Professional Documents

Culture Documents

Methods of Transmission Tower Erection - Electrical Engineering

Uploaded by

Battinapati ShivaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Methods of Transmission Tower Erection - Electrical Engineering

Uploaded by

Battinapati ShivaCopyright:

Available Formats

26/03/13 10:09 PM Methods of transmission tower erection | Electrical Engineering

Page 1 of 5 http://www.electrical4u.com/methods-of-transmission-tower-erection/

Electrical Power Transmission System

Performance of Transmission Line

ABCD Parameters of Transmission Line

Short Transmission Line

Medium Transmission Line

Long Transmission Line

Power System Stability

Skin Effect in Transmission Lines

Corona Effect in Power System

Electrical Substation

Mobile Substation

Methods of transmission tower

erection

There are four main methods of erection of

Like Send 213 people like this.

Electrical

Engineering

This is an online electrical

engineering study site

Search

Basic Electrical Electrical Machines Power System Electronics Electrical Forum

Objective Questions More

26/03/13 10:09 PM Methods of transmission tower erection | Electrical Engineering

Page 2 of 5 http://www.electrical4u.com/methods-of-transmission-tower-erection/

Electrical Bus System & Substation Layout

Electrical Insulator

Types of Electrical Insulator

Insulation Coordination

Insulator Testing

Electrical Isolator or Isolation Switch

Transmission Tower

Transmission Tower Erection

Transmission Tower Foundation Concept

Transmission Tower Foundation Design

steel transmission towers which a re

described below:

(i) Build-up method or Piecemeal method.

(ii) Section method.

(iii) Ground assembly method.

(iv) Helicopter method.

Build Up Method of transmission tower erection

This method is most commonly used in India

for the erection of 6.6 kV, 132 kV, 220 kV

and 400 kV transmission line towers due to

the following advantages :

(i) Tower materials can be supplied to site in

knowcked down condition which facilitates

easier and cheaper transportation.

(ii) It does not require any heavy machinery

such as cranes etc.

(iii) Tower erection activity can be done in any kind of terrain and mostly throughout the

year.

(iv) Availability of workmen at cheap rates.

This method consists of erecting the towers, member by member. The tower members are

kept on ground serially according to erection sequence to avoid search or time loss. The

erection progresses from the bottom upwards. The four main corner leg members of the

first section of the tower are first erected and gaud off. Sometimes more than one

contiguous leg sections of each corner leg are bolted together at the ground and erected.

The cross braces of the first section which are already assembled on the ground are raised

one by one as a unit and bolted to the already erected corner leg angles. First section of

the lower thus built and horizontal struts (belt members) if any, are bolted in position. For

assembling the second section of the tower, two gin poles are placed one each on the top of

diagonally opposite corner legs. These two poles are used, for raising parts of second

section. The leg members and braces of this section are then hoisted and assembled. The

gin poles are then shifted to the corner leg members on the top of second section to raise

the parts of third section of the lower in position for assembly. Gin poles are thus moved up

26/03/13 10:09 PM Methods of transmission tower erection | Electrical Engineering

Page 3 of 5 http://www.electrical4u.com/methods-of-transmission-tower-erection/

as the tower grows. This process is continued till the complete tower is erected. Cross-arm

members are assembled on the ground and raised up and fixed to the main body of the

tower. For heavier towers, a small boom is rigged on one of the tower legs for hoisting

purposes. The members / sections are hoisted either manually or by winch machines

operated from the ground. For smaller base towers / vertical configuration towers one gin

pole is used instead of two gin poles. In order to maintain speed and efficiency, a small

assembly party goes ahead of the main erection gang and its purpose is to sort out the

tower members, keeping the members in correct position on the ground and assembling the

panels on the ground which can be erected as a complete unit.

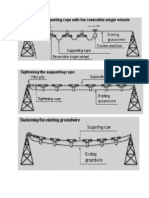

SECTION METHOD OF TRANSMISSION TOWER ERECTION

In the section method, major sections of the tower are assembled on the ground and the

same are erected as units. Either a mobile crane or a gin pole is used. The gin pole used is

approximately 10 m long and is held in place by means of guys by the side of the tower to be

erected. The two opposite sides of the tower section of the tower are assembled on the

ground. Each assembled side is then lifted clear of the ground with the gin or derrick and is

lowered into position on bolts to stubs or anchor bolts.

One side is h held in place with props while the other side is being erected. The two

opposite sides are then laced together with cross members and diagonals; and the

assembled section is lined up, made square to the line. After completing the first section,

gin pole is set on the top of the first section. The gin rests on a strut of the tower

immediately below the leg joint. The gin pole then has to be properly guyed into position.

The first face of the second section is raised. To raise the second face of this section it is

necessary to slide the foot of the gin on the strut of the opposite face of the tower. After

the two opposite faces are raised, the lacing on the other two sides is bolted up. The last

lift raises the top of the towers. After the tower top is placed and all side lacings have

been bolted up all the guyes are thrown off except one which is used to lower the gin pole.

Sometimes whole one face of the tower is assembled on the ground, hoisted and supported

in position. The opposite face is similarly assembled and hoisted and then the bracing angles

connecting these two faces are fitted.

GROUND ASSEMBLY METHOD OF TOWER ERECTION

This method consists of assembling the tower on ground, and erecting it as a complete unit.

The complete tower is assembled in a horizontal position on even ground. The tower is

assembled along the direction of the line to allow the cross arms to be fitted. One slopping

ground, however, elaborate packing of the low side is essential before assembly commences.

After the assembly is complete the tower is picked up from the ground with the help of a

crane and carried to its location, and set on its foundation. For this method of erection, a

level piece of ground close to footing is chosen from the tower assembly. This method is not

useful when the towers are large and heavy and the foundations are located in arable land

where building and erecting complete towers would cause damage to large areas or in hilly

26/03/13 10:09 PM Methods of transmission tower erection | Electrical Engineering

Page 4 of 5 http://www.electrical4u.com/methods-of-transmission-tower-erection/

terrain where the assembly of complete tower

on sloping ground may not be possible and it may

be difficult to get crane into position to raise

the complete tower.

In India, this method is not generally adopted

because of prohibitive cost of mobile crane, and

non-availability of good approach roads to tower

locations.

HELICOPTER METHOD OF TRANSMISSION

TOWER ERECTION

In the helicopter method, the transmission tower is erected in section. For example bottom

section is first lifted on to the stubs and then the upper section is lifted and bolted to the

first section and the process is repeated till the complete tower is erected. Sometimes a

completely assembled tower is raised with the help of helicopter. Helicopters are also used

for lifting completely assembled towers with guys from the marshalling yards where these

are fabricated and then transported one by one to line locations. Helicopter hovers over the

line location while the tower is securely guyued. The ground crew men connect and tighten

the tower guys. As soon as the guy wires are adequately tensioned the helicopter

disengages and files to the marshalling yard. This method is adopted where approach is v

very difficult or to speed up the construction of the transmission line.

TIGHTENING OF NUTS AND PUNCHING OF THREADS AND TACK WELDING OF NUTS OF

TRANSMISSION TOWERS

All nuts shall be tightened properly using correct sized spanners. Before tightening it is

ensured that filter washers and plates are placed in relevant gaps between members, bolt

of proper size and length are inserted and one spring washer is inserted under e each nut.

In case of step bolts, spring washer shall be placed under the outer nut. The tightening

shall be carried on progressively from the top downwards, care being taken that all bolts at

every level are tightened simultaneously. It may be better to employ four persons, each

covering one leg and the face to his right.

The threads of bolts shall be projected outside the nuts by one to two threads and shall be

punched at three positions on the top inner periphery of the nut and bolt to ensure that the

nuts are not loosened in course of time. If during tightening a nut is found to be slipping or

running over the bolt threads, the bolt together with the nut shall be changed outright.

PAINTING OF JOINTS OF TRANSMISSION TOWER

For galvanized towers is coastal or highly polluted areas, the joints shall be painted with

zinc paint on all contact surfaces during the course of erection.

CHECKING THE VERTICALITY OF ERECTED TRANSMISSION TOWERS

26/03/13 10:09 PM Methods of transmission tower erection | Electrical Engineering

Page 5 of 5 http://www.electrical4u.com/methods-of-transmission-tower-erection/

login

Log In

Username:

Password:

Remember Me

Log In

Register Lost Password

Online Study Site for Electrical Engineering

Leave a Reply

You must be logged in to post a comment.

The finally erected tower shall be truly vertical after erection and no straining is permitted

to bring it in alignment. Tolerance limit for vertical shall be one in 360 of the tower height.

Print the article

Rate this

Circuit Breaker Sales

www.swhge.com

Supply Vacuum Circuit Breaker. Email for more product details.

You might also like

- Build Up Method of Transmission Tower ErectionDocument5 pagesBuild Up Method of Transmission Tower Erectionraj100% (1)

- Tower ErectionDocument4 pagesTower Erectionparry_handa220100% (1)

- 15-II.5. Tower ErectionDocument8 pages15-II.5. Tower Erectionashok10577100% (3)

- Conductor Stringing PDFDocument42 pagesConductor Stringing PDFmanojNo ratings yet

- StringingDocument12 pagesStringingsid_3150% (2)

- STD SPN For Material & Works Vol II (Electrical) With Rev 2 DTD 17.01.2017 PDFDocument429 pagesSTD SPN For Material & Works Vol II (Electrical) With Rev 2 DTD 17.01.2017 PDFSudhir Pandey100% (1)

- Conductor Installation Manual-MegatroDocument5 pagesConductor Installation Manual-MegatromanafNo ratings yet

- A Report On: Transmission Line ConstructionDocument41 pagesA Report On: Transmission Line Constructionharshraj086100% (2)

- 3 2 Rigging of Transmission Line Towers PDFDocument5 pages3 2 Rigging of Transmission Line Towers PDFsauravkafle1No ratings yet

- Safety Precautions Should Be Taken While Working On 25 KV AC OHE System.Document1 pageSafety Precautions Should Be Taken While Working On 25 KV AC OHE System.safetyNo ratings yet

- Opgw StringingDocument3 pagesOpgw StringingNiraj SinhaNo ratings yet

- Method Statement For Transmission Line Lanco PDFDocument37 pagesMethod Statement For Transmission Line Lanco PDFAmar WadoodNo ratings yet

- Substation ReportDocument39 pagesSubstation ReportPraveen Kumar Choudhary100% (2)

- Guidelines For The Construction and Maintenance of Transmission LinesDocument5 pagesGuidelines For The Construction and Maintenance of Transmission LinesMuhammad AbuzarNo ratings yet

- Transmission Line ReportDocument7 pagesTransmission Line Reportparthichristo100% (1)

- Grid & Sub StationDocument39 pagesGrid & Sub StationPhani KumarNo ratings yet

- Method of Installation For Overhead Transmission Line Conductors & OpgwDocument17 pagesMethod of Installation For Overhead Transmission Line Conductors & OpgwInba RajNo ratings yet

- MS Panel and Equipment Installation For Signaling System Works Rev 0Document22 pagesMS Panel and Equipment Installation For Signaling System Works Rev 0halim_kidNo ratings yet

- Electrical Safety ClearanceDocument39 pagesElectrical Safety ClearanceDon Bun100% (1)

- Technical Paper-French Standard NFC 17-102 (2011)Document10 pagesTechnical Paper-French Standard NFC 17-102 (2011)Mohamad HishamNo ratings yet

- 0214 Tower DesignDocument6 pages0214 Tower DesignchontaNo ratings yet

- Field Work Procedure: 8. 8.1 Pre Hand ChecksDocument7 pagesField Work Procedure: 8. 8.1 Pre Hand Checkselsayed abdemagied100% (1)

- Technical Specification Part-IDocument800 pagesTechnical Specification Part-IPankaj UlgekarNo ratings yet

- StringingDocument4 pagesStringingFe Fatima NavarreteNo ratings yet

- STRINGINGDocument15 pagesSTRINGINGmarcelo3e3No ratings yet

- Pembangunan T/L 150 KV Otam - Molibagu Drum Schedule Conductor & GSW PULL - T. 174 - 192Document2 pagesPembangunan T/L 150 KV Otam - Molibagu Drum Schedule Conductor & GSW PULL - T. 174 - 192Andi MuliadiNo ratings yet

- WMS Erection TowerDocument15 pagesWMS Erection TowerbimoNo ratings yet

- Tower ErectionDocument13 pagesTower ErectionTechne PhobosNo ratings yet

- Transmission Line Planning, Coordination & MonitoringDocument3 pagesTransmission Line Planning, Coordination & MonitoringSanjay RoutNo ratings yet

- Underground Power Cable For AirportsDocument12 pagesUnderground Power Cable For AirportsDevrim GürselNo ratings yet

- Transmission Line Supports.Document37 pagesTransmission Line Supports.ninadpujara2007No ratings yet

- TowerSmart Tower Detailing Tips Series 2Document8 pagesTowerSmart Tower Detailing Tips Series 2gadskiNo ratings yet

- Overhead Catenary System PDFDocument19 pagesOverhead Catenary System PDFDeny IndraNo ratings yet

- Electrical Instruments Catalogue GFUVE ElectronicsDocument172 pagesElectrical Instruments Catalogue GFUVE ElectronicsRangga K NegaraNo ratings yet

- Mudhaibi Grid StationDocument14 pagesMudhaibi Grid Stationanurag_jay12464No ratings yet

- Drum Schedule Silae - Pas - Kayu Rev.02Document18 pagesDrum Schedule Silae - Pas - Kayu Rev.02Gonzalo LopezNo ratings yet

- Live Line Maintenance TechniquesDocument41 pagesLive Line Maintenance TechniquesBattinapati ShivaNo ratings yet

- BOQ - EM GI 150 KV RAJAPAKSIDocument15 pagesBOQ - EM GI 150 KV RAJAPAKSIReinhard Jesaya Simbolon0% (1)

- Topic: - Preliminary Survey - Route Alignment - Profiling - Right of Way - Compensation ProcedureDocument26 pagesTopic: - Preliminary Survey - Route Alignment - Profiling - Right of Way - Compensation ProcedureAbhishek Kumar JhaNo ratings yet

- Method Attempt - Ohtl Search - To Be UsedDocument31 pagesMethod Attempt - Ohtl Search - To Be UsedhaneeneNo ratings yet

- Stringing of Transmission Line TowerDocument9 pagesStringing of Transmission Line Towershahid rasheedNo ratings yet

- My Learnings On Transmission TowerDocument53 pagesMy Learnings On Transmission TowerSaravanan Ramalingam100% (3)

- 66kv Ha & de Type Tower Foundation DrawidngDocument2 pages66kv Ha & de Type Tower Foundation DrawidngBAWA ALEXNo ratings yet

- M. Statment Lines - OHL Instal & TestingDocument27 pagesM. Statment Lines - OHL Instal & Testingahmedshah512100% (1)

- Substation ExecutionDocument79 pagesSubstation ExecutionSunil Bhanot100% (1)

- Line ClearenceDocument2 pagesLine ClearenceNitin OhriNo ratings yet

- IEEE STD 951-1996, IEEE GUIDE TO THE ASSEMBLY AND ERECTION - Transmission-Structurespdf PDFDocument44 pagesIEEE STD 951-1996, IEEE GUIDE TO THE ASSEMBLY AND ERECTION - Transmission-Structurespdf PDFMarcosGodoyPereyra100% (2)

- Mechanical Design of Transmission Lines PDFDocument53 pagesMechanical Design of Transmission Lines PDFAkhilesh MendonNo ratings yet

- Method of Transportation GIS Ternate Transformers PDFDocument10 pagesMethod of Transportation GIS Ternate Transformers PDFAditya FirgiantoNo ratings yet

- EHV Handbook ENG LowResDocument91 pagesEHV Handbook ENG LowResRaja JagadeesanNo ratings yet

- Survey Works: Alignment FixingDocument33 pagesSurvey Works: Alignment FixingAnish PanchalNo ratings yet

- Build Up Method of Transmission Tower ErectionDocument3 pagesBuild Up Method of Transmission Tower ErectionNanban VkyNo ratings yet

- Transmission TowerDocument5 pagesTransmission Towerasimnaqvi2003No ratings yet

- Erection of Lattice TowerDocument6 pagesErection of Lattice Toweranwaya100% (1)

- Tower Erection by Various MethodDocument30 pagesTower Erection by Various MethodJaydip NathNo ratings yet

- 46 Construction Manual For Sub StationsDocument1 page46 Construction Manual For Sub Stationsman98_greyhoundzNo ratings yet

- Erection Procedure - MosDocument13 pagesErection Procedure - MosBaisel Rahuman67% (3)

- Tower Crane InstallationDocument6 pagesTower Crane Installationanon_177735386No ratings yet

- Note About Tower ErectionDocument8 pagesNote About Tower Erectionkonjoo ethNo ratings yet

- Different Methods of Bridge Construction and Their Selection (Printed)Document25 pagesDifferent Methods of Bridge Construction and Their Selection (Printed)Muhammad FarooqNo ratings yet

- VSN800 Weather Station Product ManualDocument16 pagesVSN800 Weather Station Product ManualBattinapati ShivaNo ratings yet

- Distance Protection: © ZIV Aplicaciones y Tecnología S. ADocument96 pagesDistance Protection: © ZIV Aplicaciones y Tecnología S. ABattinapati ShivaNo ratings yet

- Electrical Installation Design GuideDocument97 pagesElectrical Installation Design GuideIbrahimSamir100% (55)

- Mersen PVPN5 Sizing Fuses of PV Systems Per NECDocument4 pagesMersen PVPN5 Sizing Fuses of PV Systems Per NECchendo2006No ratings yet

- Solarpv ChecklistDocument6 pagesSolarpv ChecklistMohan KrishnaNo ratings yet

- Bus Differential Protection: Fundamental IdeasDocument8 pagesBus Differential Protection: Fundamental IdeasBattinapati ShivaNo ratings yet

- Circuit BreakerDocument137 pagesCircuit BreakerBattinapati Shiva100% (5)

- Drawingsdocumentsrequiredforsolarprojects 131110061739 Phpapp01Document4 pagesDrawingsdocumentsrequiredforsolarprojects 131110061739 Phpapp01Battinapati Shiva100% (1)

- SLDDocument1 pageSLDBattinapati ShivaNo ratings yet

- Drafting Electrical DrawingsDocument168 pagesDrafting Electrical DrawingsBattinapati Shiva0% (1)

- VCBDocument1 pageVCBBattinapati ShivaNo ratings yet

- 1hyb990052 16aDocument1 page1hyb990052 16aBattinapati ShivaNo ratings yet

- EE DiagramsDocument35 pagesEE DiagramsRai JeanNo ratings yet

- Delegation of PowerDocument68 pagesDelegation of PowerBattinapati ShivaNo ratings yet

- Intro To ERP (Induction Level Training)Document19 pagesIntro To ERP (Induction Level Training)Battinapati ShivaNo ratings yet

- HVDC PPTDocument34 pagesHVDC PPTBattinapati Shiva100% (1)

- Gas Turbine Power StationDocument43 pagesGas Turbine Power StationBattinapati Shiva100% (1)

- Oc Relay CordinationDocument47 pagesOc Relay CordinationBattinapati ShivaNo ratings yet

- Nuclear Power: Presentation By: Shri. Bharat V. Makhare Asst. Engineer, NTC, Nashik MahagencoDocument67 pagesNuclear Power: Presentation By: Shri. Bharat V. Makhare Asst. Engineer, NTC, Nashik MahagencoBattinapati ShivaNo ratings yet

- Cables, Conduits and Trunking: To The 16th Edition IEE RegulationsDocument2 pagesCables, Conduits and Trunking: To The 16th Edition IEE RegulationsBattinapati ShivaNo ratings yet

- LINK-History of ProtectionDocument7 pagesLINK-History of ProtectionBattinapati ShivaNo ratings yet

- Cables, Conduits and Trunking: To The 16th Edition IEE RegulationsDocument4 pagesCables, Conduits and Trunking: To The 16th Edition IEE RegulationsBattinapati ShivaNo ratings yet

- Newmicrosoftofficepowerpointpresentation 130309031327 Phpapp02 PDFDocument38 pagesNewmicrosoftofficepowerpointpresentation 130309031327 Phpapp02 PDFtaiptc4No ratings yet

- Live Line Maintenance TechniquesDocument41 pagesLive Line Maintenance TechniquesBattinapati ShivaNo ratings yet

- Project Management PresentationDocument15 pagesProject Management PresentationBattinapati Shiva100% (1)

- Economics of Construction - BOWDocument128 pagesEconomics of Construction - BOWAlexandreNo ratings yet

- CAE Oxford Aviation Academy - 020 Aircraft General Knowledge 1 - Airframes and Systems (ATPL Ground Training Series) - 2014 PDFDocument352 pagesCAE Oxford Aviation Academy - 020 Aircraft General Knowledge 1 - Airframes and Systems (ATPL Ground Training Series) - 2014 PDFAli96% (24)

- Rigging The Pitts: by Doug Sowder, IAC #14590Document7 pagesRigging The Pitts: by Doug Sowder, IAC #14590Rodrigo SouzaNo ratings yet

- Airframe and Systems CopieeeeDocument126 pagesAirframe and Systems Copieeeepaul100% (1)

- Landing Gear LLP ListDocument11 pagesLanding Gear LLP Listalex eckmannNo ratings yet

- Module 11A.2 (B) L2 2016-08-12Document139 pagesModule 11A.2 (B) L2 2016-08-12Abdul Aziz KhanNo ratings yet

- Vintage Airplane - Aug 1995Document36 pagesVintage Airplane - Aug 1995Aviation/Space History LibraryNo ratings yet

- Lecture 12Document15 pagesLecture 12joshuaNo ratings yet

- Design and Construction of Anchored and Strutted Sheet Pile WallsDocument37 pagesDesign and Construction of Anchored and Strutted Sheet Pile WallsphamducquangNo ratings yet

- Table of ContentsDocument84 pagesTable of ContentsRalph Michael Tejano50% (2)

- 23 - Eave StrutsDocument2 pages23 - Eave StrutsTuanQuachNo ratings yet

- German Seaplane Fighters of WWIDocument151 pagesGerman Seaplane Fighters of WWIFrancisco Alvarez100% (4)

- Taylorcraft O-57 GrasshopperDocument8 pagesTaylorcraft O-57 GrasshopperAviation/Space History Library100% (1)

- Aircraft Structural ComponentsDocument32 pagesAircraft Structural ComponentsLivil LyleNo ratings yet

- Pietenpol Sky ScoutDocument11 pagesPietenpol Sky Scoutconfused597100% (4)

- Aircraft Design 2015Document277 pagesAircraft Design 2015aga reyes100% (1)

- Structural Sizing of A Solar Powered AircraftDocument105 pagesStructural Sizing of A Solar Powered Aircraftmanikandan_murugaiahNo ratings yet

- Aircraft Structures 1Document100 pagesAircraft Structures 1vodmox100% (2)

- Quiet and Electric Flight Mag 052011 PDFDocument6 pagesQuiet and Electric Flight Mag 052011 PDFΚωνσταντίνος ΒασάλοςNo ratings yet

- Flying Scale Models July 2018Document68 pagesFlying Scale Models July 2018Nikko Limua100% (1)

- Vintage Airplane - Jun 1992Document36 pagesVintage Airplane - Jun 1992Aviation/Space History Library100% (1)

- The Aeroplane SpeaksFifth Edition by Barber, H. (Horatio), 1875-1964Document129 pagesThe Aeroplane SpeaksFifth Edition by Barber, H. (Horatio), 1875-1964Gutenberg.orgNo ratings yet

- Book 02 Aircraft General Knowledge 1 PDFDocument414 pagesBook 02 Aircraft General Knowledge 1 PDFrd meshram100% (3)

- CG (Initial) : Designed by Plans byDocument1 pageCG (Initial) : Designed by Plans byFarooq AhmadNo ratings yet

- Aerospece MaterialDocument583 pagesAerospece MaterialChin-Min Yang100% (2)

- Pa 18 150 - pcv1988Document164 pagesPa 18 150 - pcv1988Jessey StonerNo ratings yet

- Peter M. BowersDocument9 pagesPeter M. Bowersretread1100% (2)

- Air Modeller 76Document68 pagesAir Modeller 76Hernández Manzano Bernardo100% (4)

- 2 - ATPL Questions AGK1 - Aiframe - SystemsDocument38 pages2 - ATPL Questions AGK1 - Aiframe - SystemsTanvir Hasan100% (1)

- Aircraft Design Project - Ii Design of Bomber Aircraft A Project ReportDocument73 pagesAircraft Design Project - Ii Design of Bomber Aircraft A Project ReportKapil mNo ratings yet