Professional Documents

Culture Documents

Sizing Mist Eliminators For New and Retrofit Existing Separators

Uploaded by

Giang T LeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sizing Mist Eliminators For New and Retrofit Existing Separators

Uploaded by

Giang T LeCopyright:

Available Formats

.

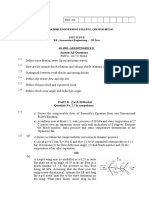

Sizing Mist Eliminators For New or Retrofit Existing Separators

Principles of Gas/Liquid Separation

Inertial Capture in Vanes and Mesh Droplet Size Strand Diameter or corrugation spacing Gas Velocity Liquid Density relative to gas density Gas Viscosity Pad Density and Thickness Interception Capture Brownian Capture

Figure 15. Droplet capture by Brownian motion in a Fiber candle or panel

Sizing Mist Eliminators

Mesh

General Purpose (9# Density) 99% of 10 Micron

Vane

99% of 30 Micron

Mesh/Vane

Comments

None Critical Equipment downstream or where Mesh plugs

Improved Design

High efficiency & 10% high capacity High efficiency high Liquid load Medium efficiency & 50% extra high capacity Ultra high efficiency 99.9% of 1 micron 99.9% 8 micron Double Pocket Vane 99.9% of 1 micron 99.9% 5 micron 99.9% 5 micron To protect compressors Catalyst & beds, etc. To avoid mesh flooding In applications where Mesh plugs To minimize solvent losses (MEA, MDEA, etc)

Ultra high efficiency 50% extra capacity

00.0% of 1 micron Double Pocket Vane

Souders Brown Equation

VG K = PL PG PG

K = vapor load factor (Souders-Brown velocity) VG = gas velocity PL = liquid density in same units as PG PG = gas density in same unit as PL

Recommended Vapor Load Factors

Mesh Pads K=0.20-0.40 Vane Unit Vertical Flow K = 0.45 (max) (no hooks) Vane Unit Vertical Flow K=0.65 (max) (no hooks) Double Pocket Vanes (Vert/Horzt Flow) K=1.2 (max)

Mist Eliminator Sizing Calculation Example:

Flow Rate: 100 ACFS Pressure: 400psig Area required 100ACFS Vd1 Vd1 = .30 42 -1 = 1.7 1.25

K=1.1 (DP vane) Wt: 1500lbs

Pg: 1.25lb/ft3 Pl: 1.21lb/ft3

K=0.30 (mesh pad) Wt: 4000lbs

K=0.5 (vane) Wt: 2800lbs

Vane Profiles

F L O W

F L O W

Amistco Six-Pass Vane Unit

Amistco Double-Pocket Vane Unit

Challenges to overcome when Providing High Capacity in smaller Separators

Limited Vessel diameter or height Restricted disengaging space for the incoming gas / bad gas distribution High gas velocity creates turbulences in the liquid phase reduces oil/water gravity separation Higher mist loading in the gas phase could flood the M.E. Build new support structure with welding to the vessel wall (Retrofit)

Configuration

Standard

One Bank

Alternative Configuration

2 Bank

4 Bank

Double Expansion Ring

Support Ring Frame Installed

Installation of support Frame

Knockout Drum Retro-fit

Support Ring Installed without welding

Vane Retro-fit

Vane Retro-fit

Vane Retro-fit

Retrofit Vane/Mesh

Double-Pocket Vane Retro-fit

Vane with Support Frame

Rukovena Consulting

Inlet distributors Impact on Separators Performance

CFD velocity profile at A-A Identified poor gas distribution as a cause. Red velocity is 3 times design velocity and 4 times green velocity

Inlet Diffuser view 1

Inlet Diffuser view 2.

Typical Situation

Corrected Situation: High Capacity/High Efficiency

You might also like

- Design Manual Mist Eliminator - NewDocument16 pagesDesign Manual Mist Eliminator - Newashif100% (2)

- Demister Sizing Using Normal Flow Conversion:: Customer: Enquiry No: Item No: DateDocument3 pagesDemister Sizing Using Normal Flow Conversion:: Customer: Enquiry No: Item No: Daterakesh3487100% (2)

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- Distillation Design and Control Using Aspen SimulationFrom EverandDistillation Design and Control Using Aspen SimulationRating: 5 out of 5 stars5/5 (2)

- Gas-Liquid Separators PDFDocument9 pagesGas-Liquid Separators PDFMubarik AliNo ratings yet

- Handbook of Vapor Pressure: Volume 4: Inorganic Compounds and ElementsFrom EverandHandbook of Vapor Pressure: Volume 4: Inorganic Compounds and ElementsNo ratings yet

- 06 - Savvy Separator - UNDERPERFORMING GAS SCRUBBERS PDFDocument8 pages06 - Savvy Separator - UNDERPERFORMING GAS SCRUBBERS PDFabhijit kharoteNo ratings yet

- Liquid Distributor DesignDocument3 pagesLiquid Distributor Designanon_414493592No ratings yet

- Design Procedure For Two Phase SeparatorsDocument6 pagesDesign Procedure For Two Phase Separatorsmadx222222No ratings yet

- Separator Fundamentals - Process DesignDocument30 pagesSeparator Fundamentals - Process Designlaleye_olumide100% (3)

- The Hydrocyclone: International Series of Monographs in Chemical EngineeringFrom EverandThe Hydrocyclone: International Series of Monographs in Chemical EngineeringRating: 5 out of 5 stars5/5 (3)

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationFrom EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationNo ratings yet

- Vertical 2 Phase Separator SizingDocument5 pagesVertical 2 Phase Separator SizingJermaine Heath100% (1)

- Sizing of The Feed Nozzles For Gas-Liquid Separator - Industrial Professionals - CheresourcesDocument5 pagesSizing of The Feed Nozzles For Gas-Liquid Separator - Industrial Professionals - CheresourcesJavierNo ratings yet

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- LP Separator SizingDocument81 pagesLP Separator SizingNadia BahloulNo ratings yet

- Demister EfficiencyDocument9 pagesDemister EfficiencyHastelloy MonelNo ratings yet

- Bell Delaware Math Cad ExampleDocument8 pagesBell Delaware Math Cad ExampleMohammed A IsaNo ratings yet

- Vacuum Engineering Calculations, Formulas, and Solved ExercisesFrom EverandVacuum Engineering Calculations, Formulas, and Solved ExercisesRating: 4.5 out of 5 stars4.5/5 (2)

- IMTPDocument16 pagesIMTPDHAVALESH AMNo ratings yet

- Advances in Solid–Liquid Flow in Pipes and Its ApplicationFrom EverandAdvances in Solid–Liquid Flow in Pipes and Its ApplicationIraj ZandiRating: 5 out of 5 stars5/5 (2)

- Random PackingDocument16 pagesRandom PackingIng Antony MatosNo ratings yet

- Falling Film Evaporator component volumesDocument2 pagesFalling Film Evaporator component volumesHemant K Patil100% (1)

- Liquid-Vapor Separation Efficiency (Envp0102)Document24 pagesLiquid-Vapor Separation Efficiency (Envp0102)jbl_No ratings yet

- Equipment - Sizing (Update) - Pacf2-Rev. ADocument52 pagesEquipment - Sizing (Update) - Pacf2-Rev. AAnonymous AtAGVssJNo ratings yet

- Vapor Liquid Vertical SeparatorDocument4 pagesVapor Liquid Vertical SeparatorIoana Popescu100% (1)

- SeparatorsDocument140 pagesSeparatorsmatteo2009No ratings yet

- Calculation of Scrubber DiameterDocument44 pagesCalculation of Scrubber DiameterRamakrishna SomuNo ratings yet

- Static MixersDocument5 pagesStatic Mixersmonaco59No ratings yet

- Buss SMS Canzler - Thin Film EvaporatorsDocument16 pagesBuss SMS Canzler - Thin Film EvaporatorsandreathomeNo ratings yet

- High Efficiency Coalescers For Gas Processing OperationsDocument9 pagesHigh Efficiency Coalescers For Gas Processing OperationsAndri SaputraNo ratings yet

- Design Data: 2" Threadolet CalculationDocument2 pagesDesign Data: 2" Threadolet Calculationgrabetty50% (2)

- Separator Sizing and DesignDocument45 pagesSeparator Sizing and DesignSedemNo ratings yet

- 3Ph Horiz Sep 2010 Weir VerA SIDocument5 pages3Ph Horiz Sep 2010 Weir VerA SIBrenda DavisNo ratings yet

- Datasheet For PACE Mist Eliminator/s (Demister) : Existing DetailsDocument1 pageDatasheet For PACE Mist Eliminator/s (Demister) : Existing DetailsAnonymous LLLK3pq50% (2)

- 6 Crystallizer Design and Operation1Document22 pages6 Crystallizer Design and Operation1Dhrumil GandhiNo ratings yet

- Falling Film Heat Transfer CoefficientDocument22 pagesFalling Film Heat Transfer CoefficientZarra FaktNo ratings yet

- Volume and Wetted Area of Partially Filled Vertical Vessels - Neutrium PDFDocument12 pagesVolume and Wetted Area of Partially Filled Vertical Vessels - Neutrium PDFdaimon_p100% (1)

- Plate Heat Exchangers Calculation Methods For Singleand Two Phase Flow PDFDocument12 pagesPlate Heat Exchangers Calculation Methods For Singleand Two Phase Flow PDFFrandhoni UtomoNo ratings yet

- Technical Design Principles for Liquid Ring Vacuum PumpsDocument18 pagesTechnical Design Principles for Liquid Ring Vacuum PumpsAgung SiswahyuNo ratings yet

- Jet Venturi Fume ScrubbersDocument7 pagesJet Venturi Fume ScrubbersihllhmNo ratings yet

- 4 SPE-77495-Increasing Separation Capacity With New and Proven TechnologiesDocument6 pages4 SPE-77495-Increasing Separation Capacity With New and Proven TechnologiesDavid VMNo ratings yet

- Sizing Packed TowersDocument7 pagesSizing Packed Towersrzq_andikaNo ratings yet

- Separator DesignDocument3 pagesSeparator Designsondung4ver80% (5)

- Baffle Selection PDFDocument7 pagesBaffle Selection PDFmaruthigabbita100% (3)

- Schoepentoeter SEPARADORDocument4 pagesSchoepentoeter SEPARADOREsau EstebanNo ratings yet

- KIRK Sep-Calc SoftwareDocument4 pagesKIRK Sep-Calc Softwaredhl_tuNo ratings yet

- Design Practices-ReboilerDocument7 pagesDesign Practices-Reboileragarwalashwin32100% (1)

- Mist EliminatorDocument4 pagesMist Eliminatorhappale2002No ratings yet

- ChemEngReliefPaper2005 PDFDocument34 pagesChemEngReliefPaper2005 PDFNoirchevalNo ratings yet

- Vertical Knock Out Drum With Wire Mesh For NDocument1 pageVertical Knock Out Drum With Wire Mesh For Nteegala_1950% (2)

- Investigating Performance of Coldfinger Dehydration TechnologyDocument13 pagesInvestigating Performance of Coldfinger Dehydration TechnologyarispriyatmonoNo ratings yet

- Claus Process CalculationDocument105 pagesClaus Process CalculationDaniel SetyadiNo ratings yet

- Liquid Liquid Separation TechnologyDocument16 pagesLiquid Liquid Separation TechnologyMurrali Raj JeyagapalNo ratings yet

- Section 7 - Separation EquipmentDocument9 pagesSection 7 - Separation Equipmentlulis171No ratings yet

- Vacuum Distillation in Petroleum RefineryDocument3 pagesVacuum Distillation in Petroleum RefineryAdelmo FilhoNo ratings yet

- Demister Design Check AnalysisDocument4 pagesDemister Design Check AnalysisshazanNo ratings yet

- Sly Venturi ScrubberDocument2 pagesSly Venturi Scrubberzguy360No ratings yet

- Process Design: Vessel Sizing (Liquid & Vapour Separators)Document36 pagesProcess Design: Vessel Sizing (Liquid & Vapour Separators)Krishanu SahaNo ratings yet

- Gears - Engineering InformationDocument138 pagesGears - Engineering InformationGiang T LeNo ratings yet

- Pumps and Seals TutorialDocument334 pagesPumps and Seals TutorialGiang T Le67% (3)

- Gears - Engineering InformationDocument138 pagesGears - Engineering InformationGiang T LeNo ratings yet

- AQMD Emissions ProgramDocument30 pagesAQMD Emissions ProgramGiang T LeNo ratings yet

- Pumps and Seals TutorialDocument334 pagesPumps and Seals TutorialGiang T Le67% (3)

- Risk Based Inspection ProgramDocument16 pagesRisk Based Inspection ProgramGiang T Le100% (3)

- A. Basic Concepts 1.0 Velocities in Gear TrainsDocument76 pagesA. Basic Concepts 1.0 Velocities in Gear TrainsLuis Balducci80% (5)

- Gear DesignDocument156 pagesGear DesignGiang T Le100% (4)

- Basics of centrifugal compressors performance and parametersDocument65 pagesBasics of centrifugal compressors performance and parametersGiang T Le100% (1)

- Basics of centrifugal compressors performance and parametersDocument65 pagesBasics of centrifugal compressors performance and parametersGiang T Le100% (1)

- Proc Eng P&I DDocument60 pagesProc Eng P&I DGiang T LeNo ratings yet

- Basics of centrifugal compressors performance and parametersDocument65 pagesBasics of centrifugal compressors performance and parametersGiang T Le100% (1)

- API RBI Tank Case Study: Lessons from Delaying InspectionsDocument26 pagesAPI RBI Tank Case Study: Lessons from Delaying InspectionsGiang T Le100% (1)

- The 6 Myths of CreativityDocument4 pagesThe 6 Myths of CreativityGiang T LeNo ratings yet

- John Crane Type 8-1 and 9 Seals Installation, Operations, MaintenanceDocument4 pagesJohn Crane Type 8-1 and 9 Seals Installation, Operations, MaintenanceGiang T LeNo ratings yet

- Compressor Calculations ReferencesDocument19 pagesCompressor Calculations ReferencesGiang T Le0% (1)

- Pile Cap Design 1Document6 pagesPile Cap Design 1kjpatel2100% (2)

- Philip Oloibe Soil Mech ReportDocument9 pagesPhilip Oloibe Soil Mech Reportsydney augustNo ratings yet

- Class 5 Mechanical Systems (Both Translation and Rotational)Document22 pagesClass 5 Mechanical Systems (Both Translation and Rotational)Acharya Mascara PlaudoNo ratings yet

- Physics 01-02 Displacement and VectorsDocument2 pagesPhysics 01-02 Displacement and VectorsAnonymous FDewQQkx3VNo ratings yet

- Torsion Design of BeamDocument14 pagesTorsion Design of Beamyyanan_11180% (1)

- Optimization Efficiency Dampers: of The of Aeolian VibrationDocument3 pagesOptimization Efficiency Dampers: of The of Aeolian VibrationServando LozanoNo ratings yet

- 1 - Introduction To Structural Steel Design-Chapter 1Document3 pages1 - Introduction To Structural Steel Design-Chapter 1Abera DeressaNo ratings yet

- Applications of DerivativesDocument4 pagesApplications of DerivativesSharaine CastilloNo ratings yet

- Ad II (Ae6503)Document2 pagesAd II (Ae6503)Raahini IzanaNo ratings yet

- Steen e Ken 1989Document20 pagesSteen e Ken 1989suryakantNo ratings yet

- Jasmine Tran - Unit 2 Free Response Question - Ap Calc PortfolioDocument2 pagesJasmine Tran - Unit 2 Free Response Question - Ap Calc Portfolioapi-574938628No ratings yet

- PPTDocument13 pagesPPTAJINKYANo ratings yet

- L4 - Application of Momentum Integral Theorem and Boundary Layer SeparationDocument25 pagesL4 - Application of Momentum Integral Theorem and Boundary Layer SeparationKar AbhishekNo ratings yet

- Physics, Chapter 4: Statics of A Rigid Body: Digitalcommons@University of Nebraska - LincolnDocument21 pagesPhysics, Chapter 4: Statics of A Rigid Body: Digitalcommons@University of Nebraska - LincolnLissa Hannah EtorNo ratings yet

- Norton M.P., Karczub D.G. Fundamentals of Noise and Vibration Analysis For Engineers (CUP, 2003) (ISBN 9780521495615) (O) (651s) - POsDocument651 pagesNorton M.P., Karczub D.G. Fundamentals of Noise and Vibration Analysis For Engineers (CUP, 2003) (ISBN 9780521495615) (O) (651s) - POsAnonymous LKUkoWqjo100% (2)

- Basic Ultrasonic TrainingDocument42 pagesBasic Ultrasonic TrainingAzrul HanifNo ratings yet

- Tensile Stress-Strain Behavior of Metallic Alloys: Transactions of Nonferrous Metals Society of China November 2017Document12 pagesTensile Stress-Strain Behavior of Metallic Alloys: Transactions of Nonferrous Metals Society of China November 2017nick amirNo ratings yet

- Jee Mains Previous Year Paper Class 12 Physics 2023 15 April Shift 1 Actual Doubtnut English Medium 2023 Web 3Document38 pagesJee Mains Previous Year Paper Class 12 Physics 2023 15 April Shift 1 Actual Doubtnut English Medium 2023 Web 3putinmodi3No ratings yet

- Application of FEA in Large Storage Tanks Shell Course RepairsDocument19 pagesApplication of FEA in Large Storage Tanks Shell Course Repairsabdelkader benabdallahNo ratings yet

- 1 ConductionDocument89 pages1 Conductionrahul prakashNo ratings yet

- Portal RuangDocument17 pagesPortal Ruangade azimaNo ratings yet

- 26-08-23 JR - Super60 Nucleus BT Jee-Main Wtm-06 Key & Sol'sDocument12 pages26-08-23 JR - Super60 Nucleus BT Jee-Main Wtm-06 Key & Sol'sSanthosh KasulavadhaNo ratings yet

- A5 - Transient Response Analysis (Analyst)Document43 pagesA5 - Transient Response Analysis (Analyst)Tomoyuki TadaNo ratings yet

- 15 Mark Essay Planner SheetDocument5 pages15 Mark Essay Planner SheetsuhaasNo ratings yet

- 02-Lignos EtAl-11NCEE ATC PaperRev1Document12 pages02-Lignos EtAl-11NCEE ATC PaperRev1faisaladeNo ratings yet

- Physics Investigatory: Young'S Double Split Experiment AND Effect of Diffraction in InterferenceDocument9 pagesPhysics Investigatory: Young'S Double Split Experiment AND Effect of Diffraction in InterferenceVarun Chaudhary50% (2)

- John Dirk Walecka - Introduction To Classical Mechanics-WSPC (2020)Document184 pagesJohn Dirk Walecka - Introduction To Classical Mechanics-WSPC (2020)Saiyad AliNo ratings yet

- Modern Physics PDFDocument20 pagesModern Physics PDFPrathm MittalNo ratings yet

- Design of Cyclone and Study of Its Performance Parameters: Research PaperDocument6 pagesDesign of Cyclone and Study of Its Performance Parameters: Research PaperManish VankudreNo ratings yet