Professional Documents

Culture Documents

NTK General Catalog 5100

Uploaded by

Henrique MarquesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NTK General Catalog 5100

Uploaded by

Henrique MarquesCopyright:

Available Formats

www.youtube.

com/ntkcuttingtools

www.ntkcuttingtools.com

5100

SHARP PEOPLE

SHARP IDEAS

SHARP TOOLS

SPARK PLUGS

(

USA

)

, INC.

App for iPad

NTK TECHNOLOGY

Gray / Ductile Cast Iron

High Temperature Alloys

Hardened Steels

Mill Rolls Grooving

Tooling For Swiss Type Lathes

Bearing Production Steel Machining High Speed Machining of

Aluminum

Metalcutting Safety

AppIlCabIe FrOOuCts FOsslbIe Rlsks Saety Neasures

GeneraI Cuttlng

TOOIs

Contact with a sharp cutting edge with bare hands may

result in injury.

Use protective gear such as protective gloves when

taking the tool out of packaging and installing into the

machine.

Misuse or using under inappropriate conditions may

cause the cutting tool to break and/or shatter into

pieces, resulting in personal injury.

Use protective equipment, machine guarding and/or

protective glasses.

Use within the range of recommended conditions.

Please refer to the instruction manual and catalogue.

Sudden increase in cutting resistance due to sudden

impact load or excessive wear may cause the cutting

tool to break and/or shatter into pieces, resulting in

personal injury.

Use protective gear such as protective gloves when

taking the tool out of packaging and installing into the

machine.

High-temperature chips may be produced and long

chips may be ejected, resulting in injury and/or burns.

Use protective equipment, machine guarding and/or

protective glasses.

Before removing chips, always stop the machine. Wear

protective gloves and use proper equipment for chip

removal.

The tool and material/work being cut can become very

hot. Touching them immediately after use may cause

burns.

Use protective gear such as protective gloves.

Sparks, heat generation due to breakage and/or chips

during cutting may cause fire.

Do not use the machine and tools in locations where

there are risks of ignition or explosion.

When using water-insoluble cutting oil, fire prevention

measures must be implemented.

Out of balance machine set ups when used at a high-

speed, may cause insert breakage due to excess

vibration or chatter, resulting in injury.

Use protective equipment, machine guarding and/or

protective glasses.

Perform a trial-run beforehand to make sure the setup is

stable, free of chatter, vibration and abnormal noise.

Touching burrs and flashes on machined work may

result in personal injury.

Use adequate hand protection.

ThrOW-AWay

Type TOOIs

(Wlth lnOexabIe

lnsert)

Inappropriately clamped inserts and/or components

may become detached from the machine during cutting,

resulting in injury.

Before installing the insert, clean the seating surface and

clamping components so that they are free of debris.

Use the wrench supplied to install the insert and check

that the insert and components are securely clamped. Do

not use any inserts or components other than the items

specified.

Excessively tightening with a device such as a pipe

extension may cause the insert and/or components to

break or detach due to over clamping.

Do not use tightening devices such as pipe extensions to

obtain further torque. Always use the supplied wrench.

At a high speeds inserts and/or components may

lose clamping pressure due to the loosening effect of

centrifugal force. This is very dangerous. Always ensure

secure clamping systems and check regularly.

Use within the range the recommended conditions.

Please refer to the instruction manual and catalogue.

Cutters anO

ROtatlOnaI TOOIs

As cutters have sharp cutting edges, contact with bare

hands may result in injury.

Use protective equipment such as protective gloves.

Imbalance or eccentric rotation may cause the tool to

break due to vibration or chatter, resulting in potential

injury.

Use at a rotational speed within the recommended

conditions.

To prevent eccentric rotation and vibration due to worn

bearings, regularly check the machine rotor/rotating

parts for the accuracy and balance and adjust as

required.

BrazeO Inserts /

TOOIs

Inserts may break or become, detached due to incorrect

brazing.

Use protective equipment such as machine guards and/

or protective glasses. Additional guarding around the

chuck and drill may be advisable.

Cthers

It is not advisable to use repeatedly brazed inserts as

the braze may progressively weaken.

Do not use repeatedly brazed inserts as the strength of

such inserts is lowered.

Use only for the original and intended purpose. Using

outside recommended parameters is very dangerous,

causing damages to machines and/or tools.

Always use and operate as specified, observing the

required safety rules and conditions.

GuIdeIInes lor CataIog

This catalog lists products as of March 2013.

Please note that specifications of the products listed in this catalog may be

changed without notice due to continuous research & development and

product improvements.

This catalog contains the major features and relevant information on all of our

products. Please contact our sales representatives or dealers if more detailed

information is needed.

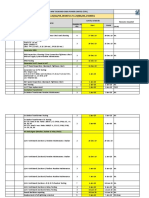

Stock Status Symbols

Standard stock available for Right-Hand, Left-Hand and neutral products

Stock available only in Right-Hand

Stock available only in Left-Hand

1-2 weeks delivery

1-2 weeks delivery only in Right-Hand

1-2 weeks delivery only in Left-Hand

While stock lasts

No symbolNot stocked

Please note that this catalog was prepared based on products intended mainly

for sale in North and South America.

StanOarO

1Holder Type Package quantity Notes

Turnlng hClCer 1 C/Case

Allllng CuLLer 1 C/Case

2Spare parts Package quantity Notes

SCrev 1U Cs/Case

Clam sCrev, Clam UClL, LCuUle sCrev,

BuLLCn sCrev

SeaL 1U Cs/Case Shlm seaL

Clam 1U Cs/Case Clam

VrenCh anC CuLLer arLs

(suCh as CarLrlCges)

5 Cs/Case VrenCh, UlL, CuLLer rCCuCL

HanCle 1 C/Case HanCle vlLh magneL, hanCle anC UlL

3Insert Type Package quantity Notes

CBM 1 C/Case , , , ,

FCL 1 C/Case FL1

CTFV lnserL lCr CuL-C 5 Cs/Case CTFV serles

STlCK LLC

SCllC CarUlCe Uar

1 C/Case SHFS, SHFB, SBFS, SBFB, SBC, SBT

All CLhers 1U Cs/Case

FaCkaglng may vary CeenClng Cn Lhe rCCuCL slze.

FCr mCre lnlCrmaLlCn, lease CCnLaCL yCur nearesL Cealer Cr Cur sales ClllCe.

Cont ent s Cont ent s Cont ent s

Cutting Tool Catalog

Table of Contents

New Froduct lnlormatIon J to 5

AppIIcatIon

lntroductIon

J to J0

TooI NaterIaIs

5eIectIon GuIde

J to J4

Grade lntroductIon

J to 3

lnsert ltem LIst

J to 5J

GeneraI TurnIng

TooIhoIders

J to 20

lD TooIIng

J to 5

GroovIng TooIs

J to J2

NIIIIng Cutter

J toJ9

For 5wIss-type Lathes

J to J33

lnlomatIon

J to J2

lndeX

J to

NEW FkODUCT5

"5X7"SlAICN CeramlC A2

"5F9"CVO COateO slIlCOn nltrlOe CeramlC A2

"EZ CUE"CBN graOes A3

"DN4 DT4"FVO COateO CarblOe A4

"TN4"FVO COateO CarblOe A4

NEW FkODUCT5 FOk

5Wl55-TYFE LATHE5

"CUT DUO''Cut-O tOOIs Or Iarge Olameter J2

"ACK DUO"NO-COmprOmlse quaIlty baCk turnlng tOOIs J3

"Thread WhIrIIng"Nake hlgh preClslOn threaOs ln a SINGLE pass J4

"CL ChIpbreaker"COvers extremeIy WlOe Cuttlng range J5

"ANX ChIpbreaker"OeslgneO Or very Ilght Oepth O Cut J

"UL ChIpbreaker"Sharp eOgeO negatlve lnserts that Cut Ilke pOsltlve J7

"D5-ACH HoIders"AOjust CenterIlne helght slmpIy Wlth a WrenCh J

"NoguI ar"Hlgh rlglOlty bOrlng bar Wlth exCeIIent Chlp COntrOI J9

"5TlCK DUO Hyper"InOex OOubIe-enOeO IO tOOIs Wlth ease JJ0

"5hIlted TooIhoIders"SOIutlOn Or extenOeO gulOe bushlng users JJJ

"D5 5Ieeve"FrOteCt Ilve tOOI statlOns JJJ

"5ATUkN DUO"FaCe grOOvlng Or smaII parts JJ2

"lndeXabIe End NIIIs"SmaII Olameter enO mlIIs Or smaII parts JJ2

A2

SP9 New coated silicon nitride ceramic

NEW NEW

HIgh speed cast Iron machInIng wIth Iow cuttIng lorces !

A EXceIIent wear resIstance and toughness

A 5maIIer edge preparatIon reduces cuttIng lorce

A 5tabIIIze nIsh appIIcatIons

A Heavy Interrupted machInIng ol cast Iron

A koughIng to FInIshIng ol cast Iron wIth Iow tooI pressure

A HIgh speed, HIgh precIsIon machInIng

Features

Features

AppIIcatIons

AppIIcatIons

SX7 New SiAION ceramic

NEW NEW

The neXt step In machInIng aerospace aIIoys !

A etter notchIng resIstance compared to

whIsker ceramIcs

No need to program rampIng when

compared to whIsker ceramIcs

A etter lIank wear resIstance compared to

other 5IAION ceramIcs

5uperIor perlormance vs. whIsker

ceramIcs under same condItIons-even

hIgher productIvIty at hIgher leed rates

AEXceIIent thermaI shock resIstance

HIgh speed mIIIIng can be perlormed at

30005FN or hIgher

A koughIng and semI lInIshIng ol heat resIstant

aIIoys

ANIIIIng, prolIIIng and groovIng ol heat resIstant aIIoys

A est grade lor pre-machIned WaspaIoy

B2D12

B4D11

N

e

w

F

r

o

d

u

c

t

s

A3

A

GraOe Naln blnOer CBN COntent NajOr appIlCatlOns

23 Tl-base 90 Hlgh speeO rOughlng O gray Cast lrOn, slntereO metaIs

30 Tl-base 95 Hlgh speeO lnlshlng O gray Cast lrOn

3 TlCN-base 65 Llght- tO lnterrupteO maChlnlng O harOeneO materlaIs

40 TlN-base 65 InterrupteO maChlnlng O harOeneO materlaIs

52 TlC-base 50 Flnlshlng O OuCtlIe Cast lrOn anO COntlnuOus maChlnlng O harOeneO materlaIs

A NuItIpIe cuttIng edges Iower cost per corner

A A varIety ol grades optImIzed lor dIerent work

materIaIs and machInIng condItIons

A FrovIdes Ionger and more stabIe tooI IIle In

hIgh-speed machInIng appIIcatIons

Gray cast ironRough Gray cast ironFinish Ductile cast ironFinish

23 30 52

.004

20

R.001

.004

20

.004

15

R.001

Hardened material Continuous Hardened material Light-interruption Hardened material Interruption

52 3 40

.004

15

R.001

25

R.001

.005

R.001

35

.006

5uItabIe lor machInIng GrayDuctIIe cast Iron 5uItabIe lor machInIng hardened materIaIs

New serIes ol muItI-corner tIpped Inserts In new CN grades !

Cut tooIIng cost even lurther by combInIng wIth NTK ceramIc tooIs!

StanOarO eOge preparatlOn StanOarO eOge preparatlOn

B23

B52

6UUU

45UU

3UUU

15UU

.U4 .U6 .12

B30

Ceramic

C

u

L

L

l

n

g

s

e

e

C

S

F

A

)

LeLh Cl CuLlnCh)

FCO

300

600

900

B36

B52

B40

Ceramic

C

u

t

t

i

n

g

s

p

e

e

d

S

F

M

)

Continuous Light-interruption Medium interruption Interruption

For cast iron For hardened materials

See CeramlC graCes lCr harC Lurnlng Cn age B6 anC B7.

ReCOmmenOeO Cuttlng COnOltlOns

WOrk materlaI

GraOe

Cuttlng speeO

SFN

FeeO rate

IFR

Oepth O Cut

lnCh

COOIant

NaterlaI/Other HarOness ORY WET

Gray Cast lrOn

HB

26U

B23, B3U 13UU33UU .UU4.U2U .UU6.U6U

OuCtlIe Cast lrOn

HB

33U

B52 3UU16UU .UU4.U16 .UU6.U6U

HarOeneO steeI

HRC

5U66

CCnLlnuCus B52 3UU1UUU .UU4.U2U .UU4.U4U

LlghL-lnLerruLlCn B36 13U6UU .UU2.UU6 .UU4.U4U

lnLerruLlCn B4U 1UU5UU .UU2.UU6 .UU4.U4U

SlntereO aIIOy

HRC

35

B23 15U1UUU .UU1.UU6 .UU2.U2U

1sL reCCmmenCaLlCn 2nC reCCmmenCaLlCn

Features

NEW NEW

New CBN grades

D24D25

N

e

w

F

r

o

d

u

c

t

s

A4

DM4 / DT4 New PVD coated carbide

NEW NEW

est grade lor TItanIum aIIoys !

EXtremeIy smooth coatIng lor eXceIIent surlace lInIsh !

Ultra Z coat

Excellent adhesion

resistance

Excellent wear

resistance

Excellent adherence to

insert substrate

SmCCLh surlaCe makes Chl

Cv easler

CCnvenLlCnal CCaLlng

Prevent adhesion

TM4 New PVD coated carbide

NEW NEW

Features

Features

UItra Z coat

A EXceIIent dImensIonaI stabIIIty and tooI IIle thanks to the trIpIe tItanIum Iayers adherIng

to the Insert substrate

A AdhesIon resIstant hard and smooth top coatIng Iayer resuIts In eXceIIent surlace nIshes

A EXceIIent oXIdatIon resIstance

enabIes hIgh temperature machInIng

A TrIpIe coatIng Iayers provIde superIor

tooI IIle and consIstancy

A FCr TlLanlum allCys

A FCr harC LC CuL maLerlals

A FCr hlgh LemeraLure allCys

DN4 DT4

Oxidation temperature

Low

Low

High

High

H

a

r

d

n

e

s

s

(

H

v

)

TiCN

DM4 / DT4

TiN TiAIN

AdhesIon resIstant Iayer TIN

Wear resIstant Iayer TICN

OXIdatIon resIstant Iayer TIAlN

CarblOe CarblOe

D36

D36

N

e

w

F

r

o

d

u

c

t

s

A5

PVD Coatings

est baIance ol

wear resIstance

and adhesIon

resIstance

A FOr smaII part

maChlnlng ln generaI

TN4 TN-Coat

est baIance ol

heat resIstance

and sharp edges

ATltanlum aIIOy

AHeat reslstant aIIOy

AStalnIess steeI

AHarOeneO materlaI

DT4 DT-Coat

est

wear resIstance

AstalnIess steeI

ACarbOn steeI

AAIIOy steeI

3J5 Q-Coat

est

edge sharpness

ATltanlum aIIOy

ANOn-errOus materlaI

AStalnIess steeI

AFIastlC

VNJ V-Coat

est

heat resIstance

A Heat reslstant aIIOy

A StalnIess steeI

A HarOeneO materlaI

DN4 DN-Coat

est

adhesIon resIstance

A GeneraI purpOse maChlnlng

Z3C7Z Z-Coat

CoatIng 5pecItIcatIons

Q-Coat TN-Coat DN-Coat DT-Coat V-Coat Z-Coat

ThlCkness ThlCk Thln ThlCk Thln Thln ThlCk

Vear ReslsLanCe

HeaL ReslsLanCe

ACheslCn ReslsLanCe

LCge Sharness

CCmCslLlCn TlCM AulLllayer AulLllayer AulLllayer TlCM TlM

1sL ChClCe 2nC ChClCe

NEW

NEW NEW

D30D37

D36

D37

D36

D36

D31D37

N

e

w

F

r

o

d

u

c

t

s

A

Come

More

to

www.youtube.com/ ntkcut tingtool s

$SSIRUL3DG

N

e

w

F

r

o

d

u

c

t

s

J

AppIIcatIon lntroductIon

A NachInIng HIgh Temperature AIIoys

wIth CeramIcs 2

A NachInIng Gray DuctIIe Cast lron

wIth CeramIcs 4

A NachInIng NIII koIIs wIth CeramIcs

A NachInIng Hardened NaterIaIs

wIth CeramIcs 7

A TooIIng lor 5wIss-type Lathes

A HIgh 5peed NIIIIng ol AIumInum J0

B

A

p

p

I

I

c

a

t

I

o

n

l

n

t

r

o

d

u

c

t

I

o

n

2

Machining High Temperature Alloys with Ceramics

5oIutIons lor the Aerospace lndustry

RCugh Turnlng vlLh sCale anC

lnLerruLlCns

5X5

MCLChlng

Flank Vear

TCughness

HeaL ShCCk

SiAlON Ceramic

SiAlON Ceramic

Can replace whisker ceramics by using higher feed rates

BeLLer nCLChlng reslsLanCe CCmareC LC vhlsker CeramlCs

MC neeC LC rCgram ramlng vhen CCmareC LC vhlsker CeramlCs

BeLLer ank vear reslsLanCe CCmareC LC CCmeLlLCr's SlAlCM CeramlCs

BesL graCe lCr re-maChlneC VasalCy

BesL graCe lCr hlgh-seeC mllllng

BesL graCe lCr sCale anC lnLerruLlCns

BesL graCe lCr maChlnlng hlgh-CCUalL allCys

kecommended Work NaterIaIs

VasalCy LClmeL 72U

716Flus Rene 41

Seml-Flnlsh FrCllng

Allllng CrCCvlng

kecommended Work NaterIaIs

lnCC 716 lnCC 625

VasalCy LClmeL 72U

kecommended AppIIcatIons

kecommended AppIIcatIons

Features

Features

TCCl Llle . 4.5mln

RCCX45,6UUSFA.UU6lFR,.U4U",VeL

lnCC 716 (re-maChlneC)

TCCl Llle . 2.Umln

RMC65,95USFA.U12lFR,.15U",VeL

VasalCy vlLh SCale

FroIIng ol lnco 7J

CCmeLlLCr's Vhlsker CeramlC

CCmeLlLCr's Vhlsker CeramlC

5X7

5X5

kough TurnIng ol WaspaIoy wIth 5caIe

SX7

SX5

TurUlne Llsk

TurUlne Case

NEW

D12

D13

nC

ons

B

e

t

t

e

r

F

l

a

n

k

W

e

a

r

R

e

s

i

s

t

a

n

c

e

S

e

m

i

R

o

u

g

h

W

a

s

p

a

l

o

y

B

e

t

t

e

r

N

o

tch

W

a

s

p

a

l

o

y

B

e

t

t

e

r

N

o

tch

B

e

t

t

e

r

F

l

a

n

k

W

e

a

r

R

e

s

i

s

t

a

n

c

e

S

e

m

i

R

o

u

g

h

A

p

p

I

I

c

a

t

I

o

n

l

n

t

r

o

d

u

c

t

I

o

n

3

T

o

u

g

h

e

r

Fin

is

h

I

n

c

o

7

1

8

ing

R

e

s

i

s

t

a

n

c

e

ing

R

e

s

i

s

t

a

n

c

e

T

o

u

g

h

e

r

Fin

is

h

I

n

c

o

7

1

8

Seml-Flnlsh FrCllng

CrCCvlng

RCugh Lurnlng vlLh sCale

Allllng

5X7 5X9 WAJ

VersaLlle graCe lCr maChlnlng Cl hlgh LemeraLure allCys

BeLLer ank vear reslsLanCe CCmareC LC SlAlCM CeramlCs

BeLLer nCLChlng reslsLanCe CCmareC LC CCmeLlLCr's vhlsker CeramlCs

TCugher vhen CCmareC LC vhlsker CeramlCs

LxLreme LCughness makes hlgher leeC anC heavler LCC maChlnlng CsslUle

BesL graCe lCr maChlnlng lnCC 716 vlLh sCale

kecommended Work NaterIaIs

kecommended Work NaterIaIs

lnCC 716 lnCC 625

lnCC 716 lnCC 7U6

lnCC 713

kecommended AppIIcatIons

kecommended AppIIcatIons

Features

Features

TCCl Llle . 5.Umln

RFCX45,6UUSFA.UU6lFR,.U4U",VeL

lnCC 716 (re-maChlneC)

TCCl Llle . 3.Umln

RMC65,6UUSFA.U1UlFR,.15U",VeL

lnCC 716 vlLh SCale

FroIIng ol lnco 7J

kough TurnIng ol lnco 7J wIth 5caIe

CCmeLlLCr's Vhlsker CeramlC

CCmeLlLCr's Vhlsker CeramlC

WAJ

5X9

Whisker-Reinforced Ceramic WA1

SiAlON Ceramic SX9

TurUlne Case

CCver ShlelC

D9

D13

Turnlng CulCanCe

CrCCvlng CulCanCe

D17

H4

AllCaLlCn CulCanCe

Allllng CulCanCe

D14

3

A

p

p

I

I

c

a

t

I

o

n

l

n

t

r

o

d

u

c

t

I

o

n

4

Machining Gray / Ductile Cast Iron with Ceramics

HIgh 5peed NachInIng ol Cast lrons

5F9

MCLChlng

Flank Vear

TCughness

HeaL ShCCk

CVD Coated Silicon Nitride Ceramic

TiC Ceramic Whisker Reinforced

Ceramic

kecommended AppIIcatIons

Cray CasL lrCn RCugh Turnlng anC mllllng

LuCLlle CasL lrCn RCugh Turnlng anC mllllng

kecommended AppIIcatIons

Cray CasL lrCn Flnlsh TurnlngHC2HC6VA1

LuCLlle CasL lrCn Flnlsh TurnlngHC6

LxLreme LCughness TCugh enCugh LC rCugh CasL lrCn vlLh

TU42U (.UU4X2U) eCge rearaLlCn

Small eCge rearaLlCn LCv LCCl ressure lCr sLaUle reClslCn maChlnlng

Turnlng aL hlgh leeC raLe Lhanks LC Lhe suerU LCughness

LramaLlCally reCuCeC ank vear Cue LC CVL CCaLlng

Features

Aake hlgh seeC nlshlng Cl CasL lrCn CsslUle

AllCaUle lCr veL CuLLlng

HC6 CLlmlzeC lCr nlshlng CuCLlle CasL lrCn

Features

NEW

SP9

HC2, HC6 WA1

D11

rced

F

i

n

i

s

h

F

i

n

i

s

h

D

R

Y

a

n

d

W

E

T

D

R

Y

a

n

d

W

E

T

kecommended CuttIng CondItIons

WOrk materlaI FurpOse GraOe

Cuttlng speeO

SFN

FeeO

IFR / IFT

Oepth O Cut

lnCh

ORY WET

Cray CasL lrCn

Turnlng

5F9

12UU27UU .U12.U24 .14U

Allllng 12UU27UU .UU2.U1U .3UU

LuCLlle CasL lrCn

Turnlng

5F9

6UU2UUU .U12.U24 .14U

Allllng 6UU2UUU .UU2.U1U .3UU

kecommended CuttIng CondItIons

WOrk materlaI FurpOse GraOe

Cuttlng speeO

SFN

FeeO

IFR

Oepth O Cut

lnCh

ORY WET

Cray CasL lrCn Turnlng

HC2HC 12UU21UU .UU4.U16 .U6U

WAJ 12UU21UU .UU4.U16 .12U

LuCLlle CasL lrCn Turnlng HC 6UU15UU .UU4.U12 .U4U

D9 D6D7

A

p

p

I

I

c

a

t

I

o

n

l

n

t

r

o

d

u

c

t

I

o

n

5

D

R

Y

D

R

Y

R

o

u

g

h

R

o

u

g

h

5X 5XJ 5F2

CVD Coated

Silicon Nitride

Ceramic

Silicon Nitride

Ceramic

Alumina Oxide

Ceramic

kecommended AppIIcatIons

Cray CasL lrCn Flnlsh Turnlng

ChllleC llners RCugh / Flnlsh TurnlngHV2

kecommended AppIIcatIons

Cray CasL lrCn RCugh Turnlng anC mllllng

LuCLlle CasL lrCn RCugh Turnlng anC mllllng

1sL ChClCe lCr rCughlng gray CasL lrCn

AllCaUle lCr veL CuLLlng

LxCellenL Lhermal shCCk reslsLanCe make hlgh seeC mllllng CsslUle

Features

1sL ChClCe lCr nlshlng gray CasL lrCn vlLh nC CCClanL

LxCellenL vear reslsLanCe make hlgh seeC nlshlng CsslUle

Features

HC1, HW2

SX6, SX1 SP2 D11

kecommended CuttIng CondItIons

WOrk materlaI FurpOse GraOe

Cuttlng speeO

SFN

FeeO

IFR

Oepth O Cut

lnCh

ORY WET

Cray CasL lrCn Turnlng

HCJ 12UU21UU .UU4.U16 .U2U.U6U

HW2 12UU21UU .UU4.U16 .U2U.U6U

ChllleC llners Turnlng HW2 6UU12UU .UU4.U12 .U2U.U6U

kecommended CuttIng CondItIons

WOrk materlaI FurpOse GraOe

Cuttlng speeO

SFN

FeeO

IFR / IFT

Oepth O Cut

lnCh

ORY WET

Cray CasL lrCn

Turnlng

5X 16UU35UU .U12.U24 .U2U.14U

5XJ 15UU3UUU .U12.U24 .U2U.14U

5F2 12UU27UU .UU6.U2U .U2U.14U

Allllng 5X 15UU42UU .UU3.U1U .U2U.14U

LuCLlle CasL lrCn

Turnlng

5X 9UU16UU .UU5.U16 .U2U.12U

5XJ 6UU16UU .UU5.U16 .U2U.12U

Allllng

5X 12UU2UUU .UU3.UU6 .U2U.12U

5XJ 1UUU16UU .UU3.UU6 .U2U.12U

Allllng CulCanCe 3

D10D11

D4D5

A

p

p

I

I

c

a

t

I

o

n

l

n

t

r

o

d

u

c

t

I

o

n

HkCD VkAON

Features

A 5everaI ceramIc and CN grades lor aII mIII-roII

turnIng appIIcatIons

A ln addItIon to standard grade "HC2", NTK oers

"HC5" and "HC7" lor hIgher productIvIty

Machining Mill Rolls with Ceramics

lmprove FroductIvIty

kecommended CuttIng CondItIons

NaterlaI

ChOlCe

Cuttlng speeO

(SFN)

FeeO

(IFR)

Oepth O Cut

(lnCh)

ORY WET

ShOre HarOness SCaIe

GraOe 55-65 65-72 72-

SLeel

ex. L2

1sL

HC7

15U5UU 1UU% 6U% 6U% .UU4.U12 .U25.U75

2nC

HC5

15U5UU 1UU% 6U% 6U% .UU4.U12 .U25.U75

3rC

HC2

15U45U 1UU% 6U% 6U% .UU4.U12 .U25.U75

ChllleC CasL lrCn

1sL

HC5

15U6UU 1UU% 6U% 6U% .UU4.U12 .U25.U75

2nC

HC7

15U6UU 1UU% 6U% 6U% .UU4.U12 .U25.U75

3rC

HC2

15U45U 1UU% 6U% 6U% .UU4.U12 .U25.U75

LuCLlle CasL lrCn

1sL

HC5

3UU6UU 1UU% 6U% 6U% .UU4.U12 .U25.U75

2nC

HC

3UU6UU 1UU% 6U% 6U% .UU4.U12 .U25.U75

CarUlCe

1sL

CN

1UU2UU .UU4.U12 .U1U

2nC

WAJ

1UU2UU .UU4.U12 .U1U

CFA RClls

ex. FCvCereC AeLal

1sL

ZC4

15U5UU .UU4.U12 .U25.U75

2nC

HC7

15U5UU .UU4.U12 .U25.U75

HoIders

F20 F19

HarCness Cl Lhe RCll ls Lhe lmCrLanL laCLCr. As Lhe rCll geLs harCer, UaCk C yCur SFA.

LCC vlll CeenC uCn Lhe amCunL Cl maLerlal LC remCve. Vhen maklng mulLlle asses vlLh Cne eCge, vary yCur LCC LC mCve Lhe vear LC anCLher arL Cl

Lhe lnserL eCge.

ll yCu enCCunLer ChaLLer, lnCrease yCur FeeC RaLe rsL LC geL rlC Cl lL. VarlaUle RFA CCnLrCllers are hellul here LC Ureak u harmCnlCs.

A

p

p

I

I

c

a

t

I

o

n

l

n

t

r

o

d

u

c

t

I

o

n

7

Machining Hardened Materials with Ceramics

DramatIcaIIy keduce Costs

ZC7 ZC4

A ZC7 and ZC4 have eXceIIent wear resIstance needed

to machIne hardened materIaIs

A ZC7 covers a wIde range ol appIIcatIons such as

carburIzed or InductIon hardened steeIs

A ZC4 perlorms the best In hardened materIaI

appIIcatIons lrom Hkc 55-70

A WIper Inserts and AG-chIpbreaker Improve

machInIng ecIency

50

50

100

200

300

400

500

600

700

800

55 60

HARDNESS (HRc)

S

P

E

E

D

(

S

F

M

)

65 70

Features

kecommended 5peed kange

kecommended CuttIng CondItIons

AG-ChIpbreaker

WIth AG-chIpbreaker

WIthout AG-chIpbreaker

Good chip control

Improve surface nish

Reduce machine down time

Price advantage vs. CBN

WOrk materlaI

HarOness

HRC

GraOe FurpOse

Cuttlng speeO

(SFN)

FeeO

(IFR)

ORY WET

HarCeneC maLerlal

3U62

ZC7

Flnlsh

CCnLlnuCus

13U7UU .UU3.UU6

557U

ZC4

D8

A

p

p

I

I

c

a

t

I

o

n

l

n

t

r

o

d

u

c

t

I

o

n

A

p

p

I

I

c

a

t

I

o

n

l

n

t

r

o

d

u

c

t

I

o

n

Tooling for Swiss type lathes

Advanced DS holders

'6$&+

J8

For front turning

&/&KLSEUHDNHU

J5

New back turning tool

%$&.'82

J3

For light depth of cut

$0;&KLSEUHDNHU

J6

For small diameter cut-of

&736+W\SH

J54

For large diameter cut-of

&87'82

J2

For negative inserts

8/&KLSEUHDNHU

J7

A must for extended guide bushing users

6KLIWHG7RROKROGHUV

J11

NEW NEW

NEW NEW NEW

NEW NEW NEW

9

A

p

p

I

I

c

a

t

I

o

n

l

n

t

r

o

d

u

c

t

I

o

n

A great solution for chip control problems

<D[LV+ROGHUV

J118

High quality polycrystalline diamond grade

3'1

D26

New swiss tooling catalog now available

For more detail

Protection for live tool spindles

'66OHHYH

J11

Hight performance thread forming

7+5($':+,5/,1*

J4

Face grooving tool

6$7851'82

J12

High rigidity boring bar

0RJXO%DU

J9

Double-ended bars with adjustable overhang

67,&.'82+\SHU

J10

F d t il

NEW

NEW NEW

NEW NEW

J0

utter utter erformance erformance igh igh

High Speed Milling of Aluminum

NEW NEW

AWIde cutter dIameter range

Ranglng rOm .79" tO 3.94"

ANo presettIng requIred

The xeO-type HFC Can be lnOexeO OnIy

by repIaClng lnserts

The aOjustabIe HFC aIIOWs aOjustment O Cutter

varlanCe tO 5 Or Iess

AHIgh rIgIdIty

Hlgh-reIlablIlty Oue tO steeI Cutter bOOy

ANaX. speed J000 kFN

AHFC cIampIng system

The HFC lnsert ls prOteCteO rOm CentrlugaI

mOvement by COmblnlng the bOOy anO CartrlOge

Wlth an lnsert CIamp sCreW

Frevents lnsert mOvement Oue tO CentrlugaI OrCe

Features

kecommended CuttIng CondItIons

WOrk materlaI GraOe

Cuttlng speeO

(SFN)

FeeO

(IFT)

Oepth O Cut

(lnCh)

ORY WET

Alumlnum

FDJ

2UUU12UUU .UU2.UU6 .22U

TNJ

1UUU5UUU .UU3.UU6 .22U

Cartridge

Body

Body

Insert clamping screw

Insert

5alety desIgn

18

A

p

p

I

I

c

a

t

I

o

n

l

n

t

r

o

d

u

c

t

I

o

n

CJ

TooI NaterIaIs 5eIectIon GuIde

A AppIIcatIon kange ol NTK lnsert

Grades C2

A kecommended Types ol NaterIaIs and

AppIIcatIons . CeramIcs and CN C4

A AN5l l5Olnsert NomencIature C

A ChIpbreakers lor FosItIve lnserts C

A ChIpbreakers lor NegatIve lnserts

CJ2

C

T

o

o

I

N

a

t

e

r

I

a

I

s

5

e

I

e

c

t

I

o

n

G

u

I

d

e

C2

AppIIcatIon kange ol NTK lnsert Grades

FVD Coated

NIcro GraIn CarbIde

DN4

DT4

TN4

QN3

VNJ

ZN3

AIumIna

CeramIc

HCJ

HW2

CubIc oron NItrIde

23

30

3

AI2O3-5IC WhIsker CeramIc

WAJ

5IIIcon NItrIde CeramIc

5XJ

5X5

5X

5X7

5X9

CVD Coated 5IIIcon NItrIde CeramIc

5F2

5F9

NIcro GraIn CarbIde

KNJ

FoIycrystaIIIne DIamond

FDJ

CVD Coated CarbIde

CFJ

Low Feed HIgh

L

o

w

C

u

t

t

I

n

g

s

p

e

e

d

H

I

g

h

AIumIna-TIC

CeramIc

HC2

ZC4

HC5

HC7

ZC7

TIC

CeramIc

HC

Cermet

XT3

C7X

XN4

FVD

Coated Cermet

QJ5

C7Z

40

52

NEW NEW

NEW

NEW

NEW

NEW

NEW

NEW NEW

TooI NaterIaIs 5eIectIon GuIde

T

o

o

I

N

a

t

e

r

I

a

I

s

5

e

I

e

c

t

I

o

n

G

u

I

d

e

C3

F

CarbOn steeI

AIIOy steeI

N

StalnIess steeI

Cast steeI

K

Gray Cast lrOn

OuCtlIe Cast lrOn

N

AIumlnum aIIOy

NOnerrOus metaI

5

InCOneI

HasteIIOy

WaspaIIOy

Rene

H

HarOeneO materlaI

SteeI NlIIs

l5O CeramlC / CBN

Cermet

FVO COateO Cermet

FCO

CarblOe

FVO COateO mlCrO-graln CarblOe

CVO COateO CarblOe

0J

J0

20

30

40

0J

J0

20

30

40

0J

J0

20

30

H

C

J

,

H

W

2

K

N

J

Q

N

3

Z

N

3

D

N

4

W

A

J

H

C

2

,

H

C

5

,

H

C

5

X

J

,

5

X

W

A

J

J

T

N

4

F

D

J

TIN COatlng

TICN COatlng

CarblOe W/O COatlng

NuItlIayer COatlng

Cermet

Whlsker CeramlC

SlIlCOn nltrlOe CeramlC

AIumlna CeramlC

C N

F C D

V

N

J

D

T

4

D

T

4

Q

N

3

T

N

4

Z

N

3

Q

N

3

C

F

J

4

X

N

4

5

F

9

5

X

9

C

7

X

C

7

Z

Z

C

7

H

C

7

Q

J

5

X

T

3

2

3

,

3

0

,

5

2

5

2

H

C

2

,

H

C

5

,

Z

C

4

4

0

5

X

9

5

X

5

5

X

7

W

e

a

r

r

e

s

l

s

t

a

n

C

e

W

e

a

r

r

e

s

l

s

t

a

n

C

e

W

e

a

r

r

e

s

l

s

t

a

n

C

e

T

O

u

g

h

n

e

s

s

T

O

u

g

h

n

e

s

s

T

O

u

g

h

n

e

s

s

W

e

a

r

r

e

s

l

s

t

a

n

C

e

T

O

u

g

h

n

e

s

s

W

e

a

r

r

e

s

l

s

t

a

n

C

e

T

O

u

g

h

n

e

s

s

C

7

X

C

7

Z

Insert graOe reCOmmenOatlOn by WOrk materlaI type

T

o

o

I

N

a

t

e

r

I

a

I

s

5

e

I

e

c

t

I

o

n

G

u

I

d

e

C4

Work materIaI TooI Grade

AppIIcatIon

ContInuous lnterruptIon LIght InterruptIon

CooIant

koughIng 5emI-lInIshIng FInIshIng

Dry Wet

Gray cast Iron

C

e

r

a

m

l

C

5X5XJ5F2

5F9

HCJHW2

HC2HC

WAJ

23

30

ChIIIed LIners

C

e

r

a

m

l

C

HW2

HC2

DuctIIe cast Iron

C

e

r

a

m

l

C

5XJ5F9

HC

52

Heat-

resIstant

aIIoy

ased on UsIng " lC lnsert

C

e

r

a

m

l

C

5X5

5X75X9

WAJ

Hardened materIaI

C

e

r

a

m

I

c

ZC4ZC7

52

3

40

koIIs

ased on UsIng

" lC lnsert

SteeI

CarblOe

C

e

r

a

m

I

c

WAJ

HC7

233

Cast lrOn

C

e

r

a

m

I

c

HC5HC2HC7

30

OuCtlIe lrOn

C

e

r

a

m

I

c

HC5HC

52

TooI NaterIaIs 5eIectIon GuIde

ReCOmmenOeO Types O NaterlaIs anO AppIlCatlOns . CeramlCs anO CBN 1sL ChClCe2nC ChClCe

Milling Turning

Turning

Turning

T

o

o

I

N

a

t

e

r

I

a

I

s

5

e

I

e

c

t

I

o

n

G

u

I

d

e

C5

CuttIng speed (5FN) Feed rate (lFk lFT) Depth ol cut (Inch)

SLarLlng seeC UaseC Cn uslng CMCA432 lnserL

.02 .04 .0 .12 .16 .004 .00 .012 .016 .020 .024

3500

Milling

Milling

Milling

Turning

Turning

Turning

300 600 900 1200 1500 100 2100 2400 2700 3000 150

Turning

Turning Turning

Turning Turning

Turning

Milling

Milling

T

o

o

I

N

a

t

e

r

I

a

I

s

5

e

I

e

c

t

I

o

n

G

u

I

d

e

C

TooI NaterIaIs 5eIectIon GuIde

J 5hape

C

0

D 55

E 75

L

F

k

5

T

V

35

W 0

2 CIearances 4 Type

U

5

7

11

15

2U

N

C

F

D

E

5

lnch

N G A

J 2 3 4

5

NetrIc

N G A

S

T

C

L K

C

m

m

C

s

3 ToIerance CIass

5ymboI d (Inch) m (Inch) s (Inch)

N toIerance

N toIerance

lnscrIbed CIrcIe

lnscrIbed CIrcIe

d (Inch)

d (Inch)

1/4"

3/8"

1/2"

5/8"

3/4"

1"

.002

.002

.003

.004

.004

.005

m (Inch)

m (Inch)

.003

.003

.005

.006

.006

.007

A

F

C

H

E

G

J

K

L

N

N

U

.0010

.0050

.0010

.0050

.0010

.0010

.0020

.002.005

.002.005

.002.005

.002.005

.003.010

.0002

.0002

.0005

.0005

.0010

.0010

.0020

.0005

.0010

.003.007

.003.007

.005.015

.0010

.0010

.0010

.0010

.0010

.0050

.0050

.0010

.0010

.0050

.0010

.0050

1/4"

3/8"

1/2"

5/8"

3/4"

.002

.002

.003

.004

.004

.004

.004

.006

.006

.007

ThIckness

ThIckness

5(Inch)

3/32"

1/8"

5/32"

3/16"

1/4"

5/16"

3/8"

1/2"

lnch NetrIc

02

03

T3

04

06

07

09

12

1.5

2

2.5

3

4

5

6

8

Special design

7U-9U

7U-9U

4U-6U

4U-6U

Type 5ymboI Type Symbol

N (E)

F

R

A

G

M

X

H

B

T

W

ANSI / ISCInsert NOmenCIature

T

o

o

I

N

a

t

e

r

I

a

I

s

5

e

I

e

c

t

I

o

n

G

u

I

d

e

C7

4 3 3 T 04 20

5 7 9 J0

J2 04 J2 T 0J0 20

C L R S

T V W

lnscrIbed

CIrcIe

1/4"

3/8"

1/2"

5/8"

3/4"

1"

lnch

NetrIc

06

09

12

16

19

25

07

11

15

19

23

31

06

09

12

15

19

25

11

16

22

27

33

44

11

16

22

27

33

44

04

06

08

10

13

17

2

3

4

5

6

8

5 5ymboI lor lnsert 5Ize

R

7 Corner kadIus

Corner kadIus lnch NetrIc

1/64"

1/32"

3/64"

1/16"

5/64"

3/32"

1/8"

1

2

3

4

5

6

8

04

08

12

16

20

24

32

U

a

r

Edge CondItIon 9 NegatIve Iand wIdth J0 NegatIve Iand angIe

5harp FNX08

E

T

Z

S

U

K

J

P

Q

Honed

Chamlered

Chamlered

and Honed

DoubIe

Chamlered

DoubIe

Chamlered

and Honed

Inch

DescrIptIon

metrIc

a

(Inch)

r

(Inch)

E

T

Z

S

U

K

J

P

Q

01

02

01

02

04

05

06

08

04

08

04

08

16

28

60

71

95

002

004

003

005

010

012

015

020

010

020

010

020

040

070

150

180

240

-

-

.001

.002

.004

.005

.006

.008

.004

.008

.004

.008

.016

.028

.060

.071

.095

.001

.002

-

-

-

-

-

-

.001

.001

.002

.002

.003

-

.001

.002

.003

MCLe. K, J, F C shCv lLs rlmary lanC vlCLh

DescrIptIon b

10

15

20

25

30

10

15

20

25

30

MCLe. K, J, F C shCv lLs rlmary lanC angle

T

o

o

I

N

a

t

e

r

I

a

I

s

5

e

I

e

c

t

I

o

n

G

u

I

d

e

C

Name Chlpbreaker GeOmetry Features Chlp COntrOI Range

NX

.U12 (U.3)

LCCT32.5U6A shCvn

1U

LxCellenL Chl CCnLrCl Cn

very llghL CeLh Cl CuL

.U16 .UU6 .UU4

.UU4

.U12

.U2U

.U4U

.116

.2UU

.UU2

FeeC (lFR)

L

e

L

h

C

l

C

u

L

(

l

n

C

h

)

AZ7

LCCT32.5U6A shCvn

.U16U.4

LxCellenL Chl CCnLrCl aL llghL

leeC anC llghL CeLh Cl CuL

.016 .008 .004

.004

.012

.020

.040

.118

.200

.002

Feed (IPR)

D

e

p

t

h

o

f

c

u

t

(

i

n

c

h

)

Zk

LCAT32.5U6 shCvn

.U31(U.6)

CCvers a vlCe range Cl CeLh

Cl CuL unCer hlgh-seeC anC

lCv-leeC CCnClLlCns

.U16 .UU6 .UU4

.UU4

.U12

.U2U

.U4U

.116

.2UU

.UU2

FeeC (lFR)

L

e

L

h

C

l

C

u

L

(

l

n

C

h

)

QD

LCAT32.5U6 shCvn

7

.U51 (1.3)

FrCvlCes sLaUle maChlnlng vlLh

LCugh CuLLlng eCge rCCesseC

Uy ne hCnlng

.U16 .UU6 .UU4

.UU4

.U12

.U2U

.U4U

.116

.2UU

.UU2

FeeC (lFR)

L

e

L

h

C

l

C

u

L

(

l

n

C

h

)

AN3

.U471.2

6

LCCT32.5U6 shCvn

All-urCse ChlUreaker

FlrsL ChClCe lCr mCsL

allCaLlCns

CreaL CCmUlnaLlCn Cl shar

eCge anC Chl CCnLrCl

.016 .008 .004

.004

.012

.020

.040

.118

.200

.002

Feed (IPR)

D

e

p

t

h

o

f

c

u

t

(

i

n

c

h

)

CL

.169 (4.6)

LCCT32.5U6A shCvn

17

LCuUle-CslLlve geCmeLry

Shar eCge anC lCv LCCl

ressure

Very vlCe Chl CCnLrCl range

.016 .008 .004

.004

.012

.020

.040

.118

.200

.002

Feed (IPR)

D

e

p

t

h

o

f

c

u

t

(

i

n

c

h

)

JL

.264 (6.7)

LCCT32.5U6 shCvn

16

LCuUle-CslLlve Ceslgn vlLh

lCv LCCl ressure

TCugh CuLLlng eCge anC

exCellenL erlCrmanCe ln

CCmUlnaLlCn vlLh CA3

.U16 .UU6 .UU4

.UU4

.U12

.U2U

.U4U

.116

.2UU

.UU2

FeeC (lFR)

L

e

L

h

C

l

C

u

L

(

l

n

C

h

)

NOIOeO Chlpbreakers Or FOsltlve Inserts

ChIpbreakers lor FosItIve Inserts

J6

J5

T

o

o

I

N

a

t

e

r

I

a

I

s

5

e

I

e

c

t

I

o

n

G

u

I

d

e

C9

Name Chlpbreaker GeOmetry Features Chlp COntrOI Range

FG

.U59 (1.5)

TFCH221 shCvn

17

LxCluslvely CeslgneC lCr lL

UCrlng

LvaCuaLe Chls BACKVARL

aL llghL CeLh Cl CuL

Shar CuLLlng eCge vlLh hlgh

rake angle

.016 .008 .004

.004

.012

.020

.040

.118

.200

.002

Feed (IPR)

D

e

p

t

h

o

f

c

u

t

(

i

n

c

h

)

AFJ

CCCT32.5U6 shCvn

5

.U31(U.6)

FrCCuCes remarkaUle

surlaCes ln seml-nlshlng Cl

sLeels

.U16 .UU6 .UU4

.UU4

.U12

.U2U

.U4U

.116

.2UU

.UU2

FeeC (lFR)

L

e

L

h

C

l

C

u

L

(

l

n

C

h

)

AN5

.U35 (U.9)

CFCH21.5U6 shCvn

6

ChlUreaker lCr UCrlng

FrCvlCes UCLh gCCC CuLLlng

erlCrmanCe anC Chl

CCnLrCl .U16 .UU6 .UU4

.UU4

.U12

.U2U

.U4U

.116

.2UU

.UU2

FeeC (lFR)

L

e

L

h

C

l

C

u

L

(

l

n

C

h

)

.12

.U6

.U4

.U2

.U2 .U4 .U6 .12

FeeC (lFR)

L

e

L

h

C

l

C

u

L

(

l

n

C

h

)

CL

ZR

AM3

AZ7

AMX

FeeC (lFR)

L

e

L

h

C

l

C

u

L

(

l

n

C

h

) .12

.U6

.U4

.U2

.U2 .U4 .U6 .12

AT/S/UHG/U/U1

F05F1

KHG/K KHG/K KHG/K KHG/K

Molded Chipbreakers Ground Chipbreakers

NOIOeO Chlpbreakers Or FOsltlve Inserts COntlnueO

J9

T

o

o

I

N

a

t

e

r

I

a

I

s

5

e

I

e

c

t

I

o

n

G

u

I

d

e

CJ0

Name Chlpbreaker GeOmetry Features Chlp COntrOI Range

KHG

LCLT32.5U6 shCvn

.U4U (1.U)

14

LxCellenL Chl CCnLrCl Cn

nlshlng CuLs

FCr suer hlgh-reClslCn

maChlnlng

FreClslOn tOIeranCe ln COrner

raOlus. .0004"

.U16 .UU6 .UU4

.UU4

.U12

.U2U

.U4U

.116

.2UU

.UU2

FeeC (lFR)

L

e

L

h

C

l

C

u

L

(

l

n

C

h

)

K

TFCHF73U6 shCvn

.U4U (1.U)

15

SuerU Chl CCnLrCl Cn

nlshlng allCaLlCns

Shar CuLLlng eCge vlLh Lhe

hlgh rake angle .U16 .UU6 .UU4

.UU4

.U12

.U2U

.U4U

.116

.2UU

.UU2

FeeC (lFR)

L

e

L

h

C

l

C

u

L

(

l

n

C

h

)

UHG

.U43 (1.1)

R

LCLT32.5U4A shCvn

Shar CuLLlng eCge

CCvers vlCe CuLLlng

CCnClLlCn range

FreClslOn tOIeranCe ln COrner

raOlus. .0004"

.U16 .UU6 .UU4

.UU4

.U12

.U2U

.U4U

.116

.2UU

.UU2

FeeC (lFR)

L

e

L

h

C

l

C

u

L

(

l

n

C

h

)

UUJ

LCCT32.5U6 shCvn

R

.U63 (1.6)

Shar CuLLlng eCge revenLs

vCrk maLerlals lrCm vCrk

harCenlng

.U16 .UU6 .UU4

.UU4

.U12

.U2U

.U4U

.116

.2UU

.UU2

FeeC (lFR)

L

e

L

h

C

l

C

u

L

(

l

n

C

h

)

5

LCCT32U.5U6 shCvn

15

.U4U (1.U)

SLanCarC grCunC ChlUreaker

vlLh vlCe CuLLlng CCnClLlCn

CCverage

Shar CuLLlng eCge vlLh

exCellenL Chl CCnLrCl

.U16 .UU6 .UU4

.UU4

.U12

.U2U

.U4U

.116

.2UU

.UU2

FeeC (lFR)

L

e

L

h

C

l

C

u

L

(

l

n

C

h

)

AT 15

.U4U (1.U)

R

LCCT32.5U6 shCvn

LxCellenL aCheslCn reslsLanCe

vlLh ClmenslCnal sLaUlllLy

BesL lCr small ClameLer

arLs anC lCr maChlnlng lCv

CarUCn sLeels

.U16 .UU6 .UU4

.UU4

.U12

.U2U

.U4U

.116

.2UU

.UU2

FeeC (lFR)

L

e

L

h

C

l

C

u

L

(

l

n

C

h

)

FN

.U26 (U.7)

LCCT32.5U6 shCvn

Full-erlheral grCunC

ChlUreaker

.U16 .UU6 .UU4

.UU4

.U12

.U2U

.U4U

.116

.2UU

.UU2

FeeC (lFR)

L

e

L

h

C

l

C

u

L

(

l

n

C

h

)

GrOunO Chlpbreakers Or FOsltlve Inserts

ChIpbreakers lor FosItIve Inserts

T

o

o

I

N

a

t

e

r

I

a

I

s

5

e

I

e

c

t

I

o

n

G

u

I

d

e

CJJ

Name Chlpbreaker GeOmetry Features Chlp COntrOI Range

F05

TFCF52U6 shCvn

3

.U51 (1.3)

LxCluslvely CeslgneC lCr lL

UCrlng

LvaCuaLe Chls BACKVARL

LxCellenL ChClCe lCr UllnC

hCle maChlnlng

Chl UaCkvarC

.U16 .UU6 .UU4

.UU4

.U12

.U2U

.U4U

.116

.2UU

.UU2

FeeC (lFR)

L

e

L

h

C

l

C

u

L

(

l

n

C

h

)

FJ

TFCF22U6 shCvn

.U71 (1.6)

3

.U16 .UU6 .UU4

.UU4

.U12

.U2U

.U4U

.116

.2UU

.UU2

FeeC (lFR)

L

e

L

h

C

l

C

u

L

(

l

n

C

h

)

J

TCCF52U6 shCvn

.U24 (U.6)

1U

.UU6

(U.15)

SLaUle CuLLlng ln UCrlng

Lhanks LC shar anC LCugh

CuLLlng eCge

.U16 .UU6 .UU4

.UU4

.U12

.U2U

.U4U

.116

.2UU

.UU2

FeeC (lFR)

L

e

L

h

C

l

C

u

L

(

l

n

C

h

)

2

TFCF73U6 shCvn

.U4U (1.U)

1U

.UU6

(U.15)

.U16 .UU6 .UU4

.UU4

.U12

.U2U

.U4U

.116

.2UU

.UU2

FeeC (lFR)

L

e

L

h

C

l

C

u

L

(

l

n

C

h

)

3

TFCF63U6 shCvn

.U51 (1.3)

1U

.U16 .UU6 .UU4

.UU4

.U12

.U2U

.U4U

.116

.2UU

.UU2

FeeC (lFR)

L

e

L

h

C

l

C

u

L

(

l

n

C

h

)

A

CFCFU3U6 shCvn

.U4U (1.U)

14

.UU6

(U.15)

TCugh CuLLlng eCge anC gCCC

Chl CCnLrCl

Ceneral-urCse lL ChlUreaker

.U16 .UU6 .UU4

.UU4

.U12

.U2U

.U4U

.116

.2UU

.UU2

FeeC (lFR)

L

e

L

h

C

l

C

u

L

(

l

n

C

h

)

A1

A

AJ

CFCF63U6 shCvn

.U31 (U.6)

14

.UU6

(U.15)

A2

LRCF52Y shCvn

.U31 (U.6)

2U

CCnLrCl Chls aL llghL leeC

anC llghL CeLh Cl CuL

Shar CuLLlng eCge Cue LC

large rake angle .U16 .UU6 .UU4

.UU4

.U12

.U2U

.U4U

.116

.2UU

.UU2

FeeC (lFR)

L

e

L

h

C

l

C

u

L

(

l

n

C

h

)

GrOunO Chlpbreakers Or FOsltlve Inserts COntlnueO

J9

J9

T

o

o

I

N

a

t

e

r

I

a

I

s

5

e

I

e

c

t

I

o

n

G

u

I

d

e

CJ2

Name Chlpbreaker GeOmetry Features Chlp COntrOI Range

UL

TMCC33U4A shCvn

2U

.157(4.U)

MegaLlve lnserL vlLh CslLlve

lnserL's ChlUreaker

ReCuCeC Uurr

lmrCveC mlCrCnlsh

SuerU aCvanLage ln CCsL er

CCrner Cver CslLlve lnserLs

.016 .008 .004

.004

.012

.020

.040

.118

.200

.002

Feed (IPR)

D

e

p

t

h

o

f

c

u

t

(

i

n

c

h

)

ZFJ

CMAC432 shCvn

CuL small CurleC Chls Cn

nlshlng CuLs

.U16 .UU6 .UU4

.UU4

.U12

.U2U

.U4U

.116

.2UU

.UU2

FeeC (lFR)

L

e

L

h

C

l

C

u

L

(

l

n

C

h

)

WN

CMAC431 shCvn

RemarkaUle Chl CCnLrCl ln

Lhe lCv leeC range

.U16 .UU6 .UU4

.UU4

.U12

.U2U

.U4U

.116

.2UU

.UU2

FeeC (lFR)

L

e

L

h

C

l

C

u

L

(

l

n

C

h

)

ZWJ

CMAC432 shCvn

.UU5 (U.13)

VersaLlle ChlUreaker vlLh

remarkaUle Chl CCnLrCl

erlCrmanCe ln a vlCe range

.U16 .UU6 .UU4

.UU4

.U12

.U2U

.U4U

.116

.2UU

.UU2

FeeC (lFR)

L

e

L

h

C

l

C

u

L

(

l

n

C

h

)

ZF

CMAC432 shCvn

LCuUle-CslLlve rake anC

shar CuLLlng eCge

LCv LCCl ressure even aL

heavy CeLh Cl CuL .016 .008 .004

.004

.012

.020

.040

.118

.200

.002

Feed (IPR)

D

e

p

t

h

o

f

c

u

t

(

i

n

c

h

)

Z5

CMAC432 shCvn

.UU6 (U.2) Very LCugh lnserL

SulLaUle lCr hlgh lCaCeC

lnLerruLeC maChlnlng

LeslgneC lCr maChlnlng vlLh

heavy lnLerruLlCn

.U16 .UU6 .UU4

.UU4

.U12

.U2U

.U4U

.116

.2UU

.UU2

FeeC (lFR)

L

e

L

h

C

l

C

u

L

(

l

n

C

h

)

WV

CMAC432 shCvn

.UU6 (U.2)

Cers Lhe aCvanLages Cl

UCLh LCugh CuLLlng eCge anC

Chl CCnLrCl

.U16 .UU6 .UU4

.UU4

.U12

.U2U

.U4U

.116

.2UU

.UU2

FeeC (lFR)

L

e

L

h

C

l

C

u

L

(

l

n

C

h

)

G

CMAC432 shCvn

.UU6 (U.2)

TCugh ChlUreaker lCr

rCughlng vlLh exCeLlCnal

sLaUlllLy

.U16 .UU6 .UU4

.UU4

.U12

.U2U

.U4U

.116

.2UU

.UU2

FeeC (lFR)

L

e

L

h

C

l

C

u

L

(

l

n

C

h

)

NOIOeO Chlpbreakers Or Negatlve Inserts

ChIpbreakers lor NegatIve Inserts

J7

T

o

o

I

N

a

t

e

r

I

a

I

s

5

e

I

e

c

t

I

o

n

G

u

I

d

e

CJ3

Name Chlpbreaker GeOmetry Features Chlp COntrOI Range

DA

TMCC33U4 shCvn

.U96 (2.5)

15

LxCellenL Chl CCnLrCl anC

shar CuLLlng eCge

.U16 .UU6 .UU4

.UU4

.U12

.U2U

.U4U

.116

.2UU

.UU2

FeeC (lFR)

L

e

L

h

C

l

C

u

L

(

l

n

C

h

)

DJ

TMLC33U6 shCvn

.U96 (2.5)

.

U

U

2

(

U

.

U

5

)

15

.U16 .UU6 .UU4

.UU4

.U12

.U2U

.U4U

.116

.2UU

.UU2

FeeC (lFR)

L

e

L

h

C

l

C

u

L

(

l

n

C

h

)

NJ

.U59 (1.5)

14

TMCC33U6 shCvn

LCuUle-CslLlve Ceslgn vlLh Lhe

large rake angle

LxCellenL Chl CCnLrCl

.U16 .UU6 .UU4

.UU4

.U12

.U2U

.U4U

.116

.2UU

.UU2

FeeC (lFR)

L

e

L

h

C

l

C

u

L

(

l

n

C

h

)

U2

TMCC33U6 shCvn

.U91 (2.3)

R

ReCuCeC Uurr anC vCrk

harCenlng Cue LC hlgh rake

Ceslgn

.016 .008 .004

.004

.012

.020

.040

.118

.200

.002

Feed (IPR)

D

e

p

t

h

o

f

c

u

t

(

i

n

c

h

)

TMCC331 shCvn

.UU6

(U.2)

.U59 (1.5)

14

Ceneral-urCse ChlUreaker

vlLh exCellenL LCughness anC

Chl CCnLrCl

.U16 .UU6 .UU4

.UU4

.U12

.U2U

.U4U

.116

.2UU

.UU2

FeeC (lFR)

L

e

L

h

C

l

C

u

L

(

l

n

C

h

)

C

TMCC33U6 shCvn

.U67 (2.2)

14

.UU6

(U.2)

.U16 .UU6 .UU4

.UU4

.U12

.U2U

.U4U

.116

.2UU

.UU2

FeeC (lFR)

L

e

L

h

C

l

C

u

L

(

l

n

C

h

)

GrOunO Chlpbreakers Or Negatlve Inserts

FeeC (lFR)

L

e

L

h

C

l

C

u

L

(

l

n

C

h

) .12

.U6

.U4

.U2

.U2 .U4 .U6 .12

UL

ZP

WWM W

ZF1

FeeC (lFR)

L

e

L

h

C

l

C

u

L

(

l

n

C

h

) .12

.U6

.U4

.U2

.U2 .U4 .U6 .12

D1

U2

DA

Molded Chipbreakers Ground Chipbreakers

T

o

o

I

N

a

t

e

r

I

a

I

s

5

e

I

e

c

t

I

o

n

G

u

I

d

e

CJ4

TooI NaterIaIs 5eIectIon GuIde

FOsltlve Inserts

.12

.U6

.U4

.U2

.U2 .U4 .U6 .12

FeeC (lFR)

L

e

L

h

C

l

C

u

L

(

l

n

C

h

)

CL

ZR

AM3

AZ7

AMX

FeeC (lFR)

L

e

L

h

C

l

C

u

L

(

l

n

C

h

) .12

.U6

.U4

.U2

.U2 .U4 .U6 .12

AT/S/UHG/U/U1

F05F1

KHG/K KHG/K KHG/K KHG/K

Negatlve Inserts

FeeC (lFR)

L

e

L

h

C

l

C

u

L

(

l

n

C

h

) .12

.U6

.U4

.U2

.U2 .U4 .U6 .12

UL

ZP

WWM W

ZF1

FeeC (lFR)

L

e

L

h

C

l

C

u

L

(

l

n

C

h

) .12

.U6

.U4

.U2

.U2 .U4 .U6 .12

D1

U2

DA

Molded Chipbreakers

Molded Chipbreakers

Ground Chipbreakers

Ground Chipbreakers

T

o

o

I

N

a

t

e

r

I

a

I

s

5

e

I

e

c

t

I

o

n

G

u

I

d

e

DJ DJ

G

r

a

d

e

l

n

t

r

o

d

u

c

t

I

o

n

Grade lntroductIon

CeramIcs DJ

AOvervIew ol CeramIc lnserts D2

AAIumIna-based CeramIcs D4

AAIumIna TIC-based CeramIcs D

AWhIsker-reInlorced CeramIcs D9

A5IIIcon NItrIde-based CeramIcs DJ0

A5IAlON CeramIcs DJ2

A GuIdeIIne lor NachInIng

Heat kesIstant AIIoys DJ4

CN FCD D23

Cermet Coated Cermet D27

CarbIde Coated CarbIde D33

D

D2

CeramIcs

AAIumIna-based ceramIcs

(WhIte ceramIcs)

FOr Gray Cast lron

A5IIIcon nItrIde-based ceramIcs

FOr Gray Cast lron

DuctIIe Cast lron

Heat kesIstant AIIoys

Advantages of ceramic cutting tool (1) Advantages of ceramic cutting tools (2)

AAIumIna TIC-based ceramIcs

(Iack ceramIcs)

FOr Gray Cast lron

DuctIIe Cast lron

Hardened NaterIaIs

NIII koIIs

AWhIsker-based ceramIcs

FOr Heat kesIstant AIIoys

Gray Cast lron

Hardened NaterIaIs

NIII koIIs

NTKs premlum CeramlC graOes ensure the user hlgher

prOOuCtlvlty. AII O the graOes shOW superlOr hlgh

temperature harOness, heat reslstanCe anO ChemlCaI

stablIlty. NTK Oers many types O CeramlC Cuttlng

tOOI materlaIs (slIlCOn nltrlOe-baseO, aIumlna-baseO

anO Whlsker-baseO) ln a varlety O geOmetrles tO meet

CustOmer OemanOs.

22

2U

16

16

14

12

1U

6

6

4

U 2UU 4UU

TemeraLure ()

CarUlCe F1U

CermeL

BlaCk CeramlC HC2

VhlLe CeramlC HC1

SlllCCn nlLrlCe-UaseC SX6

V

l

C

k

e

r

s

H

a

r

C

n

e

s

s

(

C

F

a

)

HarOness at hlgh temperature by tOOI materlaI

6UU 6UU 1UUU 12UU

The material retains

high hardness even at

increased temperatures !!

Excellent wear resistance at high cutting speed

16UU

14UU

12UU

1UUU

6UU

6UU

4UU

2UU

U

U 2UU 4UU

T

r

a

n

s

v

e

r

s

e

r

u

L

u

r

e

s

L

r

e

n

g

L

h

.

(

A

F

a

)

6UU 6UU 1UUU 12UU 14UU

CarUlCe F1U

CermeL

BlaCk CeramlC HC2

VhlLe CeramlC HC1

SlllCCn nlLrlCe-UaseC SX6

Low impact on bending

strength even under high

temperature

Breaklng strength at hlgh temperature by tOOI materlaI

Stable machining is possible in the high speed range

TemeraLure ()

G

r

a

d

e

l

n

t

r

o

d

u

c

t

I

o

n

C

e

r

a

m

l

C

s

D3

GraOe / COatlng AppIlCatlOns / Features

FhyslCaI prOpertles

AppIlCatlOn map

Oenslty

/

HarOness

HRA

BenOlng

strength

NFa

YOung's

mOOuIus

GFa

ThermaI

expanslOn

COeClent

X10

6

/K

ThermaI

COnOuCtlvlty

W/mK

W

h

l

t

e

C

e

r

a

m

l

C

s

A

I

u

m

l

n

a

-

b

a

s

e

O

C

e

r

a

m

l

C

s

HCJ

AI2C3

K

Seml-llnlsh / Flnlsh

4.U 94.U 7UU 4UU 7.6 17

Gray cast iron, Finish, DRY, White ceramics

HC1

HW2

High

High

Toughness / strength

W

e

a

r

r

e

s

i

s

t

a

n

c

e

BesL vear reslsLanCe

HW2

AI2C3

K

RCugh / Seml-llnlsh / Flnlsh

4.1 94.U 75U 39U 7.6 19

CuLsLanClng lraCLure LCughness

B

I

a

C

k

C

e

r

a

m

l

C

s

A

I

u

m

l

n

a

T

l

C

-

b

a

s

e

O

C

e

r

a

m

l

C

s

HC2

AI2C3TlC

K H

Seml-llnlsh / Flnlsh

4.3 94.5 6UU 42U 7.9 21

Gray cast iron, Finish, WET, Black ceramics

HC6 HC2

HC7/ ZC7

High

High

Toughness / strength

W

e

a

r

r

e

s

i

s

t

a

n

c

e

HC2

Machining of hardened materials

ZC4

HC7/ZC7

W

e

a

r

r

e

s

i

s

t

a

n

c

e

High

High

Toughness / strength

Ceneral UlaCk CeramlC

ZC4

AI2C3TlC

K H

Seml-llnlsh / Flnlsh

4.6 95.5 1,UUU 42U 7.6 25

CCmeLlLlve vs CBM

HC5

AI2C3TlC

K

Seml-llnlsh / Flnlsh

4.3 95.U 9UU 42U 7.6 25

SLaUle erlCrmanCe lCr Alll RClls

HC

TlCAI2C3

K

Seml-llnlsh / Flnlsh

4.7 94.U 6UU 45U 7.6 29

LxCellenL erlCrmanCe lCr LuCLlle

HC7

AI2C3TlC

K H

Seml-llnlsh / Flnlsh

4.6 95.U 1,1UU 42U 7.9 23

SLaUle erlCrmanCe lCr Alll RClls

ZC7

AI2C3TlC

TlN COat

K H

Seml-llnlsh / Flnlsh

4.6 95.U 1,1UU 42U 7.9 23

LxCellenL vear reslsLanCe ln vlCe harCness range

S

l

I

l

C

O

n

N

l

t

r

l

O

e

-

b

a

s

e

O

C

e

r

a

m

l

C

s

5XJ

Sl3N4

K

RCugh

3.2 93.5 1,2UU 32U 3.U 29

Machining of Gray cast iron / Rough

SX1

SX6

SP9

SX9

W

e

a

r

r

e

s

i

s

t

a

n

c

e

High

High

Toughness / strength

W

e

a

r

r

e

s

i

s

t

a

n

c

e

High

High

Toughness / strength

Machining of Inco 718

WA1

SX7

SX9

SX5

CCCC vear reslsLanCe anC LCughness

5F2

Sl3N4

TlNAI2C3 COat

K

RCugh

3.2 93.5 1,1UU 32U 3.U 29

CCCC llank vear reslsLanCe

5X5

SlAICN

K S

RCugh / Seml-llnlsh

3.6 92.5 1,1UU 35U 4.U 16

LxCellenL LCughness

5X

Sl3N4

K

RCugh

3.2 93.5 1,2UU 32U 3.U 5U

1sL ChClCe lCr CasL lrCn maChlnlng

5X7

SlAICN

K S

RCugh / Seml-llnlsh

3.3 93.5 9UU 29U 3.4 11

Can relaCe vhlsker CeramlC

5X9

SlAICN

K S

RCugh / Seml-llnlsh

3.3 93.5 1,2UU 33U 3.U 15

LxCellenL CCmUlnaLlCn Cl LCughness anC heaL reslsLanCe

5F9

Sl3N4

TlNAI2C3 COat

K

RCugh / Seml-llnlsh / Flnlsh

3.3 93.5 1,2UU 33U 3.U 15

LCv LCCl ressure lnCreaseC LCughness

LeCreaseC LCCl ressure

W

h

ls

k

e

r

-

r

e

ln

O

r

C

e

O

C

e

r

a

m

lC

s

WAJ

AI2C3SlC

K H S

Seml-llnlsh / Flnlsh

3.7 94.5 1,2UU 4UU 7.6 35

SuerlCr llank vear reslsLanCe

vlLh LCughness

FCr CCaLeC graCes, Lhe values Cl Lhe suUsLraLe maLerlal are lnClCaLeC.

G

r

a

d

e

l

n

t

r

o

d

u

c

t

I

o

n

C

e

r

a

m

l

C

s

D4

CeramIcs

AIumIna-based ceramIcs (WhIte ceramIcs)

CharaCterlzeO by hlgh OxlOatlOn reslstanCe anO

aOheslOn reslstanCe. Thls CeramlC utlIlzes aIumlna that

ls thermaIIy anO ChemlCaIIy stabIe. Thls CeramlC ls best

sulteO Or hlgh-speeO Cuttlng appIlCatlOns Where Cuttlng

temperature tenOs tO be hlgh Wlth nO COOIant.

HCJ

Ideal grade for high-speed nishing of cast iron !

HC1

HW2

High

High

Toughness / Strength

W

e

a

r

r

e

s

i

s

t

a

n

c

e

Brake rotor

Cray CasL lrCn

21UU SFA

.U12 lFR

.U2U LCC

LRY

NTK

HCJ

130 pCs

CCmeLlLCr's

UlaCk CeramlC

65 Cs

Gray Cast lrOn, Flnlshlng, Ory Cuttlng, Whlte CeramlC

Best wear resistance

Stable machining performance in many high-speed machining applications

Features

GraOe WOrk materlaI AppIlCatlOn FurpOse

Cuttlng speeO

(SFN)

FeeO

(IFR)

Oepth O Cut

(lnCh)

ORY WET

HCJ

Cray CasL lrCn Turnlng Flnlsh 12UU21UU .UU4.U16 .U2U.U6U

G

r

a

d

e

l

n

t

r

o

d

u

c

t

I

o

n

C

e

r

a

m

l

C

s

D5

HW2

Alumina-based ceramic grade with high toughness !

Cylinder liner

ChllleC llner

12UU SFA

.U12 lFR

.U6U LCC

LRY

NTK

HW2

70 pCs

CCmeLlLCr's

vhlLe CeramlC

3U Cs

A Outstanding fracture toughness

A Stable machining performance in many high-speed machining applications

Features

GraOe WOrk materlaI AppIlCatlOn FurpOse

Cuttlng speeO

(SFN)

FeeO

(IFR)

Oepth O Cut

(lnCh)

ORY WET

HW2

Cray CasL lrCn Turnlng RCugh-Flnlsh 12UU21UU .UU4.U16 .U2U.U6U

G

r

a

d

e

l

n

t

r

o

d

u

c

t

I

o

n

C

e

r

a

m

l

C

s

D

CeramIcs

Mill roll

24USFA

.UU6 lFR

.U2U - .12U LCC

LRY

NTK

HC2

20 pCs

CCmeLlLCr's

UlaCk CeramlC

1U Cs

HC6 HC2

HC7/ ZC7

High

High

Toughness / Strength

W

e

a

r

r

e

s

i

s

t

a

n

c

e

HC2

ZC4

HC7/ ZC7

High

High

Toughness / Strength

W

e

a

r

r

e

s

i

s

t

a

n

c

e

AIumIna TIC-based ceramIcs (Iack ceramIcs)

AIumlna TlC-baseO CeramlCs are strengtheneO by

aOOlng harO CarblOe tO hlghIy pure aIumlna. Thls

prOCess resuIts ln CeramlC materlaIs that shOWs

exCeIIent perOrmanCe ln elther Wet Or Ory Cuttlng

COnOltlOns. As an aOOeO benelt, harOness anO

tOughness has been lmprOveO WhlCh enabIes the

maChlnlng O partlaIIy lnterrupteO Cuts. Thls CeramlC

materlaI has bOth hlgh-hOt harOness anO IOW pIastlClty

neeOeO tO Cut harOeneO materlaIs.

Gray Cast lrOn, Flnlshlng, WET, BIaCk CeramlC NaChlnlng O harOeneO materlaIs

HC2

The standard grade for machining cast iron and hardened materials !

A Well-balanced content of aluminum oxide and titanium carbide (Al2O3 +TiC) sintered under pressure

A Stable performance under a wide range of machining conditions

A General purpose ceramic which works well in a wide range of cutting applications

Features

GraOe WOrk materlaI AppIlCatlOn FurpOse

Cuttlng speeO

(SFN)

FeeO

(IFR)

Oepth O Cut

(lnCh)

ORY WET

HC2

Cray CasL lrCn Turnlng Seml llnlshFlnlsh 12UU21UU .UU4.U16 .U2U.U6U

Alll rClls

(CasL lrCn)

Turnlng Seml llnlshFlnlsh 15U5UU .UU3.UU6 .U2U.14U

G

r

a

d

e

l

n

t

r

o

d

u

c

t

I

o

n

C

e

r

a

m

l

C

s

D7

Mill roll

ChllleC CasL lrCn

23U SFA

.U16 lFR

.394 LCC

LRY

55

5

3

NTK

HC5

4 pass

CCmeLlLCr's

UlaCk CeramlC

2 ass

Differential case

LuCLlle CasL lrCn

9UU SFA

.UU6 lFR

.U2U LCC

VLT

NTK

HC

60 pCs

CCmeLlLCr's

CCaLeC CarUlCe

3U Cs

HC5

Developed for Mill Rolls !

HC

For machining ductile cast iron !

ADeveloped for use in hard turning applications for mill rolls

AExcellent toughness combined with wear resistance

A Designed specifically for finish turning of ductile / nodular cast irons

A TiC-based ceramic with improved wear resistance at high cutting speed

Features

Features

GraOe WOrk materlaI AppIlCatlOn FurpOse

Cuttlng speeO

(SFN)

FeeO

(IFR)

Oepth O Cut

(lnCh)

ORY WET

HC5

Alll rCll

(CasL lrCn)

Turnlng RCughFlnlsh 15U5UU .UU3.UU6 .U2U.14U

Alll rCll

(SLeel)

Turnlng RCughFlnlsh 15U5UU .UU3.UU6 .U2U.14U

GraOe WOrk materlaI AppIlCatlOn FurpOse

Cuttlng speeO

(SFN)

FeeO

(IFR)

Oepth O Cut

(lnCh)

ORY WET

HC

LuCLlle CasL lrCn Turnlng Flnlsh 6UU15UU .UU5.U12 .U2U.U4U

G

r

a

d

e

l

n

t

r

o

d

u