Professional Documents

Culture Documents

Customer Presentation LEWA Ecoflow

Uploaded by

Mohammed ShallabyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Customer Presentation LEWA Ecoflow

Uploaded by

Mohammed ShallabyCopyright:

Available Formats

THE TECHNOLOGY ADVANTAGE

LEWA ecoflow The innovative metering pumps

Reciprocating metering pumps Survey of the modular system Function of the LEWA ecoflow drive elements Function of the M900 pump heads Summary and customer advantages

T echnik

THE TECHNOLOGY ADVANTAGE

Photos LDE

THE TECHNOLOGY ADVANTAGE

Photos LDE

THE TECHNOLOGY ADVANTAGE

Photos LDE

THE TECHNOLOGY ADVANTAGE

Photos LDE 4

THE TECHNOLOGY ADVANTAGE

Photos LDC3

THE TECHNOLOGY ADVANTAGE

LEWA ecoflow The innovative metering pumps

Reciprocating

metering pumps

T un

THE TECHNOLOGY ADVANTAGE

Oscillating metering pumps

Reciprocating

metering pumps

Drive element: Converting rotary movement to a reciprocating movement

Pump head: Metering fluid

THE TECHNOLOGY ADVANTAGE

Pressure firm pump characteristic

positice displacement pumps

rotary positive displacement pumps

flowrate

centrifugal pumps

pressure

THE TECHNOLOGY ADVANTAGE

Pulsating flowrate

flowrate Q

Vh

Vh

Vh

time t

10

THE TECHNOLOGY ADVANTAGE

Adjusting the flowrate

Q = k1*n

fowrate Q flowrate Q

Q = k2*(h-h0)

limiting stroke length h0 h0

frequency n

stroke length h

11

THE TECHNOLOGY ADVANTAGE

LEWA ecoflow Innovative Metering Pumps

Survey of the

modular system

12

T un

THE TECHNOLOGY ADVANTAGE

Drive elements and pump heads Drive elements

LDB

LDC LDD LDE

Pump heads

M900

13

THE TECHNOLOGY ADVANTAGE

Ecoflow replaces modular

EK

LDB

EL

LDC

LDD EH

LDE

14

THE TECHNOLOGY ADVANTAGE

Guidelinie 94/9/EG ATEX

absolutely suitable for group II, category 2 (zone 1), gas group IIC,

temperature class T1-T4

Special features in design

standard version provided with earthing terminals parts made of plastic are hard to charge Temperature rise tested (by worm shaft sealing,

by drive element)

no maintenance of couplings between elements

15

THE TECHNOLOGY ADVANTAGE

LEWA ecoflow Innovative metering pumps

LEWA ecoflow drive

elements

16

THE TECHNOLOGY ADVANTAGE

Function of stroke adjustment

movie

17

THE TECHNOLOGY ADVANTAGE

Multiplex pumps Common oil bath of multiplex pumps

less wear parts simple maintenance,

meets ATEXrequirements

18

THE TECHNOLOGY ADVANTAGE

LEWA ecoflow Innovative metering pumps

Function of the M900

pump heads in detail

19

T un

THE TECHNOLOGY ADVANTAGE

Function of the diaphragm pumps

First step: Starting point is the plunger pump

20

THE TECHNOLOGY ADVANTAGE

Function of the diaphragm pumps

Second step: Installation of a diaphragm

21

THE TECHNOLOGY ADVANTAGE

Function of the diaphragm pumps

Third step: Diaphragm guide and support, replenishment valve

22

THE TECHNOLOGY ADVANTAGE

Function of the diaphragm pumps

Fourth step: Pressure relief valve

23

THE TECHNOLOGY ADVANTAGE

Function of the diaphragm pumps

Fifth step: Installation of a spring

24

THE TECHNOLOGY ADVANTAGE

LEWA ecoflow M900

movie

25

THE TECHNOLOGY ADVANTAGE

DPS: Diaphragm Protection System

Diaphragm Protection System

New Diaphragm control PTFE- sandwich diaphragm with

Diaphragm condition monitor extraordinary safe pump head

trouble-free start-up New diaphragm

with extended service life

Diaphragm movement is stabilised

by overpressure in the hydraulic fluid

No gas bubbles during suction stroke

Higher suction lift capability,

comparable to plunger pump heads

Higher stroke frequencies are possible (theor. 288min-1)

26

THE TECHNOLOGY ADVANTAGE

M900 diaphragm

New diaphragm technology

(patent pending)

Longer diaphragm service life

due to central guide of diaphragm

Simple screwing-on of diaphragm

Diaphragm condition

monitor as standard

movie

27

THE TECHNOLOGY ADVANTAGE

Diaphragm mounting

The diaphragm can easily be screwed onto the diaphragm guide.

Automatic venting of sandwich diaphragm:

diaphragm is filled with grease as a standard

movie

Assembly

Disassembly

28

THE TECHNOLOGY ADVANTAGE

Time - Pressure - Curve

min. 1 bar

overpressure Pressure in the hydraulic chamber

e b ]

pressure valve opens

pressure valve closes

Decompression

replenishment valve open

Compression suction valve opens closes

Time

fluid chamber hydraulic chamber

29

THE TECHNOLOGY ADVANTAGE

Example of failure: Pressure line closed

Pressure relief valve

opens

movie

30

THE TECHNOLOGY ADVANTAGE

Example of failure: Suction line closed

Cavitation in the

fluid chamber; the pressure decreases up to the vapour pressure of the metered fluid

min. 1 bar abs.

overpressure in the hydraulic chamber

no gas bubbles in the

hydraulic chamber

movie

31

THE TECHNOLOGY ADVANTAGE

NPSHR of LEWA pumps

32

THE TECHNOLOGY ADVANTAGE

Suction features, NPSHR and min. suction pressure

Diaphragm pump heads competitors pSFmin p i + p Tfl or pSFmin p i + p H + 0.4 bar a pSFmin min. suction pressure p i inlet pressure loss (NPSHR) p H pressure losses in the hydraulic chamber, flow losses, diaphragm rigidity 0.4 bar a : limit pressure of hydraulic fluid Diaphragm pump heads M900 pSFmin p i + p Tfl pSFmin min. suction pressure

p i inlet pressure loss (NPSHR)

p Tfl vapour pressure of metering fluid

The NPSHR will not change but the minimum required suction pressure

33

THE TECHNOLOGY ADVANTAGE

Arguments creating confidence

Diaphragm technology is based on the experiences with the proven

M700 and LEWA ecodos series

Clamping technology is based on the experiences with the PTFE

high-pressure pump heads M800

LEWA ecoflow has been tested successfully for more than 500.000

hours

The diaphragm springs have been successfully tested for more than

40.000 hours operation

34

THE TECHNOLOGY ADVANTAGE

Summary and customer advantages

Simple start the pump without

diaphragm positioning

Max. pressure range: up to 400bar High suction lift capability,

allows pumping out of a vacuum

Long service life of diaphragms Simple maintenance High suction pressure safety Wide turndown range

by stroke speed and length

Full diagnostic capability Simple spare parts stocking at

customers with a high share of identical parts

35

You might also like

- Pump Documentation LEWA DOKU - 532316Document80 pagesPump Documentation LEWA DOKU - 532316miltonmontaldoNo ratings yet

- D1-170 Ecosmart en PDFDocument8 pagesD1-170 Ecosmart en PDFrakacyuNo ratings yet

- High-End Metering PumpsDocument15 pagesHigh-End Metering PumpsDaniel Saenz GonzalezNo ratings yet

- Fan Calculation MooreDocument8 pagesFan Calculation MooreArjun GirishNo ratings yet

- Iso 21630-2007Document28 pagesIso 21630-2007sleiman shokrNo ratings yet

- Ahlstar End-Suction Single-Stage Centrifugal Pumps: Flow EquipmentDocument28 pagesAhlstar End-Suction Single-Stage Centrifugal Pumps: Flow EquipmentARYAN_FATHONI_AMRINo ratings yet

- Ratchet & Pawl Brake SystemDocument2 pagesRatchet & Pawl Brake SystemmalawanyNo ratings yet

- Datos de La Bomba Tuthill PDFDocument24 pagesDatos de La Bomba Tuthill PDFRaulEfrainCharrezCastillo100% (1)

- PDFDocument16 pagesPDFdang2172014No ratings yet

- Horizontal MultiStage Pump Data SheetDocument6 pagesHorizontal MultiStage Pump Data Sheetسمير البسيونىNo ratings yet

- PD Cen-Tr 13931-2009Document32 pagesPD Cen-Tr 13931-2009Meric100% (1)

- Netzsch Nemo PumpsDocument53 pagesNetzsch Nemo PumpslwinooNo ratings yet

- API 682 BasicsDocument8 pagesAPI 682 BasicsIslam FawzyNo ratings yet

- NEMO - MultiphasenpumpeDocument9 pagesNEMO - MultiphasenpumpeCesar MerchanNo ratings yet

- Reciprocating Diaphragm Pumps PDFDocument16 pagesReciprocating Diaphragm Pumps PDFSushil GoswamiNo ratings yet

- Butterfly Flu01 Omb 04 11Document16 pagesButterfly Flu01 Omb 04 11ila_368684492No ratings yet

- PumpDocument20 pagesPumpHimanshu SharmaNo ratings yet

- Aircraft Refuelling HoseDocument4 pagesAircraft Refuelling HoseBimo IndroNo ratings yet

- HPX-SL - Semi-Open Impeller Pump: Desio Pump Catalog Typical Photo Z 1 of 1Document29 pagesHPX-SL - Semi-Open Impeller Pump: Desio Pump Catalog Typical Photo Z 1 of 1Ashwin NarayanNo ratings yet

- ActuationDocument12 pagesActuationSrimp sasaNo ratings yet

- DBB CatalogueDocument28 pagesDBB CatalogueHeri SetyantoNo ratings yet

- KCDocument3 pagesKCSandheepKumarNo ratings yet

- Nor GrenDocument5 pagesNor GrenSarlo11No ratings yet

- HELMKE Plus: Three-Phase Low Voltage Squirrel Cage MotorsDocument28 pagesHELMKE Plus: Three-Phase Low Voltage Squirrel Cage MotorsFernando SchneckenburgerNo ratings yet

- A2 - Painting Procedure PDFDocument2 pagesA2 - Painting Procedure PDFJuan Carlos Sua Sua100% (1)

- ISO-4409-07-Hydraulic Fluid Power - PositivedisplacementDocument30 pagesISO-4409-07-Hydraulic Fluid Power - PositivedisplacementantonioNo ratings yet

- Aeroquip Matchmate Crimp CatalogDocument44 pagesAeroquip Matchmate Crimp CatalogAngel Ricardo Rodrogiez MalagonNo ratings yet

- Well EquipmentsDocument51 pagesWell EquipmentssdfwexdNo ratings yet

- Is 4721Document7 pagesIs 4721dak2anshulNo ratings yet

- OBL Metering Pumps X9 BrochureDocument12 pagesOBL Metering Pumps X9 BrochureniranpaiNo ratings yet

- Resilient Seated Wedge Gate Valve Data SheetDocument2 pagesResilient Seated Wedge Gate Valve Data Sheetkbc404100% (1)

- Pump FAT Analysis Result - ISO 9906 2012Document3 pagesPump FAT Analysis Result - ISO 9906 2012Safarul Izmi100% (1)

- Compression Packing Selection Guide: Sealing Products For IndustryDocument13 pagesCompression Packing Selection Guide: Sealing Products For IndustryAdverNo ratings yet

- What Is HDPE PIPEDocument7 pagesWhat Is HDPE PIPEKarthikeyan MoorthyNo ratings yet

- Rotamat Centrifuge RodDocument6 pagesRotamat Centrifuge RodHemant KaleNo ratings yet

- Annual Book of ASTM Standards Vol 1003 ElectricalDocument2 pagesAnnual Book of ASTM Standards Vol 1003 ElectricalminhyNo ratings yet

- Bornemann MultiphaseDocument24 pagesBornemann MultiphaseReza Ghanavati100% (1)

- Pompa Lewa D1-450en Ecodos 04 11 Screen 09Document12 pagesPompa Lewa D1-450en Ecodos 04 11 Screen 0919poeNo ratings yet

- Cameron Ball ValvesDocument31 pagesCameron Ball ValvesJosé Roberto Alejo MirandaNo ratings yet

- I S En15714-2-2009Document8 pagesI S En15714-2-2009Sreeram PanigrahiNo ratings yet

- Flowserve Hydrocarbon Processing FPD 4 eDocument16 pagesFlowserve Hydrocarbon Processing FPD 4 eLUKAS3589100% (1)

- RMT 23 Series Control ValveDocument37 pagesRMT 23 Series Control ValveNymphetamine AnhNo ratings yet

- Tie Rod 70 Bar Hydraulic Cylinders PDFDocument48 pagesTie Rod 70 Bar Hydraulic Cylinders PDFNilxon Alejandro Jaramillo DíazNo ratings yet

- AIR1707B - Patterns of O-Ring FailuresDocument20 pagesAIR1707B - Patterns of O-Ring FailuresEmiliya Emiliya100% (1)

- D SeriesDocument20 pagesD SeriesJorge A VilalNo ratings yet

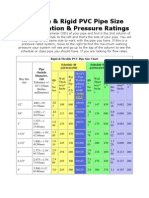

- Flexible & Rigid PVC Pipe Size IdentificationDocument4 pagesFlexible & Rigid PVC Pipe Size IdentificationAziz Khan KakarNo ratings yet

- Knife Gate ValveDocument7 pagesKnife Gate ValveAbdul RaheemNo ratings yet

- Viton Selection GuideDocument13 pagesViton Selection GuideAlexandru AndreiNo ratings yet

- Sxda/Sxwa/Syda/Sywa: Metering PumpsDocument56 pagesSxda/Sxwa/Syda/Sywa: Metering PumpsZelminha StNo ratings yet

- Dyneon PTFE BrochureDocument0 pagesDyneon PTFE BrochureXray UandNo ratings yet

- Bombas TuthillDocument3 pagesBombas TuthillBpNo ratings yet

- BFP ARC Valve FunctionDocument6 pagesBFP ARC Valve FunctionVenkat ShanNo ratings yet

- Jeida Farm Supply Corporation Catalog 2014Document10 pagesJeida Farm Supply Corporation Catalog 2014Taj Deluria100% (3)

- Case Study VR Lubricator ToolDocument2 pagesCase Study VR Lubricator ToolVictorNo ratings yet

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Profile of the International Pump Industry: Market Prospects to 2010From EverandProfile of the International Pump Industry: Market Prospects to 2010Rating: 1 out of 5 stars1/5 (1)

- Fives Cryogenics DELTA N BrochureDocument2 pagesFives Cryogenics DELTA N BrochureAhmed BenjellounNo ratings yet

- Hermatic LRVP CatalogueDocument12 pagesHermatic LRVP CatalogueSunil BawaneNo ratings yet

- Convincing Worldwide: HERMETIC Pumps in The Refrigeration IndustryDocument24 pagesConvincing Worldwide: HERMETIC Pumps in The Refrigeration IndustryWaseem HassanNo ratings yet

- CalColumns BrochureDocument2 pagesCalColumns BrochureRaya SNo ratings yet

- Oil Gas Industry GuidelinesDocument90 pagesOil Gas Industry GuidelinesAdhia Prenata Putra HuzaNo ratings yet

- ALL ICB Technical RequirementsDocument241 pagesALL ICB Technical RequirementsMohammed ShallabyNo ratings yet

- Comm Procedure For Genset Installlation in Govt Building HongkongDocument23 pagesComm Procedure For Genset Installlation in Govt Building Hongkongbhen08No ratings yet

- OILgasDocument88 pagesOILgasArunvpmNo ratings yet

- Plant Commissioning Start Up ProcedureDocument100 pagesPlant Commissioning Start Up Proceduremsaad292% (124)

- Lean Six Sigma Green Belt Certification Training - BrochureDocument8 pagesLean Six Sigma Green Belt Certification Training - BrochureSean AkirangaNo ratings yet

- 21 Tips To Improve Your Job SearchDocument3 pages21 Tips To Improve Your Job SearchMohammed ShallabyNo ratings yet

- Process Commissioning Plant - David HorsleyDocument130 pagesProcess Commissioning Plant - David Horsleyapi-3709413100% (37)

- Presentation PumpsDocument149 pagesPresentation PumpsMohammed ShallabyNo ratings yet

- Plant Commissioning Start Up ProcedureDocument100 pagesPlant Commissioning Start Up Proceduremsaad292% (124)

- Regulators Man FlowmaxDocument28 pagesRegulators Man FlowmaxMohammed ShallabyNo ratings yet

- Power Plant Startup and Commissioning Services: A Proven Plan Using Dedicated ResourcesDocument8 pagesPower Plant Startup and Commissioning Services: A Proven Plan Using Dedicated ResourcesPiyush SinhaNo ratings yet

- Steel Pipes and FittingsDocument14 pagesSteel Pipes and FittingsMohammed ShallabyNo ratings yet

- Energy:: Natural GasDocument114 pagesEnergy:: Natural GasTheCapitol.Net50% (2)

- Customer Presentation LEWA EcoflowDocument35 pagesCustomer Presentation LEWA EcoflowMohammed ShallabyNo ratings yet

- Piping Training CourseDocument411 pagesPiping Training CourseMohammed ShallabyNo ratings yet

- Presentation PumpsDocument149 pagesPresentation PumpsMohammed ShallabyNo ratings yet

- Valvula Compuerta FS RDocument6 pagesValvula Compuerta FS RAngie LondoñoNo ratings yet

- Electrical Engineering Portal - Com Principles For Controlling HarmonicsDocument3 pagesElectrical Engineering Portal - Com Principles For Controlling HarmonicsRobert GalarzaNo ratings yet

- Sandvik DU311 ITH - Descripción Técnica - EnglishDocument4 pagesSandvik DU311 ITH - Descripción Técnica - EnglishErix Alcayaga GonzálezNo ratings yet

- Cutera GIS-HP Cooling FFA Data Capture - Rev ADocument3 pagesCutera GIS-HP Cooling FFA Data Capture - Rev AMickey A CouvertierNo ratings yet

- Pulsar Extreme 3200CDocument28 pagesPulsar Extreme 3200CGuillermoNo ratings yet

- 39S Be 1977Document41 pages39S Be 1977Dre KrakNo ratings yet

- Workshop Manual: TAD1240GE, TAD1241GE/VE TAD1242GE/VE, TWD1240VEDocument104 pagesWorkshop Manual: TAD1240GE, TAD1241GE/VE TAD1242GE/VE, TWD1240VEThong Chan100% (1)

- Overfill - Valve - 442B Size 4Document3 pagesOverfill - Valve - 442B Size 4j8164322No ratings yet

- PS Range BrochureDocument16 pagesPS Range BrochureJorge Alberto LTNo ratings yet

- Introduction To Cementingwell - 2020 PDFDocument11 pagesIntroduction To Cementingwell - 2020 PDFShijuAsNo ratings yet

- De Super HeaterDocument12 pagesDe Super HeaternewprocessNo ratings yet

- Quantum EfficiencyDocument8 pagesQuantum EfficiencySurender DilipNo ratings yet

- Workshop Small NewDocument36 pagesWorkshop Small Newesteban marinkovicNo ratings yet

- Licensing Process (PPT97)Document22 pagesLicensing Process (PPT97)patrick husseinNo ratings yet

- 08 FS EtpDocument18 pages08 FS EtpKatamaneni KoteswararaoNo ratings yet

- ZTE Rectifier SettingsDocument4 pagesZTE Rectifier SettingsRicardo Chavarria50% (2)

- Poleas en V - Narrow - Ultra-VDocument70 pagesPoleas en V - Narrow - Ultra-VVladimir SepulvedaNo ratings yet

- Vaporizador 120 GPH InglesDocument54 pagesVaporizador 120 GPH InglesvictorlizcanoNo ratings yet

- INBAR-2023-Combating Climate Change With BambooDocument24 pagesINBAR-2023-Combating Climate Change With BambooKay-Uwe SchoberNo ratings yet

- 221 1 Engineering Work Suwpport by Excel Based ProgramDocument1 page221 1 Engineering Work Suwpport by Excel Based ProgramZoebairNo ratings yet

- Parts ManualDocument478 pagesParts ManualRicardo VieiraNo ratings yet

- Carrier VRF PDFDocument12 pagesCarrier VRF PDFThếSơnNguyễnNo ratings yet

- Step by Step Guide Book On Home WiringDocument50 pagesStep by Step Guide Book On Home WiringquangspktNo ratings yet

- Usui Reiki Master Level Certification CoDocument42 pagesUsui Reiki Master Level Certification CoFabian DeeNo ratings yet

- Toyota 1NZ - IgnitionDocument7 pagesToyota 1NZ - IgnitionMaycol Pauccarima Alfaro100% (3)

- MOC-Vasant Delivery Checklist For Crew REV - 0 Dated 31 Aug 2020Document95 pagesMOC-Vasant Delivery Checklist For Crew REV - 0 Dated 31 Aug 2020Piyush KumarNo ratings yet

- Rad Lec 1 Machine OverviewDocument4 pagesRad Lec 1 Machine OverviewTiti DarabanNo ratings yet

- ST 50g ManualDocument103 pagesST 50g ManualrichardNo ratings yet

- Procedure Qualification RecordDocument2 pagesProcedure Qualification RecordDan ClarkeNo ratings yet

- DDDDocument1 pageDDDKashif AliNo ratings yet