Professional Documents

Culture Documents

Generator Foundation Mountings

Uploaded by

Suresh GunasekaraOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Generator Foundation Mountings

Uploaded by

Suresh GunasekaraCopyright:

Available Formats

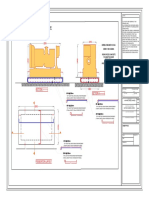

Generator Foundation Mountings

Considerations for Generator Set Foundations

Foundations supporting generator sets must meet flotation, alignment and vibration parameters for successful operation. Specifications that consider the following criteria will help ensure trouble-free installation and operation. Foundations must be able to withstand the installations weight and prevent deflection. To determine the pressure exerted by a generator set, use the following equation: P = W/A Where: P = pressure in PSI (kPa) W = generator set wet weight in lbs (kg) A = Area in sq. in. (m2) of the rails, pads or vibration mounts. Note: This pressure must be less than the load-carrying capability of the soil foundation pad. General load bearing capabilities of underfoot are listed in Table 1. Table 1 - Bearing Load Capacities Material Rock, hardpan Hard clay, gravel and coarse sand Loose medium sand and medium clay Loose fine sand Soft clay psi 70 56 28 14 0-14 kPa 482 386 193 96.4 0-96.4

Note: The foundation should weigh at least as much as the generator sets wet weight. Use this equation to calculate the necessary foundation depth: Foundation depth = W/DxBxL Where: W = Total wet weight of genset (lb or kg) D = Density of concrete (150.b/cu.ft3 or 2,400 kg/m3) B = Foundation width (ft or m) L = Foundation length (ft or m) Note: This equation assumes a concrete mixture ratio of 1:2:3 (cement:sand:aggregate) with maximum 4 inch (101.6mm) slump and 29-day compressive strength of 3,000 psi (20.67MPa). If no vibration isolators are used, the floor must support 125% of the generator set weight. If gensets are paralleled, possible out-of-phase paralleling could cause torque reactions. Here, foundations must be designed to withstand twice the generator set wet weight. The foundation should be reinforced with No. 8 gauge steel wire fabric of No. 6 reinforcing bars on 12 (304.8mm) centers horizontally. Bars should be imbedded in the concrete at least 3 (76.2mm) from foundation surface. NOTE: All above are suggestions only. Neither Caterpillar nor Cashman publish certified pad requirements. Local seismic and structural codes should be reviewed and the final pad design should be done by a properly certified structural engineer.

Maintaining Alignment

Modern multi-cylinder medium-speed generators sets do not require massive concrete foundations to maintain engine/ generator alignment. In most applications, a single-bearing generator set can be installed and operated on the base it was shipped on.

Generator Foundation Mountings

Two-bearing generators, generators driven from either end of one engine, tandem generators or generators with tandem engines require a much heavier boxed base that resists bending forces exerted by the generator sets. The base also must prevent resonant vibration during operation.

Flexible Connections

Any supply line or hose connected to the generator set--including exhaust coupling and exhaust pipe hangers, jacket water connections, heat recovery systems and fuel lines--must be fitted with a flexible section that can withstand vibrations incurred by the operating generator set. These flexible connections should be installed as close to the generator set as possible and be designed to prevent line leaks or breaks.

Service Considerations

Convenience and serviceability can be designed into a generator set foundation. Consider specifying conduit for electric starting systems, generator leads and fuel and water connections.

You might also like

- 1.5MVA Transformer Foundation Layout 25.12.14 R4 4Document1 page1.5MVA Transformer Foundation Layout 25.12.14 R4 4sathishNo ratings yet

- Cable Trench DesignDocument24 pagesCable Trench DesignIrshad Khan100% (1)

- Design of Transformer FoundationDocument6 pagesDesign of Transformer FoundationManan MansoorNo ratings yet

- Cable Trench Sections Icb 29 (All Locations)Document1 pageCable Trench Sections Icb 29 (All Locations)Anoop DikshitNo ratings yet

- Machine FoundationDocument11 pagesMachine Foundationsujayan2005100% (1)

- Foundation ComputationDocument10 pagesFoundation ComputationCris TopperNo ratings yet

- D.G Set FoundationDocument27 pagesD.G Set Foundationurs_harji100% (2)

- 60641561-DWG-706-EIRGRID 220 KV GIS BUILDING SECTIONS AND LAYOUTDocument1 page60641561-DWG-706-EIRGRID 220 KV GIS BUILDING SECTIONS AND LAYOUTWael Ab100% (1)

- Retaining Wall DesignDocument11 pagesRetaining Wall Designeric bargasNo ratings yet

- TB FoundationAndSkidDesignDocument4 pagesTB FoundationAndSkidDesigndicktracy11100% (1)

- Footing Design ExcelDocument13 pagesFooting Design Excelsujan100% (2)

- How To Fix STAAD Warning WWW - UniquecivilDocument5 pagesHow To Fix STAAD Warning WWW - UniquecivilMohdDanishNo ratings yet

- Transformer Foundation Along With Blast WallDocument11 pagesTransformer Foundation Along With Blast Wallkrmurali2000No ratings yet

- Transformer Foundation 5Document1 pageTransformer Foundation 5A.K.M Shafiq MondolNo ratings yet

- Monorail-DesignDocument8 pagesMonorail-Designdicktracy11No ratings yet

- 10MT Gantry DesignDocument7 pages10MT Gantry Designvinit soodNo ratings yet

- 30 MVA Transformer Foundation DesignDocument19 pages30 MVA Transformer Foundation DesignSagun KatuwalNo ratings yet

- Genset Concrete Pad Detail-SignedDocument1 pageGenset Concrete Pad Detail-SignedJOSEPH ANTHONY VINCE MOICONo ratings yet

- Tower Thumb Rule CalculationDocument5 pagesTower Thumb Rule CalculationBalakrishnan0% (1)

- Hyundai Electric BrochureDocument36 pagesHyundai Electric BrochurebadbenzationNo ratings yet

- STP Blower Room Detail STP Concrete PadDocument1 pageSTP Blower Room Detail STP Concrete PadjoeyNo ratings yet

- Base Foundation of Generator: SECTION I - I SECTION II - IIDocument1 pageBase Foundation of Generator: SECTION I - I SECTION II - IIHayman AhmedNo ratings yet

- Checklist For Transformer Burnt Oil Tank Design & DrawingDocument3 pagesChecklist For Transformer Burnt Oil Tank Design & DrawingRupesh KhandekarNo ratings yet

- Formwork Design For Concrete Duct Bank and ManholeDocument35 pagesFormwork Design For Concrete Duct Bank and ManholeshihabNo ratings yet

- Generator Set RoomsDocument7 pagesGenerator Set RoomsAnonymous TvOpvXNo ratings yet

- Wood Stove ReportDocument5 pagesWood Stove ReportAbdul SabirNo ratings yet

- PT Foundation ApprovedDocument6 pagesPT Foundation ApprovedSujit RasailyNo ratings yet

- 5 - 04 Fundation, Rigid and Resilient Mounted Gen-SetDocument11 pages5 - 04 Fundation, Rigid and Resilient Mounted Gen-SetHelder Norberto SilvaNo ratings yet

- My Experience For Professional ReviewDocument23 pagesMy Experience For Professional ReviewSuresh Gunasekara100% (2)

- Base of Generator PDFDocument1 pageBase of Generator PDFHayman Ahmed100% (1)

- Technical Specification - PSC PoleDocument8 pagesTechnical Specification - PSC PoleJogendra Nath NeogNo ratings yet

- DRAWINGSDocument41 pagesDRAWINGSsparkCE100% (1)

- Behavior of Unsaturated Soils For Road Pavement Structure Under Cyclic LoadingDocument272 pagesBehavior of Unsaturated Soils For Road Pavement Structure Under Cyclic LoadingDiana CapisondaNo ratings yet

- Light Pole DesignDocument43 pagesLight Pole DesignArnab MondalNo ratings yet

- Sample For A Design ProposalDocument7 pagesSample For A Design ProposalSuresh Gunasekara100% (2)

- DGS 1482-004 REV 2 - Geotechnical InvestigationDocument13 pagesDGS 1482-004 REV 2 - Geotechnical InvestigationcarloNo ratings yet

- Mast DesignDocument18 pagesMast DesignPoulomi BiswasNo ratings yet

- Anchor Bolt: Steel Structures in IndustryDocument15 pagesAnchor Bolt: Steel Structures in Industryvenugopal BedadakotaNo ratings yet

- Pipe Riser Support Systems: Mason Industries, IncDocument4 pagesPipe Riser Support Systems: Mason Industries, IncAbdul RaheemNo ratings yet

- Section Page No.: Analysis & Design Calculation For BFP FoundationDocument39 pagesSection Page No.: Analysis & Design Calculation For BFP FoundationAnonymous fLgaidVBhzNo ratings yet

- Proposed Godown at Gikomba Market - BQ-1Document28 pagesProposed Godown at Gikomba Market - BQ-1michaelNo ratings yet

- Oil Sump PitDocument5 pagesOil Sump PitIrshad KhanNo ratings yet

- 01A Design Criteria For TowersDocument3 pages01A Design Criteria For TowersNisarg TrivediNo ratings yet

- Electrical Transmission Tower Types and Design PDFDocument6 pagesElectrical Transmission Tower Types and Design PDFjuga2013No ratings yet

- Service Excellence Position PaperDocument14 pagesService Excellence Position PaperSuresh GunasekaraNo ratings yet

- Service Excellence Position PaperDocument14 pagesService Excellence Position PaperSuresh GunasekaraNo ratings yet

- Pump HouseDocument1 pagePump HouseASRAR AHMED KHANNo ratings yet

- Foundation Design ComputationDocument1 pageFoundation Design ComputationMark Kevin BechaydaNo ratings yet

- Autoclaved Aerated Concrete (AAC) Blocks Project - Brief ReportDocument12 pagesAutoclaved Aerated Concrete (AAC) Blocks Project - Brief ReportVishal Kansagra77% (31)

- TrussesDocument49 pagesTrussesnamrataavyas95% (19)

- 30.rain Water HarvestingDocument5 pages30.rain Water HarvestingmariyaNo ratings yet

- Revised Foundation For 315 Mva Transformer 28 10 09 Model PDFDocument1 pageRevised Foundation For 315 Mva Transformer 28 10 09 Model PDFepe civilNo ratings yet

- RC Retaining Wall NoteDocument17 pagesRC Retaining Wall NoteMat Zoul100% (2)

- Airport Underground Electrical Duct Banks and ConduitsDocument8 pagesAirport Underground Electrical Duct Banks and ConduitsDevrim Gürsel0% (1)

- STAADDocument15 pagesSTAADBaladad HaroldNo ratings yet

- 1m X 1m Single Cell Box CulvDocument6 pages1m X 1m Single Cell Box CulvKush Deka100% (1)

- Hoisting FacilitiesDocument22 pagesHoisting FacilitiesArmie May RicoNo ratings yet

- Power Grid Corporation of India Limited: Pit MarkingDocument12 pagesPower Grid Corporation of India Limited: Pit Markingshanmugam.sNo ratings yet

- QES PEVC-ENG260 - Checklist For Gantry Foundation Design & DrawingDocument2 pagesQES PEVC-ENG260 - Checklist For Gantry Foundation Design & DrawingRupesh KhandekarNo ratings yet

- India Wind ZoneDocument1 pageIndia Wind ZonedhawanaxitNo ratings yet

- Indoor + Outdoor Substation With Generator RoomDocument1 pageIndoor + Outdoor Substation With Generator RoomMukterNo ratings yet

- Design BDR For Load PebDocument4 pagesDesign BDR For Load Pebknight1729No ratings yet

- EqualAngle PDFDocument2 pagesEqualAngle PDFGalih PutraNo ratings yet

- Anx 1Document17 pagesAnx 1mecon bhilaiNo ratings yet

- Compressor Shelter: Velocity of PressureDocument3 pagesCompressor Shelter: Velocity of PressurerohitnrgNo ratings yet

- Design Calculation of Oc+15 MTR TowerDocument14 pagesDesign Calculation of Oc+15 MTR TowerGuru MishraNo ratings yet

- Strip Footing Analysis & Design (BS8110) Beam Size ReduceDocument3 pagesStrip Footing Analysis & Design (BS8110) Beam Size ReduceHimura_No ratings yet

- 53-Steel Structures (Gantry Structure)Document13 pages53-Steel Structures (Gantry Structure)Sarmad HussainNo ratings yet

- Power Evacuation Study of The Lower Solu 82Document17 pagesPower Evacuation Study of The Lower Solu 82Sirish ShresthaNo ratings yet

- Anexo 2 - 2 Calculo para Base de Concreto - InglesDocument1 pageAnexo 2 - 2 Calculo para Base de Concreto - InglesArnaldo UrquidiNo ratings yet

- Proposed Residential Apartment Complex at Tangalle CalculationsDocument1 pageProposed Residential Apartment Complex at Tangalle CalculationsSuresh GunasekaraNo ratings yet

- G A E M A: Sri Lanka Sustainable Energy AuthorityDocument19 pagesG A E M A: Sri Lanka Sustainable Energy AuthoritySuresh GunasekaraNo ratings yet

- Column Layout of The DesignDocument1 pageColumn Layout of The DesignSuresh GunasekaraNo ratings yet

- Institution of Engineers Sri Lanka: Professional Review ExaminationDocument1 pageInstitution of Engineers Sri Lanka: Professional Review ExaminationSuresh GunasekaraNo ratings yet

- Content Page For The ProposalDocument1 pageContent Page For The ProposalSuresh GunasekaraNo ratings yet

- SGR 2009Document92 pagesSGR 2009Suresh GunasekaraNo ratings yet

- National Anti-Corruption Strategy Framework: Royal Government of BhutanDocument30 pagesNational Anti-Corruption Strategy Framework: Royal Government of BhutanSuresh GunasekaraNo ratings yet

- Suresh - Final Viva07122010Document31 pagesSuresh - Final Viva07122010Suresh GunasekaraNo ratings yet

- DRC Unit WiseDocument12 pagesDRC Unit WiseSasikumar Viswanathan100% (1)

- ActivityDocument5 pagesActivitysenior highNo ratings yet

- Case Study Al Ain Juice MBR ETP3Document3 pagesCase Study Al Ain Juice MBR ETP3Rohit AdhikariNo ratings yet

- Stonecutters BridgeDocument20 pagesStonecutters BridgeMarcos MorrisonNo ratings yet

- Wall SleevesDocument26 pagesWall SleevesSekhil DevNo ratings yet

- Intze Tank - Seismic Behaviour - SAP2000 PDFDocument7 pagesIntze Tank - Seismic Behaviour - SAP2000 PDFAnonymous fQLEF2tQpqNo ratings yet

- DEFLECTION Using Simplified Method of IsDocument8 pagesDEFLECTION Using Simplified Method of IsWHITE SHADOWNo ratings yet

- We've Got You Covered: Cold To Hot Industrial InsulationDocument4 pagesWe've Got You Covered: Cold To Hot Industrial InsulationniltonNo ratings yet

- Hyd N Hyd Machines-Compiled-NBSDocument55 pagesHyd N Hyd Machines-Compiled-NBSSbs Smrt LtaNo ratings yet

- Assignment & Project For Hydropwer EngineeringDocument3 pagesAssignment & Project For Hydropwer Engineeringashenafi negusNo ratings yet

- Civil Sub DataDocument2 pagesCivil Sub DataSaravana KumarNo ratings yet

- Metric - A. Volume and Height Between Tubing and Hole, and Casing and HoleDocument78 pagesMetric - A. Volume and Height Between Tubing and Hole, and Casing and HoleNorfolkingNo ratings yet

- Brick MasonryDocument27 pagesBrick MasonryKumar AbhishekNo ratings yet

- TCVN Water PipeDocument43 pagesTCVN Water PipeTuan DangNo ratings yet

- Fields of Engineering, Physics and ChemistryDocument52 pagesFields of Engineering, Physics and ChemistryEmmanuel de LeonNo ratings yet

- Harmonic Analysis and Design of Skew BridgeDocument16 pagesHarmonic Analysis and Design of Skew BridgesarikareddyNo ratings yet

- C - Ficha Tecnica - M2T MEGAFLEX SAE 100 R16Document1 pageC - Ficha Tecnica - M2T MEGAFLEX SAE 100 R16Rafael TorresNo ratings yet

- Types of ArchesDocument14 pagesTypes of ArchesPrashant PalNo ratings yet

- Internal Forced Convection: Chapter 6Document14 pagesInternal Forced Convection: Chapter 6jfl2096No ratings yet

- Sewer Appurtenance SDocument26 pagesSewer Appurtenance SParthi BanNo ratings yet

- 3LPE Low Temp Pipe CoatingDocument2 pages3LPE Low Temp Pipe CoatingChegg ChemNo ratings yet

- Ground Improvement Using Vibro Stone Columns - Capacity of Stone ColumnDocument4 pagesGround Improvement Using Vibro Stone Columns - Capacity of Stone Columndarji_jayesh19846074No ratings yet

- A Case Study On Implementation of Hydraulic Jack To Heavy Loaded VehiclesDocument8 pagesA Case Study On Implementation of Hydraulic Jack To Heavy Loaded VehiclesmamaNo ratings yet