Professional Documents

Culture Documents

Breaker Maintenance Format

Uploaded by

ThirumalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Breaker Maintenance Format

Uploaded by

ThirumalCopyright:

Available Formats

BREAKER MAINTENANCE FORMAT

1. Coil Resistance Monitoring. Trip Coil Resistance Under Voltage Coil CRC Application Resistance TC-1 TC-2 2. Insulation Resistance: Contact Resistance Measurement RR YY BB 3. Arc shutter Monitoring Operation Monitoring Close Open Close-Open 4. Contact Finger Monitoring Contact Resistance Measurement RR YY BB 5. Service of Breaker Visual Inspection insulating materials CRC Application Defectives Defectives

Terminal Phase-Phase Phase-Earth

CRC & Greece

Cleaning vacuum , cleaning solvents, use only solvents recommended by the manufacturer

Operational

Contacts

Arc Interrupters

Operating Mechanism

Auxiliary Devices

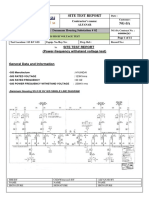

Inspect for signs of corona, tracking, arcing, or thermal or physical damage. Ensure that insulation is left clean and dry All Contacts Are Clean, Smooth, Draw-out contacts on the And In Proper Alignment. Ensure circuit breaker and the that spring pressures are maintained stationary contacts in the according to manufacturers cubicle should be cleaned and specifications. inspected for overheating, alignment, and broken or weak springs Clean all ceramic materials of loose Dielectric testing of arc shields dirt and examine for signs of may be recommended by the moisture, make sure the assemblies manufacturer. are clean and dry. Inspect for loose, broken, worn, or Repair or replace as necessary missing parts, Observe that operating mechanisms function properly without binding, hanging, or without delayed action. Ensure all indicating devices are Protective relays and circuit fully functional and properly set. breaker trip devices should be inspected and tested according to manufacturers specifications and applicable industry standards

thirumaleee@gmail.com

You might also like

- Typical Limiting Values of SubStation Equipments.Document10 pagesTypical Limiting Values of SubStation Equipments.Jeya KannanNo ratings yet

- DCRP Written Test QuestionsDocument1 pageDCRP Written Test QuestionsSiva NandhamNo ratings yet

- Substation Equipment Limiting ValuesDocument7 pagesSubstation Equipment Limiting ValuesAnil MarturiNo ratings yet

- HT Cable Termination Kit 14.3.22Document8 pagesHT Cable Termination Kit 14.3.22JIGSNo ratings yet

- A: The Circuit NamesDocument1 pageA: The Circuit Namessmi1989No ratings yet

- Malaysian Indonesian CIGRE Committee SF6 Gas PresentationDocument9 pagesMalaysian Indonesian CIGRE Committee SF6 Gas PresentationHilmy FadlyNo ratings yet

- SEC Distribution Materials TestingDocument14 pagesSEC Distribution Materials TestingMaktoob M Knif100% (1)

- CVT vs EMVT ComparisonDocument1 pageCVT vs EMVT ComparisondseshireddyNo ratings yet

- Transformer Testing and Maintenance EssentialsDocument44 pagesTransformer Testing and Maintenance Essentialsniyaz100% (3)

- Site Test Report Ng-Sa Name of SubstationDocument11 pagesSite Test Report Ng-Sa Name of Substationessam khalilNo ratings yet

- Notes On Tripping RelaysDocument7 pagesNotes On Tripping RelaysSenthil KumarNo ratings yet

- Transformer MaintenancDocument13 pagesTransformer MaintenancAnonymous m4MF1gNo ratings yet

- Gis Busbar Contact Resistance TestDocument2 pagesGis Busbar Contact Resistance Testsikander843562No ratings yet

- Test Performed By: SWCC Witness: SWCC Engineer: Date of Test Name: Jabirali. P Rashed A.Murshed 26-DEC-2020 SignatureDocument5 pagesTest Performed By: SWCC Witness: SWCC Engineer: Date of Test Name: Jabirali. P Rashed A.Murshed 26-DEC-2020 SignatureAnonymous dH3DIEtzNo ratings yet

- CT CVT LaDocument66 pagesCT CVT LaMidhun VargheseNo ratings yet

- Generator Assessment Process - Level 2Document30 pagesGenerator Assessment Process - Level 2Anil PanjaniNo ratings yet

- Hazardous Area Classification ChecklistDocument2 pagesHazardous Area Classification ChecklistRisharto YustitiardiNo ratings yet

- HT Breaker ChecklistDocument1 pageHT Breaker ChecklistElectrial DeptNo ratings yet

- Details of Accepted Test Equipments For Electrical Works From DesconDocument3 pagesDetails of Accepted Test Equipments For Electrical Works From DesconB GirishNo ratings yet

- Common SSR 2010-11 PDFDocument55 pagesCommon SSR 2010-11 PDFrizu230% (1)

- Electrical Site Tests ProceduresDocument105 pagesElectrical Site Tests ProceduresMohd SalehNo ratings yet

- Electrical Pre-Commissioning ProtocolsDocument85 pagesElectrical Pre-Commissioning ProtocolsAlok NayakNo ratings yet

- High Voltage Testing Techniques and EquipmentDocument16 pagesHigh Voltage Testing Techniques and Equipmenthadrien100% (1)

- Motor ProtectionDocument50 pagesMotor ProtectionYajidNo ratings yet

- Basics of Load CentersDocument98 pagesBasics of Load Centersvda0904No ratings yet

- Electrical Testing SkillsDocument2 pagesElectrical Testing Skills322399mk7086No ratings yet

- Overview of Lightning ArrestorDocument7 pagesOverview of Lightning ArrestorAnkur KumarNo ratings yet

- SIP5 6MD85-86 V07.50 Manual C015-9 en PDFDocument1,216 pagesSIP5 6MD85-86 V07.50 Manual C015-9 en PDFandreabautista1982No ratings yet

- Current Transformer QuestionsDocument2 pagesCurrent Transformer Questionsதுரைராஜ் இலட்சுமணன்No ratings yet

- Electricalnotes Wordpress Com 2011 11 27 What Is Earthing PDFDocument20 pagesElectricalnotes Wordpress Com 2011 11 27 What Is Earthing PDFArie Amri MartaNo ratings yet

- Power Xpert UX - Presentation PDFDocument47 pagesPower Xpert UX - Presentation PDFpayolin77No ratings yet

- Switchyard Protection EssentialsDocument60 pagesSwitchyard Protection Essentialsbijoy100% (1)

- PGCIL GIS Test Reqmts.Document56 pagesPGCIL GIS Test Reqmts.JaiNo ratings yet

- Final ProjectDocument57 pagesFinal ProjectKumar JiNo ratings yet

- Pantograph Isolator Hot Spot EliminationDocument40 pagesPantograph Isolator Hot Spot Eliminationjilu_siluNo ratings yet

- National Grid: Checklist For Commissioning of Oil-Immersed Power TransformerDocument8 pagesNational Grid: Checklist For Commissioning of Oil-Immersed Power TransformerSanthosh Kumar VinayagamNo ratings yet

- Lightning Arrestor: To:-Deepa S NDocument11 pagesLightning Arrestor: To:-Deepa S NMadhu SagarNo ratings yet

- Session 2 Protection TrendsDocument43 pagesSession 2 Protection Trendslikamika123No ratings yet

- MS For PD Sensor Installation For 220KV - MibDocument7 pagesMS For PD Sensor Installation For 220KV - MibSumit SawaiNo ratings yet

- Gen Circuit Breaker Testing SchedulesDocument3 pagesGen Circuit Breaker Testing ScheduleslrpatraNo ratings yet

- TRFR Test FormatDocument8 pagesTRFR Test FormatdilipelineNo ratings yet

- Questions From Relay and Protection SchemeDocument2 pagesQuestions From Relay and Protection SchemeChandan ChetriNo ratings yet

- Condition Monitoring of Instrument Transformers - POWERGRID ExperienceDocument36 pagesCondition Monitoring of Instrument Transformers - POWERGRID ExperiencebcqbaoNo ratings yet

- Communication Scheme PUTTDocument8 pagesCommunication Scheme PUTTCesar Gabriel Berdejo RiveraNo ratings yet

- ASR StarterDocument2 pagesASR Starterrajan_2002eee100% (3)

- Directional Overcurrent RelayingDocument23 pagesDirectional Overcurrent RelayingTamjid KabirNo ratings yet

- PresentationDocument16 pagesPresentationதுரைராஜ் இலட்சுமணன்No ratings yet

- Transformer BushingDocument11 pagesTransformer BushingNunna BaskarNo ratings yet

- اسئلة مقابلات مهندس وفني كهرباءDocument28 pagesاسئلة مقابلات مهندس وفني كهرباءazoozNo ratings yet

- 415v Air Circuit Breaker-14Document2 pages415v Air Circuit Breaker-14Subhransu MohapatraNo ratings yet

- Pre-Commissioning Tests AC Equipment ListDocument5 pagesPre-Commissioning Tests AC Equipment ListnagarajanNo ratings yet

- Technical Specification FOR 220Kv Isolators: Gujarat State Electricity Corporation LTDDocument22 pagesTechnical Specification FOR 220Kv Isolators: Gujarat State Electricity Corporation LTDVelu SamyNo ratings yet

- Areva RelaysDocument28 pagesAreva RelaysMourad BenderradjiNo ratings yet

- Project Title: Operating Area: Main Contractor: T&C Contractor: Contract No.: SubstationDocument1 pageProject Title: Operating Area: Main Contractor: T&C Contractor: Contract No.: SubstationRam KumarNo ratings yet

- HVPE Operation and MaintenanceDocument116 pagesHVPE Operation and MaintenanceMinerva AbantoNo ratings yet

- Monthly Substation InspectionsDocument174 pagesMonthly Substation InspectionsashwaniNo ratings yet

- Pre Commissioning Check List of GeneratorDocument26 pagesPre Commissioning Check List of GeneratorSUROHMAN ROHMANNo ratings yet

- SLPG Gtg-2yDocument5 pagesSLPG Gtg-2yAshraf MohammedNo ratings yet

- Lighting CalculationDocument13 pagesLighting Calculationram27_rajiNo ratings yet

- 150 AutoCAD Command and Shortcut ListDocument49 pages150 AutoCAD Command and Shortcut ListAnudeep Gubba100% (1)

- DC Battery Bank Sizing PDFDocument37 pagesDC Battery Bank Sizing PDFflyzalNo ratings yet

- Battery Sizing CalculationDocument7 pagesBattery Sizing CalculationThirumalNo ratings yet

- A. B. C. D.: Answer: ExplanationDocument2 pagesA. B. C. D.: Answer: ExplanationThirumalNo ratings yet

- Battery Sizing CalculationDocument7 pagesBattery Sizing CalculationThirumalNo ratings yet

- Book Kolkata to Nagpur FlightDocument2 pagesBook Kolkata to Nagpur FlightROCKY SINGH0% (1)

- Radial Feeder Protection ExperimentDocument10 pagesRadial Feeder Protection ExperimentThirumal100% (1)

- Battery Sizing CalculationDocument7 pagesBattery Sizing CalculationThirumalNo ratings yet

- Setting of Distance RelaysDocument4 pagesSetting of Distance RelaysMohamed WahidNo ratings yet

- Guidelines Relay SettingDocument468 pagesGuidelines Relay Setting1453h100% (5)

- Substation Design ManualDocument20 pagesSubstation Design ManualThirumal100% (1)

- Guide For Direct Lightning Stroke Shielding of SubstationsDocument1 pageGuide For Direct Lightning Stroke Shielding of SubstationsThirumalNo ratings yet

- Lighting Design ConsiderationsDocument42 pagesLighting Design Considerationsshivam007No ratings yet

- Cooper Ls Brochure Lighting Design GuideDocument32 pagesCooper Ls Brochure Lighting Design GuideMeenal SwarnakarNo ratings yet

- Transformer Protection and Transformer FaultDocument3 pagesTransformer Protection and Transformer FaultThirumalNo ratings yet

- Cooper Ls Brochure Lighting Design GuideDocument5 pagesCooper Ls Brochure Lighting Design GuideThirumalNo ratings yet

- Distance Relay Protection ExplainedDocument2 pagesDistance Relay Protection ExplainedThirumalNo ratings yet

- Course 1 Distribution SystemDocument5 pagesCourse 1 Distribution SystemThirumalNo ratings yet

- Principle of Weak InFeed Echo Permissive Over Reach Transfer Trip SchemesDocument6 pagesPrinciple of Weak InFeed Echo Permissive Over Reach Transfer Trip SchemesThirumalNo ratings yet

- CT ParameterDocument2 pagesCT ParameterThirumalNo ratings yet

- Busbar Size and Calculation-2Document4 pagesBusbar Size and Calculation-2ThirumalNo ratings yet

- REF ProtectionDocument4 pagesREF ProtectionThirumalNo ratings yet

- Micro Station V 8 I Quick Start GuideDocument57 pagesMicro Station V 8 I Quick Start GuideThirumalNo ratings yet

- Calculate Size of Contactor CB FUSE OLRDocument3 pagesCalculate Size of Contactor CB FUSE OLRThirumalNo ratings yet

- Transformer Ref Protectoin Scheme and CalculationDocument1 pageTransformer Ref Protectoin Scheme and CalculationThirumalNo ratings yet

- CB Sizing CalculationDocument2 pagesCB Sizing CalculationThirumalNo ratings yet

- Busbar Size and Calculation-1Document5 pagesBusbar Size and Calculation-1ThirumalNo ratings yet

- Akiqja: - QR C. DR QJBR B. Abckq) R XR Ms. S. Afr Bjaukiq. at CQMTBJBZ Tkbir P G Abop WDocument1 pageAkiqja: - QR C. DR QJBR B. Abckq) R XR Ms. S. Afr Bjaukiq. at CQMTBJBZ Tkbir P G Abop WThirumalNo ratings yet