effect Diagram :

Health Spirit Encouragement

Pride

Relaxation

Fighting spirit

Rest

Nutrition Calories Patience Devotion

Amusement Calmness

Meal Carefulness

Time

C

Quantity

Sleep Concentration

omposure

Depth Defeat in a

Confidence

Theory Information Po sports match

Schedule

Study of wer

Planning opponent Speed

Motion Exercise

A Q

nalysis Cooperatio uality

Common Rules Observation n Quantity

Advice

sense Judgement of situation Function

Teamwork Form

Strategy Experience of matches Model Repetition

Techniqure Slide No. 25

PDF created with pdfFactory Pro trial version www.pdffactory.com

Example of Cause-and-Effect Diagram :

MAN MACHINE

Milling Depth

under size

Wrong assembly

M/c condition

New operator not ok

Valve Plate

High variation Projecting out

Importance not in the process of cyl.head in

known to operator 94 dia cylinder

head

Hole location not taken

assembly

during assembly

Gap less at WHY?

suction side

No Poka yoke Hole position shifted

In adequate Valve plate outer

In adequate

dimension oversize

Fixture design design Improper

METHOD MATERIAL blanking

Property of ACT ( ACMA Centre for Slide No. 26

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Points to remembered.

1) Once Cause and Effect diagram is made, check for its

completeness. If required get reviewed from the experts.

2) A good Cause and Effect diagram gives an excellent

understanding of a complex problem in a simple way.

3) Cause and Effect diagram is not an answer of the problem.

4) Main cause to be found out by collecting data or on collective

experience.

5) Less educated persons and with poor knowledge about process

can be benefited by this.

Property of ACT ( ACMA Centre for Slide No. 27

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Graph and Control Chart

UCL

C/L

LCL

Property of ACT ( ACMA Centre for Slide No. 28

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

What is Graph :

Graph is a pictorial representation of data which is easily

understandable at a glance. It is a visual representation of

data made up of points, lines, letters, words, numbers,

shades etc.

Property of ACT ( ACMA Centre for Slide No. 29

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Types of Graphs :

1) Line graph

2) Bar chart / graph

3) Pie chart or Circle graph

4) Radar chart

5) Compound graphs - bar and line

6) Gantt chart

Property of ACT ( ACMA Centre for Slide No. 30

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Line Graph :

709

700

662

550

400 376

330

275 273

250

Jan'03 Feb Mar Apr May June

Month

Production details

Property of ACT ( ACMA Centre for Slide No. 31

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Bar Chart / Graph :

10

9

8

7

7 6.3

6

5

4 4

4 3.4

3

3

2

1

0

Jan'01 Feb'01 Mar'01 Apr'01 May'01 Jun'01

HMC Machine Breakdown

Property of ACT ( ACMA Centre for Slide No. 32

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Pie chart or Circle graph :

Unwanted - 61

Tags removed - 59

Easy to CLI - 855 Leakage - 845

Tags removed - 850 Tags removed - 825

Electrical - 332 Missing - 385

Tags removed - 325 Tags removed - 380

Loose - 393

Damage & Broken - 340 Tags removed - 390

Tags removed - 334

Classification of abnormality tags.

Property of ACT ( ACMA Centre for Slide No. 33

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Radar chart

Plant performance : 2001-2002

unit1

100% 100%

50%

unit5 unit2

0.85 80%

0%

unit4 60% unit3

90%

Property of ACT ( ACMA Centre for Slide No. 34

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Compound graph - Bar and Line

10 9.25

9 8.75 Frequency

8

7 7

7

Hours

6

4.75 5

5

4 4 4.75

4

3 3 3.5

3

2

1

0

Jan'01 Feb'01 Mar'01 Apr'01 May'01 Jun'01

HMC Machine Breakdown

Property of ACT ( ACMA Centre for Slide No. 35

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Gantt chart

Property of ACT ( ACMA Centre for Slide No. 36

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

What is Control Chart :

1) Control chart is a graphical device to aid in process control.

2) It consist of a graph with a central line denoting the target value

control limit” and “Limit control limit” and two limit lines on either side

of the central

3) Quality line called

measured “Upper

periodically is plotted on the chart and status of

control assessed.

4) The control chart was first proposed by Dr.Walter A Shewhart, an

engineer in the Bell Telephone Laboratories,USA with a view

to eliminate abnormal variation.

Property of ACT ( ACMA Centre for Slide No. 37

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Two Types of Variations :

1. Chance Causes.

2. Assignable Causes.

1. Chance Causes :

Which are uncontrollable and comprising very small

differences in raw materials in the same batch or machines,

actual conditions etc.

2. Assignable Causes :

Such as different settings of a machine, different raw

material batches, changes in operators, operator errors etc.

Property of ACT ( ACMA Centre for Slide No. 38

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Types of Control Chart

Characteristic Value Name

x - R Chart (average value and range)

Continuous value

x chart (measured value)

pn chart (number of defective units)

p chart (fraction defective)

Discrete value

c chart (number of defects)

u chart (number of defects per unit)

Property of ACT ( ACMA Centre for Slide No. 39

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Types of Control Chart :

x - R Chart

1) It is used for controlling and analyzing a process using

continuous values of product quality such as length, weight or

concentration and this provides the larger amount of information on the

process.

2) x represents an average value of a subgroup and R represents the

range of the subgroup.

3) An R chart is used usually in combination with an x chart to

control the variation within a subgroup.

Property of ACT ( ACMA Centre for Slide No. 40

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Procedure to make control charts :

x - R Chart

1) Collect the data.

2) Calculate x

x = x1 + x2 +……+ xn

n - Size of a sub group

n

3) Calculate x

x = x1 + x2 +……+ xk

k - Number of subgroups

k

Property of ACT ( ACMA Centre for Slide No. 41

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Procedure to make control charts (contd.) :

x - R Chart

4) Calculate R

R = (Maximum value in a subgroup) -(Minimum Value in a subgroup)

5) Calculate R

R = Rx1 + Rx2 +……+ Rn

Property of ACT ( ACMA Centre for Slide No. 42

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Procedure to make control charts (contd.) :

x - R Chart

6) Calculate the control lines

x Chart

Central line :

CL = x

Upper control limit :

UCL = x +

A2R.

Lower control limit :

UCL = x - A2R

Property of ACT ( ACMA Centre for Slide No. 43

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Procedure to make control charts (contd.) :

x - R Chart

7) Calculate the control lines

R Chart

Central line :

CL = R

Upper control limit :

UCL = D4R.

Lower control limit :

LCL = D3R

Property of ACT ( ACMA Centre for Slide No. 44

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Procedure to make control charts(contd.) :

8) List of Coefficients for x - R Chart.

Size of Subgroup x Chart R Chart

n

A2 D3 D4 d2

2 1.88 --- 3.267 1.128

3 1.023 --- 2.575 1.693

4 0.729 --- 2.282 2.059

5 0.577 --- 2.115 2.326

6 0.483 --- 2.004 2.534

Property of ACT ( ACMA Centre for Slide No. 45

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Procedure to make control charts(contd.) :

x - R Chart

9) Plot the points.

10) Draw the control lines.

11) Write the necessary items.

Property of ACT ( ACMA Centre for Slide No. 46

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Examples of Control Chart :

UCL

C/L

LCL

Control Chart for Controlled State

UCL

C/L

LCL

Control Chart for Uncontrolled State

Property of ACT ( ACMA Centre for Slide No. 47

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Examples of Control Chart :

Average chart (X)

READINGS

52.043 USL

LSL

52.039

Xdbar

52.035 UCL XBAR

LCL XBAR

52.031

1 3 5 7 9 11 13 15 17 19 21 23 25

Samples

Property of ACT ( ACMA Centre for Slide No. 48

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

How to Read Control Charts :

1) Out of control limits.

Ten out of 11 consecutive

2) Run. points occurring on one

Seven-point length of

run is abnormal. side is abnormal.

Run

Property of ACT ( ACMA Centre for Slide No. 49

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

How to Read Control Charts (contd.) :

3) Trend

Seven upward points Drastic downward trend

Property of ACT ( ACMA Centre for Slide No. 50

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

How to Read Control Charts (contd.) :

4) Approach to the control limits (2 out of 3 points)

3-sigma line

2-sigma line

2-sigma line

3-sigma line

Property of ACT ( ACMA Centre for Slide No. 51

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

How to Read Control Charts :

5) Approach to the central line.

3-sigma line

1.5-sigma line

Property of ACT ( ACMA Centre for Slide No. 52

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

How to Read Control Charts (contd.) :

6) Periodicity

Property of ACT ( ACMA Centre for Slide No. 53

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Histogram

40

38

35 34

30

25

20

15

9.9

10 9

4 4 4.5

5

2.5 2.5

0

0

0 3.3 3.35 3.4 3.45 3.5 3.55 3.6 3.65 3.7

Property of ACT ( ACMA Centre for Slide No. 54

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

What is Histogram :

Histogram is a graphical representation of a

frequency distribution which is a summary of variation

in a product or process.

Property of ACT ( ACMA Centre for Slide No. 55

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Steps to construct the Histogram :

1) Collect 100 reading.

2) Find out lowest and highest value of reading row wise.

3) Find out lowest and highest from all the rows.

4) Compute the range . R = Max - Min.

5) Follow standard table for no of classes.

No of Observations No of Classes ( k )

< 50 6

51 - 100 7

101 - 200 8

201 - 500 9

501 - 1000 10

Property of ACT ( ACMA Centre for Slide No. 56

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Graph to Determine K

20

18

16

14

k 12

10

0

1 2 3 4 5 678 10 20 50 200 500 1,000

n n - Numbers of Measurements.

Property of ACT ( ACMA Centre for Slide No. 57

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Steps to construct the Histogram :

1) Calculate the approximate width of class with the help of

formula ( R + W ) / K

Where “ R “ is the range. “ W “ is accuracy in the observation

and “ K “ is no.of classes.Make the frequency table and then

draw the histogram.

Note

1) Classes should be continuous.i.e 1-5,5-10,10-15 etc.

2) All classes should have same width.

Property of ACT ( ACMA Centre for Slide No. 58

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Histogram data sheet

1 104.1 11 104.5 21 104.4 31 104.4 41 104.6

2 104.4 12 104.3 22 104.5 32 104.3 42 104.4

3 104.3 13 104.4 23 104.4 33 104.4 43 104.6

4 104.5 14 104.5 24 104.3 34 104.7 44 104.7

5 104.4 15 104.4 25 104.2 35 104.2 45 104.3

6 104.3 16 104.5 26 104.4 36 104.4 46 104.5

7 104.2 17 104.2 27 104.6 37 104.3 47 104.2

8 104.5 18 104.4 28 104.4 38 104.5 48 104.5

9 104.3 19 104.3 29 104.3 39 104.4 49 104.4

10 104.5 20 104.4 30 104.1 40 104.3 50 104.3

Property of ACT ( ACMA Centre for Slide No. 59

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Tally Data Sheet

104.1 - //

104.2 - ////

104.3 - //// //// //

104.4 - //// //// //// /

104.5 - //// ////

104.6 - ///

104.7 - //

Property of ACT ( ACMA Centre for Slide No. 60

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Examples of Histogram :

20

16

15

12

10

10

5

5 3

2 2

0

104.1 104.2 104.3 104.4 104.5 104.6 104.7

in mm

Property of ACT ( ACMA Centre for Slide No. 61

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Interpretation of Histogram

Minimum Maximum Minimum Maximum

Limit Limit Limit Limit

1 4

2 5

6

3

Property of ACT ( ACMA Centre for Slide No. 62

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Types of Histogram :

a) General type b) Comb type

c) Positively skew type d) Left-hand precipice type

Property of ACT ( ACMA Centre for Slide No. 63

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Types of Histogram :

e) Plateau type f) Twin-peak type

g) Isolated-peak type

Property of ACT ( ACMA Centre for Slide No. 64

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Uses of Histogram :

1) To know the pattern of variation.

2) To assess states of control

3) To assess conformance to specifications

4) To assess spread or variation with reference to specification.

5) To assess process capability.

6) To get clues for bringing process under control - whether to shift

mean or to reduce variation or both.

7) To get clues for possible assignable causes for observed variation -

mixture of lots, suppliers, instruments /measurements errors, bias of

written results etc.

Property of ACT ( ACMA Centre for Slide No. 65

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Stratification

50 48%

40

30

20 16% 18%

12%

10 6%

0

A B C D E

Types of Defect

Property of ACT ( ACMA Centre for Slide No. 66

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

What is Stratification :

Stratification is the process of separation of data into

categories. It is normally done for identifying the categories

contributing to the problem tackled.

Property of ACT ( ACMA Centre for Slide No. 67

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Types of Stratification :

A. Material Based :

48%

50

40

30

20 16 % 15%

10

0

A B C

Supplier

Defective Quality - Supplier Wise.

Property of ACT ( ACMA Centre for Slide No. 68

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Types of Stratification :

B. Quality Based :

50

48%

40

30

20 16% 18%

12%

10 6%

0

A B C D C

Type of Defect

Defects Data For Each Hour in a Shift

Property of ACT ( ACMA Centre for Slide No. 69

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Types of Stratification :

C. Worker Based :

30

25 22%

20

15

10

5%

5

3%

0

A B C

Worker

Defective Assemblies

Property of ACT ( ACMA Centre for Slide No. 70

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Types of Stratification :

D. Machine Based :

100

90

80

70

60 57%

50 43%

40

30

20

10

0

A B

Machine

Production Machine Wise

Property of ACT ( ACMA Centre for Slide No. 71

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Types of Stratification :

E. Processing Based :

50

40

32%

30

25% 26%

20

12%

10 5%

0

A B C D E

Process Area

Power Consumption Process Area Wise

Property of ACT ( ACMA Centre for Slide No. 72

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Scatter Diagram

4.5

4.4

4.3

4.2

4.1

4.0 y axis

4 430 x axis

3.9

3.8

3.7

3.6

3.5

3.4

100 150 200 250 300 350 400 450 500 550 600 650

Average Experience of Training Team (in days)

Property of ACT ( ACMA Centre for Slide No. 73

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

What is Scatter Diagram :

Scatter diagram is a graphical representation of

relationship between two variables. It can be between a Cause

and Effect and between causes.

In 1837 J.F.W.Herswchal,an Englishman, used scatter diagram.

In 1950s Dr.K.Ishikawa popularized the use of scatter diagram.

Property of ACT ( ACMA Centre for Slide No. 74

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Steps to draw Scatter Diagram :

1) Collect paired data (x,y)

2) Find the maximum and minimum values for

both the x and y.

3) Plot the data.

4) Enter all necessary items.

Property of ACT ( ACMA Centre for Slide No. 75

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

The horizontal (x axis) and vertical (y axis) lines of the diagram:

The measurement scales generally increase as you move up

the vertical axis and to the right on the horizontal axis.

4.5

4.4

4.3 Dependent variable (“effect”)

4.2

4.1

4.0

3.9 * Looking for relationships

3.8 not cause & effect

3.7 Independent variable (“cause”)

3.6

3.5

150 200 250 300 350 400 450 500 550 600 650

Property of ACT ( ACMA Centre for Slide No. 76

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Examples of Scatter Diagram :

4.5

4.4

4.3

4.2

4.0 y axis

4.1 430 x axis

4

3.9

3.8

3.7

3.6

3.5

3.4

100 150 200 250 300 350 400 450 500 550 600 650

Average Experience of Training Team (in days)

Property of ACT ( ACMA Centre for Slide No. 77

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

Possibilities after plotting the points

a. Positive relationship

b. No correlation.

c. Negative correlation.

d. Positive and Negative correlation.

e. Negative and Positive correlation.

Property of ACT ( ACMA Centre for Slide No. 78

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

n = 30 r = 0.9 n = 30 r = 0.6 n = 30 r = 0.0

y y y

6 6 6

4 4 4

2 2 2

0 0 0

0 2 4 6 x 0 2 4 6 x 0 2 4 6 x

Positive Correlation Positive Correlation No Correlation

May Be Present

n = 30 r = 0.9 n = 30 r = 0.6

y y

6 6

4 4

2 2

0 0

0 2 4 6 x 0 2 4 6 x

Negative Correlation Negative Correlation May Be Present

Property of ACT ( ACMA Centre for Slide No. 79

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

The Journey is Never Ending

Property of ACT ( ACMA Centre for Slide No. 80

Technology ) 2007

PDF created with pdfFactory Pro trial version www.pdffactory.com

You might also like

- Instructions © 2010 Knowware International Inc: Sheet 2253 S Oneida ST Ste 3D Denver, Co 80224Document9 pagesInstructions © 2010 Knowware International Inc: Sheet 2253 S Oneida ST Ste 3D Denver, Co 80224Marco Antonio Jimenez CervantesNo ratings yet

- AggFlow Sample Training AgendaDocument26 pagesAggFlow Sample Training Agendaaggflow100% (3)

- 11 Steps of Automation ProjectDocument12 pages11 Steps of Automation Projecteng_xenon100% (1)

- 19M S4hana1909 BPD en UsDocument31 pages19M S4hana1909 BPD en UsBiji RoyNo ratings yet

- LamboSkyDocument54 pagesLamboSkyphuoclee733No ratings yet

- 7 QC Tools-Trg Module - ACT - Advance ClusterDocument80 pages7 QC Tools-Trg Module - ACT - Advance ClusterjgprasadNo ratings yet

- Automation Testing Training: Introduction To QTPDocument89 pagesAutomation Testing Training: Introduction To QTPRaj KiranNo ratings yet

- QTP - Automation Testing TrainingDocument89 pagesQTP - Automation Testing Trainingapi-3817447100% (1)

- QTP Automation Testing Training Scenatic Space TechnologiesDocument89 pagesQTP Automation Testing Training Scenatic Space TechnologiesRamu PalankiNo ratings yet

- QCDP 2016: QC Data Processing SystemDocument10 pagesQCDP 2016: QC Data Processing SystemTeuku FaisalNo ratings yet

- RayBox Product Manual V2.2 1Document18 pagesRayBox Product Manual V2.2 1maintenanceNo ratings yet

- Capability Questionaire Master-Completat CNCDocument19 pagesCapability Questionaire Master-Completat CNCAurel PascuNo ratings yet

- Resource Management ArchitectureDocument7 pagesResource Management ArchitectureUma GloriousNo ratings yet

- Gas Transport and Distribution System Based On Web ApplicationDocument27 pagesGas Transport and Distribution System Based On Web Applicationpushpamurugesan19622No ratings yet

- Connected Component Workbench v13Document6 pagesConnected Component Workbench v13Guillermo Jimenez CamarenaNo ratings yet

- Six Sigma BustedDocument7 pagesSix Sigma BustedOmar AlasNo ratings yet

- SAP AdaptersDocument189 pagesSAP Adapterssaikumar bhoppleNo ratings yet

- Topic 5 - The Tools of QualityDocument65 pagesTopic 5 - The Tools of QualityÁnh LêNo ratings yet

- Case StudyDocument13 pagesCase Studyshamini6No ratings yet

- Release Notes 5 0 r20 1 Final - EngDocument13 pagesRelease Notes 5 0 r20 1 Final - EngA MNo ratings yet

- Tailored E-Commerce ProductDocument33 pagesTailored E-Commerce ProductIbrahim SiddiqueNo ratings yet

- Kathmandu University: Presentation On Simulation of CSTR Using Pro/Ii & Process Control Through PythonDocument19 pagesKathmandu University: Presentation On Simulation of CSTR Using Pro/Ii & Process Control Through Pythonramesh pokhrelNo ratings yet

- 01 Edu Cat e Nci Fs v5r14Document92 pages01 Edu Cat e Nci Fs v5r14Silas MendesNo ratings yet

- AccuDuct Manual PDFDocument38 pagesAccuDuct Manual PDFX ERNo ratings yet

- Machine Learning For Prediction AnalysisDocument4 pagesMachine Learning For Prediction AnalysisSandy BujjiNo ratings yet

- 14377A IC C-D v8.3 Release NotesDocument2 pages14377A IC C-D v8.3 Release NotesСергей КакаровNo ratings yet

- SRS Document Group2.-WordDocument9 pagesSRS Document Group2.-WordArya ANo ratings yet

- Icap Q / Icap RQ Icp-Ms: Software ManualDocument100 pagesIcap Q / Icap RQ Icp-Ms: Software ManualMaicol EligioNo ratings yet

- Software Quality Metrics MethodologyDocument17 pagesSoftware Quality Metrics MethodologySumit RajputNo ratings yet

- Visual Basic Application For Statistical Process Control: A Case of Metal Frame For Actuator Production ProcessDocument6 pagesVisual Basic Application For Statistical Process Control: A Case of Metal Frame For Actuator Production ProcessJeromeNo ratings yet

- Six Sigma RoadmapDocument2 pagesSix Sigma RoadmapSanjoy sharmaNo ratings yet

- RayBox Product Manual V2.11Document18 pagesRayBox Product Manual V2.11Mohamad HaziqNo ratings yet

- CA 1012134 Agc A01 A01 MSA GRR 3. Process Bracket AssemblyDocument25 pagesCA 1012134 Agc A01 A01 MSA GRR 3. Process Bracket AssemblyEnano000No ratings yet

- PAC Productivity Suite: Integrated PLC and SCADA SolutionDocument6 pagesPAC Productivity Suite: Integrated PLC and SCADA Solutionsharib26No ratings yet

- Benchmarking Single-Point Performance On National Instruments Real-Time HardwareDocument8 pagesBenchmarking Single-Point Performance On National Instruments Real-Time HardwaremafmonteNo ratings yet

- Test Strategies For Data Processing Pipelines: Lars Albertsson, Independent Consultant (Mapflat)Document36 pagesTest Strategies For Data Processing Pipelines: Lars Albertsson, Independent Consultant (Mapflat)dharmsmart19No ratings yet

- Jksimmet: Steady State Processing Plant SimulatorDocument47 pagesJksimmet: Steady State Processing Plant SimulatorfabiolaNo ratings yet

- Watermarking Scheme EvaluationDocument7 pagesWatermarking Scheme EvaluationJerald RoyNo ratings yet

- Paper Automation Regression TestingDocument19 pagesPaper Automation Regression TestingVasu VenkatarayappaNo ratings yet

- Computer-Aided System For Defect Inspection in The PCB Manufacturing ProcessDocument6 pagesComputer-Aided System For Defect Inspection in The PCB Manufacturing ProcessHugo CheahNo ratings yet

- Testing in InformaticaDocument10 pagesTesting in InformaticaEsHwarNo ratings yet

- An Introduction To Six Sigma: Jeffrey T. Gotro, PH.DDocument44 pagesAn Introduction To Six Sigma: Jeffrey T. Gotro, PH.DRocker byNo ratings yet

- Get To Know PCS 7 - Features & BenefitsDocument4 pagesGet To Know PCS 7 - Features & BenefitsJessica RoyNo ratings yet

- Data Flow Diagrams: Amity Global Business SchoolDocument15 pagesData Flow Diagrams: Amity Global Business SchoolSrinath SundareswaranNo ratings yet

- General Store Inventory System: Design Document 1Document23 pagesGeneral Store Inventory System: Design Document 1Adnan HamidNo ratings yet

- DES and Industrial AutomationDocument26 pagesDES and Industrial AutomationVăn Nghĩa NguyễnNo ratings yet

- Lab 18 - Time Series Anomaly DetectionDocument37 pagesLab 18 - Time Series Anomaly DetectionUno de MadridNo ratings yet

- QC-CALC Real-Time 40Document2 pagesQC-CALC Real-Time 40dadiNo ratings yet

- (8 Marks) : Activity Description Optimistic Likely Pessimistic PredecessorsDocument6 pages(8 Marks) : Activity Description Optimistic Likely Pessimistic PredecessorspavanNo ratings yet

- UntitledDocument3 pagesUntitledjust weirdNo ratings yet

- GreyOrange Product - Supply Chain Automation CompanyDocument12 pagesGreyOrange Product - Supply Chain Automation CompanyronalddragoNo ratings yet

- Config Advisor 5.7 - OverviewGuideDocument24 pagesConfig Advisor 5.7 - OverviewGuidemukiveNo ratings yet

- Creating Transparency, Expecting Accountability: (RFID Shop Floor Data Tracking System)Document6 pagesCreating Transparency, Expecting Accountability: (RFID Shop Floor Data Tracking System)Jahangir Alam SohagNo ratings yet

- Development of ERP SystemsDocument16 pagesDevelopment of ERP SystemsAbhishek ChadagaNo ratings yet

- Pro QMSDocument23 pagesPro QMSSudhir KumarNo ratings yet

- Dynatrace Training BRI Sessi 2Document129 pagesDynatrace Training BRI Sessi 2Muhammad NasrudinNo ratings yet

- The Architecture of Supercomputers: Titan, a Case StudyFrom EverandThe Architecture of Supercomputers: Titan, a Case StudyNo ratings yet

- Distributed Process Control ReportFrom EverandDistributed Process Control ReportNo ratings yet

- Mastering Go Network Automation: Automating Networks, Container Orchestration, Kubernetes with Puppet, Vegeta and Apache JMeterFrom EverandMastering Go Network Automation: Automating Networks, Container Orchestration, Kubernetes with Puppet, Vegeta and Apache JMeterNo ratings yet

- Hira RM Recpt.Document2 pagesHira RM Recpt.SANKUSINo ratings yet

- Daily Audit Observation On 24-11-22Document3 pagesDaily Audit Observation On 24-11-22SANKUSINo ratings yet

- TRANING MATERIAL SafetyDocument6 pagesTRANING MATERIAL SafetySANKUSINo ratings yet

- SPC BasicsDocument32 pagesSPC BasicsSANKUSINo ratings yet

- Daily Line AuditDocument3 pagesDaily Line AuditSANKUSINo ratings yet

- Fish Bone - KP Taper BoreDocument6 pagesFish Bone - KP Taper BoreSANKUSINo ratings yet

- IATF 16949 Awareness 1Document90 pagesIATF 16949 Awareness 1SANKUSINo ratings yet

- Awarenessofiatf16949 170816052510Document27 pagesAwarenessofiatf16949 170816052510SANKUSINo ratings yet

- IRIS TrianingDocument66 pagesIRIS TrianingSANKUSINo ratings yet

- IATF 16949 Awareness Presentation enDocument16 pagesIATF 16949 Awareness Presentation enSANKUSINo ratings yet

- 3 Types of SLADocument2 pages3 Types of SLAMujahid Ali KhanNo ratings yet

- Chapter 1Document28 pagesChapter 1Audrey ConcepcionNo ratings yet

- Balance of Payment: DR - Pinki ShahDocument12 pagesBalance of Payment: DR - Pinki ShahRain StarNo ratings yet

- G Ym 6 F 8 HEtoev 4 GEbDocument6 pagesG Ym 6 F 8 HEtoev 4 GEbPrakhar AgarwalNo ratings yet

- Assessment PDFDocument6 pagesAssessment PDFVamsi aravetiNo ratings yet

- REFERENCESDocument10 pagesREFERENCESRona Faith TanduyanNo ratings yet

- Chapter Five: Risk, Return, and The Historical RecordDocument37 pagesChapter Five: Risk, Return, and The Historical RecordAreej AlGhamdi100% (1)

- ISACA PerformanceReport FINAL3 24Document26 pagesISACA PerformanceReport FINAL3 24Fabio SilvaNo ratings yet

- Marketing Strategies of Britannia by Subharth SahaDocument21 pagesMarketing Strategies of Britannia by Subharth Sahasubharth saha43% (7)

- Bpmn3023 Strategic Audit Report Group 6Document65 pagesBpmn3023 Strategic Audit Report Group 6Nadzirah SalahuddinNo ratings yet

- Third Party Ownership and Multi-Club OwnershipDocument36 pagesThird Party Ownership and Multi-Club OwnershipBruno ToniniNo ratings yet

- Profood International CorporationDocument26 pagesProfood International CorporationYew MercadoNo ratings yet

- PART 1 An Overview of Strategic Retail Management 21: Chapter 1 An Introduction To Retailing 22Document1 pagePART 1 An Overview of Strategic Retail Management 21: Chapter 1 An Introduction To Retailing 22AlesmanNo ratings yet

- PERSONAL FINANCE Lesson Two Money ManagementDocument6 pagesPERSONAL FINANCE Lesson Two Money ManagementJohn Greg MenianoNo ratings yet

- CFA一级百题预测 财务Document90 pagesCFA一级百题预测 财务Evelyn YangNo ratings yet

- Deed of Sale of Motor VehicleDocument1 pageDeed of Sale of Motor VehicleJoemar CalunaNo ratings yet

- Siebel Systems Sales Part 2Document4 pagesSiebel Systems Sales Part 2he20003009No ratings yet

- Manipal Academy CaseDocument6 pagesManipal Academy CaseDhananjay DubeyNo ratings yet

- BIOMED Case StudyDocument3 pagesBIOMED Case StudyGanesh BirleNo ratings yet

- Operational Data StoreDocument0 pagesOperational Data StorerajsalgyanNo ratings yet

- December 2022 InvoiceDocument2 pagesDecember 2022 InvoiceMegha NandiwalNo ratings yet

- Group-1 PPT of TQMDocument19 pagesGroup-1 PPT of TQMVazhaNo ratings yet

- Loan LetterDocument1 pageLoan LetterMuhd HisyamuddinNo ratings yet

- Sfom Impl B2ceDocument28 pagesSfom Impl B2cesergio paredesNo ratings yet

- Project List & KPI - Ahmad Dzikrul FikriDocument3 pagesProject List & KPI - Ahmad Dzikrul Fikrikenny williamNo ratings yet

- ANTICHRESISDocument4 pagesANTICHRESISmichellouise17No ratings yet

- ACS 1000 Preventive MaintenanceDocument2 pagesACS 1000 Preventive Maintenanceazultenue780% (1)

- Midterm Examination in Business MathematicsDocument3 pagesMidterm Examination in Business MathematicsRica De CastroNo ratings yet