Professional Documents

Culture Documents

CLUTCHES All Details

Uploaded by

Arunav0 ratings0% found this document useful (0 votes)

21 views36 pagesOriginal Title

CLUTCHES all details

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views36 pagesCLUTCHES All Details

Uploaded by

ArunavCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 36

CLUTCHES

Classification of clutches: Single plate, Multi-plate, Cone diaphragm

spring, centrifugal, clutch materials, electromagnetic, vacuum operated,

fluid flywheel,

Gearbox: manual gearbox, Constant mesh, synchromesh, geared

automatic transmission, torque converter, epicycle, continuous variable

transmission, electronic transmission control, overdrive, propeller shaft,

constant velocity joint, Differential and final drive, Non-slip differential.

CLUTCHES:

The purpose of the clutch is to allow the driver to couple or decouple

the engine and transmission. When the clutch is in the engaged position,

the engine power flows to the transmission through it (clutch).

When gears are to be changed while the vehicle is running, the clutch

permits temporary decoupling of the engine and wheels so that gears

can be shifted. In a scooter, the clutch is operated by hand whereas in a

car the clutch is operated by foot.

It is necessary to interrupt the flow of power before gears are changed.

Without a clutch, it will be very difficult.

REQUIREMENTS OF A CLUTCH

1. Pick up its load smoothly without grabbing or clattering.

2. Have a driven disc of low moment of inertia to permit easy shifting.

3. Damp out any vibration of the crankshaft to prevent gear clatter.

4. Require little pedal pressure to operate it.

5. Be easy to adjust and service.

6. Be cheap to manufacture.

BASIC PRINCIPLE OF THE FRICTION TYPE CLUTCH

To understand the working principle of the clutch, let’s take two sanding

discs, first one driven by a power drill corresponds to the flywheel of a car,

driven by the engine. If a second sanding disc is brought into contact with

the first, friction makes it revolve too but more slowly.

But when the second disc pressed against the first disc which is connect to

the power drill, as the pressure increases the two discs revolve as one. This

is how a friction clutch works.

TYPES OF CLUTCHES

(i) Positive Clutches (ii) Friction clutches

Positive Clutches: In this type of clutch, the engaging clutch surfaces

interlock to produce rigid joints that are suitable for situations requiring

simple and rapid disconnection. Although they must be connected while

shafts are stationary and unloaded, the engaging surfaces are usually of

jaw type.

The jaws may be square jaw type or spiral jaw type. They are designed

empirically by considering the compressive strength of the material used.

The merits of the positive clutches are

• Simple

• No slip

• No heat-generated compact and low cost

Friction Clutches: Friction Clutches work on the basis of the frictional

forces developed between two or more surfaces in contact. Friction

clutches are usually – over-the-jaw clutches due to their better

performance. There is a slip in the friction clutch.

The merits are

• They friction surfaces can slip during engagement which enables the

driver to Pick up and accelerate the load with minimum shock.

• They can be used at high engagement speeds since they do not have jaw

or teeth

• Smooth engagement due to the gradual increase in normal force.

Different types of clutches are as follows:

1. Friction clutch:

(a) Single plate clutch.

(b) Multiplate clutch: (1) Wet clutch, (2) Dry clutch, and (c) Cone clutch: (1)

External clutch, (2) Internal clutch.

2. Centrifugal clutch.

3. Semi-centrifugal clutch.

4. Diaphragm clutch: (a) Tapered finger type, (b) Crown spring type.

5. Positive clutch: (a) Dog and Spline clutch.

6. Hydraulic clutch.

7. Electro-magnetic clutch.

8. Vacuum clutch.

9. Overrunning clutch or free-wheel unit.

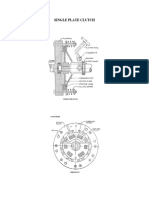

SINGLE PLATE CLUTCH:

A single plate friction clutch consisting of a clutch disk between the

flywheel and a pressure plate. Both the pressure plate and the flywheel

rotate with the engine crankshaft or the driving shaft. Both sides of the

clutch disc are faced with friction material (usually of ferrodo).

The clutch disc is mounted on the hub which is free to move axially along

the splines of the driven shaft but not turnable towards the transmission

input shaft.

The pressure plate pushes the clutch plate towards the flywheel by a set of

strong springs which are arranged radially inside the body. The three levers

(also known as release levers or fingers) are carried on pivots suspended

from the case of the body. These are arranged in such a manner so that the

pressure plate moves away from the flywheel by the inward movement of a

thrust bearing.

The bearing is mounted upon a forked shaft and moves forward when the

clutch pedal is pressed. By pressing the clutch pedal down, the thrust

bearing moves towards the flywheel by means of linkage force, and press

the longer end of the lever inwards.

Due to this, the lever turns on its suspended pivot and forces the pressure

plate to move away from the flywheel this action compresses the clutch

springs which in turn moves the pressure plate away from the clutch plate

and removes the pressure from the clutch plate. This enables the clutch

plate to move back from the flywheel and thus, the driven shaft becomes

stationary.

By moving the foot back from the clutch pedal, the thrust bearing moves

back and allows the spring to extend which pushes the clutch plate

backward the flywheel. This engages the flywheel and the clutch plate

which starts the motion of the driven shaft.

MULTI-COIL SPRING SINGLE PLATE CLUTCH CONSTRUCTION

A typical clutch actuated by a number of coil springs on a pitch circle near

the periphery is shown. The driven shaft which normally is a forward

extension of the gearbox primary shaft is supported at its front end in a ball

bearing in a hole in the center of the flywheel web, which is spigot and

bolted onto a flange at the rear end of the crankshaft.

In this clutch, the coil springs force the pressure plate forward to clamp the

driven plate between it and the rear face of the flywheel. Three lugs extend

rearwards from the periphery of the pressure plate both to rotate the

pressure plate and to cause it to rotate with the rest of the assembly. The

driven plate of course is splined onto the shaft.

There are three release levers pressing the coil springs at the outer end. The

inner ends of the levers can be forced forward by means of a thrust bearing

made of graphite and slide along the clutch shaft when the clutch pedal is

depressed.

The driven plate mounted between the flywheel and pressure plate makes

the clutch shaft rotate to transmit power. It has a clutch facing made of

friction materials around the periphery of the disc.

WORKING

When the clutch is engaged, the clutch plate is gripped between the

flywheel and the pressure plate. The friction linings are on both sides of

the clutch plate. Due to friction between the flywheel, clutch plate, and

pressure plate, the clutch plate revolves with the flywheel. As the clutch

plate revolves the clutch shaft also revolves. Thus, engine power is

transmitted to the clutch shaft.

When the clutch pedal is pressed the pressure plate moves back against

the spring force and the clutch plate becomes free between the flywheel

and pressure plate. Thus flywheel remains rotating as long as the clutch

pedal is pressed, the clutch is said to be disengaged and the clutch shaft

speed reduces slowly and finally, it stops rotating.

DIAPHRAGM SPRING SINGLE PLATE CLUTCH

Diaphragm spring pressure plate assemblies are widely used in most

modern cars. The diaphragm spring is a single thin sheet of metal that

yields when pressure is applied to it.

When pressure is removed the metal springs back to its original shape.

The center portion of the diaphragm spring is slit into numerous fingers

that act as release levers. During disengagement of the clutch, the fingers

are moved forward by the release bearing.

The spring pivots over the fulcrum ring and its outer rim moves away

from the flywheel. The retracting spring pulls the pressure plate away

from the clutch plate thus disengaging the clutch.

When engaged the release bearing and the fingers of the diaphragm spring

move towards the transmission. As the diaphragm pivots over the pivot

ring its outer rim forces the pressure plate against the clutch disc so that

the clutch plate is engaged to the flywheel.

ADVANTAGES OF DIAPHRAGM SPRING CLUTCH

1. It is more compact than other designs.

2. It is easier to balance rotationally and is less subjected to unwanted

effects due to centrifugal force at high rotational speeds.

3. It gives uniformly distributed pressure on the pressure plate.

4. It needs no release levers.

5. Minimum effort is sufficient to disengage the clutch.

6. It provides a minimum number of moving components and hence

minimum internal friction is experienced.

7. This is very commonly used in cars, light Lorries, and mini trucks but is

not much used in heavy vehicles

MULTIPLATE CLUTCH

The multi-plate clutch is an extension of the single plate type where the

number of frictional and metal plates is increased. The increase in the

number of friction surfaces obviously increases the capacity of the clutch

to transmit torque, the size remaining fixed.

Alternatively, the overall diameter of the clutch is reduced for the same

torque transmission as a single-plate clutch. This type of clutch is, used in

some heavy transport vehicles, in epicyclic gearboxes and racing cars

where high torque is to be transmitted.

Besides, this finds applications in the case of scooters and motorcycles,

where space available is limited.

The extension of the flywheel is a drum; which on its inner

circumference is splined to carry a number of thin metal plates. These

must consequently revolve with a drum but are able to slide axially.

Interleaved with these outer plates are a number of inner plates that are

splined to an inner drum which is coupled rotationally to the gearbox

shaft. The clutch is disengaged by pulling the inner drum right against

the spring force. The plates of multi-plate clutch were at one time made

alternately of steel and phosphor bronze but now are all of steel or one

set may be lined with a friction material.

With metal contact lubrication is essential and so the clutch is made oil-

tight and partly filled with oil. The oil tends to make the plates drag when

the clutch is disengaged so some means should be provided to avoid this

drag.

DRY MULTI-PLATE CLUTCH

Multi-plate clutches are also made to work dry, without any oil. The

driving plates are then lined on each side with a friction fabric. In such

clutches, the driving plates are sometimes carried on a number of studs

screwed into the web of flywheel in the same way as the outer plate of a

Single Plate Clutch is carried. This construction is inconvenient when oil

is used. Several small springs can be used instead of a single spring.

AUTOMATIC CLUTCH

Many attempts have been made to produce motor vehicles that can be

controlled by the accelerator pedal and brakes only. This can be done in

several ways. A centrifugal clutch that automatically disengages itself

when the speed falls below and re-engages when the speed rises above

some predetermined values may be used. Alternatively, a fluid coupling,

and fluid torque converter may be employed.

CENTRIFUGAL CLUTCH

In this type of clutch, the springs are eliminated altogether and only the

centrifugal force is used to apply the required pressure for keeping the

clutch in engagement position.

The advantage of the centrifugal clutch is that no separate clutch pedal is

required. The clutch is operated automatically depending on the engine

speed. This means that the car can be stopped in gear without stalling the

engine. Similarly while starting, the driver can first select the gear, put the

car into the gear, and simply press the accelerator pedal. This makes the

driving operation very easy.

Centrifugal Clutch

Figure shows a schematic diagram of a centrifugal clutch. As the speed

increases, the weight A flies off, thereby operating the bell crank lever B

that presses plate C. This force is transmitted to the plate D by means of

springs E. The Plate D containing friction lining is thus pressed against the

flywheel F thereby engaging the clutch. Spring G serves to keep the clutch

disengaged at low speed say 500 rpm. The stop H limits the amount of

centrifugal force.

The operating Characteristics of this type of clutch will be then as shown

in the figure. Force P is proportional to the centrifugal force at a particular

speed, while force Q exerted by spring G is constant at all speeds. The firm

line in the figure shows the net force on plate D for various engine speeds.

At the upper end, the curve is made flat by means of stop H.

SEMI CENTRIFUGAL CLUTCH

It uses both centrifugal and spring force to keep it in an engaged position.

The springs are designed to transmit torque at normal speed, while

centrifugal force assists in torque transmission at high speed. This clutch

consists of three hinged and weighted levers and three clutch springs

alternately arranged at equal spaces on the pressure plate.

At low speeds, the springs keep the clutch engaged and the weighted

levers do not have any pressure on the pressure plate. At high speeds

when power transmission is high, weights fly off and the levers also exert

pressure on the plate, keeping the clutch firmly engaged.

Semi centrifugal clutch

When the speed decreases the weights do not exert any pressure on the

pressure plate. Only spring pressure is exerted on the pressure plate which

keeps the clutch engaged. An adjusting screw is provided at the end of the

lever by means of which the centrifugal force on the pressure plate can be

adjusted.

At low speeds pressure on the spring is sufficient to transmit the torque

required. However, at high speeds, the centrifugal force due to weight

moves about the fulcrum thereby pressing the pressure plate. The

centrifugal force is proportional to the square of speed so that an adequate

pressure level is attained. The graph shows the variation of force on the

pressure plate as speed increases. At low speeds spring along applies the

force on the pressure plate. But when the speed of the engine rises the

centrifugal force is also applied by the weights.

ELECTROMAGNETIC CLUTCH

• Figure shows an electromagnetic clutch.

• In this type of clutch, the flywheel consists of winding from the battery

or dynamo.

• when the current passes through the winding. it produced an

electromagnetic field that attracted the pressure plate.

• Thereby engaging the clutch.

• When the supply is cut-off the clutch is disengaged.

• The gear lever consists of a clutch release switch.

• When the driver holds the gear lever to change the gear, the switch is

operated

• Cutting off the current to the winding which causes the clutch to

disengage.

• At low speed when the dynamo output is low, the clutch is not firmly

engaged.

• Therefore, three springs are also provided on the pressure plate which

helps the

• Clutch engaged firmly at low speed also.

• This type of clutch is used in some Renault cars.

CLUTCH LINKAGE

A clutch linkage mechanism uses levers and rods to transfer motion from

the clutch pedal to the clutch fork. One configuration is shown in Figure

When the pedal is pressed, a pushrod shoves on the bell crank and the bell

crank reverses the forward movement of the clutch pedal. The other end of

the bell crank is connected to the release rod. The release rod transfers bell

crank movement to the clutch fork. It also provides a method of

adjustment for the clutch.

FLUID COUPLING

It is a device for transmitting rotation between shafts by means of the

acceleration and deceleration of a hydraulic fluid (such as oil). Also

known as hydraulic coupling. Structurally, a fluid coupling consists of

an impeller on the input or driving shaft and a runner on the output or

driven shaft. The two contain the fluid.

The impeller and runner are bladed rotors, the impeller acting as a

pump and the runner reacting as a turbine. Basically, the impeller

accelerates the fluid from near its axis, at which the tangential

component of absolute velocity is low, to near its periphery, at which

the tangential component of absolute velocity is high. This increase in

velocity represents an increase in kinetic energy. The fluid mass

emerges at high velocity from the impeller, impinges on the runner

blades, gives up its energy, and leaves the runner at low velocity.

Fluid coupling clutch

Hydraulic fluid couplings transfer rotational force from a transmitting

axis to a receiving axis.

The coupling consists of two toroids -doughnut-shaped objects -in a

sealed container of hydraulic fluid. One toroid is attached to the driving

shaft and spins with the rotational force. The spinning toroid moves the

hydraulic fluid around the receiving toroid. The movement of the fluid

turns the receiving toroid and thus turns the connected shaft.

THANK YOU

You might also like

- ClutchDocument22 pagesClutchIsaiah LuleNo ratings yet

- CRAFTSMAN 917273180 - Owners - Manual LT-2000 42 in DECK 17.5 HPDocument60 pagesCRAFTSMAN 917273180 - Owners - Manual LT-2000 42 in DECK 17.5 HPIvan Panin100% (2)

- IC 400 ManualDocument102 pagesIC 400 ManualRAFAEL OLIVEIRANo ratings yet

- Safety Operation of Crawler CraneDocument47 pagesSafety Operation of Crawler Craneminthu khitNo ratings yet

- Fuel SystemDocument37 pagesFuel SystemPhan DungNo ratings yet

- 140 International Harvester TractorDocument91 pages140 International Harvester Tractormario santiago100% (1)

- Hitachi ZW180 220 250 ZX310 Wheel Loader Operation and Maintenance Manual PDF DownloadDocument334 pagesHitachi ZW180 220 250 ZX310 Wheel Loader Operation and Maintenance Manual PDF DownloadSergey100% (3)

- Mega Series OmDocument51 pagesMega Series OmJose Guerra0% (1)

- Shell Answer Book 07 The Driving Emergency BookDocument8 pagesShell Answer Book 07 The Driving Emergency BookKenneth100% (2)

- SE4310 ATC, DescriptionDocument6 pagesSE4310 ATC, DescriptionBrando ImanuelNo ratings yet

- SR-300L Im (E)Document233 pagesSR-300L Im (E)Fatho Jamyl100% (10)

- Single Plate ClutchDocument4 pagesSingle Plate Clutchsaffrin0% (2)

- Clutch PDFDocument60 pagesClutch PDFAyush Kumar50% (2)

- Yale Veracitor Series PneumaticDocument2 pagesYale Veracitor Series PneumaticJosé G. MolinaNo ratings yet

- Auto Transmission - NotesDocument34 pagesAuto Transmission - Notesvandanaharikumar100% (2)

- Assignment ClutchDocument624 pagesAssignment ClutchSubhash KNo ratings yet

- Manuel de Réparation 15-16 TonnesDocument204 pagesManuel de Réparation 15-16 TonnesFaouzi Zorgati100% (1)

- Product Guide B 300 - 400Document58 pagesProduct Guide B 300 - 400Александр НиколаевNo ratings yet

- TM 9-811 DIAMOND T CARGO, PONTON, WRECKER, DUMPDocument394 pagesTM 9-811 DIAMOND T CARGO, PONTON, WRECKER, DUMPAdvocate100% (3)

- F2880, F3680, RCK72-F36, RCK72R-F36, RCK60-F36, RCK60R-F36: Workshop ManualDocument315 pagesF2880, F3680, RCK72-F36, RCK72R-F36, RCK60-F36, RCK60R-F36: Workshop Manualrgcsadlerhotmail.comNo ratings yet

- Ms 534 13 PDFDocument134 pagesMs 534 13 PDFFabianNo ratings yet

- 21 H135-155FT-BTG PDFDocument20 pages21 H135-155FT-BTG PDFAndrés Felipe Gutiérrez RodríguezNo ratings yet

- 1221.2 1221.3 en Year 2009Document295 pages1221.2 1221.3 en Year 2009crismg1100% (1)

- Unit-2-Automobile EnggDocument23 pagesUnit-2-Automobile EnggPrashant BhumireddyNo ratings yet

- AT6501 UwDocument132 pagesAT6501 UwAjithNo ratings yet

- Automotive TransmissionDocument146 pagesAutomotive TransmissionTony Neal100% (1)

- AT6501 (R-13) Notes PDFDocument131 pagesAT6501 (R-13) Notes PDFAashiq NawinNo ratings yet

- Transmission Systems OverviewDocument168 pagesTransmission Systems Overviewriyaz ahmedNo ratings yet

- EXPERIMENT No 3 - Clutch SystemDocument4 pagesEXPERIMENT No 3 - Clutch SystemVaibhav RathoreNo ratings yet

- Automotive Transmission NewDocument147 pagesAutomotive Transmission NewhodvmkvecautoNo ratings yet

- Unit 3 ClutchesDocument54 pagesUnit 3 Clutchesswapnil pandeNo ratings yet

- Automobile Engg (Unit-05)Document38 pagesAutomobile Engg (Unit-05)SUDHARSHAN REDDYNo ratings yet

- AE Unit 3 Transmission System NotesDocument15 pagesAE Unit 3 Transmission System Notessemmat1802No ratings yet

- Jose Valen 10Document19 pagesJose Valen 10Meghan NielsenNo ratings yet

- Single Plate ClutchDocument15 pagesSingle Plate ClutchKyaw MinAungNo ratings yet

- Clutch and Types of Clutches (C)Document11 pagesClutch and Types of Clutches (C)Rahul Kumar100% (1)

- Keshav Jangir Seminar Front PageDocument39 pagesKeshav Jangir Seminar Front Pagevideo songNo ratings yet

- Vacuum ClutchDocument8 pagesVacuum Clutchprithvi mannNo ratings yet

- Different Types of Clutch Explained in Detail Notes PDFDocument10 pagesDifferent Types of Clutch Explained in Detail Notes PDFMahihu KuriaNo ratings yet

- Cert Drive TrainDocument30 pagesCert Drive TrainOKIDI Thomas BecketNo ratings yet

- Clutch & Gearbox Guide in 38 CharactersDocument30 pagesClutch & Gearbox Guide in 38 CharactersManjunath Shettar100% (1)

- Automotive (2) Lab: EXP1: ClutchesDocument7 pagesAutomotive (2) Lab: EXP1: ClutchesMohammad YahyaNo ratings yet

- Transmission Unit 3Document103 pagesTransmission Unit 3Ram SaaceNo ratings yet

- Differential Gear MechanismDocument32 pagesDifferential Gear MechanismMohammad Amir100% (2)

- Working of Single Plate ClutchDocument1 pageWorking of Single Plate ClutchBikash Das50% (2)

- Single Plate and Multiplate ClutchDocument13 pagesSingle Plate and Multiplate ClutchParitosh ParasharNo ratings yet

- Power Units and TransmissionDocument42 pagesPower Units and TransmissionAmarjeet RaiNo ratings yet

- DoME Report (009 & 019)Document9 pagesDoME Report (009 & 019)Muhammad WaleedNo ratings yet

- 0.rahat Sir AutomobileDocument157 pages0.rahat Sir AutomobileTahammul Islam IbonNo ratings yet

- Brakes and ClutchesDocument20 pagesBrakes and ClutchesHuzaifa YousafNo ratings yet

- CLUTCHES AND BRAKES: MOTION CONTROL ELEMENTSDocument33 pagesCLUTCHES AND BRAKES: MOTION CONTROL ELEMENTSToleraNo ratings yet

- Transmission and Steering Systems ExplainedDocument24 pagesTransmission and Steering Systems ExplainedSai RamNo ratings yet

- It Is The Total Mechanism That Transmit The Power Developed of The Engine Going To The Drive Wheels of The VehicleDocument90 pagesIt Is The Total Mechanism That Transmit The Power Developed of The Engine Going To The Drive Wheels of The VehicleManny AnacletoNo ratings yet

- How a Clutch Works: Parts, Principle and MaterialsDocument6 pagesHow a Clutch Works: Parts, Principle and MaterialsSai Prajwal ReddyNo ratings yet

- Manual Transmission and Clutch ComponentsDocument23 pagesManual Transmission and Clutch ComponentsLatif MohdNo ratings yet

- Automobile Clutch: Aim To Study and Prepare Report On The Constructional Details, Working Principles andDocument4 pagesAutomobile Clutch: Aim To Study and Prepare Report On The Constructional Details, Working Principles andசிவ சங்கர்No ratings yet

- Aman Cad CamDocument16 pagesAman Cad CamAmanuel tadiwosNo ratings yet

- ClutchDocument15 pagesClutchRavi SoniNo ratings yet

- ClutchesDocument22 pagesClutchesravi100% (1)

- ClutchesDocument12 pagesClutchesJeremiahNo ratings yet

- Mechanics of Machines ME2031: Lab Instructor: Awais LiaqatDocument21 pagesMechanics of Machines ME2031: Lab Instructor: Awais LiaqatAnonymous B0cm7LZhNo ratings yet

- 92 Automotive Power Train Service RevisedDocument92 pages92 Automotive Power Train Service Reviseddmc constructionNo ratings yet

- AE Unit 3 Transmission SystemDocument107 pagesAE Unit 3 Transmission Systemsemmat1802No ratings yet

- Automobile Engg-UNIT-1Document28 pagesAutomobile Engg-UNIT-1Muthuvel MNo ratings yet

- Rohini 70563202173Document41 pagesRohini 70563202173Ss AMINE sSNo ratings yet

- How Automobile Clutches Work - Transmitting Power from Engine to WheelsDocument3 pagesHow Automobile Clutches Work - Transmitting Power from Engine to WheelsAshok Pradhan100% (1)

- ClutchhhDocument3 pagesClutchhhAshok PradhanNo ratings yet

- Mechanism and Types of ClutchesDocument41 pagesMechanism and Types of Clutchessarath100% (1)

- Mbeya University of Science and Technology: Mechanical and Industrial Engineering DepartmentDocument65 pagesMbeya University of Science and Technology: Mechanical and Industrial Engineering DepartmentEmmanuel ChachaNo ratings yet

- Friction Clutch: 1.single Plate Clutch (Disc Clutch)Document5 pagesFriction Clutch: 1.single Plate Clutch (Disc Clutch)Ashok PradhanNo ratings yet

- ClutchDocument5 pagesClutchyudhisthar0110% (1)

- ClutchesDocument17 pagesClutchesRanjit RajendranNo ratings yet

- Clutch 2Document30 pagesClutch 2P.Prem Kumar AP - I - MechanicalNo ratings yet

- Experiment No. 7: ObjectiveDocument3 pagesExperiment No. 7: ObjectiveMoiz AamirNo ratings yet

- Module 2Document54 pagesModule 2HarshithNo ratings yet

- Operator'S Manual: Pneumatic-Tired WheelsDocument30 pagesOperator'S Manual: Pneumatic-Tired WheelsХелфор УкраинаNo ratings yet

- Wa8003e0 BrochureDocument6 pagesWa8003e0 BrochureJimmy CordovaNo ratings yet

- THINK City User ManualDocument124 pagesTHINK City User ManualSaleB81No ratings yet

- Puch Magnum Owners ManualDocument34 pagesPuch Magnum Owners Manualrdf12345No ratings yet

- Operation Section GuideDocument15 pagesOperation Section GuidePreett Rajin MenabungNo ratings yet

- Agricultural Machinery Laboratory: Research Paper 1: Agricultural TractorDocument59 pagesAgricultural Machinery Laboratory: Research Paper 1: Agricultural TractorAce Gerson GamboaNo ratings yet

- Cat Forklift E3000 Operation Maintenance ManualDocument27 pagesCat Forklift E3000 Operation Maintenance Manualxycedfsf100% (32)

- Accellency Motorbike Cables: BackgroundDocument3 pagesAccellency Motorbike Cables: BackgroundAFTAB ASLAMNo ratings yet

- Kioti CK3520, CK4020, CK4220 Tractor Operator's ManualDocument15 pagesKioti CK3520, CK4020, CK4220 Tractor Operator's ManualLisakolyNo ratings yet

- Install 6f50nDocument4 pagesInstall 6f50nmedicaluvNo ratings yet

- How To Drive Using Manual TransmissionDocument8 pagesHow To Drive Using Manual TransmissionCharmaine AlipayoNo ratings yet

- Codigo de Falha E45-70xnDocument7 pagesCodigo de Falha E45-70xnSuziane Sousa Victor100% (1)