Professional Documents

Culture Documents

3 Do Hyd

3 Do Hyd

Uploaded by

Le HoangOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3 Do Hyd

3 Do Hyd

Uploaded by

Le HoangCopyright:

Available Formats

Dissolved Oxygen & Hydrazine Monitoring On Power Plant

Introduction

Extensive on-line chemical monitoring of both the water/ steam cycle and water treatment plant on modern power stations is now a very well established practice. This enables careful control of the water chemistry, to achieve peak efficiency and minimise down time due to excessive boiler corrosion or scaling. The measurement of dissolved oxygen and hydrazine on boiler plants is vital if the plant is to run efficiently, and to be cost effective, with minimum down time. Even small quantities of dissolved oxygen in boiler water are capable of causing severe pitting in boilers of all pressures, and will reduce the boiler life dramatically. In boilers where high chloride levels exist, the effect of oxygen corrosion is increased. Therefore, the need to reduce dissolved oxygen content to a very low level is even more important. One of the properties of hydrazine is that it is an oxygen scavenger, and because of this, hydrazine is dosed into the boiler system to remove the remaining trace levels of dissolved oxygen. It is for this reason that the measurement of dissolved oxygen and hydrazine is imperative on power station plant.

TECHNICAL NOTE

This Technical Note points out typical sample points for on-line dissolved oxygen and hydrazine monitors found on power stations, and describes the information which the measurement provides.

What is Oxygen?

Oxygen is a colourless gas without smell or taste; it occurs in the free state as a gas and has the chemical formula O2. It is present in the atmosphere to the extent of 21% by volume and 23% by weight. Oxygen becomes a liquid of pale blue colour below a temperature of -183C, and is appreciably magnetic. Combined oxygen occurs in: water; vegetable tissues; animal tissues; nearly all rocks; and many metals. Oxygen is the most abundant element, occurring to a larger extent (about 50%) than any other, in the earth's crust. It is only sparingly soluble in water. Water which is fully air saturated contains approximately 10mg kg-1 of dissolved oxygen. In solution, oxygen is very corrosive to most metals, including mild steel used for boiler tubes.

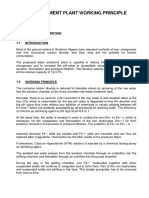

Superheated Steam

! Turbines @ Condenser Superheater Extractor Pump

Electrical Power Output Makeup Water

Cooling Water 4

Boiler 8 Boiler Tubes Chemical Dosing

Condensate Polishing Plant 5

Chemical Dosing

7 Feed Pump H-P Heater Deaerator

6 L-P Heater

Fig. 1 Typical Generating Station Steam/Water Cycle for a Once-through Boiler

ABB Instrumentation

1

Saturated Steam

Superheated Steam Electrical Power Output

Boiler Drum

Steam Water

Turbines Makeup Water @ Super Heater Economiser Condenser Condensate Extractor Pump 4 Cooling Water Chemical Dosing

Boiler Tubes Blowdown

Boiler Chemical Dosing

7 Feed Pump H-P Heater Deaerator

6 L-P Heater

Fig. 2 Typical Generating Station Steam/Water Cycle for a Drum Boiler

What is hydrazine?

Hydrazine is a colourless liquid which boils at 113C and is very soluble in water. It is not a naturally occurring substance, and being a compound of nitrogen and hydrogen, it has the chemical formula N2H4. It is a powerful reducing agent and will reduce oxygen to form nitrogen and water as follows: N2H4 + O2 N2 = 2H2O At high temperature and pressure, ammonia is also formed, which increases the feedwater pH level, reducing the risk of acidic corrosion. Hydrazine also reacts with soft haematite layers on the boiler tubes and forms a hard magnetite layer, which subsequently protects the boiler tubes from further corrosion. This occurs as a result of the chemical reaction: N2H4 + 6Fe2O3 4Fe3O4 + N2 + 2H2O

6 / 7 De-aerator inlet/outlet

Dissolved oxygen levels in the condensate and in the make-up water will be higher than acceptable. The mixture of condensate and added make-up water is pumped into the aerator, which heats the water, under vacuum, and thus removes most of the dissolved oxygen. The deaerator inlet and outlet are monitored for dissolved oxygen to check the efficiency of the de-aerator, as to whether it has developed any leaks through its casing, glands, fittings etc.

8 Economiser Inlet (Boiler Feed); Boiler Inlet (Once Through Boilers)

The boiler feedwater is dosed with hydrazine as an oxygen scavenger. To monitor the effectiveness of the hydrazine dosing, a dissolved oxygen monitor is placed at the economiser inlet. This is to check that acceptable levels of dissolved oxygen have been removed (normally to below 5gkg-1). A hydrazine monitor is also placed at the economiser inlet to check that the feedwater is being dosed with the correct amount of hydrazine. Too much hydrazine is wasteful and costly; too little hydrazine will result in higher amounts of dissolved oxygen passing into the boiler, causing corrosion, and inhibiting the formation of magnetite. Typically, the most effective dosage of hydrazine is 3:1 parts hydrazine to the expected level of dissolved oxygen.

Sample Points

The typical sample points for chemical monitoring are as shown in Fig. 1. Details of specific sample points where dissolved oxygen and hydrazine monitoring is carried out are as follows:

4 Extraction Pump Discharge

The extraction pump, which operates under a vacuum, draws water out of the condenser. By monitoring the dissolved oxygen levels at the extraction pump discharge, oxygen ingress via extraction pump glands or condenser leaks can be monitored. Technical Support Department October 1997

ABB Instrumentation

2

You might also like

- Boiler Water TreatmentDocument1 pageBoiler Water TreatmentRommel Cena Nepalar100% (1)

- 4 - Silica in BoilerDocument3 pages4 - Silica in BoilerKrishnan ManiNo ratings yet

- Super Critical Boiler TechnologyDocument22 pagesSuper Critical Boiler TechnologySurendar Perumal100% (1)

- Boiler EfficiencyDocument24 pagesBoiler EfficiencyAmit ChauhanNo ratings yet

- Report #1: Alternating-Current Project: Steam-Electric Power PlantDocument41 pagesReport #1: Alternating-Current Project: Steam-Electric Power PlantKian TecsonNo ratings yet

- U4OHREPORT2008Document88 pagesU4OHREPORT2008Anonymous pKsr5vNo ratings yet

- Boiler ConstructionDocument4 pagesBoiler ConstructionrpshvjuNo ratings yet

- History of Thermal Power PlantsDocument9 pagesHistory of Thermal Power PlantsAnonymous gr5Pr9AV100% (1)

- Steam TurbineDocument46 pagesSteam TurbineIbrahim Mostafa67% (3)

- Training ReportPDF PDFDocument42 pagesTraining ReportPDF PDFAman Raj100% (1)

- Salaya PowerDocument30 pagesSalaya Powersridharchowdary349No ratings yet

- Cold-Start Up of Coal Fired PowerplantsDocument6 pagesCold-Start Up of Coal Fired PowerplantsAbdulyunus AmirNo ratings yet

- Ramgarh Gas and Thermal Power Plant Jaisalmer RajastahnDocument20 pagesRamgarh Gas and Thermal Power Plant Jaisalmer RajastahnSaradeen KhanNo ratings yet

- Bottom Ash Hopper CollectionsDocument11 pagesBottom Ash Hopper Collectionsatgsganesh0% (1)

- Draught System Gyanendra Sharma NPTI DelhiDocument24 pagesDraught System Gyanendra Sharma NPTI DelhiNPTI100% (1)

- SUPER CRITICAL BOILER (660 MW) at PROJECTDocument53 pagesSUPER CRITICAL BOILER (660 MW) at PROJECTWahedali SayyedNo ratings yet

- Condensate Extraction Pump: GeneralDocument5 pagesCondensate Extraction Pump: GeneralAnonymous DKv8vpNo ratings yet

- Project Report On Rihand STPP Stage-II 2x500mwDocument175 pagesProject Report On Rihand STPP Stage-II 2x500mwSathesh ThangathuraiNo ratings yet

- U#2 Oh Report 2003Document45 pagesU#2 Oh Report 2003Sony RamaNo ratings yet

- Boiler Cleaning Technologies - Water Lance VsDocument3 pagesBoiler Cleaning Technologies - Water Lance VsDSGNo ratings yet

- Thermal Power PlantDocument13 pagesThermal Power PlantSanat KumarNo ratings yet

- Tds Contro Heat RecoverylDocument31 pagesTds Contro Heat RecoverylHélder PascoalNo ratings yet

- Monitoring Update Defect UPDATEDocument268 pagesMonitoring Update Defect UPDATEGita RushenantoNo ratings yet

- ME6701-Power Plant EngineeringDocument16 pagesME6701-Power Plant EngineeringNizam MANo ratings yet

- Bi-Drum Vs Single Drum - Research Paper 2Document6 pagesBi-Drum Vs Single Drum - Research Paper 2Parth Merchant100% (1)

- Report On Boiler Performance Audting in A Paper Plant by K.K.parthibanDocument129 pagesReport On Boiler Performance Audting in A Paper Plant by K.K.parthibanparthi20065768No ratings yet

- Extraction Flow Calculation by IterationDocument6 pagesExtraction Flow Calculation by Iterationarunrajmech09No ratings yet

- Emergency Operations: Shaikh Feroz AliDocument15 pagesEmergency Operations: Shaikh Feroz AliEXECUTIVE ENGINEEER BOILER MAINTENANCENo ratings yet

- Coal MillDocument6 pagesCoal MillAnonymous NxpnI6jCNo ratings yet

- Steam TurbineDocument58 pagesSteam TurbineJoy Prokash RoyNo ratings yet

- 660 MW Sipat BoilerDocument88 pages660 MW Sipat BoilerKrishnan Santhanaraj100% (3)

- Balance of Plant DetailsDocument11 pagesBalance of Plant Detailskvrao44No ratings yet

- Basics of Thermal Power PlantDocument119 pagesBasics of Thermal Power Plantsiva7448163No ratings yet

- Question & Answers On Steam TurbinesDocument37 pagesQuestion & Answers On Steam TurbinesManbkk Bkk100% (1)

- Boiler EfficiencyDocument28 pagesBoiler EfficiencyRintu BiswasNo ratings yet

- Once Through and Drum Type Boiler Designs ComparedDocument3 pagesOnce Through and Drum Type Boiler Designs ComparedagusfaizinNo ratings yet

- HP Heaters Operation During Start Up of UnitDocument1 pageHP Heaters Operation During Start Up of UnitMuhammad luqman100% (1)

- Water Treatment Plant Working PrincipleDocument2 pagesWater Treatment Plant Working PrincipleTosin Opawole100% (1)

- Power Plant Combustion TheoreyDocument6 pagesPower Plant Combustion TheoreySaiVenkat0% (1)

- Furnace Explosion in CFBC BoilersDocument6 pagesFurnace Explosion in CFBC BoilersHardik Kumar MendparaNo ratings yet

- Stopping of One Pa FanDocument1 pageStopping of One Pa FanShift Incharge BrbclNo ratings yet

- High Thrust Bearing Temperature of Centrifugal Compressor 1701931178Document21 pagesHigh Thrust Bearing Temperature of Centrifugal Compressor 1701931178Talha Aamir100% (1)

- Boiler Types and ClassificationsDocument26 pagesBoiler Types and ClassificationshardikNo ratings yet

- ME LAB MANUAL RevisedDocument64 pagesME LAB MANUAL RevisedClint Baring ArranchadoNo ratings yet

- Boe (Boiler Operation Engineer) Short Type Question Answer-3 For Examination - AskpowerplantDocument14 pagesBoe (Boiler Operation Engineer) Short Type Question Answer-3 For Examination - AskpowerplantRaju Maity100% (1)

- National Power Training Institute New Delhi: B. TechDocument14 pagesNational Power Training Institute New Delhi: B. TechAditya Pandey100% (1)

- An Introduction To Condensate PolishingDocument10 pagesAn Introduction To Condensate PolishingclesncronNo ratings yet

- Fluid Mechanics NotesDocument12 pagesFluid Mechanics Notessubha_aeroNo ratings yet

- 57-62 1m809 - Eng72dpiDocument6 pages57-62 1m809 - Eng72dpiAbhinav TewariNo ratings yet

- DEH ManualDocument28 pagesDEH ManualErfan AhmedNo ratings yet

- BCP Installation & CommissioningDocument18 pagesBCP Installation & CommissioningKrishnan Santhanaraj100% (1)

- Power Plant-1Document32 pagesPower Plant-1marlito100% (1)

- Condition Based Maintenance of Pumps PDFDocument22 pagesCondition Based Maintenance of Pumps PDFumair saleemNo ratings yet

- Nalco Captive Power Plant: Presented by Swaraj Kumar Swain RA1711002010065Document26 pagesNalco Captive Power Plant: Presented by Swaraj Kumar Swain RA1711002010065Swaraj kumar SwainNo ratings yet

- Deaeration Process: Deaeration Is The Process of Removal of Oxygen, Carbon Dioxide and Other NonDocument5 pagesDeaeration Process: Deaeration Is The Process of Removal of Oxygen, Carbon Dioxide and Other NonGovindarajan Chandrasekaran100% (1)

- Heat Rate of TG PDFDocument9 pagesHeat Rate of TG PDFTapash Nag0% (1)

- TP UreaDocument7 pagesTP UreawaqasNo ratings yet

- Aquatherm Hot Water GeneratorDocument2 pagesAquatherm Hot Water GeneratorNakul AhirraoNo ratings yet

- 01 SteamTurbinePPDocument35 pages01 SteamTurbinePPMd. Aseer Jawad Chowdhury Enan100% (2)

- Brochure Power Industry EN WebDocument32 pagesBrochure Power Industry EN Websudheer kumarNo ratings yet

- Corruption Ecological: Rio-Empty-SeatsDocument5 pagesCorruption Ecological: Rio-Empty-SeatsAnonymous 3HTgMDONo ratings yet

- Ecof 1Document27 pagesEcof 1Anonymous 3HTgMDONo ratings yet

- Keda's SAP ImplementationDocument1 pageKeda's SAP ImplementationAnonymous 3HTgMDONo ratings yet

- Keda's SAP ImplementationDocument1 pageKeda's SAP ImplementationAnonymous 3HTgMDONo ratings yet

- RiskFactorsERPSumner PDFDocument12 pagesRiskFactorsERPSumner PDFAnonymous 3HTgMDONo ratings yet

- Alpha For Directional Test (1-Tailed) Alpha For Non-Directional Test (2-Tailed)Document1 pageAlpha For Directional Test (1-Tailed) Alpha For Non-Directional Test (2-Tailed)Anonymous 3HTgMDONo ratings yet

- RiskFactorsERPSumner PDFDocument12 pagesRiskFactorsERPSumner PDFAnonymous 3HTgMDONo ratings yet

- Planetary Gear Ratio CalculationsDocument5 pagesPlanetary Gear Ratio CalculationsAnonymous 3HTgMDO100% (1)

- Boiler Efficiency: Heat Input Is Pulverised Coal Heat Output Is Superheated SteamDocument21 pagesBoiler Efficiency: Heat Input Is Pulverised Coal Heat Output Is Superheated SteamAnonymous 3HTgMDONo ratings yet

- Power-to-X - WikipediaDocument5 pagesPower-to-X - Wikipediapowew28978No ratings yet

- Safety Data Sheet CB-9099: 1. Product and Company IdentificationDocument6 pagesSafety Data Sheet CB-9099: 1. Product and Company IdentificationJust Rysdan0% (1)

- Glow Discharge Mass Spectrometry Gdms Services TN102Document2 pagesGlow Discharge Mass Spectrometry Gdms Services TN102Johnny B. BaddNo ratings yet

- CHE4350 Lab Manual S12Document99 pagesCHE4350 Lab Manual S12DesmondNo ratings yet

- Gate 2003 2017 Papers Solved PDFDocument445 pagesGate 2003 2017 Papers Solved PDFraghavNo ratings yet

- Tea and Herbal InfusionsDocument10 pagesTea and Herbal InfusionsNada PetrovićNo ratings yet

- Ice CreemDocument28 pagesIce CreemVinay MorganNo ratings yet

- 12 Oil and Gas SeparatorsDocument44 pages12 Oil and Gas SeparatorsGadhoumiWalidNo ratings yet

- Sae J526 PDFDocument1 pageSae J526 PDFkoalaboiNo ratings yet

- Lab Manual FRS581Document5 pagesLab Manual FRS581Nur Atiqah AhmadNo ratings yet

- Basics of Energy and Its Various FormsDocument7 pagesBasics of Energy and Its Various FormszohaibNo ratings yet

- Catalytic Oxidation Techology - Sud Chemie (Very Good)Document25 pagesCatalytic Oxidation Techology - Sud Chemie (Very Good)daraj darajNo ratings yet

- Chemistry Project To Study The Quantity of Caesin in MilkDocument4 pagesChemistry Project To Study The Quantity of Caesin in MilkAbhishek Kohli100% (1)

- Vapour Phase Grown Carbon FibreDocument3 pagesVapour Phase Grown Carbon FibreJOGHEE MANIVANNANNo ratings yet

- Daikin VRV SelectionDocument61 pagesDaikin VRV SelectionAshok100% (1)

- Cryo-SFM: Instruction ManualDocument1 pageCryo-SFM: Instruction Manualவேல் முருகன்No ratings yet

- Daily InventoryDocument3 pagesDaily InventoryGrace SevillaNo ratings yet

- Rod Mcconnell: Chemical Engineering DegreeDocument15 pagesRod Mcconnell: Chemical Engineering Degreeslamet suryantoNo ratings yet

- Daftar Nama Obat Dan BHP Yang Telah Kadaluwarsa Di PKM Daieko NO Nama Obat Satuan Jumlah Tanggal Kadaluwarsa Tanggal Produksi No. Batch Nama PabrikDocument4 pagesDaftar Nama Obat Dan BHP Yang Telah Kadaluwarsa Di PKM Daieko NO Nama Obat Satuan Jumlah Tanggal Kadaluwarsa Tanggal Produksi No. Batch Nama PabrikCitraNo ratings yet

- Separating Mixtures Exam QuestionsDocument35 pagesSeparating Mixtures Exam QuestionsMichael WestNo ratings yet

- SS215 - Symphony of The Soil Reaction PaperDocument4 pagesSS215 - Symphony of The Soil Reaction PaperJustien Nixon TangpuzNo ratings yet

- BIOLS 404 Lab ManualDocument25 pagesBIOLS 404 Lab ManualGhufran MatooqNo ratings yet

- Simple Methods For Determination of The Release Limits For Drug ProductsDocument13 pagesSimple Methods For Determination of The Release Limits For Drug Productslhthang1990No ratings yet

- Chapter 10 Planetary Atmospheres: Earth and The Other Terrestrial WorldsDocument27 pagesChapter 10 Planetary Atmospheres: Earth and The Other Terrestrial WorldsEdwin ChuenNo ratings yet

- Mek Motor BMP KMDocument8 pagesMek Motor BMP KMVenkatarama KrishnanNo ratings yet

- A ReviewDocument17 pagesA ReviewkanomasiNo ratings yet

- Effect of Mixed Starters On Proteolysis and Formation of Biogenic Amines in Dry Fermented Mutton SausagesDocument15 pagesEffect of Mixed Starters On Proteolysis and Formation of Biogenic Amines in Dry Fermented Mutton SausagesRoberto DegenhardtNo ratings yet

- Recent Developments in Reactive Dyes: John TaylorDocument16 pagesRecent Developments in Reactive Dyes: John TaylorNakib Ibna BasharNo ratings yet

- Effect of Physico-Chemical Properties of Drug On AbsorptionDocument37 pagesEffect of Physico-Chemical Properties of Drug On AbsorptionnoamaliaNo ratings yet

- Pharmaceutical Calculation Lecture-4 Isotonic Solution: Assist. Prof. Dr. Wedad K. AliDocument20 pagesPharmaceutical Calculation Lecture-4 Isotonic Solution: Assist. Prof. Dr. Wedad K. AliKarren ReyesNo ratings yet