Professional Documents

Culture Documents

Welding Imperfections

Uploaded by

susanwebCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding Imperfections

Uploaded by

susanwebCopyright:

Available Formats

THE WELDING INSTITUTE

Welding Imperfections:

What are welding imperfections?

Welding imperfections are material discontinuities caused by, or during, the process of welding. All things contain imperfections, but it is only when they fall outside of a level of acceptance that they should be termed defects, as they may render the product defective, or unfit for its purpose. As welds can be considered as castings they may contain all kinds of imperfections associated with the casting of metals, plus any other particular imperfections associated with the specific welding process being used. Welding imperfections can be classified as follows: 1) ) %) )) Cracks !olid incl"sions !"rface and profile 'isalignment 2) #) &) Gas pores and cavities $ack of f"sion 'echanical(!"rface damage

1)

Cracks:

Cracks sometimes occur in welded materials, and may be caused by a great number of factors. Generally, we can say that for any crack like imperfection to occur in a material, there are 3 criteria that must be present: a * force +) ,estraint c) * weakened str"ct"re

!ypical types of hot and cold cracks that will be discussed later in the course are: 1) -2 Cracks 2) !olidification Cracks ) $amellar .ears

A "aterial#s likelihood to crack during welding can be e$aluated under the term Welda+ilit/0 !his may be defined as: .he ease with which materials ma/ +e welded +/ the common welding processes All cracks ha$e sharp edges, which produce high stress concentrations. !his generally results in rapid progression, howe$er this also depends on the properties of the metal. Cracks are classed as planar imperfections as they generally ha$e only % $isible, or measurable dimensions i.e. length and depth. "ost fall into the defects category, though some standards will allow a degree of so called crater, or star cracking.

Welding &nspection of 'teels WI! % !ection 1 Welding Imperfections (e$ 1231231 Copyright %))3, !W& *td

3. +

world centre for materials joining technology

THE WELDING INSTITUTE

2)

Gas pores4 porosit/ and cavities:

Gas pores: !hese are defined as singular gas filled ca$ities 5 10&mm diameter, which are created during final solidification by e,pulsion of gases from solution in solidifying weld metal. 6orosit/: -orosity is a term used to describe a collection, or area of gas pores. !hese areas may be classified by their number, si.e and grouping of the pores within the area. /i.e. 0ine, or coarse cluster porosity -orosity is mainly produced when welding improperly cleaned plate, or when using damp welding consumables. Gases may also be formed by the breakdown of paints, oil based products, corrosion or anti corrosion products that ha$e been left on the plates to be welded. A singular gas filled ca$ity 1 or 2 +.3mm diameter is termed a +low hole -orosity can be fre4uently formed during the 'IG or .IG process by the temporary loss of gas shield, and ingress of air into the arc column. !his may be caused by mo$ement of the surrounding atmosphere, or wind. -orosity may also be caused by improper settings of shielding gas flow rate. Gas pores may also be break the welds surface where they are collecti$ely known as surface porosities. -orosity may also found in deep !"+ *rc welds due to the distance that trapped gases formed in the root area need to tra$el to escape from the surface, and may also occur when using damp ''* welding electrodes, or damp !"+ *rc 0lu,es. -orosity may be pre$ented by correct cleaning of materials, correct setting and shielding when using the !&G or "&G welding processes, and using dry welding consumables. -orosity may generally be identified on a radiograph as a spherical imperfection that has $arying density shades, from highest in the centre, decreasing to its outer edges i.e.

!hrinkage cavit/ 7ine cl"ster porosit/

!"rface +reaking cl"ster porosit/ Coarse cl"ster porosit/ 8low hole 9 10& mm :

-ollow root +ead !hrinkage cavities: !hese are internal $oids, or ca$ities that are formed during the solidification of single welds of high depth to width ratio /d:w as with 'AW or "&G. !hey may be defined as a hot plastic tears caused by opposing contractional strains. 'hrinkage ca$ities produce high stress concentrations at their sharp edges, and are thus generally treated as cracks.

Welding &nspection of 'teels WI! % !ection 1 Welding Imperfections (e$ 1231231 Copyright %))3, !W& *td

3. %

world centre for materials joining technology

THE WELDING INSTITUTE

!olid incl"sions:

'olid inclusions include metallic and non3metallic inclusions that may be trapped in the weld during the process of welding. !he type of solid inclusion that may be e,pected is really dependant on the welding process being used. &n welding processes that use flu,es to form all the re4uired functions of shielding and chemical cleaning, such as ""A and 'ubmerged Arc welding, slag inclusions may occur. 5ther welding processes such as "&G and !&G use silicon, aluminium and other elements to de6o,idise the weld. !hese may form silica, or alumina inclusions. Any of these non6metallic compounds may be trapped inside a weld during welding. !his often happens after slag traps, such as undercut ha$e been formed. 'lag traps are mostly caused by incorrect welding techni4ue. "etallic inclusions include tungsten inclusions that may be produced during !&G welding by a poor welding techni4ue, an incorrect tungsten $erte, angle, or too high amperage for the diameter of tungsten being used. Copper inclusions may be caused during "&G7"AG welding by a lack of welding skill, or incorrect settings in mechanised, or automated "&G welding. /"ainly welding Aluminium alloys 5ther welding phenomena such 8arc blow9 or the de$iation of the electric arc by magnetic forces, can cause solid inclusions to be trapped in welds. !he locations of these inclusions may be within the centre of a deposited weld, or between welds where the result causes 8*ack of inter6run fusion9, or at the sidewall of the weld preparation causing 8*ack of side wall fusion9 Generally solid internal inclusions may be caused by: 1) 2) ) #) %) &) $ack of welder skill0 ;Incorrect welding techni<"e) 6oor manip"lation of the welding process4 or electrode0 Incorrect parameter settings4 i0e0 voltage4 amperage4 speed of travel0 'agnetic arc +low0 Incorrect positional "se of the process4 or cons"ma+le0 Incorrect inter3r"n cleaning0

!"rface +reaking solid incl"sion Internal solid incl"sion ca"sing a lack of inter3r"n Internal solid incl"sion ca"sing a f"sion lack of sidewall f"sion

Internal solid incl"sion !olid incl"sions from +ase metal "nderc"t in the root r"n4 or hot pass ;!lag traps)

#)

$ack of f"sion:

3. 3

world centre for materials joining technology

Welding &nspection of 'teels WI! % !ection 1 Welding Imperfections (e$ 1231231 Copyright %))3, !W& *td

THE WELDING INSTITUTE

*ack of fusion imperfections, are defined as a lack of union between two adjacent areas of material. !his may be accompanied, or caused by other imperfections as e,plained in the last section. *ack of fusion can be considered a serious imperfection, as like cracks, they produce areas of high stress concentration. *ack of fusion, or o$erlap /a form of lack of fusion may occur in the weld face area during positional welding caused by the action of gra$ity and incorrect use of the process. *rc +low is a prime cause of lack of fusion imperfections, particularly when using high current processes, such as 'ub Arc using high direct electric currents. /:C; or :C 6 *ack of fusion may also be formed in the root area of the weld where it may be found on one, or both plate edges. &t may also be accompanied by incomplete root penetration. *ack of fusion is also a common imperfection in 8:ip transfer "&G welding9 of metals o$er 3mm thickness, especially when welding $ertically down. !his is caused by the inherent coldness of this form of metal transfer, and the action of gra$ity. $ike solid incl"sions4 lack of f"sion imperfections ma/ +e ca"sed +/: 1) 2) ) #) %) 3 )) $ack of welder skill0 ;Incorrect welding techni<"e) 6oor manip"lation of the welding process4 or electrode0 Incorrect parameter settings4 i0e0 voltage4 amperage4 speed of travel0 'agnetic arc +low0 Incorrect positional "se of the process4 or cons"ma+le0 Incorrect inter3r"n cleaning0 Incorrect or non3feathered tack welds0 ;$ightl/ gro"nd prior to welding)

$ack of sidewall f"sion ;*lso ca"sing an Incompletel/ filled groove) =verlap ;Ca"sing a Cold laps)

$ack of inter3r"n f"sion $ack of sidewall f"sion $ack of root f"sion

Welding &nspection of 'teels WI! % !ection 1 Welding Imperfections (e$ 1231231 Copyright %))3, !W& *td

3. <

world centre for materials joining technology

THE WELDING INSTITUTE

%)

!"rface and profile:

'urface and profile imperfections are generally caused by poor welding techni4ues. !his includes the use of incorrect welding parameters, electrode7blowpipe si.es and7or manipulation and joint set up. !his category may be split into two further groups of weld face and weld root. 'urface and profile imperfections are shown pictorially in * = 8 below:

*:

!patter is not a major factor in lowering the weldments strength, though it may mask other imperfections, and should therefore be cleaned off before inspection. 'patter may also hinder >:! and be detrimental to coatings. &t can also cause micro cracking or hard spots in some materials due to the localised heating74uenching effect. *n incompletel/ filled groove may bring the weld below its :!!. &t is a major stress concentration when accompanied by lack of sidewall fusion. $ack of root f"sion causes a serious stress concentration to occur in the root. &t may also render the root area more susceptible to corrosion in ser$ice

!patter *n Incompletel/ filled groove

$ack of root f"sion

Welding &nspection of 'teels WI! % !ection 1 Welding Imperfections (e$ 1231231 Copyright %))3, !W& *td

3. ?

world centre for materials joining technology

THE WELDING INSTITUTE

8:

* +"l+o"s conto"r is an imperfection as it causes sharp stress concentrations at the toes of indi$idual passes and may also contribute to o$erall poor toe blend *rc strikes, 'tray6arcing, or 'tray flash may cause many problems including se$eral types of cracks to occur. !hey can also cause depressions in the plate bringing it below its :!!. Arc strikes would normally be >:! inspected and then repaired. Incomplete root penetration may be caused by too small a root gap, insufficient amperage, or poor welding techni4ue. &t also causes high stress concentrations to occur. &t also generally produces a weld with less throat thickness than the :!! of the joint.

8"l+o"s conto"r *rc !trikes 6oor toe +lend

Incomplete root penetration +ead

C:

Welding &nspection of 'teels WI! % !ection 1 Welding Imperfections (e$ 1231231 Copyright %))3, !W& *td

3. 3

world centre for materials joining technology

THE WELDING INSTITUTE

*n irreg"lar +ead width is a surface imperfection, which is often referenced in application standards as. The weld bead should be regular along its linear length

>nderc"t: @ndercut can be defined as a depression at the toe of a weld in a pre$ious deposited weld, or base metal, caused by welding. @ndercut is generally caused by incorrect welding techni4ue, including the use of too high a current for the electrode being used, and the welding position. &t is often caused in the top toe of fillet welds when attempting to produce a large leg length fillet weld in one run. @ndercut can also be considered a serious imperfection particularly if it is sharp, as again it causes high stress concentrations. &t is gauged in se$erity by its length4 depth and sharpness. 6arent metal4 s"rface "nderc"t

6arent metal4 top toe "nderc"t

Weld metal4 s"rface "nderc"t

Welding &nspection of 'teels WI! % !ection 1 Welding Imperfections (e$ 1231231 Copyright %))3, !W& *td

3. A

world centre for materials joining technology

THE WELDING INSTITUTE

,oot ,"n or -ot 6ass "nderc"t

!hrinkage grooves: 'hrinkage groo$es may occur in the root area and are caused by contractional forces pulling on the hot plastic base metal in the root area. &t is often mistakenly termed as root !hrinkage grooves undercut.

,oot concavit/: /!"ck +ack

Welding &nspection of 'teels WI! % !ection 1 Welding Imperfections (e$ 1231231 Copyright %))3, !W& *td

3. B

world centre for materials joining technology

THE WELDING INSTITUTE

!his may be caused when using too high a gas backing pressure in purging. &t may also be produced when welding with too large a root gap and depositing too thin a root bead, when the hot pass may pull back the root bead through contractional strains.

,oot concavit/

?@cess penetration: 5ften caused by using too high a welding current, and7or, slow tra$el speed, coupled with a large root gap, and7or a small root face for the current or process being used. &t is often accompanied by burn through, which can be defined as a local collapse of the weld puddle causing a hole, or depression in the final weld root bead. ,oot o@idation: (oot o,idation may take place when welding re6acti$e metals such as stainless steels with contaminated or inade4uate purging gas flow. Incompletel/ f"sed Tack Welds: &t is often a procedural re4uirement for tack welds to be feathered /*ightly ground and blended prior to welding. !his re4uirement is mainly dependent upon the class of work. 0eathering should enable the tack welds to be more easily fused and thus more smoothly blended into the root7penetration bead during welding. 0ailure to achie$e this correctly may result in a degree of lack of root f"sion(penetration occurring in the weld root run. *n "n3feathered root tack weld *dAacent "n3smooth area showing a lack of root f"sion and(or root penetration Crater pipes:

Welding &nspection of 'teels WI! % !ection 1 Welding Imperfections (e$ 1231231 Copyright %))3, !W& *td

3. C

world centre for materials joining technology

THE WELDING INSTITUTE

!his often occurs during !&G welding in the crater at the end of a weld run during final solidification. &t is caused by insufficient filler material to meet the solidification process and can be eliminated by applying ade4uate filler metal, or using a slope o"t control.

Crater pipe

,oot o@idation in !tainless !teel

?@cess root penetration +ead

.his ma/ lead to a burn through A local collapse of the weld pool leaving a hole in the root area.

!o summari.e, we can list surface or profile welding imperfections as follows: 1) Incompletel/ filled grove(lack of f"sion0

Welding &nspection of 'teels WI! % !ection 1 Welding Imperfections (e$ 1231231 Copyright %))3, !W& *td

3. +)

world centre for materials joining technology

THE WELDING INSTITUTE

2) !patter0 ) *rc strikes0 ;!tra/ arcs) #) Incomplete root penetration0 %) $ack of root f"sion0 &) 8"l+o"s or irreg"lar conto"r0 )) 6oor toe +lend0 B) Irreg"lar +ead width0 2) >nderc"t0 ;Weld and 8ase metal) 11) ++ 12) ,oot concavit/0 ,oot shrinkage grooves0 ?@cess penetration0 8"rn thro"gh0 ,oot o@idation0

&)

'echanical(!"rface damage:

'echanical(!"rface damage: !his can be defined as any surface material damage caused during the manufacturing process, or in6ser$ice conditions. !his can include damage caused by: 1) ) %) )) Grinding0 -ammering0 Chiselling0 Corrosion0 2) #) &) Chipping0 8raking off welded attachments +/ hammering0 >sing needle g"ns to compress weld capping r"ns0

As with the stray arcing, the abo$e imperfections can be detrimental as they reduce the through thickness dimension of the plate in that area. !hey can cause local stress concentrations and should be repaired prior to completing the job.

Chisel 'arks

6itting Corrosion

Grinding 'arks

))

'isalignment:

!here are % main forms of misalignment in plate materials, which are termed:

Welding &nspection of 'teels WI! % !ection 1 Welding Imperfections (e$ 1231231 Copyright %))3, !W& *td

3. ++

world centre for materials joining technology

THE WELDING INSTITUTE

1)

$inear misalignment0

2)

*ng"lar misalignment0

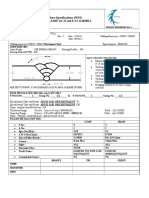

$inear misalignment: can be controlled during weld set up by the correct use7control of the weld set up techni4ue i.e. tacking, bridging, clamping etc. ?@cess weld metal height and the root penetration +ead are alwa/s meas"red from the lowest plate to the highest point of the weld metal4 as shown +elow0 ?@cess weld metal height

3 mm $inear misalignment meas"red in mm *ng"lar misalignment: may be controlled by the correct application of distortion control techni4ues, i.e. balanced welding, offsetting, or use of jigs, clamps, etc.

+? *ng"lar misalignment meas"red in degrees -i3$o is a term that is generally used to describe the une$enness across the root faces between pipes found during setting up for welding. !his une$enness is often caused by an un6matching and7or irregular wall thickness, or between pipes ha$ing any degree of o$ality. &t is not a term that should be used when describing misalignment in plates.

-i3$o

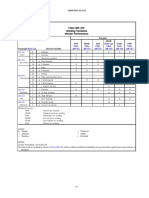

!"mmar/ of Welding Imperfections:

Gro"p

1) Cracks

Welding &nspection of 'teels WI! % !ection 1 Welding Imperfections (e$ 1231231 Copyright %))3, !W& *td

./pe

Centreline 3. +%

Ca"ses($ocation

Weld "etal

world centre for materials joining technology

THE WELDING INSTITUTE

2) 6orosit/(Cavities

) !olid Incl"sions

#) $ack of 7"sion

%) !"rface C 6rofile

&) 'echanical damage )) 'isalignment

D% *amellar !ears -orosity Gas pore G +.3mm Flow hole 2 +.3mm 'hrinkage ca$ity 'lag ""A7'AW 'ilica !&G7"AG/0e steels !ungsten !&G Copper /"&G7"AG *ack of side wall fusion ;Can +e s"rface +reaking) *ack of root fusion Cold lapping -oor toe blend Arc 'trikes &ncomplete penetration &ncompletely filled groo$e 'patter Fulbous contour @ndercut: 'urface and internal 'hrinkage groo$e /(oot (oot conca$ity H,cess -enetration Furn through Crater -ipes /"ainly !&G Dammer7Grinding marks etc. Angular "isalignment / *inear "isalignment /mm Di6*o /mm) =nl/ in pipe

Weld "etal = DAE Fase metal :amp electrodes @n6cleaned plates7pipes *oss of gas shield Weld metal /high d:w -oor &nter6run cleaning 'lag traps. Arc blow :ipping tungsten in pool :ipping contact tip in pool Arc Flow &ncorrect welding techni4ue >on feathering of tack welds -ositional welding techni4ue &ncorrect welding techni4ue -oor welding techni4ue G (oot gap7Amps. 2 (oot face &ncorrect welding techni4ue :amp consumables &ncorrect welding techni4ue !oo high an amperage -oor welding techni4ue Contractional strains !oo high gas pressure 2 (oot gap7Amps G (oot face &ncorrect current decay -oor workmanship -oor fit6up. :istortion -oor fit6up. &rregular pipe wall, or o$ality

Dotes: .he ca"ses given in the a+ove ta+le sho"ld not +e considered as the onl/ possi+le ca"ses of the imperfection given4 +"t as an e@ample of a pro+a+le ca"se0 Good working practices and correct welder training will minimise the occ"rrence of "naccepta+le welding imperfections4 or welding defects.

Identif/ and name the following Welding Imperfections:

;*s indicated within the ovals)

Welding &nspection of 'teels WI! % !ection 1 Welding Imperfections (e$ 1231231 Copyright %))3, !W& *td

2 3. +3

world centre for materials joining technology

THE WELDING INSTITUTE

# * *

& *

* 8

* 8

)

Welding &nspection of 'teels WI! % !ection 1 Welding Imperfections (e$ 1231231 Copyright %))3, !W& *td

B 3. +<

*

world centre for materials joining technology

THE WELDING INSTITUTE

2 *

11

11 * 8

12 * 8

* 8

* 8

1

Welding &nspection of 'teels WI! % !ection 1 Welding Imperfections (e$ 1231231 Copyright %))3, !W& *td

1# 3. +?

world centre for materials joining technology

THE WELDING INSTITUTE

* *

1% *

1&

1) 8

1B

* 8

* 8

!ol"tions:

6age :1#

Welding &nspection of 'teels WI! % !ection 1 Welding Imperfections (e$ 1231231 Copyright %))3, !W& *td

3. +3

world centre for materials joining technology

THE WELDING INSTITUTE

10 20 0 #0 %a0 &a0

Weld metal "nderc"t $ack of root f"sion ,oot concavit/ Incomplete root penetration $ack of sidewall f"sion !lag incl"sion %+ &a Cold lap ;8"l+o"s conto"r) 8ase metal "nderc"t

6age :1%

)0 B0 20 110 6itting Corrosion $ack of sidewall f"sion with an incompletel/ filled groove !patter 8"l+o"s conto"r with a 6oor toe +lend 11+0 12+0 $ack of root f"sion Weld metal "nderc"t

11a0 *rc strikes 12a0 8ase metal "nderc"t

6age :1&

1 0 1#0 1%0 1&0 Chisel marks Incompletel/ filled groove with a +"l+o"s conto"r !hrinkage grooves 8"rn thro"gh 1)+0 1B+0 >nderc"t ;In the top toe) 8"rn thro"gh

1)a0 !patter 1Ba0 ?@cess root penetration +ead

Welding &nspection of 'teels WI! % !ection 1 Welding Imperfections (e$ 1231231 Copyright %))3, !W& *td

3. +A

world centre for materials joining technology

You might also like

- Weld GaugesDocument15 pagesWeld GaugesHaleemUrRashidBangashNo ratings yet

- PronunciationDocument166 pagesPronunciationSteven Donahue94% (52)

- Welding DefectsDocument94 pagesWelding DefectsesamhamadNo ratings yet

- CSWIP Welding Inspection Notes and QuestionsDocument133 pagesCSWIP Welding Inspection Notes and Questionslram70100% (20)

- Gray Shades PDFDocument1 pageGray Shades PDFbgonzalez1981No ratings yet

- Prof. Ir. Jamasri, PH.D., IPU., AER. Department of Mechanical & Industrial Engineering Engineering Faculty UGMDocument43 pagesProf. Ir. Jamasri, PH.D., IPU., AER. Department of Mechanical & Industrial Engineering Engineering Faculty UGMKeristiyantoNo ratings yet

- Bolt Torque ASME B16.5 Flanges - Spiral Wound GasketsDocument31 pagesBolt Torque ASME B16.5 Flanges - Spiral Wound Gasketsbakelly100% (5)

- O-RING Cross Section in MMDocument10 pagesO-RING Cross Section in MMSuresh Kumar MittapalliNo ratings yet

- Welding Gauge: Crown Height Fillet Weld Leg HeightDocument1 pageWelding Gauge: Crown Height Fillet Weld Leg Heightabhics67No ratings yet

- Geometric shape welding imperfections causes and typesDocument12 pagesGeometric shape welding imperfections causes and typesbipete69No ratings yet

- 1 WELDING INSPECTION - STEELSDocument115 pages1 WELDING INSPECTION - STEELSrahim_335162856100% (3)

- Welding Gauges PDFDocument4 pagesWelding Gauges PDFsopan kharcheNo ratings yet

- Welddefects As Per Iso 5817Document40 pagesWelddefects As Per Iso 5817shruthiNo ratings yet

- Weld DefectsDocument47 pagesWeld DefectsPratikNo ratings yet

- Everything You Need to Know About WeldingDocument49 pagesEverything You Need to Know About WeldingproxywarNo ratings yet

- Submerged Arc Welding of Mild Steel Pipes - Amrish PatelDocument17 pagesSubmerged Arc Welding of Mild Steel Pipes - Amrish PateltangouzeNo ratings yet

- Grade 11 Plan I. Objectives: Different Types of WeldingDocument3 pagesGrade 11 Plan I. Objectives: Different Types of WeldingCrisTopher L CablaidaNo ratings yet

- ISO 5817 WELD INSPECTIONDocument59 pagesISO 5817 WELD INSPECTIONaravindan100% (1)

- Qap Wo 7 r0 (Ion Exchange)Document1 pageQap Wo 7 r0 (Ion Exchange)KailasNo ratings yet

- Draft Wps Astm A 743 GR - Ca6nmDocument2 pagesDraft Wps Astm A 743 GR - Ca6nmIlham PaneNo ratings yet

- Intoduction To WeldingDocument334 pagesIntoduction To WeldingAsad Bin Ala QatariNo ratings yet

- Weld Defects TWIDocument96 pagesWeld Defects TWISabir Shabbir100% (7)

- Cordon Off - 4 (00000003)Document1 pageCordon Off - 4 (00000003)Anonymous PlyxbQ3tNo ratings yet

- EIS-ESL-Engine ECU - ISM-VGS Connection PinoutDocument19 pagesEIS-ESL-Engine ECU - ISM-VGS Connection Pinoutalaa100% (5)

- LamelerDocument5 pagesLamelerPrasetyaOne NugraHantoeNo ratings yet

- Overview of NDT Methods & ApplicationsDocument7 pagesOverview of NDT Methods & Applicationsgeorgescribd1103No ratings yet

- Chap 4 PDFDocument35 pagesChap 4 PDFKamarul Nizam100% (1)

- Position of Welds ComparisonDocument3 pagesPosition of Welds ComparisonYuvaraj SathishNo ratings yet

- Welding & Cutting ProcessDocument16 pagesWelding & Cutting ProcesscvNo ratings yet

- Significance of Defects in WeldsDocument9 pagesSignificance of Defects in Weldsssk48100% (1)

- Geometric shape imperfections types and causes reviewDocument18 pagesGeometric shape imperfections types and causes reviewamit4709No ratings yet

- Primavera P6 ManualDocument230 pagesPrimavera P6 ManualDionne Solito MonteloyolaNo ratings yet

- Tesab 1012t Parts Manual 2003 PDFDocument81 pagesTesab 1012t Parts Manual 2003 PDFMiroslav MomchilovNo ratings yet

- Comparison ASTM A 3388 & ISO 11496Document1 pageComparison ASTM A 3388 & ISO 11496Rahul MoottolikandyNo ratings yet

- Blank Sample WPS Form (GMAW & FCAW) Welding Procedure Specification (WPS)Document1 pageBlank Sample WPS Form (GMAW & FCAW) Welding Procedure Specification (WPS)GMNo ratings yet

- WeldingDocument193 pagesWeldingavutu_kunduruNo ratings yet

- Defect IIWDocument3 pagesDefect IIWPPMNo ratings yet

- How To Read Welding Gauges PDFDocument5 pagesHow To Read Welding Gauges PDFjimbox88No ratings yet

- Welding Notes 1Document4 pagesWelding Notes 1api-440145703No ratings yet

- BS 4190 PDFDocument30 pagesBS 4190 PDFquang thanhNo ratings yet

- Welding NotesDocument39 pagesWelding NotesSabir JadejaNo ratings yet

- Primavera TipsDocument5 pagesPrimavera TipsShital PatilNo ratings yet

- Welding Defect: Hydrogen EmbrittlementDocument8 pagesWelding Defect: Hydrogen EmbrittlementShajin Mohammed ShamsudhinNo ratings yet

- Casting DefectDocument8 pagesCasting DefectlabregopalNo ratings yet

- 1.2 Resistance and Special WeldingDocument14 pages1.2 Resistance and Special WeldingnikhilbathamNo ratings yet

- A General Review of The Causes and Acceptance of Shape ImperfectionsDocument7 pagesA General Review of The Causes and Acceptance of Shape ImperfectionsMuhammed SulfeekNo ratings yet

- Welding Defects Causes & SolutionsDocument30 pagesWelding Defects Causes & SolutionsAkshay Kumar100% (1)

- Spec Sheet - Handler 187Document4 pagesSpec Sheet - Handler 187Hobart Welding ProductsNo ratings yet

- Identify Welding Defects & DiscontinuitiesDocument21 pagesIdentify Welding Defects & DiscontinuitiesJoanna AprilNo ratings yet

- Wis5 TermsDocument29 pagesWis5 Termsravi00098No ratings yet

- Welding Standard Ver1Document4 pagesWelding Standard Ver1Sowmen ChakrobortyNo ratings yet

- Visual Examination Procedure: 1 - PurposeDocument4 pagesVisual Examination Procedure: 1 - PurposeElvin MenlibaiNo ratings yet

- 03 Welding Imperfections 30-03-07 (2Document20 pages03 Welding Imperfections 30-03-07 (2geokovoorNo ratings yet

- Welding Processes ExplainedDocument20 pagesWelding Processes ExplainedNawaz RafiqueNo ratings yet

- IS Standard Changes for Steel Grades and Chemical CompositionDocument2 pagesIS Standard Changes for Steel Grades and Chemical CompositionTuhin Subhra Mondal100% (4)

- 008a.rtfi - AbbrevationsDocument2 pages008a.rtfi - AbbrevationsVivekanandan JNo ratings yet

- Visual TestingDocument1 pageVisual TestingAnonymous GE8mQqxNo ratings yet

- Casting Material CA15BASD PDFDocument4 pagesCasting Material CA15BASD PDFAditya GuptaNo ratings yet

- General Level-II QuestionsDocument4 pagesGeneral Level-II QuestionsGomathi SankarNo ratings yet

- Ultrasonic NotesDocument5 pagesUltrasonic NotesannapoornaavulaNo ratings yet

- Ultrasonic Testing of Ferritic Steel Welds Under 40 CharactersDocument1 pageUltrasonic Testing of Ferritic Steel Welds Under 40 Characterssdmkl85No ratings yet

- Dye Penetrant Inspection - Wikipedia, The Free EncyclopediaDocument5 pagesDye Penetrant Inspection - Wikipedia, The Free Encyclopediaviswamanoj100% (1)

- Cast Steel GradesDocument5 pagesCast Steel Gradessohan_miyawala1906No ratings yet

- Surface Preparation & Painting ProcedureDocument9 pagesSurface Preparation & Painting ProcedureRam ThevarNo ratings yet

- Basic Weld MetallurgyDocument34 pagesBasic Weld Metallurgydaha333No ratings yet

- Positive Material IdentificationDocument2 pagesPositive Material IdentificationGovindKrishnanNo ratings yet

- GTAW Welding of CP Titanium and Ti6Al4VDocument1 pageGTAW Welding of CP Titanium and Ti6Al4VDeepak KumarNo ratings yet

- Astm A239Document4 pagesAstm A239Ngô Trung NghĩaNo ratings yet

- RESPONSIBILITY: G - Galvanized D - Designer B - Builder/Fabricator S - Steel Type/SurfaceDocument11 pagesRESPONSIBILITY: G - Galvanized D - Designer B - Builder/Fabricator S - Steel Type/SurfaceLaxit100% (1)

- DR 10.01 Instructions For Non-Destructive Testing of Welds REV 05 2011-07Document13 pagesDR 10.01 Instructions For Non-Destructive Testing of Welds REV 05 2011-07SasaNo ratings yet

- QAP Seamless PipeDocument2 pagesQAP Seamless Pipechetan85No ratings yet

- Difference between SS316 and SS316L Stainless Steel GradesDocument1 pageDifference between SS316 and SS316L Stainless Steel GradesSableen SinghNo ratings yet

- P Q R - 005Document2 pagesP Q R - 005Courtney DukeNo ratings yet

- Blasting &painting Pocedures MTD SOP 15 01Document1 pageBlasting &painting Pocedures MTD SOP 15 01vinothNo ratings yet

- Armstech Training Division Brochure NewDocument12 pagesArmstech Training Division Brochure NewAnoop ChandranNo ratings yet

- Home Education Resources NDT Course Material Ultrasound: Calibration MethodsDocument7 pagesHome Education Resources NDT Course Material Ultrasound: Calibration MethodspanduranganraghuramaNo ratings yet

- Advanced Project Management WorkbookDocument75 pagesAdvanced Project Management Workbooksharan67890% (1)

- CDC UP Project Charter TemplateDocument15 pagesCDC UP Project Charter TemplateDurán JoseNo ratings yet

- EVM Intent GuideDocument90 pagesEVM Intent Guidemarkgil21No ratings yet

- Duration TypesDocument1 pageDuration TypesbizhanjNo ratings yet

- Primavera P6 V3,1 - Ch5!10!19Document54 pagesPrimavera P6 V3,1 - Ch5!10!19gsolenoNo ratings yet

- Advanced Project Management WorkbookDocument75 pagesAdvanced Project Management Workbooksharan67890% (1)

- Automatically update activity progress using Apply Actuals or Update ProgressDocument5 pagesAutomatically update activity progress using Apply Actuals or Update ProgressbizhanjNo ratings yet

- Updating BaselinesDocument1 pageUpdating BaselinesbizhanjNo ratings yet

- Calculate Average Unit LabelDocument2 pagesCalculate Average Unit LabelHashim MuhammudNo ratings yet

- Assign BaselineDocument7 pagesAssign BaselinebizhanjNo ratings yet

- 001 Part2resourcesandcostsDocument19 pages001 Part2resourcesandcostsRic S. MalongaNo ratings yet

- Baselines/Updates Updating The Schedule P6Document14 pagesBaselines/Updates Updating The Schedule P6abhishekchoubeyNo ratings yet

- Changing P6 Settings To Import Budget Costs From Excel Into P6Document11 pagesChanging P6 Settings To Import Budget Costs From Excel Into P6Ahmed AmrNo ratings yet

- Des Tat UsDocument3 pagesDes Tat UsPaul W. BonkyNo ratings yet

- 001 Part1resourcesandcostsDocument20 pages001 Part1resourcesandcostsbizhanjNo ratings yet

- Slide 04Document16 pagesSlide 04nguyennd_56No ratings yet

- Business Process Modeling Notation (BPMN)Document18 pagesBusiness Process Modeling Notation (BPMN)Sophia HasanNo ratings yet

- Road Maps: A Guide To Learning System DynamicsDocument16 pagesRoad Maps: A Guide To Learning System DynamicsbizhanjNo ratings yet

- Ibs 13 p16Document12 pagesIbs 13 p16bizhanjNo ratings yet

- Good Ref For System DynamicsDocument21 pagesGood Ref For System DynamicsbizhanjNo ratings yet

- Tools For Systems Thinking and Modeling: Dynamics: Graphs Over Time Structure: Causal-Loop DiagramsDocument38 pagesTools For Systems Thinking and Modeling: Dynamics: Graphs Over Time Structure: Causal-Loop DiagramsbizhanjNo ratings yet

- Introduction To L Tex: A Document Preparation System: Produced With L TEX by G Baker and G MoloneyDocument34 pagesIntroduction To L Tex: A Document Preparation System: Produced With L TEX by G Baker and G MoloneybizhanjNo ratings yet

- 000 VensimusersguideDocument298 pages000 Vensimusersguidek155meNo ratings yet

- Systems Causal LoopsDocument44 pagesSystems Causal LoopsbizhanjNo ratings yet

- Wel 23 BDocument8 pagesWel 23 BWilly UioNo ratings yet

- CE6002 CT Important Questions Iat 1Document2 pagesCE6002 CT Important Questions Iat 1Ñivéthã SùvíNo ratings yet

- Table - QW-416 Welding Variables For Welder Performance PDFDocument1 pageTable - QW-416 Welding Variables For Welder Performance PDFAnonymous VohpMtUSNNo ratings yet

- Welding Machine MonitorningDocument1 pageWelding Machine MonitorningmehdiNo ratings yet

- Iso 898-7:1992Document7 pagesIso 898-7:1992Anastasia Potapova50% (2)

- Arc Welding - Introduction and FundamentalsDocument30 pagesArc Welding - Introduction and FundamentalsweldmindNo ratings yet

- DR - 011123 - Project Fujimaki - EDKDocument2 pagesDR - 011123 - Project Fujimaki - EDKMuhammad RozaqNo ratings yet

- Resume Randy C. QuijanoDocument4 pagesResume Randy C. QuijanoKeneth Samson Del CarmenNo ratings yet

- 90° Anchor BoltDocument2 pages90° Anchor BoltJovito EdillonNo ratings yet

- Printer Friendly Page: Close WindowDocument2 pagesPrinter Friendly Page: Close WindowFerdnand RiverNo ratings yet

- Keyhole GTAW & GTAW Variants ExplainedDocument2 pagesKeyhole GTAW & GTAW Variants ExplainedThiago Ribeiro da SilvaNo ratings yet

- CN384 - A6 Hopper To Coin Mech Cable AssemblyDocument1 pageCN384 - A6 Hopper To Coin Mech Cable AssemblyAymen CheffiNo ratings yet

- Sheet No 10 - Concise title for structural steel sheet drawingDocument1 pageSheet No 10 - Concise title for structural steel sheet drawingKarikalan JayNo ratings yet

- 2G +5GDocument1 page2G +5GRahul Moottolikandy0% (1)

- ASME & ISO EN Welding Process Abbreviations PDFDocument1 pageASME & ISO EN Welding Process Abbreviations PDFkishortilekarNo ratings yet

- Er308l PDFDocument1 pageEr308l PDFnargissuhailNo ratings yet

- Boq Mei Isbl Refinery Glycerine Plant - For TenderDocument64 pagesBoq Mei Isbl Refinery Glycerine Plant - For TenderIsnanto AjaNo ratings yet

- OR O-Rings in Static Radial Sealing, Metric Sizes - TCM - 12-163250Document16 pagesOR O-Rings in Static Radial Sealing, Metric Sizes - TCM - 12-163250Sebastian AndreoliNo ratings yet

- 2014-07 RHI Reference List CARSIT SOL M10-6Document2 pages2014-07 RHI Reference List CARSIT SOL M10-6engr kazamNo ratings yet