Professional Documents

Culture Documents

GDT-Terms and Rules

Uploaded by

riskirahmatuloh3300 ratings0% found this document useful (0 votes)

2 views17 pagesOriginal Title

04. GDT-Terms and Rules

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

2 views17 pagesGDT-Terms and Rules

Uploaded by

riskirahmatuloh330Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 17

Geometric Dimensioning and

Tolerancing (GDT)

TRM46007

Terms and Rules

Program Studi Teknologi Rekayasa Manufaktur

Politeknik Negeri Banyuwangi

2024

Tujuan Pembelajaran

• Mendefinisikan istilah-istilah kritis dalam GDT

• Menjelaskan empat aturan umum dalam GDT

Terms

1. Actual mating envelope: The actual mating envelope is defined

separately for internal and external features.

• External feature: The actual mating envelope for an external feature of size is

the smallest, similar, perfect, feature counterpart that can be circumscribed

around the feature so that it just contacts the surface(s) at the highest points.

• Internal feature: The actual mating envelope for an internal feature of size is

the largest, similar, perfect, feature counterpart that can be inscribed within

the feature so that it just contacts the surface(s) at the highest points.

Terms

Terms

2. Basic dimension: A basic dimension is a numerical value used to

describe the theoretically exact size, profile, orientation, or location

of a feature or datum target. Basic dimensions are used to define or

position tolerance zones. Title block tolerances do not apply to

basic dimensions. The tolerance associated with a basic dimension

usually appears in a feature control frame or a note.

Terms

3. Datum: A datum is a theoretically exact point, line, or plane derived

from the true geometric counterpart of a specified datum feature. A

datum is the origin from which the location or geometric

characteristics of features of a part are established.

4. Datum feature: A datum feature is an actual feature on a part used to

establish a datum

5. Datum feature simulator: A datum feature simulator is a real surface

with a sufficiently precise form, such as a surface plate, machine

table, or gage pin used to contact datum features to establish

simulated datums. The datum is understood to exist in and be

simulated by the datum feature simulator

Terms

Terms

6. Feature: A feature is a physical portion of a part, such as a flat

surface, pin, hole, tab, or slot.

7. Feature of size : Features of size are features that have a size

dimension. A feature of size takes four forms:

• Cylindrical surfaces

• Two opposed parallel surfaces

• A spherical surface

• Two opposed elements

Terms

8. Least material condition (LMC): The least material condition of a

feature of size is the least amount of material within the stated limits

of size.

9. Maximum material condition (MMC): The maximum material

condition of a feature of size is the maximum amount of material

within the stated limits of size

10. Regardless of feature size (RFS): Regardless of feature size is a

material condition modifier used in a feature control frame to indicate

that a geometric tolerance or datum reference applies at each

increment of size of the feature within its limits of size. RFS specifies

that no bonus tolerance is allowed.

Terms

11. Resultant condition: The resultant condition of a feature specified at MMC

is a variable boundary generated by the collective effects of the LMC limit

of size of a feature, the specified geometric tolerance, and any applicable

bonus tolerance. Features specified with an LMC modifier also have a

resultant condition.

12. True position: True position is the theoretically exact location of a feature

established by basic dimensions. Tolerance zones are located at true

position.

13. Virtual condition: The virtual condition of a feature specified at MMC is a

constant boundary generated by the collective effects of the MMC limit of

size of a feature and the specified geometric tolerance. Features specified

with an LMC modifier also have a virtual condition.

Terms

Terms

Terms

14. Worst-case boundary: The worst-case boundary of a feature is a

general term that describes the smallest or largest boundary

generated by the collective effects of the MMC or LMC of the

feature and any applicable geometric tolerance.

• Inner boundary specified at MMC

The worst-case inner boundary is the virtual condition of an internal feature

and the extreme resultant condition of an external feature.

• Outer boundary specified at MMC

The worst-case outer boundary is the extreme resultant condition of an internal

feature and the virtual condition of an external feature.

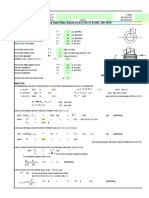

Rules

• Rule #1; where only a tolerance of size is specified, the limits of size of

an individual feature prescribe the extent to which variations in its

geometric form, as well as size, are allowed.

Rules

• Rule #2; in a feature control frame, RFS automatically applies to

individual tolerances of size and to datum features of size. MMC and

LMC must be specified when these conditions are required.

Rules

• The Pitch Diameter Rule; each geometric tolerance or datum

reference specified for screw threads applies to the axis of the thread

derived from the pitch diameter. Exceptions to this rule may be

specified by placing a note, such as MAJOR DIA or MINOR DIA,

beneath the feature control frame, or beneath or adjacent to, the

datum feature symbol.

Rules

• The Virtual Condition Rule; where a datum feature of size is

controlled by a geometric tolerance and is specified as a secondary or

tertiary datum, the datum applies at virtual condition with respect to

orientation.

You might also like

- Geometrical Dimensioning and Tolerancing for Design, Manufacturing and Inspection: A Handbook for Geometrical Product Specification Using ISO and ASME StandardsFrom EverandGeometrical Dimensioning and Tolerancing for Design, Manufacturing and Inspection: A Handbook for Geometrical Product Specification Using ISO and ASME StandardsRating: 4.5 out of 5 stars4.5/5 (3)

- Matrix Methods for Advanced Structural AnalysisFrom EverandMatrix Methods for Advanced Structural AnalysisRating: 5 out of 5 stars5/5 (1)

- GD&T NotesDocument24 pagesGD&T NotesDarshan Sn100% (1)

- F 5 Geo TolerancesDocument23 pagesF 5 Geo TolerancesRodrigo RomeroNo ratings yet

- T13mra001 Mra STR 103 SLD 004 Rev B Pile Soil InteractionDocument19 pagesT13mra001 Mra STR 103 SLD 004 Rev B Pile Soil InteractionTannaz HadizadeNo ratings yet

- Fundamentals of Geometric Dimensioning & TolerancingDocument109 pagesFundamentals of Geometric Dimensioning & Tolerancingkiran.katsNo ratings yet

- GD & T - Training Material Note PagesDocument252 pagesGD & T - Training Material Note Pageslokelooks92% (26)

- Basicuma GD&TDocument258 pagesBasicuma GD&Tashu_adbnelNo ratings yet

- Rules and Concepts of GD&TDocument31 pagesRules and Concepts of GD&TSumeet Saini75% (4)

- GD&T SymbolsDocument6 pagesGD&T Symbolschethan048100% (1)

- Introduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsFrom EverandIntroduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsNo ratings yet

- GD& T Interview QuestionsDocument3 pagesGD& T Interview Questionsgsgsuresh100% (3)

- Geometric Dimension IngDocument106 pagesGeometric Dimension IngjamesliouNo ratings yet

- GD&T PPT GeneralDocument197 pagesGD&T PPT GeneraldramiltNo ratings yet

- Mathematical Analysis of Quasi-Simultaneous Laser Welding on PolymersFrom EverandMathematical Analysis of Quasi-Simultaneous Laser Welding on PolymersNo ratings yet

- Geometric Dimensioning and TolerancingDocument50 pagesGeometric Dimensioning and TolerancingeizharNo ratings yet

- ElementsDocument75 pagesElementsAbhishek AnandNo ratings yet

- Dimensioning and TolerancingDocument22 pagesDimensioning and TolerancingArnobNo ratings yet

- Cleat Connection For PlatformsDocument29 pagesCleat Connection For PlatformsRajveer SinghNo ratings yet

- Geometric Dimensioning and Tolerancing (GD&T) : College of Engineering and TechnologyDocument7 pagesGeometric Dimensioning and Tolerancing (GD&T) : College of Engineering and TechnologyDienies TorresNo ratings yet

- GD & TDocument90 pagesGD & TgurlambaNo ratings yet

- CH 1 Sustainable Energy CengageDocument40 pagesCH 1 Sustainable Energy CengageDr Mohammad AlzoubyNo ratings yet

- Radioscopy: Standard Guide ForDocument20 pagesRadioscopy: Standard Guide ForsanthakumarNo ratings yet

- Rules &conceptsDocument55 pagesRules &conceptsLokesh RajaNo ratings yet

- 1 Exercises Product Quatity Control Geometrical TolerancingDocument66 pages1 Exercises Product Quatity Control Geometrical TolerancingHasan Can MuratNo ratings yet

- Rules and Concepts of GD&T PDFDocument31 pagesRules and Concepts of GD&T PDFMahender KumarNo ratings yet

- Introduction To Geometric Dimensioning and TolerancingDocument3 pagesIntroduction To Geometric Dimensioning and TolerancinganandparasuNo ratings yet

- GDNT PDFDocument80 pagesGDNT PDFjoyalNo ratings yet

- Geo TolerancesDocument23 pagesGeo TolerancesMaureen BairdNo ratings yet

- Basics of GD&TDocument50 pagesBasics of GD&T2023ht30006No ratings yet

- GD&T 1Document41 pagesGD&T 1Sai CharanNo ratings yet

- Terms: The Definitions of 16 Critical Terms Defined by The 2009 StandardDocument6 pagesTerms: The Definitions of 16 Critical Terms Defined by The 2009 StandardLikith LikiNo ratings yet

- Positional Tolerancing PresDocument19 pagesPositional Tolerancing PresManish PatilNo ratings yet

- TolerancingDocument19 pagesTolerancingKRKSANNo ratings yet

- What Is A "Material Condition Modifier?"Document3 pagesWhat Is A "Material Condition Modifier?"Arun ManoNo ratings yet

- Geometric Tolerances: Overview of Geometric Tolerances Form Tolerances Orientation Tolerances Location TolerancesDocument23 pagesGeometric Tolerances: Overview of Geometric Tolerances Form Tolerances Orientation Tolerances Location TolerancessaravanaNo ratings yet

- Counter BoreDocument11 pagesCounter BoreSURYA20051961No ratings yet

- Geometric Dimensioning and TolerancingDocument10 pagesGeometric Dimensioning and Tolerancing25aprilNo ratings yet

- Maximum Material Condition (MMC) : Principle of Independency - ISO RuleDocument2 pagesMaximum Material Condition (MMC) : Principle of Independency - ISO RuleMichael Robin B. SevillaNo ratings yet

- Latest Report 2Document13 pagesLatest Report 2Piyush BariNo ratings yet

- Symbol: None - Always Implied Default Condition (Abreviated: RFS) Category: Feature of Size DefinitionDocument2 pagesSymbol: None - Always Implied Default Condition (Abreviated: RFS) Category: Feature of Size Definitionvin_ckNo ratings yet

- Report On Dimensional Tolerance: DefinationDocument10 pagesReport On Dimensional Tolerance: DefinationPiyush BariNo ratings yet

- Report On Dimensional Tolerance: DefinationDocument10 pagesReport On Dimensional Tolerance: DefinationPiyush BariNo ratings yet

- Geometric Dimensioning Tolerancing 102Document51 pagesGeometric Dimensioning Tolerancing 102Vidjeane MourthyNo ratings yet

- GD&T TolerancesDocument26 pagesGD&T TolerancesTamas RaduNo ratings yet

- GD&T BasicsDocument27 pagesGD&T BasicsfreelanNo ratings yet

- GD& T ReviewDocument92 pagesGD& T ReviewMoham'medAlthafAs'lamNo ratings yet

- GD&T For Mpii 26-4-22Document134 pagesGD&T For Mpii 26-4-22sai tejaNo ratings yet

- Questionnaire On Geometric Dimensions and TolerancesDocument5 pagesQuestionnaire On Geometric Dimensions and TolerancesPOOJA KUMARINo ratings yet

- GDN TDocument27 pagesGDN Tjayannakollangi83% (12)

- 5.5. Tolerance1Document25 pages5.5. Tolerance1Chung Nguyễn PhúcNo ratings yet

- F5eGeoTolerances RKGDocument23 pagesF5eGeoTolerances RKGsundar301No ratings yet

- Magna Supplier Quality Requirements Manual Rev2Document26 pagesMagna Supplier Quality Requirements Manual Rev2gflores65No ratings yet

- GD&TDocument10 pagesGD&TestampariaitupevaNo ratings yet

- GDNTDocument27 pagesGDNTrakshithmpNo ratings yet

- GD&T SyllabusDocument4 pagesGD&T SyllabusyuvarajaNo ratings yet

- Location ToleranceDocument16 pagesLocation ToleranceMohannad BamigdadNo ratings yet

- GD&TDocument6 pagesGD&Tdhruv001No ratings yet

- F 5 GeotolerancesDocument23 pagesF 5 Geotolerancesவிவேக் குருசாமிNo ratings yet

- High Order Large Eddy Simulation for Shock-Boundary Layer Interaction Control by a Micro-ramp Vortex GeneratorFrom EverandHigh Order Large Eddy Simulation for Shock-Boundary Layer Interaction Control by a Micro-ramp Vortex GeneratorNo ratings yet

- Numerical Methods and Implementation in Geotechnical Engineering – Part 2From EverandNumerical Methods and Implementation in Geotechnical Engineering – Part 2No ratings yet

- Book 1 The Fundamental Particles of Physics 1Document37 pagesBook 1 The Fundamental Particles of Physics 1Subhash DhoundiyalNo ratings yet

- Exce-Anclaje Al Concreto - Rosales Mendoza WaldoDocument5 pagesExce-Anclaje Al Concreto - Rosales Mendoza WaldoGabbo pnukNo ratings yet

- Revision Chap14pdfDocument12 pagesRevision Chap14pdfadlinaNo ratings yet

- A Comparative Study On Several ControlDocument103 pagesA Comparative Study On Several ControlTaddese DiribaNo ratings yet

- Luc TDS ING 2016 Stability Analysis of Nonlinear Systems PDFDocument21 pagesLuc TDS ING 2016 Stability Analysis of Nonlinear Systems PDF黃元貞No ratings yet

- Welcome To Category ZeroDocument38 pagesWelcome To Category ZeroParesh Chandra DebnathNo ratings yet

- Stewart Swerdlow - Blue Blood True BloodDocument125 pagesStewart Swerdlow - Blue Blood True BloodZoltán NagyNo ratings yet

- Fuchs1991 - Ten Years of Experience With Leak Detection by Acoustic Signal AnalysisDocument19 pagesFuchs1991 - Ten Years of Experience With Leak Detection by Acoustic Signal AnalysisHenriqueNo ratings yet

- Lesson 4 - Ferromagnetism, Paramagnetism and DiamagnetismDocument5 pagesLesson 4 - Ferromagnetism, Paramagnetism and DiamagnetismMohit sadhNo ratings yet

- Effects If Depth of Footing and Water Table On Bearing Capacity of Soil PDFDocument4 pagesEffects If Depth of Footing and Water Table On Bearing Capacity of Soil PDFOkino CharlesNo ratings yet

- Wide Range Drive of Hybrid Stepping Motor With Flux-Weakening ControlDocument7 pagesWide Range Drive of Hybrid Stepping Motor With Flux-Weakening ControlTrần Tấn LộcNo ratings yet

- Probability DistributionDocument15 pagesProbability Distributionpatty444No ratings yet

- 2.12. Inverse Kinematics ProblemDocument18 pages2.12. Inverse Kinematics ProblemEce TaşdemirNo ratings yet

- Module 7 - Kinematics of Rigid Bodies Translation and Rotation About A Fixed AxisDocument5 pagesModule 7 - Kinematics of Rigid Bodies Translation and Rotation About A Fixed AxisGaEl EthelNo ratings yet

- STS Module 1 - Lesson 1Document8 pagesSTS Module 1 - Lesson 1jjjjjemNo ratings yet

- WRCEDocument1 pageWRCERichmark MacuhaNo ratings yet

- Examination Notes: 1. Answer ALL The Questions 2. Encircle of Highlight Your Answer With Yellow ColorDocument18 pagesExamination Notes: 1. Answer ALL The Questions 2. Encircle of Highlight Your Answer With Yellow ColorDovah KiinNo ratings yet

- Chap. 1: Vertical PhotographsDocument22 pagesChap. 1: Vertical PhotographsLarasaty Ayu0% (1)

- Grade 5 - Fourth Grading Periodic Test in MathematicsDocument5 pagesGrade 5 - Fourth Grading Periodic Test in MathematicsoninlampaNo ratings yet

- Physics Investigatory Project BAR MAGNET 2Document11 pagesPhysics Investigatory Project BAR MAGNET 2Lol hole GamerNo ratings yet

- Method For Preliminary Sizing of Large Propeller Driven AircraftsDocument52 pagesMethod For Preliminary Sizing of Large Propeller Driven AircraftsHARISH PNo ratings yet

- RDM4 C ch4 BucklingDocument17 pagesRDM4 C ch4 BucklingThomas BernardNo ratings yet

- Worksheet Week 5Document4 pagesWorksheet Week 5Jaybie TejadaNo ratings yet

- Chennal Public School Class Xii Mathematics: Chapter1: Relations and Functions Equivalence RelationDocument2 pagesChennal Public School Class Xii Mathematics: Chapter1: Relations and Functions Equivalence Relation12A07 Nikitha SNo ratings yet

- PR - Module 10 - JRDocument4 pagesPR - Module 10 - JRSamuel Dela CruzNo ratings yet

- Ahmed Elmoghazy - IGCSE - Physics - Worksheet 14 - Energy Transfers PDFDocument3 pagesAhmed Elmoghazy - IGCSE - Physics - Worksheet 14 - Energy Transfers PDFAhmed Elmoghazy100% (1)