Professional Documents

Culture Documents

0.25 In. Min. 1:3 Max. Slope 0.25 In. Min

Uploaded by

Panchal ShaileshOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

0.25 In. Min. 1:3 Max. Slope 0.25 In. Min

Uploaded by

Panchal ShaileshCopyright:

Available Formats

ASME B16.

5-2003

ANNEX F

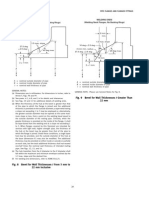

WELDING ENDS (Welding Neck Flanges, No Backing Rings)

WELDING ENDS (Welding Neck Flanges, No Backing Rings)

0.25 in. min.

0.25 in. min.

1:3 max. slope

1:3 max. slope

37.5 deg 2.5 deg

t

10 deg 2.5 deg

45 deg max.

0.12 R min. radius 37.5 deg 2.5 deg

t

3/ 4

45 deg max.

in.

0.06 in. 0.03

0.06 0.03

A

A p nominal outside diameter of pipe B p nominal inside diameter of pipe t p nominal wall thickness of pipe GENERAL NOTES: (a) Dimensions are in inches. For dimensions in millimeters, refer to Figs. 8 and 9. (b) See paras. 6.7, 6.8, and 7.4 for details and tolerances. (c) See Figs. F10 and F11 for additional details of welding ends. (d) When the thickness of the hub at the bevel is greater than that of the pipe to which the flange is joined and the additional thickness is provided on the outside diameter, a taper weld having a slope not exceeding 1 to 3 may be employed or, alternatively, the greater outside diameter may be tapered at the same maximum slope or less, from a point on the welding bevel equal to the outside diameter of the mating pipe. Similarly, when the greater thickness is provided on the inside of the flange, it shall be taper-bored from the welding end at a slope not exceeding 1 to 3. When flanges covered by this Standard are intended for services with light wall, higher strength pipe, the thickness of the hub at the bevel may be greater than that of the pipe to which the flange is joined. Under these conditions, a single taper hub may be provided, and the outside diameter of the hub at the base (dimension X ) may also be modified. The additional thickness may be provided on either inside or outside or partially on each side, but the total additional thickness shall not exceed one-half times the nominal wall thickness of intended mating pipe. See Figs. 12, 13, and 14. (e) The hub transition from the A diameter to the X diameter shall fall within the maximum and minimum envelope outlined by the 1:3 max. slope and the dashed line. (f) For welding end dimensions, refer to ASME B16.25

A p nominal outside diameter of pipe B p nominal inside diameter of pipe t p nominal wall thickness of pipe GENERAL NOTE: Please see General Notes for Fig. F8.

Fig. F9 Bevel for Wall Thicknesses t Greater Than 0.88 in.

Fig. F8 Bevel for Wall Thicknesses t from 0.19 in. to 0.88 in. Inclusive

116

You might also like

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Specifying Bolt Length For High-Strength Bolts: Manual of Steel ConstructionDocument12 pagesSpecifying Bolt Length For High-Strength Bolts: Manual of Steel Constructionpreds1717No ratings yet

- Spreadsheet For Design of Concrete PipesDocument12 pagesSpreadsheet For Design of Concrete PipesAli Akbar67% (3)

- Quick ReferenceDocument32 pagesQuick ReferenceManoj RautNo ratings yet

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsFrom EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNo ratings yet

- Pipe Sizing and CalculationsDocument17 pagesPipe Sizing and CalculationsJaykumar100% (6)

- SPREADSHEETS SERIES No. 0009S - 2Document4 pagesSPREADSHEETS SERIES No. 0009S - 2Emma DNo ratings yet

- Branch RF CalcDocument6 pagesBranch RF CalcHarish Harish0% (1)

- Unit 7 (DESIGN DETAILS OF BEAMS)Document35 pagesUnit 7 (DESIGN DETAILS OF BEAMS)Zara Nabilah94% (16)

- Branch Reinforcement Pad Requirement CalculationDocument1 pageBranch Reinforcement Pad Requirement Calculations.mladinNo ratings yet

- Sif B31 3Document24 pagesSif B31 3vuqar0979100% (1)

- A L F I: Cceptance Imit OR MperfectionsDocument29 pagesA L F I: Cceptance Imit OR MperfectionsDavid MacatangayNo ratings yet

- Pipe Thickness Calculation Internal Pressure Design Thickness As Per ASME B313Document7 pagesPipe Thickness Calculation Internal Pressure Design Thickness As Per ASME B313mohamed samyNo ratings yet

- Connection Design - Its Role in Steel DetailingDocument9 pagesConnection Design - Its Role in Steel DetailingEduardo De Castro Cruz Jr.No ratings yet

- Branch Reinforcement Pad Requirement CalculationDocument2 pagesBranch Reinforcement Pad Requirement CalculationAntoshal100% (4)

- API 570 Day 2 Book (1 To 51)Document65 pagesAPI 570 Day 2 Book (1 To 51)AbdulQuddus100% (3)

- Column SplicesDocument3 pagesColumn Spliceseric bargasNo ratings yet

- 06c PDFDocument29 pages06c PDFProcess EngineerNo ratings yet

- Pipe Support SpanDocument3 pagesPipe Support Spanabhishek gorkarNo ratings yet

- Development LengthDocument22 pagesDevelopment LengthAlok MamNo ratings yet

- API 5L Line Pipes Wall Thickness Outside Diameter Tolerance - Stainless SteeDocument2 pagesAPI 5L Line Pipes Wall Thickness Outside Diameter Tolerance - Stainless Steewilxj100% (1)

- Sif B31 3Document10 pagesSif B31 3Sergio SmithNo ratings yet

- Acceptance Criteria of Weld Defects As Per Different CodesDocument17 pagesAcceptance Criteria of Weld Defects As Per Different CodesNavanitheeshwaran Sivasubramaniyam100% (3)

- 2007 03 Piping Design, Part 2 - FlangesDocument6 pages2007 03 Piping Design, Part 2 - FlangeskglorstadNo ratings yet

- Connections and Tension Member DesignDocument9 pagesConnections and Tension Member DesignVigneshwari MahamuniNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- DIN-2605-2-95 StandartDocument9 pagesDIN-2605-2-95 StandartGürolNo ratings yet

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- 6 MM Min. 1:3 Max. Slope 6 MM MinDocument1 page6 MM Min. 1:3 Max. Slope 6 MM MinPanchal ShaileshNo ratings yet

- Unequal Wall ThicknessDocument1 pageUnequal Wall ThicknessChamseddine MerdasNo ratings yet

- ASME B16.9 2007 (Metric Dimensions)Document16 pagesASME B16.9 2007 (Metric Dimensions)Joseph CruzNo ratings yet

- Ibr BookDocument33 pagesIbr BookRaja JayachandranNo ratings yet

- Notes To Table F11Document1 pageNotes To Table F11Panchal ShaileshNo ratings yet

- Structural Design of Reinforcements For Fittings in Factory-Made Corrugated Steel Pipe For Sewers and Other ApplicationsDocument18 pagesStructural Design of Reinforcements For Fittings in Factory-Made Corrugated Steel Pipe For Sewers and Other ApplicationsAleksei AvilaNo ratings yet

- Rebar Tables BS 8666:2005:: User GuideDocument4 pagesRebar Tables BS 8666:2005:: User GuideDushyantNo ratings yet

- Unit 2 Design of Boiler Revited JointDocument7 pagesUnit 2 Design of Boiler Revited Jointaditya.1540011No ratings yet

- PipelineDocument3 pagesPipelineKrystle FlowersNo ratings yet

- Specifying Bolt Length For High-Strength Bolts: Manual of Steel ConstructionDocument12 pagesSpecifying Bolt Length For High-Strength Bolts: Manual of Steel ConstructionalbertoxinaNo ratings yet

- USD T BeamDocument10 pagesUSD T BeammanowarNo ratings yet

- 3Document8 pages3Muhammad HannanNo ratings yet

- 5 6327619470013497828Document6 pages5 6327619470013497828shaijukvNo ratings yet

- ACI Concrete Beam DetailingDocument12 pagesACI Concrete Beam DetailingShaik Eliyas BashaNo ratings yet

- 7 - Analysis and Design of T-BeamsDocument16 pages7 - Analysis and Design of T-BeamsgarhgelhNo ratings yet

- Branch Reinforcement CalcDocument2 pagesBranch Reinforcement CalcNisarg PandyaNo ratings yet

- 171CE113-bolted ConnectionDocument9 pages171CE113-bolted ConnectionARJUN RNo ratings yet

- ANSI B16.5 Flange ToleranceDocument2 pagesANSI B16.5 Flange TolerancevmrameshbeNo ratings yet

- Heat Exchanger PTR Day2Document2 pagesHeat Exchanger PTR Day2siraj.hoteccNo ratings yet

- Free English GrammarDocument20 pagesFree English GrammarrajeshNo ratings yet

- TRTRTRDocument2 pagesTRTRTRazhagu duraiNo ratings yet

- D D D W D D L: Reinforcing PlateDocument6 pagesD D D W D D L: Reinforcing PlateMohamed RjebNo ratings yet

- Asme Sec Viii D1 Ma App 2 Part2 PDFDocument21 pagesAsme Sec Viii D1 Ma App 2 Part2 PDFjuanfco1965No ratings yet

- Piping FormulaeDocument9 pagesPiping FormulaeVashish RamrechaNo ratings yet

- MixtureDocument12 pagesMixtureNaseer Ahmed SokhalNo ratings yet

- 11 - Concrete Flexural DesignDocument20 pages11 - Concrete Flexural Designa2508401No ratings yet

- Jis G3455 PDFDocument12 pagesJis G3455 PDFhbookNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Sec-I 139Document1 pageSec-I 139Panchal ShaileshNo ratings yet

- Table Pw-39 Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and Attachments (Conrd)Document1 pageTable Pw-39 Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and Attachments (Conrd)Panchal ShaileshNo ratings yet

- Sec-I 132Document1 pageSec-I 132Panchal ShaileshNo ratings yet

- Table Pw-39 Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and Attachments (Coiijt'D)Document1 pageTable Pw-39 Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and Attachments (Coiijt'D)Panchal ShaileshNo ratings yet

- Sec-I 136Document1 pageSec-I 136Panchal ShaileshNo ratings yet

- Table Pw-39 (Cont'D) Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and AttachmentsDocument1 pageTable Pw-39 (Cont'D) Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and AttachmentsPanchal ShaileshNo ratings yet

- Sec-I 140Document1 pageSec-I 140Panchal ShaileshNo ratings yet

- Sec-I 138Document1 pageSec-I 138Panchal ShaileshNo ratings yet

- Sec-I 133Document1 pageSec-I 133Panchal ShaileshNo ratings yet

- Sec-I 128Document1 pageSec-I 128Panchal ShaileshNo ratings yet

- Sec-I 130Document1 pageSec-I 130Panchal ShaileshNo ratings yet

- FIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Cont'D)Document1 pageFIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Cont'D)Panchal ShaileshNo ratings yet

- Sec-I 131Document1 pageSec-I 131Panchal ShaileshNo ratings yet

- Sec-I 129Document1 pageSec-I 129Panchal ShaileshNo ratings yet

- Sec-I 126Document1 pageSec-I 126Panchal ShaileshNo ratings yet

- Sec-I 127Document1 pageSec-I 127Panchal ShaileshNo ratings yet

- Sec-I 121Document1 pageSec-I 121Panchal ShaileshNo ratings yet

- Sec-I 119Document1 pageSec-I 119Panchal ShaileshNo ratings yet

- Sec-I 116Document1 pageSec-I 116Panchal ShaileshNo ratings yet

- FIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Co NT'D)Document1 pageFIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Co NT'D)Panchal ShaileshNo ratings yet

- FIG. PW-19.4 (A) Some Acceptable Types of Diagonal Braces For Installation by WeldingDocument1 pageFIG. PW-19.4 (A) Some Acceptable Types of Diagonal Braces For Installation by WeldingPanchal ShaileshNo ratings yet

- FIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Cot/Inections To Shells, Drums, and HeadersDocument1 pageFIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Cot/Inections To Shells, Drums, and HeadersPanchal ShaileshNo ratings yet

- FIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Cont'D)Document1 pageFIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Cont'D)Panchal ShaileshNo ratings yet

- Design: FIG. PW-9.1 Butt Welding of Plates of Unequal Thici NessDocument1 pageDesign: FIG. PW-9.1 Butt Welding of Plates of Unequal Thici NessPanchal ShaileshNo ratings yet

- Sec-I 112Document1 pageSec-I 112Panchal ShaileshNo ratings yet

- Sec-I 114Document1 pageSec-I 114Panchal ShaileshNo ratings yet

- Sec-I 117Document1 pageSec-I 117Panchal ShaileshNo ratings yet

- FIG. PW-15 Examples of Weld Strength Calculations: 2007 Section IDocument1 pageFIG. PW-15 Examples of Weld Strength Calculations: 2007 Section IPanchal ShaileshNo ratings yet

- Manufacturer'S Data Report Forms: 2007 Section IDocument1 pageManufacturer'S Data Report Forms: 2007 Section IPanchal ShaileshNo ratings yet

- Sec-I 113Document1 pageSec-I 113Panchal ShaileshNo ratings yet