Professional Documents

Culture Documents

Amrutvahini Polytechnic, Sangamner: Subject: Design of Machine Elements

Uploaded by

Keshav AroteOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Amrutvahini Polytechnic, Sangamner: Subject: Design of Machine Elements

Uploaded by

Keshav AroteCopyright:

Available Formats

Roll No.

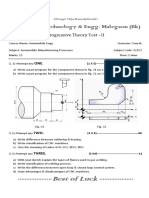

12241 Amrutvahini Polytechnic, Sangamner

UNIT TEST 1 Course: ME 6E (A& B) (2012-13)

Subject: Design of Machine Elements

Max.Marks: 25 Marks Instructions: 1) Use appropriate data if necessary. 2) Figures to right indicate full marks. Q.1 Attempt any three from the following a) Explain steps in design procedure. b) Explain the term stress concentration with its minimum two remedies. c) State four Types of theories of elastic failure and explain any one. d) Explain Wahls Stress factor. Q.2 Attempt any two from the following (2X4= 8 marks) (3X3= 9 marks) Time: 01.30 Hr

-----------------------------------------------------------------------------------------------------

a) For a square key equally strong in shearing and crushing , show that the permissible crushing stress is twice the shear stress. b) Explain Endurance limit and draw typical S-N curve for steel. c) A cast iron protective type flange coupling for a steel shaft is used for transmitting 20 kw at 250 rpm. Design i) Hub ii)Flange if following permissible stresses are used Shear stress for shaft material 40MPa, Shear stress for cast iron 15MPa. Q.3 Attempt any two from the following a) Differentiate between Solid and Hollow Shaft. ( Minimum 4 points) b) Explain Leaf spring with neat sketch. c) Design a compression Heliacal valve spring with square and ground ends for load range 80N-145 N.The axial deflection of the spring is 6.5 mm. Spring index is 8. Permissible shear stress 380 Mpa, Take Design stress 25% excess of permissible stress. (2X4= 8 marks)

You might also like

- B.Tech. Degree Examination Civil Engineering: (EURCE-501)Document3 pagesB.Tech. Degree Examination Civil Engineering: (EURCE-501)Rajeev BujjiNo ratings yet

- Eurme 505 OkDocument2 pagesEurme 505 OksaitejaNo ratings yet

- SMA Quiz-I Solution 5Document2 pagesSMA Quiz-I Solution 5Kumar KartikeyNo ratings yet

- Computer OrganizationDocument2 pagesComputer OrganizationGirish KotraNo ratings yet

- Me 304 (Material Science)Document2 pagesMe 304 (Material Science)Sri KayNo ratings yet

- B. Tech. Degree Examination Cse & It: (Nov-12) (EURCS-304/EURIT-304)Document2 pagesB. Tech. Degree Examination Cse & It: (Nov-12) (EURCS-304/EURIT-304)sahsNo ratings yet

- MCA Degree Examination: (Nov-14) (SPRCA-305A)Document2 pagesMCA Degree Examination: (Nov-14) (SPRCA-305A)sharmilakoraiNo ratings yet

- Question Papers of Two Year M. Tech I Semester Regular Examinations April - 2012Document29 pagesQuestion Papers of Two Year M. Tech I Semester Regular Examinations April - 2012mdphilipNo ratings yet

- Fem Question PaperDocument4 pagesFem Question PaperARSNo ratings yet

- M.E. (Mechanical) (Automotive Engineering) Finite Element Method (2010 Course) (502302 (B) ) (Elective - I)Document1 pageM.E. (Mechanical) (Automotive Engineering) Finite Element Method (2010 Course) (502302 (B) ) (Elective - I)suyogbhaveNo ratings yet

- ada 2023 (1)Document3 pagesada 2023 (1)Chaitanya JagarwalNo ratings yet

- Modern Control Theory Exam Questions NR/R09Document3 pagesModern Control Theory Exam Questions NR/R09IbmWasuserNo ratings yet

- Previous Question Papers For Four Year B. Tech I Semester Regular Examinations February 2012Document20 pagesPrevious Question Papers For Four Year B. Tech I Semester Regular Examinations February 2012prasaad08No ratings yet

- Eurec 606Document2 pagesEurec 606haziqhazriNo ratings yet

- 2016-1 Advanced Automatic Control Final Exam PDFDocument2 pages2016-1 Advanced Automatic Control Final Exam PDFIslam Saqr67% (3)

- B.Tech. Degree Examination: (EUREE-604A)Document3 pagesB.Tech. Degree Examination: (EUREE-604A)Parupally Bharath ChowdaryNo ratings yet

- CNC Lathe and Milling Programs for Automobile PartsDocument1 pageCNC Lathe and Milling Programs for Automobile PartsPramod DhaigudeNo ratings yet

- Image Processing Exam QuestionsDocument2 pagesImage Processing Exam QuestionsyaswanthNo ratings yet

- Metal Forming TechniquesDocument2 pagesMetal Forming Techniquesdeepu1009No ratings yet

- B.Tech. Degree Examination Mechanical Engineering: (Nov-11) (EURME-302)Document2 pagesB.Tech. Degree Examination Mechanical Engineering: (Nov-11) (EURME-302)JayPhaneendraNo ratings yet

- Techno NJR Institute of TechnologyDocument4 pagesTechno NJR Institute of TechnologyIrfanNo ratings yet

- Optimization Techniques Apr2011Document2 pagesOptimization Techniques Apr2011avinash_k007No ratings yet

- Department of Mechatronics Engineering Unit Test-IIDocument1 pageDepartment of Mechatronics Engineering Unit Test-IIKannanNo ratings yet

- Best of Luck: Institute of Technology & Engg. Malegaon (BK)Document1 pageBest of Luck: Institute of Technology & Engg. Malegaon (BK)Pramod DhaigudeNo ratings yet

- B.Tech Database Management Systems Exam QuestionsDocument2 pagesB.Tech Database Management Systems Exam QuestionsAvijoy SircarNo ratings yet

- Department of Mechatronics Engineering Unit Test-IDocument1 pageDepartment of Mechatronics Engineering Unit Test-IKannanNo ratings yet

- PR 2303Document4 pagesPR 2303Karthik Srinivas0% (1)

- CNC Lathe and Milling Machine Part Programs for Automobile ComponentsDocument1 pageCNC Lathe and Milling Machine Part Programs for Automobile ComponentsPramod DhaigudeNo ratings yet

- Optimization Techniques - Oct 2011-1Document2 pagesOptimization Techniques - Oct 2011-1avinash_k007No ratings yet

- OT I Test IIDocument3 pagesOT I Test IIRobertBellarmineNo ratings yet

- IE 312 First Quiz (45 MIN) : QuestionDocument4 pagesIE 312 First Quiz (45 MIN) : QuestionthienmakbNo ratings yet

- Exam Roll No. MCA Operating Systems ExamDocument2 pagesExam Roll No. MCA Operating Systems ExampraveenNo ratings yet

- Optimization Techniques Exam QuestionsDocument1 pageOptimization Techniques Exam QuestionsDeepak AgrawalNo ratings yet

- IE AssignmentDocument2 pagesIE Assignment200110039No ratings yet

- Here are the answers to the multiple choice questions on machine tools:1. A2. C 3. B4. C5. A6. B7. D8. B9. A10. B11. D12. A13. B14. D15. C16. FalseDocument80 pagesHere are the answers to the multiple choice questions on machine tools:1. A2. C 3. B4. C5. A6. B7. D8. B9. A10. B11. D12. A13. B14. D15. C16. FalseAdinath DhamdhereNo ratings yet

- Monthly Test Question Paper Manufacturing ProcessDocument1 pageMonthly Test Question Paper Manufacturing ProcessKailas Sree ChandranNo ratings yet

- NCRD's Sterling Institute of Management Studies, Nerul, Navi MumbaiDocument11 pagesNCRD's Sterling Institute of Management Studies, Nerul, Navi MumbaiAditya DetheNo ratings yet

- Answer The Following Questions: Best WishesDocument1 pageAnswer The Following Questions: Best WishesAbdelhay Mohamed HassanNo ratings yet

- Ot I II Int (2 Pages)Document3 pagesOt I II Int (2 Pages)RobertBellarmineNo ratings yet

- Engineering and Managerial Economics EHU-501Document2 pagesEngineering and Managerial Economics EHU-501Anonymous kj9KW15CQnNo ratings yet

- Midterm Exam II (20%) : Winter 2007 Date: Monday 2 April Instructor: Dr. Nizar Bouguila Time: 14:45-16:45Document13 pagesMidterm Exam II (20%) : Winter 2007 Date: Monday 2 April Instructor: Dr. Nizar Bouguila Time: 14:45-16:45sanjay_cssNo ratings yet

- DSP Lab 1Document9 pagesDSP Lab 1Bilal KhalidNo ratings yet

- Filename: MCA-Science Question - Paper PDFDocument75 pagesFilename: MCA-Science Question - Paper PDFatulzendeNo ratings yet

- Performance Modelling and Analysis of Manufacturing SystemsDocument2 pagesPerformance Modelling and Analysis of Manufacturing SystemsJithesh VNo ratings yet

- 01feb2016-Industrial Robotics,Design With Advanced Materials,Applied Mathematics,Optical Communication Technology,Advanced Data Structures and Algorithm Analysis,Mathematical Modeling,Analysis OfDocument15 pages01feb2016-Industrial Robotics,Design With Advanced Materials,Applied Mathematics,Optical Communication Technology,Advanced Data Structures and Algorithm Analysis,Mathematical Modeling,Analysis OfsirapuNo ratings yet

- SE 2008 ElectricalDocument46 pagesSE 2008 ElectricalMuhammad MujtabaNo ratings yet

- Complex Loading Systems and Beams AnalysisDocument14 pagesComplex Loading Systems and Beams Analysismahibalan74No ratings yet

- EM - Unit-I Exam For DCE - 1 Year OnDocument2 pagesEM - Unit-I Exam For DCE - 1 Year OnPenumudi JabezNo ratings yet

- JNTU M.Tech Precision Engineering Previous Year Question PapersDocument5 pagesJNTU M.Tech Precision Engineering Previous Year Question Paperssimalaravi100% (1)

- 2015 - 15CD 002 - Advanced Mechanics of Materials PIIDocument1 page2015 - 15CD 002 - Advanced Mechanics of Materials PIIselva_raj215414No ratings yet

- CIA Question Paper TemplateDocument1 pageCIA Question Paper Templatekpreddy_6171No ratings yet

- CAD/CAM Program for Drilling OperationDocument4 pagesCAD/CAM Program for Drilling OperationideepujNo ratings yet

- Narasus'S Sarathy Institute of Technology, Salem Internal Test - I (Common To ECE/EEE/IT)Document2 pagesNarasus'S Sarathy Institute of Technology, Salem Internal Test - I (Common To ECE/EEE/IT)Dhivya DuraisamyNo ratings yet

- Eee.2017 Syllabus 7th&8thDocument29 pagesEee.2017 Syllabus 7th&8thDawit Adane KebedeNo ratings yet

- Optimization Techniques - Oct 2011-2Document2 pagesOptimization Techniques - Oct 2011-2avinash_k007No ratings yet

- Review of KinematicsDocument2 pagesReview of Kinematicsकरळे सुरजNo ratings yet

- CTRJun2010 (حديث)Document3 pagesCTRJun2010 (حديث)Eng M. EissaNo ratings yet

- SYBSc Computer Science Exam Question PaperDocument85 pagesSYBSc Computer Science Exam Question PaperPiyush AnnadateNo ratings yet

- Mathematical and Computational Modeling: With Applications in Natural and Social Sciences, Engineering, and the ArtsFrom EverandMathematical and Computational Modeling: With Applications in Natural and Social Sciences, Engineering, and the ArtsRoderick MelnikNo ratings yet

- Safety Guidance For Roller Shutter or Other Industrial DoorsDocument3 pagesSafety Guidance For Roller Shutter or Other Industrial DoorsKeshav Arote100% (1)

- Recid THPR Subid Subject Year Course Shift DivDocument24 pagesRecid THPR Subid Subject Year Course Shift DivKeshav AroteNo ratings yet

- List of Approved PHD GuidesDocument1 pageList of Approved PHD GuidesKeshav AroteNo ratings yet

- Ty MeDocument14 pagesTy MeKeshav AroteNo ratings yet

- List of Approved PHD GuidesDocument1 pageList of Approved PHD GuidesKeshav AroteNo ratings yet

- E Filing PresentationDocument14 pagesE Filing PresentationKeshav AroteNo ratings yet

- He Coils Are Consistent With No Pitch Change Through The End of The SpringDocument1 pageHe Coils Are Consistent With No Pitch Change Through The End of The SpringKeshav AroteNo ratings yet

- StandardsDocument1 pageStandardsKeshav AroteNo ratings yet

- Numerical ControlDocument30 pagesNumerical ControlKeshav AroteNo ratings yet

- Training Calendar Tuv IndiaDocument3 pagesTraining Calendar Tuv IndiaKeshav AroteNo ratings yet