Professional Documents

Culture Documents

Nozzle Design Under Internal Pressure

Uploaded by

Kumar KumarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nozzle Design Under Internal Pressure

Uploaded by

Kumar KumarCopyright:

Available Formats

OWNER

PURCHASER

MECHANICAL CALCULATION BOOK FOR EA-TEST DOCUMENT NO. XXXXXXX Rev. 1

VENDOR

DESIGNER

Sabz Engineering Company

SWAGED NOZZLE CALCULATION

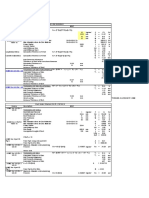

DESIGN DATA:

P = Design pressure (barg) C1 = Corrosion Allowance (mm) NP = Inlet Nozzle Size (in) Nozzle Material 2 Sn = Nozzle Allowable stress (N/mm ) Nozzle Thickness (mm) Stiffener Material Sr = Stiffener Allowable stress (N/mm2) tr = Stiffener Thickness (mm) Er = Weld Joint efficiency of Stiffener C2 = Guarantee Tolerance (mm) De = External Diameter (mm) C = Factor UG-34(c)(3) E = Weld Joint efficiency Plug Sheet Material Tensile Allowable Stress (N/mm2) 2 Bending Allowable Stress(N/mm ) T = Plug Sheet Thickness (mm) Holes O.D. (mm) Vertical Pitch (mm) EL = Ligament Efficiency a/3 = Opening Size (mm)

D

a

ich al p c i t r Ve

EL = VERTICAL PITCH - O.D. TUBE VERTICAL PITCH

d 2d L

M a 2d

a/3

a/3

a/3

82 3 8 SA-333 117.9 18.57 SA-516 Gr.70 137.9 12.5 0.55 2.28 219.1 0.33 1.0 SA-516 Gr.70 137.9 (1.5 * Stensile) 206.9 20.0 34.9 115.6 0.70 81.0

Size(in) Size (in) L (mm) M (mm) 2d (mm) d (mm) D (mm) R (mm) Z (mm) 8.0 230.0 100.0 130.0 95.0 135.0 50.0 2.5 L M 2d d D R Z 6 230 100 130 95 111 50 2.5 8 230 100 130 95 135 50 2.5 10 375 100 275 137.5 155 60 2.5 12 405 160 255 127.5 163 75 2.5

Check the flat part of the Swaged Nozzle - ASME VIII DIV.1 - UG-34(c)(3) t = (d/3) * SQRT(Z * P * C / Sn *E) + C1 + C2 12.87 mm Check the Stiffener of the Nozzle tr = ((P * d) / (3 * Sr * Er)) + 2 * C1

O.K. O.K. O.K.

9.42

mm

Check the Cylindrical part of the Nozzle - ASME VIII Div. 1 -App. 1 t = (P *De/2) / (Sn *E + 0.4P) + C1 + C2 12.69 Check the Header Nozzle Opening- ASME VIII Div. 1 -U-2(g) Bending Moment (Semiclamped Beam) M = (1/16) * P *(a/3)2 Sb = 6 * M / ((T - C1)2 * EL)

mm

3,363 100.0

N.mm N.mm

2

Sb <= Bending Allowable Stress, So The assumed Thicknesses are O.K.

You might also like

- How To Review PV Elite Design Report PDFDocument9 pagesHow To Review PV Elite Design Report PDFprocess process100% (1)

- Weight Estimation of Vessels AppsDocument39 pagesWeight Estimation of Vessels Appsmacwan23No ratings yet

- Padeye Design CheekDocument3 pagesPadeye Design CheekBolarinwa89% (9)

- External Pressure - Pressure Vessel EngineeringDocument15 pagesExternal Pressure - Pressure Vessel Engineeringarjun100% (1)

- Modification Thickness of A FlangeDocument3 pagesModification Thickness of A FlangePeter PerezNo ratings yet

- Design of Circular Flat Endplate With Stiffeners - Boiler and Pressure Vessel Engineering - Eng-TipsDocument2 pagesDesign of Circular Flat Endplate With Stiffeners - Boiler and Pressure Vessel Engineering - Eng-Tipsisrar khanNo ratings yet

- Design Procedure For Aes He PDFDocument30 pagesDesign Procedure For Aes He PDFRyan Goh Chuang HongNo ratings yet

- Skid Structure Calculation Rev.a - MBD - APPROVEDDocument45 pagesSkid Structure Calculation Rev.a - MBD - APPROVEDnamasral100% (6)

- Design For External Pressure-13022018Document14 pagesDesign For External Pressure-13022018ToniNo ratings yet

- Mechanical Design of ColumnDocument12 pagesMechanical Design of ColumnfarahanisiliasNo ratings yet

- Section VIII CalDocument19 pagesSection VIII CalPradeep Kothapalli100% (1)

- E.4 Leg Support CalculationDocument2 pagesE.4 Leg Support Calculationnaim100% (1)

- CHORD lENGTH cALCULATIONDocument4 pagesCHORD lENGTH cALCULATIONmukesh50% (2)

- Shell and Tube HE CalculationDocument16 pagesShell and Tube HE CalculationPradip ShindeNo ratings yet

- MDMT Calculations For A Pressure Vessel - Abdel Halim GalalaDocument12 pagesMDMT Calculations For A Pressure Vessel - Abdel Halim Galalabego00No ratings yet

- Crossover Area Calc For Floating HeadDocument2 pagesCrossover Area Calc For Floating HeadRitesh VishambhariNo ratings yet

- Pipe Database WeeblyDocument8 pagesPipe Database WeeblynamasralNo ratings yet

- H200141 - Calculation of Basering Rev 0 PDFDocument9 pagesH200141 - Calculation of Basering Rev 0 PDFSani Adipura WinataNo ratings yet

- Ral Colours For Coloursplash LockersDocument5 pagesRal Colours For Coloursplash Lockersnamasral100% (1)

- Lesson 09 UW16 UG37 New2Document38 pagesLesson 09 UW16 UG37 New2Kandregula Mohan BabuNo ratings yet

- PV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Document32 pagesPV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Priyo Jati WahyonoNo ratings yet

- Ibr Stand PipeDocument11 pagesIbr Stand PipeP s JagatheesanNo ratings yet

- Lug SupportDocument2 pagesLug SupportSachin5586No ratings yet

- Thickness Calculation of Pressure Vessel ShellDocument22 pagesThickness Calculation of Pressure Vessel ShellAkshat Jain88% (26)

- Detail B: Page 1 of 2Document5 pagesDetail B: Page 1 of 2namasralNo ratings yet

- 2 - 1 Ellipsoidal Head Blank DiameterDocument1 page2 - 1 Ellipsoidal Head Blank Diameterdombipin100% (1)

- Check List For Design of Pressure VesselsDocument2 pagesCheck List For Design of Pressure Vesselssuresh_vikiNo ratings yet

- Tolerance-E and Chord LengthDocument2 pagesTolerance-E and Chord LengthLcm TnlNo ratings yet

- Cs & Las Impact Req - Asme Sec Viii Div 2Document16 pagesCs & Las Impact Req - Asme Sec Viii Div 2AmitNarayanNitnawareNo ratings yet

- Asme Viii Shell & Se HeadDocument5 pagesAsme Viii Shell & Se HeadSnr George RaczNo ratings yet

- MD He Tema Asme v0.1Document31 pagesMD He Tema Asme v0.1Sharon Lambert100% (1)

- Roof Calculation Book - UBC DESIGN PDFDocument70 pagesRoof Calculation Book - UBC DESIGN PDFStephanie CampbellNo ratings yet

- Design Calculation Sheet: H2So4 Neutralization TankDocument43 pagesDesign Calculation Sheet: H2So4 Neutralization TankEkki Petrus BubunNo ratings yet

- New - Reinforcement of NozzleDocument31 pagesNew - Reinforcement of NozzleChagar HarshpalNo ratings yet

- WRC 297 RWE NODE 6340 25febDocument4 pagesWRC 297 RWE NODE 6340 25febnamasralNo ratings yet

- Swing Bolt Closure Design - Pressure VesselDocument12 pagesSwing Bolt Closure Design - Pressure VesselRasatja Yongskulrote100% (2)

- Flange KOD Vessel Calculation - Actual ConditionDocument21 pagesFlange KOD Vessel Calculation - Actual ConditionPeter PerezNo ratings yet

- PPE-STD-CAL-ME-006 Rectangular Tank Thickness CalculationDocument4 pagesPPE-STD-CAL-ME-006 Rectangular Tank Thickness CalculationNadya Askar100% (1)

- ThicknessDocument53 pagesThicknessRajul MuraliNo ratings yet

- External Template UG-29 UG-80 - 81 Calculation - Rev.0Document5 pagesExternal Template UG-29 UG-80 - 81 Calculation - Rev.0souren1975100% (1)

- 7-12-0008 Rev6 (Lug Support For Vertical Vessel) PDFDocument1 page7-12-0008 Rev6 (Lug Support For Vertical Vessel) PDFsumit kumar100% (1)

- Section VIII CalDocument21 pagesSection VIII CalRuben Samoel Barros RochaNo ratings yet

- Documents - Tips - Pressure Vessel Design Calc Asme VIII Div 1Document35 pagesDocuments - Tips - Pressure Vessel Design Calc Asme VIII Div 1bainNo ratings yet

- Aspen HX Design ReportDocument78 pagesAspen HX Design ReportberylqzNo ratings yet

- 2 - 1 Ellipsoidal Head Blank DiameterDocument1 page2 - 1 Ellipsoidal Head Blank Diameterdownloadmonster100% (2)

- 7-12-0006 Rev6 (Angle Leg Support)Document2 pages7-12-0006 Rev6 (Angle Leg Support)sumit kumarNo ratings yet

- Skirt Design - For Small VesselsDocument7 pagesSkirt Design - For Small VesselsSakthi VelNo ratings yet

- Skirt Support Analysis Per en 13445Document13 pagesSkirt Support Analysis Per en 13445karthik1amar100% (1)

- Swing Bolt CalculationDocument2 pagesSwing Bolt CalculationNicolaSavili100% (2)

- ASME Fatigue Life CurvesDocument3 pagesASME Fatigue Life CurvesnamasralNo ratings yet

- Cpp-Tank DSGN Calc-Rev CDocument42 pagesCpp-Tank DSGN Calc-Rev CnamasralNo ratings yet

- IBR CalculationsDocument20 pagesIBR CalculationsSivi NallamothuNo ratings yet

- Boiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFDocument4 pagesBoiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFAlexandru AsmarandeiNo ratings yet

- Thickness Calculation of Pressure Vessel ShellDocument16 pagesThickness Calculation of Pressure Vessel ShellClaudia BonocoreNo ratings yet

- Rectangular Tank Design ExelDocument43 pagesRectangular Tank Design ExelNguyễn Quốc PhượngNo ratings yet

- Sample Design Calculation - Vessel Supported On LugsDocument11 pagesSample Design Calculation - Vessel Supported On LugsSiva baalan100% (2)

- AES Type Heat ExchangerDocument8 pagesAES Type Heat ExchangerSudhanshu67100% (1)

- Pressure Vessel Lifting Lug CalculationDocument2 pagesPressure Vessel Lifting Lug Calculationtekstep767% (3)

- Studding FlangeDocument6 pagesStudding FlangeDarshan PanchalNo ratings yet

- 03 - Lifting Lug - 2nd Stage Separator (New)Document5 pages03 - Lifting Lug - 2nd Stage Separator (New)Alessio BarboneNo ratings yet

- Breech Lock CalculationsDocument11 pagesBreech Lock CalculationsPrasad PingleNo ratings yet

- 500-KL Tank Calculation Report Rev. BDocument64 pages500-KL Tank Calculation Report Rev. Bmochammad reygyansyahNo ratings yet

- Skirt To Dish Joint PDFDocument64 pagesSkirt To Dish Joint PDFPrajwal ShettyNo ratings yet

- Ladder Rung Calc.Document1 pageLadder Rung Calc.Azwan ShahNo ratings yet

- 7-12-0024 Rev 7Document1 page7-12-0024 Rev 7cynideNo ratings yet

- API 650 Tank Nozzle Stand Out - EditableDocument20 pagesAPI 650 Tank Nozzle Stand Out - EditableShaaban NoamanNo ratings yet

- E4.5.1 6 PTB 4 2015 PDFDocument50 pagesE4.5.1 6 PTB 4 2015 PDFKingston RivingtonNo ratings yet

- 12 Bar Air Receiver Thickness Calculation of Pressure Vessel ShellDocument16 pages12 Bar Air Receiver Thickness Calculation of Pressure Vessel ShellVipul GandhiNo ratings yet

- Tank Calculation Sheet: I. Design Parameters: TK-9291-01 Demulsifier Injection TankDocument1 pageTank Calculation Sheet: I. Design Parameters: TK-9291-01 Demulsifier Injection TanknamasralNo ratings yet

- 10 Most Popular Excel TricksDocument27 pages10 Most Popular Excel Tricksjoamer66No ratings yet

- Allowable Secondary Stress..Document7 pagesAllowable Secondary Stress..namasralNo ratings yet

- Typical P&ID Arrangement - Pig LAUNCHERDocument3 pagesTypical P&ID Arrangement - Pig LAUNCHERnamasralNo ratings yet

- 2013.10.03 - Pocket Welding Detail PDFDocument1 page2013.10.03 - Pocket Welding Detail PDFnamasralNo ratings yet

- B (MM) L (MM) B + L Length (M) Qty No of Face Area: ChannelDocument8 pagesB (MM) L (MM) B + L Length (M) Qty No of Face Area: ChannelnamasralNo ratings yet

- Legend: Marine Energy Sdn. Bhd. SapurakencanaDocument1 pageLegend: Marine Energy Sdn. Bhd. SapurakencananamasralNo ratings yet

- Butt Weld Branch OutletDocument2 pagesButt Weld Branch OutletnamasralNo ratings yet

- COADE's Application of Welding Research Council Bulletins 107, 297 and 368Document3 pagesCOADE's Application of Welding Research Council Bulletins 107, 297 and 368shivabtowin3301100% (3)