Professional Documents

Culture Documents

Check List For Design of Pressure Vessels

Uploaded by

suresh_vikiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Check List For Design of Pressure Vessels

Uploaded by

suresh_vikiCopyright:

Available Formats

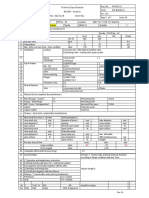

DESIGN INPUT SUMMARY FOR PRESSURE VESSELS

JOB CARD NO : 1005512

PROJECT :

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

Manufacturer's Serial No

Design Code

U stamp

NBR

Internal Design Pressure

External Design Pressure

Int. Design Temperature

Ext. Design Temperature

Operating medium

Density of Operating

medium and Liquid Head for

design

HydroTest Pressure &

Position

MDMT

Service(Lethal, sour,

Hydrogen etc.,)

Corrosion Allowance

PWHT

Impact Testing

Seismic Data

Wind Data

Snow Loading

20 Nozzle loads

21

Cycling loading and Fatigue

Analysis

22 FEA analysis required if any?

23 Radiography

24 MAWP

25 Wind vibration check

Series of ASME B16.47

26

Flanges (>24")

ASME Large Calculation

27 option (Applicable only

ASME VIII Division 1)

28 Vessel Orientation

29 Vessel Dimensions

30

Vessel standard to be

followed for general design

FUJAIRAH F2 PLANT SPM

PROJECT

CLIENT

VERMEER PROCESS

EQUIPMENT &

TAG NO

CARTRIDGE FILTER VESSELS

(2 Nos)

PV-12-46 & 47

ASME Sec VIII. Div.1 2010 Addenda 2011

YES

16.7 Barg @ 85C

F.V @ 85C

85C

-

UG-99(b) & Horizontal

As per code

No

UBC 1997, I=1.25,Zone 0

ASCE-93,Wind speed=82 km/h, EXP=C

No

No client specification is available. Client to

confrim the proposed loads

Adopted from 1005492

Adopted from 1005492

No

No

RT-1 as per ASME Sec. VIII Div.1

Limited by design

NA due to Horizontal vessel

Assumed

Assumed

DESIGN INPUT SUMMARY FOR PRESSURE VESSELS

JOB CARD NO : 1005512

PROJECT :

31

Nozzle Elevations,

projections and orientations

32 Whether Davit requirted?

33 Lifting attachments

34 Earthing lug

35 Weld toe-toe distance

36 NAME PLATE

37 MOC

Origin of material

NACE

38 Supprt type & Dimensions

39

40

41

42

43

Nozzle schedule

Ladder platform

Internals

Insulation clips

Fireproofing clips

FUJAIRAH F2 PLANT SPM

PROJECT

CLIENT

VERMEER PROCESS

EQUIPMENT &

TAG NO

CARTRIDGE FILTER VESSELS

(2 Nos)

You might also like

- Short Checklist To Complete A Design Calculation According To The ASME Boiler and Pressure Vessel Code Section VIIIDocument3 pagesShort Checklist To Complete A Design Calculation According To The ASME Boiler and Pressure Vessel Code Section VIIIRamesh sivanNo ratings yet

- Design Procedure For Aes He PDFDocument30 pagesDesign Procedure For Aes He PDFRyan Goh Chuang HongNo ratings yet

- Nozzle Design CalculationDocument1 pageNozzle Design CalculationSachin55860% (1)

- Design Calculation for Horizontal Filter VesselDocument4 pagesDesign Calculation for Horizontal Filter VesselHasmukh DaveNo ratings yet

- Project of Pressure VesselDocument25 pagesProject of Pressure VesselKalkidan DanielNo ratings yet

- Cover Pages For PV Elite VenvelDocument14 pagesCover Pages For PV Elite VenvelSakthi VelNo ratings yet

- Manual Design Validation CalculationDocument21 pagesManual Design Validation CalculationToniNo ratings yet

- Nozzle Design Under Internal PressureDocument1 pageNozzle Design Under Internal PressurenamasralNo ratings yet

- Documents - Tips - Pressure Vessel Design Calc Asme VIII Div 1Document35 pagesDocuments - Tips - Pressure Vessel Design Calc Asme VIII Div 1bainNo ratings yet

- Pressure Vessel DesignDocument21 pagesPressure Vessel Designscranderi100% (1)

- Oil Gas Construction Factory L.L.CDocument2 pagesOil Gas Construction Factory L.L.CRenny DevassyNo ratings yet

- Elliptical Head Design Tool: Pressure Vessel Engineering LTDDocument1 pageElliptical Head Design Tool: Pressure Vessel Engineering LTDJaveed KhanNo ratings yet

- Compress CalculationDocument106 pagesCompress CalculationKrupal Patel100% (1)

- Balaji S - Static Equipment Design - 7 Years - Resume - NEWDocument5 pagesBalaji S - Static Equipment Design - 7 Years - Resume - NEWkanchanabalajiNo ratings yet

- PV Elite BrocDocument6 pagesPV Elite BrocprasadgssNo ratings yet

- Saddle Calc PD5500Document4 pagesSaddle Calc PD5500rsubramaniNo ratings yet

- Vessel Allowable LoadingsDocument50 pagesVessel Allowable LoadingsfahadfiazNo ratings yet

- Fatigue Analysis in PV EliteDocument3 pagesFatigue Analysis in PV EliteCostynhaNo ratings yet

- CHORD lENGTH cALCULATIONDocument4 pagesCHORD lENGTH cALCULATIONmukesh50% (2)

- 6-12-0031 - Standard Specification For Storage Tanks For Package Items PDFDocument13 pages6-12-0031 - Standard Specification For Storage Tanks For Package Items PDFpl_arunachalam79No ratings yet

- ASME VIII-1 Calculations for Sample Pressure VesselDocument21 pagesASME VIII-1 Calculations for Sample Pressure VesselTrishul Nath Pallay100% (1)

- Pvelite OutputDocument44 pagesPvelite OutputRam MurtyNo ratings yet

- Sample Design Calculation - Vessel Supported On LugsDocument11 pagesSample Design Calculation - Vessel Supported On LugsSiva baalan100% (2)

- External Template UG-29 UG-80 - 81 Calculation - Rev.0Document5 pagesExternal Template UG-29 UG-80 - 81 Calculation - Rev.0souren1975100% (1)

- PVElite Course by Mr. AsgarzadeganDocument79 pagesPVElite Course by Mr. AsgarzadeganSaam Sasanian33% (3)

- Storage Tank Design Calculations for Hydrogen PeroxideDocument12 pagesStorage Tank Design Calculations for Hydrogen Peroxidechompink6900No ratings yet

- Impact Test Exemptions PEDDocument7 pagesImpact Test Exemptions PEDoberaiNo ratings yet

- Pressure Vessel FormulaDocument9 pagesPressure Vessel FormulaNasir Khan JadoonNo ratings yet

- Studding Outlet Calculation - PV Elite 2016Document8 pagesStudding Outlet Calculation - PV Elite 2016Liu YangtzeNo ratings yet

- Design of Pressure Vessel NewDocument200 pagesDesign of Pressure Vessel NewneelNo ratings yet

- 015 DH 1003 Rectangular TanksDocument12 pages015 DH 1003 Rectangular TanksAndrew PopeNo ratings yet

- TDC For Flanges SA 105NDocument2 pagesTDC For Flanges SA 105NRenny DevassyNo ratings yet

- External PressureDocument22 pagesExternal PressureAbhijeet SahuNo ratings yet

- Pressure Vessel Design Excel Sheet Basic Designing Non Critical PDocument1 pagePressure Vessel Design Excel Sheet Basic Designing Non Critical PAnonymous kbPP3CCcNo ratings yet

- VVD Info PDFDocument6 pagesVVD Info PDFVicky GautamNo ratings yet

- Mechanical Design Calculations of Pressure Vessel - SampleDocument27 pagesMechanical Design Calculations of Pressure Vessel - SampleSakthi Vel100% (1)

- Sight Glass Flange AnalysisDocument4 pagesSight Glass Flange AnalysisOmil Rastogi0% (2)

- New - Reinforcement of NozzleDocument31 pagesNew - Reinforcement of Nozzlehardik5818No ratings yet

- MDMT Calculations For A Pressure Vessel - Abdel Halim GalalaDocument12 pagesMDMT Calculations For A Pressure Vessel - Abdel Halim Galalabego00No ratings yet

- National Board Number Air Receiver Data ReportDocument3 pagesNational Board Number Air Receiver Data ReportSalman KhanNo ratings yet

- Ped Eam-0526-24-1-2006-03Document6 pagesPed Eam-0526-24-1-2006-03nathachaiNo ratings yet

- Cs & Las Impact Req - Asme Sec Viii Div 2Document16 pagesCs & Las Impact Req - Asme Sec Viii Div 2AmitNarayanNitnawareNo ratings yet

- Mozzle Repad Design ToolDocument2 pagesMozzle Repad Design ToolSiddiqui Muhammad AshfaqueNo ratings yet

- TDC 516 GR 70Document2 pagesTDC 516 GR 70I Kailash Rao100% (2)

- Nozzle Calculations 01Document32 pagesNozzle Calculations 01Rohith V VNo ratings yet

- Pressure Vessel Design Safety in Gas ProcessingDocument7 pagesPressure Vessel Design Safety in Gas ProcessingTeuku Muhammad ArrahmanNo ratings yet

- Nozzle Load & Saddle CalculationDocument26 pagesNozzle Load & Saddle CalculationSACHIN PATEL100% (1)

- DESIGN COLUMN WALL THICKNESS AND VESSEL SUPPORTDocument12 pagesDESIGN COLUMN WALL THICKNESS AND VESSEL SUPPORTfarahanisiliasNo ratings yet

- ASME DIV 2 Class 1 Vs Class 2Document3 pagesASME DIV 2 Class 1 Vs Class 2Idris SiddiquiNo ratings yet

- Boiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFDocument4 pagesBoiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFAlexandru AsmarandeiNo ratings yet

- Lethal Service - Quick Guide - Pressure Vessel EngineeringDocument4 pagesLethal Service - Quick Guide - Pressure Vessel EngineeringVilas AndhaleNo ratings yet

- Oil & Gas Production Enterprise (Ogpe) : H) Pressure GaugeDocument2 pagesOil & Gas Production Enterprise (Ogpe) : H) Pressure GaugeMRRogueNo ratings yet

- Oil & Gas Production Enterprise (Ogpe) : Final Documentation 20" Bi-Directional Pipe Prover ProjectDocument2 pagesOil & Gas Production Enterprise (Ogpe) : Final Documentation 20" Bi-Directional Pipe Prover ProjectMRRogueNo ratings yet

- Oil & Gas Production Enterprise (Ogpe) : I) Manual Ball ValveDocument2 pagesOil & Gas Production Enterprise (Ogpe) : I) Manual Ball ValveMRRogueNo ratings yet

- Y-Strainer Technical SpecificationDocument7 pagesY-Strainer Technical SpecificationKailas NimbalkarNo ratings yet

- Design CalcDocument308 pagesDesign CalcPeja Jusoh100% (1)

- DC S3-1301 REV.0 OriginalDocument93 pagesDC S3-1301 REV.0 OriginalPeja JusohNo ratings yet

- VD-SRU-V-004-100-Rev ADocument51 pagesVD-SRU-V-004-100-Rev ASYedZYnAleNo ratings yet

- Scrubber DatasheetDocument3 pagesScrubber DatasheetShima Ash100% (2)

- PE-D-A06124222143-01-ME-DAS-015-01-E - Net Oil Storage Tanks - TFRJ-33-TK-1101A - BDocument7 pagesPE-D-A06124222143-01-ME-DAS-015-01-E - Net Oil Storage Tanks - TFRJ-33-TK-1101A - B7radu7No ratings yet

- 01 Samss 035Document27 pages01 Samss 035Ahmed Shaban KotbNo ratings yet

- MSS SP 97 PDFDocument15 pagesMSS SP 97 PDFgowtham_venkat_4100% (1)

- 09-SAMSS-069 - Epoxy Coating For Atmospheric Service PDFDocument10 pages09-SAMSS-069 - Epoxy Coating For Atmospheric Service PDFsuresh_viki100% (1)

- 7-12-0038 Rev 0 PDFDocument4 pages7-12-0038 Rev 0 PDFsuresh_vikiNo ratings yet

- Pipe Schedule PDFDocument1 pagePipe Schedule PDFSrinivasan SeenuNo ratings yet

- ASME-B1-20-1 - (Pipe Threads) 1983 PDFDocument32 pagesASME-B1-20-1 - (Pipe Threads) 1983 PDFsuresh_vikiNo ratings yet

- 7-12-0029 Rev 5 PDFDocument1 page7-12-0029 Rev 5 PDFsuresh_vikiNo ratings yet

- 02 Samss 011Document31 pages02 Samss 011Nicu Man100% (1)

- Asme B46.1 2002Document5 pagesAsme B46.1 2002Suryanarayanan Venkataramanan14% (7)

- Catalogo VictaulicDocument136 pagesCatalogo VictaulicGerardo Sanchez100% (1)

- Ayuda Asme B36.10M PDFDocument26 pagesAyuda Asme B36.10M PDFEdgargar100% (1)

- Beam Design Formulas With Shear and MomentDocument20 pagesBeam Design Formulas With Shear and MomentMuhammad Saqib Abrar100% (8)

- Material Selection GuideDocument1 pageMaterial Selection Guidesuresh_vikiNo ratings yet

- Surface Finish TableDocument1 pageSurface Finish Tablesuresh_vikiNo ratings yet

- EN 1092-1-Flange PDFDocument18 pagesEN 1092-1-Flange PDFSimona Adriana100% (1)

- Is: 1239part 2 Mild Dteel Tube PipeDocument36 pagesIs: 1239part 2 Mild Dteel Tube PipeRathnakar NaikNo ratings yet

- BS 4504 PN16 Flange DimensionsDocument3 pagesBS 4504 PN16 Flange Dimensionssuresh_vikiNo ratings yet

- Handrail CalculationDocument8 pagesHandrail Calculationsuresh_viki100% (1)

- Pipe ChartDocument1 pagePipe Chartsuresh_vikiNo ratings yet

- Nitrile Butadiene Rubber Gasket Material SubmittalDocument2 pagesNitrile Butadiene Rubber Gasket Material Submittalsuresh_vikiNo ratings yet

- BS 499 Part 2Document18 pagesBS 499 Part 2whitebrosNo ratings yet

- Incoloy Alloy 825Document4 pagesIncoloy Alloy 825Roman PaduaNo ratings yet

- Asme Q&aDocument21 pagesAsme Q&asuresh_vikiNo ratings yet

- Nitrile Butadiene Rubber Gasket Material SubmittalDocument2 pagesNitrile Butadiene Rubber Gasket Material Submittalsuresh_vikiNo ratings yet

- Nitrile Butadiene Rubber Gasket Material SubmittalDocument2 pagesNitrile Butadiene Rubber Gasket Material Submittalsuresh_vikiNo ratings yet

- Understanding Welding Symbols Terms and DefinitionsDocument23 pagesUnderstanding Welding Symbols Terms and DefinitionsseymaNo ratings yet

- Spot Radiography & No RadiographyDocument2 pagesSpot Radiography & No Radiographysuresh_vikiNo ratings yet

- Pressure Conversion TableDocument1 pagePressure Conversion Tablesuresh_vikiNo ratings yet

- ASTM A573-00a Structural Carbon Steel Plates of Improved ToughnessDocument1 pageASTM A573-00a Structural Carbon Steel Plates of Improved Toughnesssuresh_vikiNo ratings yet