Professional Documents

Culture Documents

PDF Created With Fineprint Pdffactory Trial Version: (Extra Order)

Uploaded by

Thanh Phuc NguyenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PDF Created With Fineprint Pdffactory Trial Version: (Extra Order)

Uploaded by

Thanh Phuc NguyenCopyright:

Available Formats

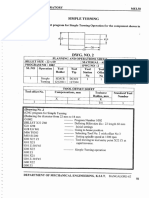

Training Material Model: TCM-X200

No. KNC - 07 - 02 - 116E Title: CX Series Jig & Tool List

Issued: July 24, 2003 Page 1 continue to Pate 2

1. Purpose Tools and jigs are called by their names but it is difficult to match the name/jig No. and the appearance. To make it easy to identify, this list is prepared. 2. List No. Jig. No. Name 1 JG-0086 P.E.C. Recognition Calibration Jig

Picture

Use Application This is used for P.E.C. recognition calibration.

JG-0123 Component Recognition

Camera Offset Teaching Jig Glass Print Jig Nozzle (CZ-012) (Accessory of JG-0123) Parallelism Correction Jig

(Extra Order)

This is used for component recognition calibration.

JG-0124 Component Recognition

Lighting Intensity Data Teaching Jig Glass (White) Jig Nozzle (CZ-012) (Accessory of JG-0123) Cutter Lower Blade Clearance Adjustment Jig

This is used for component recognition lighting data teaching.

JG-0127

This is used for the cutter lower blade lever replacement or the clearance adjustment at angular bearing replacement. This is used to perform ultrasonic cleaning for miniature SB.

JG-0128 Miniature SB Cleaning Base

JG-0129 Chip Removing Sensor Setting Nozzle

This is used for low nozzle detection sensitivity adjustment of the chip removing section.

PDF created with FinePrint pdfFactory trial version http://www.pdffactory.com

Training Material Model: TCM-X200

No. KNC - 07 - 02 - 116E Title: CX Series Jig & Tool List Picture

Issued: July 24, 2003 Page 2 continue to Page 3 Use Application

This is used for linear scale encoder sensitivity adjustment.

No. Jig. No. Name 7 JG-0130 Linear Scale Setting Jig

Encoder Adjustment Jig (PWB-18)

Pulse Counter jig (ND221B)

This is used for linear scale tension adjustment.

JG-0131 Connector Positioning Jig

This is used for positioning when the head connector is connected to the linear guide.

JG-0132 Top Block Positioning Jig

This is used for top block positioning relative to the linear guide.

10 JG-0133 Nozzle Change Lever Setting Jig

This is used for the nozzle change (return) lever forward limit setting.

11 JG-0134 Unselected Nozzle Detection Sensor Setting Check Jig

This is used to check the setting level.

PDF created with FinePrint pdfFactory trial version http://www.pdffactory.com

Training Material Model: TCM-X200

No. KNC - 07 - 02 - 116E Title: CX Series Jig & Tool List Picture

Issued: July 24, 2003 Page 3 continue to Page 4 Use Application

This is used for MZ ball screw positioning.

No. Jig. No. Name 12 JG-0136 MZ Ball Screw Positioning Jig

13 JG-0137 Resolver Centering Jig

This is used for resolver positioning.

14 JG-0138 Camera XY Recognition Level Adjusting Jig

This is used to check camera XY level.

15 JG-0139 Master Jig for Machine Adjustment

16 JG-0140 Hook/Template Alignment Jig

This is used to check setting of Tape Feed/ Tape End Detection Sensor/Feeder MisSet Detection Shilhouette Template/Tape Cut Error Detection, etc. F-Axis: This is used for hook positioning.

17 JG-0141 Master Head

This is used for Pick-up Positioning Placement Positioning Nozzle Detection Sensor Positioning Line Sensor Positioning Zeroing Component Recognition

Accessory Nozzle

PDF created with FinePrint pdfFactory trial version http://www.pdffactory.com

Training Material Model: TCM-X200

No. KNC - 07 - 02 - 116E Title: CX Series Jig & Tool List Picture

Issued: July 24, 2003 Page 4Ccontinue to Page 5 Use Application This is used for line sensor positioning.

No. Jig. No. Name 18 JG-0142 Line Sensor Positioning Jig

19 JG-0143 Master Nozzle (2) (Nozzle with collar)

This is used for pick-up level check.

20 JG-0145 Motor/Rotary Turret Centering Jig

This is used for centering of the Haxis motor and the rotary turret input axis.

21 JG-0146 Reference Pin Jig (X200)

This is used for XY table origin positioing. This is used together with the JG-0056 to check between pin and chute.

-

JG-0147 (X201)

22 JG-0149 Placement Level Check Jig (XY Chute/Nozzle Height Check Jig)

This is used for Chute height check Nozzle Height at Placement

23 JG-0154 Cutter Base Positioning Jig

This is used for cutter base XY positioning.

PDF created with FinePrint pdfFactory trial version http://www.pdffactory.com

Training Material Model: TCM-X200

No. KNC - 07 - 02 - 116E Title: CX Series Jig & Tool List Picture

Issued: July 24, 2003 Page 5D continue to Page 6 Use Application This is used for timing adjustment.

No. Jig. No. Name 24 JG-0155 Main Timing Belt Timing Setting Jig

25 JG-0156 Tape Feed Pusher Height Setting Jig

This is used for tape feed pusher height setting (pass-stop).

26 JG-0157 Robot Cable Tightening Jig

This is used to attach/detach and loosen/tighten the robot cable.

27 JG-0158 Nozzle Change Unit Height Adjusting Jig

This is used for nozzle change unit height (Z) adjustment.

28 JG-0159 Cutter Lower Blade Master Jig

This is used to adjust the cutter lever.

29 -----Long Medium Short

F-axis Yoke Removing Jig

This is used for F-axis magnet yoke replacement . (Picture: L & S type)

30 JG-0056

Jig between Pin and Chute

This is used to check between the pin and the chute. (pass-stop)

31 Standard

Miniature SB Insertion

Accessory Nozzle (630 085 8846)

32 Standard

Accessory (630 057 4517)

Jig Nozzle (3)

This is used for cleaning and lubrication of the miniature stroke bearing. This is used to check Pick-up position Nozzle Height at Placement

PDF created with FinePrint pdfFactory trial version http://www.pdffactory.com

Training Material Model: TCM-X200

No. KNC - 07 - 02 - 116E Title: CX Series Jig & Tool List Picture

Issued: July 24, 2003 Page 6E Use Application This is used for F-axis magnet yoke replacement.

No. Jig. No. Name 33 IB-34108 Allen Wrench (For M10) (Standard) (Antimagnetic)

34 (T25)

Torx Driver for M5

(T20) 35

Torx Driver for M4

M5: Nozzle Up/Down Unit Anchor Bolt, Cutter Cover M4: Nozzle Roller Rest (CZ/MZ) Bolt

KANON Rotary Slip Clutch 12LTDK Torque Driver (630 044 2786) Bit M1.5 M2.0

This is used for torque control for disassembly/assembly of the miniature stroke bearing of the head section. This is used to tighten the head holder. This is used to tighten the diffusion plate of the head. Nozzle Detection Section Positioning (Line Sensor Tipe)

36 Standard

Accessory

(630 116 3659) (630 116 3673) 37

JG-177 Line Sensor Positioning Jig

PDF created with FinePrint pdfFactory trial version http://www.pdffactory.com

You might also like

- CNC Turning Programming Exellent ExplainationDocument29 pagesCNC Turning Programming Exellent ExplainationschrienerNo ratings yet

- CNC Programming WRKB Lathe Sample LockedDocument51 pagesCNC Programming WRKB Lathe Sample Lockedkree_bigdaddy100% (1)

- Internal Gears: KHK Products Are Available From Maryland MetricsDocument6 pagesInternal Gears: KHK Products Are Available From Maryland MetricsbtfreekNo ratings yet

- Inkoma Shaft Hub ConnectionsDocument31 pagesInkoma Shaft Hub ConnectionsnikitaNo ratings yet

- Turning: Chapter ObjectivesDocument78 pagesTurning: Chapter ObjectivesDany EscobarNo ratings yet

- MSC Lecture 6Document28 pagesMSC Lecture 6Chán Chênh VênhNo ratings yet

- SJ 201Document14 pagesSJ 201Oliveira400No ratings yet

- My CNCDocument5 pagesMy CNCzoranteicNo ratings yet

- NTP Thread Program Rev. ADocument1 pageNTP Thread Program Rev. Arajkumar931No ratings yet

- GTCNC 150it IiDocument4 pagesGTCNC 150it Iilukman hakimNo ratings yet

- CNC Programming BasicsDocument53 pagesCNC Programming Basicspramod ChouguleNo ratings yet

- CNC CodeDocument9 pagesCNC CodeMochammad Karim Al AminNo ratings yet

- Experiment No 1: CNC TURNING: MEP310 - Manufacturing Process Automation Lab ManualDocument10 pagesExperiment No 1: CNC TURNING: MEP310 - Manufacturing Process Automation Lab ManualBandam Nitish kumarNo ratings yet

- Example of CNC Programming: What Must Be Done To Ona CNC Vertical Milling MachineDocument14 pagesExample of CNC Programming: What Must Be Done To Ona CNC Vertical Milling MachinePatel NikhilNo ratings yet

- DG1000 OpsDocument24 pagesDG1000 OpsYury GonzalesNo ratings yet

- NT Series enDocument40 pagesNT Series en223ABDULTEF faresNo ratings yet

- 00 EAGLE FANUC OiDocument60 pages00 EAGLE FANUC OiFranciscoDanielRamirezFloresNo ratings yet

- Albert JacksDocument0 pagesAlbert JacksDado Maja ArseninNo ratings yet

- Homework Project 23-24Document24 pagesHomework Project 23-24xdff5png8zNo ratings yet

- Technical Report: Sharp CorporationDocument2 pagesTechnical Report: Sharp Corporationphu polyfaxNo ratings yet

- Wa0000.Document18 pagesWa0000.21P410 - VARUN MNo ratings yet

- ZWP 18Document9 pagesZWP 18Ing Lizbeth GuzmánNo ratings yet

- 5 - G-CodeDocument55 pages5 - G-CodefamilyumaNo ratings yet

- Machine Mate Inc - Full List of CNC CodesDocument5 pagesMachine Mate Inc - Full List of CNC CodesEr Zorawar SinghNo ratings yet

- G-Code - Wikipedia, The Free EncyclopediaDocument6 pagesG-Code - Wikipedia, The Free EncyclopediajoydeepNo ratings yet

- NC CodesDocument6 pagesNC CodesSayeed AndrabiNo ratings yet

- 13 Threading PDFDocument46 pages13 Threading PDFrefaeNo ratings yet

- Chapter 6Document56 pagesChapter 6gashawletaNo ratings yet

- Catálogo de Acoplamientos Lovejoy - JISDocument8 pagesCatálogo de Acoplamientos Lovejoy - JISJavier Salas ZavaletaNo ratings yet

- Analisis Dan Perencanaan Roda Gigi Lurus Pembawa Eretan Mesin Bubut Krisbow Tipe KW 15-178 Jusuf TalaperuDocument7 pagesAnalisis Dan Perencanaan Roda Gigi Lurus Pembawa Eretan Mesin Bubut Krisbow Tipe KW 15-178 Jusuf TalaperuIchsandz CybzNo ratings yet

- Nikon Af-S DX Zoom-Nikkor 18-105mm RepairDocument149 pagesNikon Af-S DX Zoom-Nikkor 18-105mm RepairCreaciones CC67% (3)

- Thread G76Document4 pagesThread G76winkymanNo ratings yet

- CNC ProgDocument38 pagesCNC ProgPoornima JoshiNo ratings yet

- 20J3XB - Programming - EN M80 VER00Document142 pages20J3XB - Programming - EN M80 VER00maxvelyrNo ratings yet

- Calculating Cylinder Liner Projection For G3500Document7 pagesCalculating Cylinder Liner Projection For G3500NimNo ratings yet

- Fanuc CNC Parts: Rigid Tapping TroubleshootingDocument6 pagesFanuc CNC Parts: Rigid Tapping TroubleshootingTony AntonyNo ratings yet

- Appendix A - G and M Codes: This Part Program Is Used With The Ballbar TestDocument40 pagesAppendix A - G and M Codes: This Part Program Is Used With The Ballbar TestIvan Hren100% (1)

- 8 Fixed Canned Cycles (CNC Course CD) PDFDocument24 pages8 Fixed Canned Cycles (CNC Course CD) PDFVeerasamy SureshbabuNo ratings yet

- CIM LAB ManualDocument58 pagesCIM LAB ManualBruce ColonNo ratings yet

- 11 Cad Cam CNC Programming MVVDocument37 pages11 Cad Cam CNC Programming MVVbassem smatiNo ratings yet

- ER-26 en Hold-Down Bolting To Resist Shaking Forces and Couples in Reciprocating CompressorsDocument3 pagesER-26 en Hold-Down Bolting To Resist Shaking Forces and Couples in Reciprocating CompressorsCamilo Andres Cardozo FajardoNo ratings yet

- Er 26 PDFDocument3 pagesEr 26 PDFCamilo Andres Cardozo FajardoNo ratings yet

- Chapter Two 2. Manual NC Part ProgrammingDocument33 pagesChapter Two 2. Manual NC Part ProgrammingMulugeta WoldeNo ratings yet

- Tool:-Single Point Cutting Tool 25Document10 pagesTool:-Single Point Cutting Tool 25HITESH SONAWANENo ratings yet

- A2100 Iso PDFDocument202 pagesA2100 Iso PDFAmit JholaparaNo ratings yet

- Reading Assignments:: Automation of Manufacturing ProcessesDocument11 pagesReading Assignments:: Automation of Manufacturing ProcessessigmasundarNo ratings yet

- CNC-Lab Mechanical ManualDocument21 pagesCNC-Lab Mechanical ManualHaresh RaisinghaniNo ratings yet

- A-53866E-387 - 02 - 050120 Startup SpindleDocument44 pagesA-53866E-387 - 02 - 050120 Startup SpindleAntonio LucasNo ratings yet

- TNG Release Notes 502Document11 pagesTNG Release Notes 502alecandro_90No ratings yet

- MachineMate Inc - Full List of CNC CodesDocument6 pagesMachineMate Inc - Full List of CNC CodesDejan StalovicNo ratings yet

- CNC Programming "Milling": Module ObjectivesDocument37 pagesCNC Programming "Milling": Module Objectiveshasan alsarrafNo ratings yet

- Part Programming On MillingDocument32 pagesPart Programming On MillingVidhanNo ratings yet

- CNC Programming and OperationDocument80 pagesCNC Programming and OperationMohammed Habeeb100% (1)

- Recondition Bearing PivotDocument17 pagesRecondition Bearing PivotMaimun maimunNo ratings yet

- G - Code M - CodeDocument3 pagesG - Code M - CodeblashkogNo ratings yet

- Lab#8: Complex Part Using Tool Diameter Compensation: DescriptionDocument4 pagesLab#8: Complex Part Using Tool Diameter Compensation: DescriptionAbdul MunimNo ratings yet

- Medidas para Mecanizar Alojamiento Anillo Sello EspejoDocument11 pagesMedidas para Mecanizar Alojamiento Anillo Sello EspejoJhonatan Valencia MillanNo ratings yet

- Reconditioning of Bearing Surfaces and Shaft Ends (4153) : PivotDocument15 pagesReconditioning of Bearing Surfaces and Shaft Ends (4153) : PivotTASHKEEL100% (1)

- Issued HSD A TS M TR 0018 - Rev F01 TR For HSD Immersion HeaterDocument25 pagesIssued HSD A TS M TR 0018 - Rev F01 TR For HSD Immersion HeaterThanh Phuc NguyenNo ratings yet

- Above Ground Storage Tanks: Wyoming Storage Tank ProgramDocument19 pagesAbove Ground Storage Tanks: Wyoming Storage Tank ProgramThanh Phuc NguyenNo ratings yet

- HSD-A-TS-M-DS-0010 - Rev-A01 Mechanical Datasheet For Closed Drain Vessel Immersion HeaterDocument2 pagesHSD-A-TS-M-DS-0010 - Rev-A01 Mechanical Datasheet For Closed Drain Vessel Immersion HeaterThanh Phuc Nguyen100% (1)

- Issued HSD A TS M TR 0018 - Rev F01 TR For HSD Immersion HeaterDocument26 pagesIssued HSD A TS M TR 0018 - Rev F01 TR For HSD Immersion HeaterThanh Phuc NguyenNo ratings yet

- HSD-A-TS-M-DS-0010 - Rev-A01 Mechanical Datasheet For Closed Drain Vessel Immersion HeaterDocument2 pagesHSD-A-TS-M-DS-0010 - Rev-A01 Mechanical Datasheet For Closed Drain Vessel Immersion HeaterThanh Phuc NguyenNo ratings yet

- Assembly DetailsDocument1 pageAssembly DetailsThanh Phuc NguyenNo ratings yet

- ASME VIII Division 1 & 2 Pressure Vessel SeriesDocument6 pagesASME VIII Division 1 & 2 Pressure Vessel SeriesThanh Phuc NguyenNo ratings yet

- 9 Storage TanksDocument10 pages9 Storage TanksThanh Phuc NguyenNo ratings yet

- IJESS Volume2, Issue6 (June-2012) ISSN: 2249-9482 Installation and Maintenance of Belt Conveyor System in A Thermal Power PlantDocument13 pagesIJESS Volume2, Issue6 (June-2012) ISSN: 2249-9482 Installation and Maintenance of Belt Conveyor System in A Thermal Power PlantThanh Phuc NguyenNo ratings yet

- M.E. Mech. Design Eng.Document35 pagesM.E. Mech. Design Eng.vikaskolage86No ratings yet

- 9 Storage TanksDocument10 pages9 Storage TanksThanh Phuc NguyenNo ratings yet

- Conversion of Existing Thermal Power Plants To CoalDocument22 pagesConversion of Existing Thermal Power Plants To CoalThanh Phuc NguyenNo ratings yet

- Base Ring AnalysisDocument9 pagesBase Ring Analysisasirul_meNo ratings yet

- 8.8 - Specification For Top Loading ArmDocument22 pages8.8 - Specification For Top Loading ArmReza Ismail Hasan100% (1)

- 8 - C - Tankage Work - Specs - For TK RDSDocument3 pages8 - C - Tankage Work - Specs - For TK RDSThanh Phuc NguyenNo ratings yet

- 650 SCM PDFDocument103 pages650 SCM PDFThanh Phuc NguyenNo ratings yet

- M.E. Mech. Design Eng.Document35 pagesM.E. Mech. Design Eng.vikaskolage86No ratings yet

- Consideration of Damages of A Floating Roof-Type Oil Storage Tank Due To Thermal StressDocument7 pagesConsideration of Damages of A Floating Roof-Type Oil Storage Tank Due To Thermal Stressthanhphucbr87No ratings yet

- IJESS Volume2, Issue6 (June-2012) ISSN: 2249-9482 Installation and Maintenance of Belt Conveyor System in A Thermal Power PlantDocument13 pagesIJESS Volume2, Issue6 (June-2012) ISSN: 2249-9482 Installation and Maintenance of Belt Conveyor System in A Thermal Power PlantThanh Phuc NguyenNo ratings yet

- Concrete Silo DesignDocument19 pagesConcrete Silo DesignSnehendu Biswas50% (2)

- 3 Bundle DetailsDocument1 page3 Bundle Detailspokemon02No ratings yet

- 92F10G07 Poc1Document27 pages92F10G07 Poc1Thanh Phuc NguyenNo ratings yet

- M.E. Mech. Design Eng.Document35 pagesM.E. Mech. Design Eng.vikaskolage86No ratings yet

- 9 Storage TanksDocument10 pages9 Storage TanksThanh Phuc NguyenNo ratings yet

- Tender Enquiry: OfficeDocument17 pagesTender Enquiry: OfficeThanh Phuc NguyenNo ratings yet

- 10C-0043-0053 Rev B - ManualDocument20 pages10C-0043-0053 Rev B - Manualpokemon02No ratings yet

- 9 Storage TanksDocument10 pages9 Storage TanksThanh Phuc NguyenNo ratings yet

- 8 - C - Tankage Work - Specs - For TK RDSDocument3 pages8 - C - Tankage Work - Specs - For TK RDSThanh Phuc NguyenNo ratings yet

- 3 Bundle DetailsDocument1 page3 Bundle Detailspokemon02No ratings yet