Professional Documents

Culture Documents

RC18 Column02

RC18 Column02

Uploaded by

cornel_bursucel7099Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RC18 Column02

RC18 Column02

Uploaded by

cornel_bursucel7099Copyright:

Available Formats

18

18

Combined Axial-Bending

Mongkol JIRAVACHARADET

Reinforced Concrete Design Reinforced Concrete Design

S U R A N A R E E INSTITUTE OF ENGINEERING

UNIVERSITY OF TECHNOLOGY SCHOOL OF CIVIL ENGINEERING

Design of Columns 2

Interaction Diagram

Biaxially Loaded Column

Combined Axial Load and Bending Moments Combined Axial Load and Bending Moments

Bending moments can occur in columns because:

- Unbalance gravity loads

- Lateral loads: wind, earthquake

Column2_02

P

M

P

e

Working Stress Design (WSD):

P

a

P, M

a

M

Equivalent Eccentricity Equivalent Eccentricity e e = = M M/ /P P

Minimum Eccentricity: e

min

= 0.6 + 0.03h

Strength Design Method (SDM):

P

n

P

u

, M

n

M

u

Column2_03

Column subjected to eccentric compression Column subjected to eccentric compression

P

n

e

h

width = b

c

d

d

s

cu

a

s s

A f

s s

A f

0.85

c

f

0.85

n c s s s s

P f a b A f A f = +

y

F (

L

| |

C

M 0.85

2 2 2 2

n n c s s s s

h a h h

M P e f ab A f d A f d

| | | | | |

= = + +

| | |

\ \ \

Equilibrium between external and internal axial forces requires that

Moment about centerline of the section of internal stresses and forces must be

equal and opposite to the moment of external force P

n

, so that

Column2_04

Moment Strength of Column

1

2 2 2 2

n c s

n

h a h h

M C C d T d

P e

| | | | | |

= + +

| | |

\ \ \

=

Taking moment about centroid of section:

( )

2

2

2

n c s

n

a

M C d C d d

h

P e d

| |

= +

|

\

| |

= +

|

\

Taking moment about tension steel:

T C

s

C

c

C

L

d

a/2

h/2

d

h

P

n

e

d - h/2

Column2_05

c

d

d

s

cu

a

s s

A f

s s

A f

0.85

c

f

Tension steel:

s cu

s s s cu s y

d c

c

d c

f E E f

c

= =

Compression steel:

s cu

s s s cu s y

c d

c

c d

f E E f

c

=

= =

Concrete stress block:

1

0.85

c

a c h

C f a b

=

=

Column2_06

If we know

Neutral axis (c, a)

Strain condition

(

s

,

s

)

Stress condition

( f

s

, f

s

)

Column strength

( M

n

, P

n

)

Column2_07

Small e f

s

< f

y

when

c

=

cu

= 0.003 (compression failure)

Large e f

s

= f

y

when

c

=

cu

= 0.003 (tension failure)

P

n

e

P

n

e

P

n

e

P

n

e

Small Eccentricity Large Eccentricity

Column2_08

P

n

M

n

Interaction Diagram for Combined Bending and Axial Load Interaction Diagram for Combined Bending and Axial Load

For any eccentricity, there is a unique pair of P

n

and M

n

.

P

0

e

=

0

e

s

m

a

l

l

Compression failure range

By plotting series of pairs coresponding to a different

eccentricity, will result in an interaction diagram.

Radial lines show constant e = M

n

/P

n

e e

b b

: Balance failure : Balance failure

e large

Tension failure range

e =

Column2_09

Balanced Failure, Balanced Failure, e e

b b

b b b

M P e = Condition of failure that :

Concrete reaches the strain limit:

cu

and

Tensile steel reaches the yield strain:

y

c

b

d

d

y

cu

6,120

6,120

cu

b

cu y y

c d d

f

= =

+ +

1 b b

a c =

0.85

b c b s s s y

P f a b A f A f = +

b

s s s cu s y

b

c d

f E E f

c

= =

0.85

2 2 2 2

b

b c b s s s y

a h h h

M f a b A f d A f d

| | | | | |

= + +

| | |

\ \ \

/

b b b

e M P =

Column2_10

Failure Mode Justification using e

b

Case 1: e < e

b

cu

c

b

y

M

b

M<M

b

c > c

b

s

<

y

f

s

< f

y

Compression Failure

Case 2: e > e

b

cu

c

b

M

b

M>M

b

c < c

b

s

>

y

f

s

> f

y

Tension Failure

Column2_11

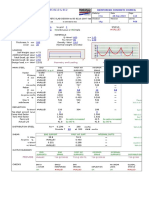

EXAMPLE 1 Column strength interaction diagram. A 25 x 40 cm column is

reinforced with 4DB28. Concrete strength f

c

= 280 ksc and the steel

yield strength f

y

= 4,000 ksc

20 cm 20 cm

12.5 cm

12.5 cm

5 cm 5 cm

P

n

M

n

P

n

e

Balance condition:

6,120

35 21.2 cm, 0.85(21.2) 18.0 cm

6,120 4,000

b b

c a

| |

= = = =

|

+

\

0.85(0.28)(18)(25) 107 ton

c

C = =

21.2 5

6,120 4,677 ksc

21.2

s s cu

c d

f E

c

| | | |

= = =

| |

\ \

Yielding 4,000 ksc

s

f =

12.32(4.0) 49.3 ton

s s y

C A f = = =

Column2_12

40 cm

5 cm

35 cm

18 cm

h

d

d

a

=

=

=

=

12.32(4.0) 49.3 ton

s y

T A f = = =

107 49.3 49.3 107 ton

b c s

P C C T = + = + =

2 2 2 2

107(20 18/ 2) 49.3(20 5) 49.3(35 20)

2,656 ton-cm 26.6 ton-m

b c s

h a h h

M C C d T d

| | | | | |

= + +

| | |

\ \ \

= + +

= =

2,656

24.8 cm

107

b

b

b

M

e

P

= = =

For c smaller than c

b

= 21.2 cmwill give e larger than e

b

: tension failure

For example, choose c = 10 cm. By definition f

s

= f

y

10 5

6,120 3,060 ksc

10

s

f

| |

= =

|

\

0.85 10 8.5 cm a = =

0.85(0.28)(8.5)(25) 50.6 ton C = =

50.6 12.32 3.06 12.32 4.0 39 ton

n

P = + =

Column2_13

50.6(20 8.5/ 2) 12.32 3.06(20 5) 12.32 4.0(35 20)

2,102 ton-cm 21.0 t-m

n

M = + +

= =

2,102

53.9 cm

39

n

n

M

e

P

= = =

For c larger than c

b

= 21.2 cmwill give e smaller than e

b

: compression failure

For example, choose c = 30 cm.

0.85 30 25.5 cm a = =

0.85(0.28)(25.5)(25) 152 ton C = =

35 30

6,120 1,020 ksc

30

s s cu

d c

f E

c

| | | |

= = =

| |

\ \

30 5

6,120 5,100 ksc

30

s

f

| |

= =

|

\

Yielding 4,000 ksc

s

f =

152 12.32 4.0 12.32 1.02 189 ton

n

P = + =

152(20 25.5/ 2) 12.32 4.0(20 5) 12.32 1.02(35 20)

2,030 ton-cm 20.3 t-m

n

M = + +

= =

2,030

10.7 cm

189

n

n

M

e

P

= = =

Column2_14

M

n

M

0

Balanced strain

condition

e

=

eb

P

b

n

n

M

e

P

=

P

n

P

0

e=0

M

b

e =

Compression controlled

Transition zone

Tension controlled

0.003

0.003

0.003

s y

<

s y

=

s y

>

Interaction Diagram

Column2_15

( )

( )

Tied column: 0.80 0.85

Spiral column: 0.85 0.85

n c g st y st

n c g st y st

P f A A f A

P f A A f A

( = +

( = +

Maximum Strength in Axial Compression-ACI Code

Minimum eccentricity: e = 0.6 + 0.03 h

e

=

0

.

6

+

0

.

0

3

h

P

n

P

0

A

P

n(max)

USE P

n(max)

e

=

0

.

6

+

0

.

0

3

h

P

n

P

0

A

P

n(max)

USE P

n

at point A

Column2_16

Column strength interaction diagram. A 25 x 40 cm column is reinforced with 4DB28.

Concrete strength f

c

= 280 ksc and the steelyield strength f

y

= 4,000 ksc

20 cm 20 cm

12.5 cm

12.5 cm

5 cm

5 cm

40 cm

5 cm

35 cm

h

d

d

=

=

=

Column2_17

Interaction Diagram for Design

P

n

D

M

n

Nominal strength

0.1

c g

f A

M

n

D

P

n

Design

curve

= 0.70 for tied column

= 0.90 for beam

0.70 0.90

Column2_18

0.00

50.00

100.00

150.00

200.00

250.00

300.00

0.00 20.00 40.00 60.00 80.00 100.00 120.00

Interaction Diagram of Rectangular Columns

h

h

b

75 . 0

kg/cm 4000

kg/cm 210

2

2

=

=

=

y

c

f

f

ksc ,

g

n

A

P

ksc ,

h A

M

g

n

g

= 0.01

0.02

0.03

0.04

0.05

0.06

0.07

0.08

Column2_19

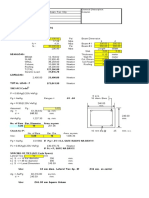

Example: Design a rectangular reinforced concrete column with ties for service

dead and live loads of 120 and 80 tons, respectively. Service dead and live load

moments at the top about the strong axis are 15 and 8 t-m, respectively.

Moments are negligible about weak axis. Assume moments at the bottom of the

column as half those at the top. The column has unsupported height of 2.5 m and

is bent in double curvature about strong axis and single curvature about the weak

axis. Use f

c

= 210 ksc and f

y

= 4,000 ksc.

1) Determine required strength

P

u

= 1.4(120) + 1.7(80) = 304 ton

M

u

= 1.4(15) + 1.7(8) = 34.6 t-m

2) Check column slenderness. Assume a 40 x 60 cm column size

a. Slenderness about weak axis (40 cm width)

k = 1.0 for braced compression member

r = 0.3x40 = 12 cm

kL

u

/r = (1.0)(250)/12 = 20.8

Column2_20

With negligible moment about the weak axis, assume M

1

/M

2

= 1.0

kL

u

/r < 34 - 12(M

1

/M

2

) = 22 (single curvature)

Therefore, slenderness may be neglect about the weak axis.

b. Slenderness about strong axis (60 cm width)

k = 1.0 for braced compression member

r = 0.3x60 = 18 cm

kL

u

/r = (1.0)(250)/18 = 13.9

M

1

/M

2

= -0.5

kL

u

/r < 34 - 12(-0.5) = 40

Therefore, slenderness may be neglect about the strong axis.

Column2_21

3) Design of column reinforcement

304(1,000)

Compute 126.7

40 60

34.6(1,000)(100)

24.03

40 60 60

u

g

u

g

P

A

M

A h

= =

= =

From interaction diagram, read

g

= 0.025

A

st

=

g

A

g

= 0.025(40)(60) = 60.0 cm

2

USE 10DB28(A

s

=61.58cm

2

) Place 5DB28 bars on each 40 cm side.

4) Select lateral reinforcement

Use DB10 ties with DB28 longitudinal bars

Spacing not greater than: 16(2.8) = 44.8 cm

48(1.0) = 48.0 cm

column size = 40 cm (control)

USE DB10 @40 cm

Column2_22

0.00

0.20

0.40

0.60

0.80

1.00

1.20

1.40

1.60

1.80

2.00

0.00 0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80 0.90 1.00 1.10

'

n

g c

P

A f

'

n

g c

M

A hf

h

h

b

= 0.80

g

m=0

0.5

1.0

1.5

2.0

2.5

3.0

Normalized Interaction Diagram

Column2_23

Biaxial Biaxial Bending and Compression Bending and Compression

e

x

e

y

P

n

h

b

x x

y

y

M

nx

= P

n

e

nx

M

ny

= P

n

e

ny

Load Contour Method Load Contour Method: :

Cut failure surface at constant P

n

P

n

P

n

M

ny

M

nx

M

0x

M

0y

Load contour

M

nx

M

ny

M

0x

M

0y

2

1

0 0

1.0

ny

nx

x y

M M

M M

| | | |

+ =

| |

|

\ \

Column2_24

Modified Load Contour Method Modified Load Contour Method

The interaction expression for the load and bending moments about the two axes is

1.5

1.5

ny

n nb nx

no nb nbx nby

M

P P M

1.0

P P M M

| |

| | | |

+ + =

|

| |

|

\ \

\

where

P

n

= nominal axial compression (positive), or tension (negative)

M

nx

, M

ny

= nominal bending moments about the x- and y-axis respectively

P

no

= maximum nominal axial compression (positive) or axial tension (negative)

= 0.85 f

c

(A

g

A

st

) + f

y

A

st

P

nb

= nominal axial compression at the limit strain states (

t

= 0.002 )

M

nbx

, M

nby

= nominal bending moment about the x- and y-axis respectively,

at the limit strain state (

t

= 0.002 )

Column2_25

T

C

s

C

c

C

L

d

a/2

h/2

d

h

P

n

e

d - h/2

d

nb c 1 b s s s y

P 0.85f c b A f A f = +

The value of P

nb

and M

nb

can be obtained from:

nb nb b c s

a

M P e C d d C (d d d ) Td

2

| |

= = + +

|

\

where

a = depth of the equivalent block =

1

c

b

b

y s

0.003 6,120

c d d

f / E 0.003 6,120 4,000

| |

| |

= =

|

|

|

+ +

\

\

s

f

= stress in the compressive reinforcement

y s y

f if f f =

T = Force in the tensile side reinforcement

Column2_26

EXAMPLE 18 3 : Design of a Biaxially Loaded Column by the Modified Load

Contour Method

A nonslender corner column is subjected to a factored compressive load P

u

= 100 ton,

a factored bending moment M

ux

= 18 t-m about the x axis, and a factored bending

moment M

uy

= 12 t-m about y axis. Given f

c

= 280 ksc, f

y

= 4,000 ksc

x

y

M

uy

M

ux

x

y

P

u

= 100 ton

e

x

e

y

Solution: Step 1: Calculate equivalent uniaxial bending moment assuming equal

numbers of bars on all faces

Assume that = 0.70 for tied columns.

Required nominal P

n

= 100/0.7 = 143 ton

Column2_27

Required nominal M

nx

= 18/0.7 = 25.7 t-m

Required nominal M

ny

= 12/0.7 = 17.1 t-m

e

y

= M

nx

/ P

n

= 25.7(100)/143 = 18.0 cm

e

x

= M

ny

/ P

n

= 17.1(100)/143 = 12.0 cm

x

y

P

u

e

x

e

y

b

h

M

ux

M

uy

x : axis parallel to the shorter side b

y : axis parallel to the longer side h

Assume column section : b = 30 cm, h = 50 cm, d = 5 cm, and A

s

= 8DB25

s

=

y

= 0.002

Balance failure

cu

= 0.003

c

b = 30 cm

h

=

5

0

c

m

5 cm

5 cm

d

=

4

5

c

m

c 0.003

0.6

d 0.003 0.002

= =

+

c = 0.6(45) = 27 cm

a =

1

c = 0.85(27) = 23 cm

Column2_28

s

=

y

= 0.002

cu

= 0.003

c

=

2

7

c

m

T = A

s

f

y

0.85f

c

a

=

2

3

c

m

C

c

C

s1

C

s2

f

s

= 6120(1-d/c) = 6120(1-5/27)

= 4987 ksc USE f

y

= 4000 ksc

f

s

= 6120(1-25/27) = 453 ksc

P

nb

= nominal axial compression at the limit strain

= C

c

+ C

s1

+ C

s2

T

C

c

= 0.85f

c

b a = 0.85(0.28)(30)(23) = 164.2 ton

C

s1

= (3DB25=14.73)(4.0) = 58.9 ton

C

s2

= (2DB25=9.82)(0.453) = 4.5 ton

T = (3DB25=14.73)(4.0) = 58.9 ton

P

nb

= 164.2 + 58.9 + 4.5 58.9 = 168.7 ton

Compute P

nb

:

Column2_29

M

nbx

= 164.2(25 23/2) + 58.9(25 5) + 58.9(45 25)

Compute M

nbx

:

T = A

s

f

y

0.85f

c

a

=

2

3

c

m

C

c

C

s1

C

s2

nbx c s

h a h h

M C C d T d

2 2 2 2

| | | | | |

= + +

| | |

\ \ \

= 4573 t-cm = 45.7 t-m

nbx

by

nb

M 4573

e 27.1 cm

P 168.7

= = =

e

by

> e

y

= 17.8 cm, hence compression failure

Compute M

nby

:

b = 30 cm

h

=

5

0

c

m

M

y

cu

=

0.003

y

=

0.002

c

nbx

a

nbx

=

1

c

nbx

= 0.85(0.6)(d=25) = 13 cm

M

nby

= 0.850.285012.75(15 13/2) + 58.9(15 5)

+ 58.9(25 15)

= 2468 t-cm = 24.7 t-m

Column2_30

no c g st st y

P 0.85f (A A ) A f = +

= 0.85 x 0.24 (30 x 50 8 x 4.91) + 8 x 4.49 x 4.0

= 442 ton

Using the interaction surface expression for biaxial bending

1.5

1.5

ny

n nb nx

no nb nbx nby

M

P P M

P P M M

| |

| | | |

+ + |

| |

|

\ \

\

1.5 1.5

143 168.7 25.7 17.1

442 168.7 45.7 24.7

| | | |

= + +

| |

\ \

= -0.094 + 0.422 + 0.576 = 0.904 < 1.00 OK

Hence, accept the design, namely,

b = 30 cm, h = 50 cm, d = 45 cm, and A

s

= 8DB25

Column2_31

You might also like

- Module 1.3 - Singly Reinforced Beams (USD)Document25 pagesModule 1.3 - Singly Reinforced Beams (USD)Dopias Fake100% (1)

- Numerical Analysis of Piled Raft Foundation in Sandy and Clayey SoilsDocument4 pagesNumerical Analysis of Piled Raft Foundation in Sandy and Clayey Soilspperic13No ratings yet

- Design Shear WallDocument26 pagesDesign Shear WallCaoTrungThành100% (2)

- Strap Footing TheoryDocument4 pagesStrap Footing TheorySwopnilOjhaNo ratings yet

- Design of Two Way Slab: 2nd/3rd Floor Slab S1Document14 pagesDesign of Two Way Slab: 2nd/3rd Floor Slab S1John Paul Hilary EspejoNo ratings yet

- Lecture 11-1 Bases by H.J. MtyanaDocument29 pagesLecture 11-1 Bases by H.J. MtyanaHarold Jackson Mtyana100% (1)

- Two Way Slab (First Slab Level Slabs)Document15 pagesTwo Way Slab (First Slab Level Slabs)Anjali DudhyalNo ratings yet

- Astm A513 PDFDocument20 pagesAstm A513 PDFpradelles89% (9)

- 2way Slab & FootingDocument52 pages2way Slab & FootingMuhammad Saqib Abrar0% (1)

- Spreadsheets To BS 8110: The Concrete CentreDocument14 pagesSpreadsheets To BS 8110: The Concrete CentreCioabla BogdanNo ratings yet

- Column Design Design of Short Braced ColumnsDocument17 pagesColumn Design Design of Short Braced ColumnsPimpa MwiingaNo ratings yet

- Design of Flat Slabs For PunchingDocument8 pagesDesign of Flat Slabs For PunchingAli Alskeif100% (1)

- Advanced Structural AnalysisDocument24 pagesAdvanced Structural Analysisbhkedar0% (1)

- Basketball Court 10m, CR 500kDocument26 pagesBasketball Court 10m, CR 500kNayr EnitsirhcNo ratings yet

- Column Design - As Per BS CodeDocument16 pagesColumn Design - As Per BS CodeFar AwayNo ratings yet

- Drop Panel CalculationDocument2 pagesDrop Panel Calculationsandiok86No ratings yet

- RC WALL-6f MDocument1 pageRC WALL-6f MNazmi DhiyauddinNo ratings yet

- Wk7 Raft Foundations + EccentricityDocument20 pagesWk7 Raft Foundations + EccentricityAli SaeedNo ratings yet

- Mat Foundation Design FinalDocument15 pagesMat Foundation Design FinalGerard VelicariaNo ratings yet

- Chapter 8 Design of Short ColumnsDocument64 pagesChapter 8 Design of Short ColumnsiiMa sticNo ratings yet

- Theory of Structures - Floor SystemsDocument31 pagesTheory of Structures - Floor SystemsLawrence Babatunde OgunsanyaNo ratings yet

- 2a - Design of Spread Footing-Usd MethodDocument27 pages2a - Design of Spread Footing-Usd MethodLouise LuyNo ratings yet

- Power Plant Piping Materials Rev 2 WIPDocument133 pagesPower Plant Piping Materials Rev 2 WIPGustavo FamaNo ratings yet

- NASA - Creation of A Ceramic (1976)Document292 pagesNASA - Creation of A Ceramic (1976)Rakesh SandarativjuNo ratings yet

- 1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12Document7 pages1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12asuncionNo ratings yet

- Eccentric FootingsDocument34 pagesEccentric FootingsMelaku Seyoum0% (1)

- Staad Basics: - Notes On The Effective Use of Staad-Pro Rel 3.1Document17 pagesStaad Basics: - Notes On The Effective Use of Staad-Pro Rel 3.1kardels100% (14)

- Fem 9.341Document6 pagesFem 9.341rafael1978No ratings yet

- STADIUMDocument8 pagesSTADIUMAkshai Anand GuruNo ratings yet

- Surface Preparation and Painting FinalDocument45 pagesSurface Preparation and Painting FinalthanghanvicoNo ratings yet

- RCC Two Way Slab BS 8110Document9 pagesRCC Two Way Slab BS 8110sourabdaroch100% (1)

- BSI Standards Publication: Concrete - Complementary British Standard To BS EN 206Document52 pagesBSI Standards Publication: Concrete - Complementary British Standard To BS EN 206edward maisibaNo ratings yet

- Structural Design Calculations: Spread Footing For Temporary BridgeDocument3 pagesStructural Design Calculations: Spread Footing For Temporary BridgeFeras TemimiNo ratings yet

- Shear Wall DesignDocument6 pagesShear Wall DesignAayush AdhikariNo ratings yet

- Concrete Lectures Slab.2 Direct Design Method - PPT ExamplesDocument58 pagesConcrete Lectures Slab.2 Direct Design Method - PPT ExamplesUmer WaheedNo ratings yet

- Shear Wall - BS8110-97-007Document4 pagesShear Wall - BS8110-97-007Kavin TamNo ratings yet

- Manual Design of One Way Slab (Continous Slab)Document5 pagesManual Design of One Way Slab (Continous Slab)Struct Soft CentreNo ratings yet

- RCC Isolated Footings DesignDocument25 pagesRCC Isolated Footings DesignShaikh Muhammad Ateeq100% (1)

- Vertical Reinforcement For Wall DesignDocument5 pagesVertical Reinforcement For Wall DesignSamuel AntobamNo ratings yet

- A Spreadsheet of RC Two Way Slab DesigningDocument1 pageA Spreadsheet of RC Two Way Slab DesigningTRPMEINHARDTNo ratings yet

- Assignment 1 - RCCDocument7 pagesAssignment 1 - RCCRichard WestonyNo ratings yet

- Learn Raft-RC Raft Foundation Analysis Design and Drawing SoftwareDocument108 pagesLearn Raft-RC Raft Foundation Analysis Design and Drawing SoftwareRahul Kumar100% (2)

- Analysis and Design of SlabsDocument6 pagesAnalysis and Design of SlabsricardoNo ratings yet

- Slender Column - Sway Frame - ACI 318-08 Reinforced Concrete Design Example HassounDocument8 pagesSlender Column - Sway Frame - ACI 318-08 Reinforced Concrete Design Example HassounMike2322100% (1)

- Column Design (WSD) Axially LoadedDocument1 pageColumn Design (WSD) Axially Loadedapi-19753598100% (2)

- Column Design As Per BS 8110-1:1997: PHK/JSNDocument16 pagesColumn Design As Per BS 8110-1:1997: PHK/JSNopulithe0% (1)

- Time Period Calculation in ETABS As Per IS 1893 Part 1Document2 pagesTime Period Calculation in ETABS As Per IS 1893 Part 1NAYAN RANPURA100% (1)

- Torsion in Concrete BeamsDocument9 pagesTorsion in Concrete BeamsMisqal A IqbalNo ratings yet

- Beam On Elastic Foundation AnalysisDocument5 pagesBeam On Elastic Foundation AnalysisMagdy BakryNo ratings yet

- ProkonDocument7 pagesProkonmark7301158No ratings yet

- STAIRS Corbel Design-26-Oct-2013Document2 pagesSTAIRS Corbel Design-26-Oct-2013Misqal A IqbalNo ratings yet

- MAAE 3202 Formula SheetDocument3 pagesMAAE 3202 Formula SheetJohnNo ratings yet

- Table (3) Shows Results of Neutral Axis Depth Against Various Reinforcing Steel Ratios ForDocument1 pageTable (3) Shows Results of Neutral Axis Depth Against Various Reinforcing Steel Ratios ForgetNo ratings yet

- Lecture - 08 Shaft IDocument23 pagesLecture - 08 Shaft Iwkho0007No ratings yet

- (Prestressed Concrete) Lecture 05 Dr. ZubairDocument62 pages(Prestressed Concrete) Lecture 05 Dr. ZubairAhmed RiadNo ratings yet

- StrucTheor FormulasDocument3 pagesStrucTheor FormulasMJ Dela CruzNo ratings yet

- Tos 1Document1 pageTos 1Maevin WooNo ratings yet

- Useful formulas and data: sin θ = A/C cos θ = B/C tan θ = A/B sin²θ+cos²θ = 1 / 81 - 9 0 0 0 = =Document1 pageUseful formulas and data: sin θ = A/C cos θ = B/C tan θ = A/B sin²θ+cos²θ = 1 / 81 - 9 0 0 0 = =HoangViet NguyenNo ratings yet

- 03 Strength of MaterialsDocument86 pages03 Strength of MaterialsMichael Vincent MirafuentesNo ratings yet

- Rectangular - Columns As Per ACI-318 Using MathcadDocument11 pagesRectangular - Columns As Per ACI-318 Using Mathcadkartik vNo ratings yet

- SM Chapter 9Document31 pagesSM Chapter 9White LightNo ratings yet

- Exam 2 Meem 2150 April 9Th, 2003Document3 pagesExam 2 Meem 2150 April 9Th, 2003NhanNo ratings yet

- Formula SheetDocument8 pagesFormula SheetCIYA ELIZANo ratings yet

- 8.2 Columns DesignDocument29 pages8.2 Columns Designsaleh34534rf34No ratings yet

- C Line MethodDocument8 pagesC Line MethodwindellacsonNo ratings yet

- Chapter 13Document23 pagesChapter 13Marjorie Anne VilledoNo ratings yet

- Diseño Muro de ContencionDocument15 pagesDiseño Muro de ContencionVaniss506No ratings yet

- SEI FEDRO Guidelines For Integral BridgesDocument6 pagesSEI FEDRO Guidelines For Integral BridgesÁlvaro SerranoNo ratings yet

- Stainless Series S115-43 or S6115-43 (Globe), S1115-43 or S61115-43 (Angle) Installation InstructionsDocument2 pagesStainless Series S115-43 or S6115-43 (Globe), S1115-43 or S61115-43 (Angle) Installation InstructionsWattsNo ratings yet

- Ms - Sarayu EstimateDocument13 pagesMs - Sarayu EstimateSandgrouse RajNo ratings yet

- 7TS600 Mud Pump With C18 EngineDocument20 pages7TS600 Mud Pump With C18 EngineandreaNo ratings yet

- PP RCT The Innovative Solution For Higher Competitiveness and PerformanceDocument2 pagesPP RCT The Innovative Solution For Higher Competitiveness and Performanceمحمود أبو الحسنNo ratings yet

- AISI 1005 Steel: Metal Ferrous Metal Carbon Steel AISI 1000 Series Steel Low Carbon SteelDocument2 pagesAISI 1005 Steel: Metal Ferrous Metal Carbon Steel AISI 1000 Series Steel Low Carbon SteelIsrael BenavidesNo ratings yet

- Kawabata SystemDocument17 pagesKawabata Systemshahadat hossainNo ratings yet

- Project DRCCDocument4 pagesProject DRCCThejasezo NohoNo ratings yet

- Juzer Janab House EstimateDocument2 pagesJuzer Janab House EstimateMustafa HusainNo ratings yet

- ICE-DataSheet FLATFLAME Burners 03 2018 PDFDocument2 pagesICE-DataSheet FLATFLAME Burners 03 2018 PDFLuis Eduardo NavasNo ratings yet

- Process Variables & Trouble ShootingDocument20 pagesProcess Variables & Trouble ShootingrkneyveliNo ratings yet

- Photonic Crystal Based LEDsDocument5 pagesPhotonic Crystal Based LEDsChandan PathakNo ratings yet

- Residential Timber Decks: Technical Data SheetDocument6 pagesResidential Timber Decks: Technical Data SheetPamela HerreraNo ratings yet

- Lighting Design For SchoolsDocument9 pagesLighting Design For SchoolsAashrayaNo ratings yet

- Elect WorkDocument34 pagesElect WorkNath YauNo ratings yet

- Basis of Electrical Design MemoDocument9 pagesBasis of Electrical Design MemoBashir HashimNo ratings yet

- Vernacular Architecture OF GujaratDocument21 pagesVernacular Architecture OF Gujaratshashank joshiNo ratings yet

- Hot Dry ClimateDocument20 pagesHot Dry ClimateTlvs Murthy100% (1)

- Precast (1) - A1 PDFDocument1 pagePrecast (1) - A1 PDFShubham DuaNo ratings yet

- Hometown CatalogueDocument36 pagesHometown CatalogueDeepan KapadiaNo ratings yet

- SIAPRA OPzV enDocument2 pagesSIAPRA OPzV enAsher KhanNo ratings yet

- AbstractDocument12 pagesAbstractanmolNo ratings yet