90% found this document useful (10 votes)

5K views15 pagesTransformer Sizing

This document provides guidelines for sizing distribution transformers based on calculated load. It defines relevant terms like demand factor and diversity factor. It then outlines a 3-step process: [1] Calculate total working load from continuous and intermittent loads while applying diversity factors; [2] Select transformer capacity as 105% of total working load to allow 5% spare capacity; [3] Determine allowable voltage drops and target transformer regulation based on system configuration, with a 4% regulation target given as an example. Sample calculations are provided to demonstrate sizing a 500kVA transformer for a given load list.

Uploaded by

RajCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd

90% found this document useful (10 votes)

5K views15 pagesTransformer Sizing

This document provides guidelines for sizing distribution transformers based on calculated load. It defines relevant terms like demand factor and diversity factor. It then outlines a 3-step process: [1] Calculate total working load from continuous and intermittent loads while applying diversity factors; [2] Select transformer capacity as 105% of total working load to allow 5% spare capacity; [3] Determine allowable voltage drops and target transformer regulation based on system configuration, with a 4% regulation target given as an example. Sample calculations are provided to demonstrate sizing a 500kVA transformer for a given load list.

Uploaded by

RajCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd

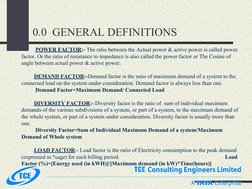

- General Definitions: Explains various electrical factors like power factor, demand factor, load factor, relevant to transformer sizing.

- Purpose: Details the objective of providing guidelines for transformer sizing and verification processes.

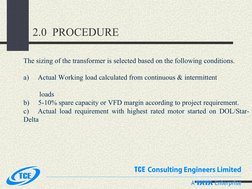

- Procedure: Outlines the methods and conditions under which transformer sizing is determined, including working load calculations.

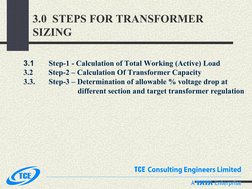

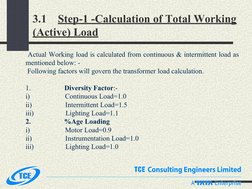

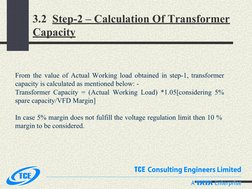

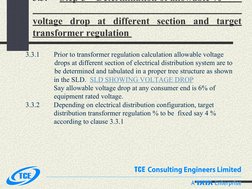

- Steps for Transformer Sizing: Describes the sequential steps involved in calculating working load, transformer capacity, and voltage regulation.

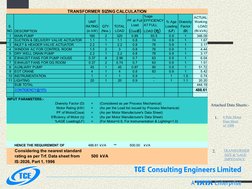

- Transformer Sizing Calculation: Presents a detailed table for transformer sizing including input parameters and resulting requirements.

- Voltage drop on Transformer due to Motor Starting: Analyzes voltage drop calculations when motors start, with detailed parameters and formulas.

- Conclusion: Summarizes the findings related to voltage drop and transformer selection criteria.