Professional Documents

Culture Documents

Codes and Standards For CSWIP 3.1 & 3.2

Codes and Standards For CSWIP 3.1 & 3.2

Uploaded by

varadha184Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Codes and Standards For CSWIP 3.1 & 3.2

Codes and Standards For CSWIP 3.1 & 3.2

Uploaded by

varadha184Copyright:

Available Formats

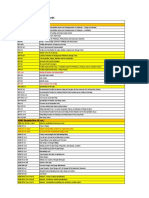

1of 7 Standards

European Standards for destructive test methods

EN875 Destructive test on welds in metallic materials impact tests test specimen location, notch orientation and examination. Destructive tests on welds in metallic materials-Transverse tensile test Destructive tests on welds in metallic materials Bend tests Destructive tests on welds in metallic materials. Macroscopic and microscopic examination of welds. Metallic materials Tensile testing psrt1: Method of test at ambient temperature. Tensile testing of metallic materials. Part 5: Method of test at elevated temperature.

EN 895 EN910 EN 1321

BS EN 10002 BS EN 10002

The principal European Standards for Procedure qualifications.

EN ISO 15614 Specification and qualification of welding procedures for metallic materials.Welding procedure test Arc and gas welding of steels and arc welding of nickel and nickel alloys. Arc welding of aluminum and its alloys

Part 1 Part 2

The principal American standards for procedure qualifications are:

ASME SECTION IX AWS D1.1 AWS D1.2 For pressure system(vessels and pipework) For structural welding of steels For structural welding of ALIMINIUM

WELDING STANDARDS FOR WELDER QUALIFICATIONS

EN 287-1 EN ISO 9606-2 Qualification test of welders-Fusion welding Part1: Steels Qualification test of welders Fusion 1 of 7 Standards

2of 7 Standards welding Part 2: Aluminum and aluminum alloys EN 1418 Welding personnel Approval testing of welding operators for fusion welding and resistance weld setters for fully mechanized and automatic welding of metallic materials

The principal American standards that specify requirements for welder qualifications are

ASME SECTION IX AWS D1.1 AWS D1.2 For pressure system(vessels and pipe work) For structural welding of steels For structural welding of ALIMINIUM

BS number

BS 499: Part 1 Bs 709 BS 1113

Title

Glossary of welding terms Methods of destructive testing fusion welded joints and weld metal in steel Specification for design and manufacture of water-tube steam generating plant .

BS number

BS 1453 BS 1821

Title

Specifications for filler materials for gas welding. Specification for class I oxyacetylene welding of ferritic steel pipe work for carrying fluids. Low alloy steel electrodes for MMA welding. Specification for class I arc welding of ferritic steel pipe work for carrying fluids. Specification for class II arc welding of carbon steel pipe work for carrying fluids. Specification for manufacture of vertical steel welded non-refrigerated storage 2 of 7 Standards

BS 2493 BS 2633

BS 2640

BS 2654

3of 7 Standards tanks with butt welded shells for the petroleum industry. BS 2901: part 3 BS 2926 Filler rods and wires for copper and copper alloys. Specification for chromium and chromium nickel steel electrodes for MMA Tig welding Steel pipes and tubes for pressure purposes: Ferritic alloy steel with specified elevated temperature properties for pressure purposes Specifications for seamless tube. Specifications for welding of steel pipelines on land and offshore Specifications for fusion welding of steel castings. Specifications for arc welding of austenitic stainless steel pipe work for carrying fluids Approval testing of welders when procedure approval is not required. Fusion welding of steels Tig or Mig welding of Aliminium and it`s alloys. Specifications for seamless and welded steel tubes for automobile, mechanical and general engineering purposes Method for determination of diffusible hydrogen in weld metal Code of practice for welding on steel pipes containing process fluids or their residues Specifications for weldable structural steels for fixed offshore structures. Code of practice for validation of arc welding equipment Qualification test of welders Fusion welding Steels 3 of 7 Standards

BS 3019 BS 3604

BS 3605 BS 4515 BS 4570 BS 4677

BS 4872 Part1:

BS 4872 Part2: BS 6323

BS 6693 BS 6990

BS7191 BS 7570. BS EN 287 Part 1

4of 7 BS EN 440 Standards Wire electrodes and deposits for gas shielded metal arc of non-alloy and fine grain steels

BSEN 499

Covered electrodes for manual metal arc welding of non alloy and fine grain steels Quality requirements for fusion welding of metallic materials Wire electrodes and flux wire combinations for submerged arc welding of non alloy and fine grain steel. Fluxes for submerged arc welding Non-destructive examination of fusion welds-visual examination. Destructive test on welds in metallic materials-Bend tests Filler rods and wires for stainless steel Aliminium aliminium alloys and magnesium alloys.Nickel and Nickel alloys. Welding recommendations for welding of metallic materials General guidance for arc welding Arc welding of ferritic steel Arc welding of stainless steel Arc welding of aliminium and it`s alloys Destructive test on welds in metallic materials Non destructive examination of welds Radiographic examination of welded joints Tensile testing of metallic materials Definition and classification of grades of steels Designation systems for steels 4 of 7 Standards

BS EN 3834- Parts 1to 5 BS EN 756

BS EN 760 BS EN 970 BS EN 910 BS EN 12072 BS EN ISO 18274

BS EN1011

Part 1 Part 2 Part 3 Part 4 EN 1320 EN 1435

BS EN 10002 BS EN 10020 BS EN 10027

5of 7 BS EN 10045 BS EN 10204 BSEN 22553(European standard ) Standards Charpy impact test on metallic materials Metallic products-Types of inspection documents Welded, brazed and soldered joints Symbolic representations on drawings Welding, brazing, soldering and braze welding of metal. Nomenclature of process and reference numbers for symbolic representations on drawings Arc welded joints in steel. Guidance on quality levels for imperfections Classifications of imperfections in metallic fusion welds, with explanations. Specification for tungsten electrodes for inert gas shielded arc welding and for plasma cutting and welding

BS EN 24063

BS EN 25817 BSEN 26520

BSEN 26848

ISO Number

ISO 857-1 ISO 6947 ISO 9606-2 ISO 15607

TITLE

Welding and ailed process-VocabularyPart 1-metal welding Welds working positions Definitions of angles of slope and rotation. Qualification test of welders Fusion welding. Specification and qualification of welding procedures for metallic materials-General rules WELDING-Guidelines for metallic 5 of 7 Standards

ISO 15608

6of 7 Standards material grouping system ISO 15609 Specification and qualification of welding procedures for metallic materials-welding procedure specification-Part 1-arc welding Specification and qualification of welding procedures for metallic materials Qualification based on tested welding consumables. Specification and qualification of welding procedures for metallic materials Qualification based on previous welding experience. Specification and qualification of welding procedures for metallic materials. Qualification based on pre-productionwelding test Specification and qualification of welding procedures for metallic materials Welding procedure test Arc and gas welding of steels and arc welding of nickel and nickel alloys Arc welding aluminum and its alloys Welding procedure test for the arc welding of cast irons Finishing welding of aluminum castings Arc welding of titanium Copper and Copper alloys Not used Welding of tubes tube-plate joints Underwater Hyperbaric wet welding. Hyperbaric dry welding Electron and laser beam welding Spot, Seam, and projection welding. Resistance butt and flush welding

ISO 15610

ISO 15611

ISO 15613

ISO 15614

Part 1

Part 2 Part 3 Part 4 Part 5 Part 6 Part 7 Part 8 Part 9 Part 10 Part 11 Part 12 Part 13

Note : The inspector should have awareness of

6 of 7 Standards

7of 7 Standards

standards that are printed in bold

7 of 7 Standards

You might also like

- Hardness Test Lab Report PDFDocument9 pagesHardness Test Lab Report PDFKalKatu MaLam76% (42)

- GUIDELINES For SEISMIC DESIGN of BURIED PIPELINESDocument23 pagesGUIDELINES For SEISMIC DESIGN of BURIED PIPELINESVinoth SathyaNo ratings yet

- BD 212Document75 pagesBD 212Zayyan RomjonNo ratings yet

- Q10Document21 pagesQ10Ian Naylor100% (1)

- MS Pipes Technical SpecificationDocument46 pagesMS Pipes Technical SpecificationIraqui Arif Nawaz100% (1)

- Stainless Steel Socket Head Cap Screws: Standard Specification ForDocument8 pagesStainless Steel Socket Head Cap Screws: Standard Specification ForMarcelo BarretosNo ratings yet

- Procedure For: J164 (Rev 11/02)Document21 pagesProcedure For: J164 (Rev 11/02)tomcanNo ratings yet

- 8329 2000 DI PipeDocument29 pages8329 2000 DI PipeSanjay Prakash100% (1)

- Is 12818-2010 PDFDocument22 pagesIs 12818-2010 PDFINFOHEPL RCLNo ratings yet

- Bs+en+12517-2-2008 NDT PDFDocument16 pagesBs+en+12517-2-2008 NDT PDFPham CongNo ratings yet

- Astm D2657Document7 pagesAstm D2657Romeo Ramos MéndezNo ratings yet

- Bd 78-99 Design of Road Tunnels 第四章Document7 pagesBd 78-99 Design of Road Tunnels 第四章fei maNo ratings yet

- 1143 Ewf Iiw Diploma August 2013Document4 pages1143 Ewf Iiw Diploma August 2013Marcus BarberNo ratings yet

- Basic Steel Selection Based On BS 970 en SeriesDocument8 pagesBasic Steel Selection Based On BS 970 en SeriesAmarendra Pendse100% (1)

- bd6110 PDFDocument161 pagesbd6110 PDFOng George SammyNo ratings yet

- T/SP/P/1: Specification ForDocument48 pagesT/SP/P/1: Specification Formichael7michlovsky0% (1)

- BS en Iso 15614-12-2021 - (2021-11-04 - 07-41-00 PM)Document18 pagesBS en Iso 15614-12-2021 - (2021-11-04 - 07-41-00 PM)MuhammedNo ratings yet

- Iso 4427-5 - 2007Document14 pagesIso 4427-5 - 2007Emmanuel BoquetNo ratings yet

- Nzta Protective Coatings For Steel Bridges PDFDocument53 pagesNzta Protective Coatings For Steel Bridges PDFMehman NasibovNo ratings yet

- Eurocodes ListDocument7 pagesEurocodes ListmayurjannuNo ratings yet

- Basics: Standards, Sizes, Grades Din / en / AsmeDocument6 pagesBasics: Standards, Sizes, Grades Din / en / AsmeRajeshwar KumdaleNo ratings yet

- Nfa 49 310 Grade Tu 52 B Tubes PDFDocument1 pageNfa 49 310 Grade Tu 52 B Tubes PDFMitul MehtaNo ratings yet

- BS 3604-2 - 1991 Steel Pipes and Tubes For Pressure Purposes Ferritic Alloy Steel With Specified ElevatedDocument24 pagesBS 3604-2 - 1991 Steel Pipes and Tubes For Pressure Purposes Ferritic Alloy Steel With Specified ElevatedtienlamNo ratings yet

- CladtekPresentation16 02 2011Document30 pagesCladtekPresentation16 02 2011Chee Hong LeeNo ratings yet

- Weld Decay 2Document8 pagesWeld Decay 2Ahmed M. HashimNo ratings yet

- QCF312 WPQRDocument2 pagesQCF312 WPQRminhnnNo ratings yet

- Standard: I.S. CEN/TR 14549:2004Document7 pagesStandard: I.S. CEN/TR 14549:2004Cengiz KARAKOSENo ratings yet

- Pub 157 Preventing Bio Fouling With Copper NickelDocument4 pagesPub 157 Preventing Bio Fouling With Copper NickelBiyong SantocildesNo ratings yet

- Iso 3834 4 2021Document7 pagesIso 3834 4 2021M NurNo ratings yet

- API 5L - 43rd and 44th Ed - Comparison r1Document68 pagesAPI 5L - 43rd and 44th Ed - Comparison r1gopidhan100% (1)

- 1055 Attachment 9 - QP GRP Piping SpecifiDocument8 pages1055 Attachment 9 - QP GRP Piping SpecifikarunaNo ratings yet

- Steel Pipes Tubes Eng PDFDocument21 pagesSteel Pipes Tubes Eng PDFsintaprisilliaNo ratings yet

- BS 5276-2-2003Document20 pagesBS 5276-2-2003anoopkumarNo ratings yet

- A L F I: Cceptance Imit OR MperfectionsDocument29 pagesA L F I: Cceptance Imit OR MperfectionsDavid MacatangayNo ratings yet

- BS 7668.2004Document19 pagesBS 7668.2004yy2010No ratings yet

- Life Assessment of High Temperature HeadersDocument31 pagesLife Assessment of High Temperature HeadersAnonymous UoHUag100% (1)

- Astm International Bsi - British Standards Institute: 1387 (Bs en 10255:2004)Document13 pagesAstm International Bsi - British Standards Institute: 1387 (Bs en 10255:2004)prasad_kcpNo ratings yet

- 3LPE 1d44a0 PDFDocument33 pages3LPE 1d44a0 PDFHotnCrispy CrispyNo ratings yet

- Corus Prevention of Corrosion On Structural Steelwork PDFDocument28 pagesCorus Prevention of Corrosion On Structural Steelwork PDFvonipkoNo ratings yet

- Certified Welding Inspector or CWI or Special InspectorDocument4 pagesCertified Welding Inspector or CWI or Special Inspectorapi-77497104No ratings yet

- Heat - Treatment of SteelDocument39 pagesHeat - Treatment of Steel113314No ratings yet

- ChosunDocument201 pagesChosunsanketpavi21No ratings yet

- En Iso 15614-12 (E) Direnc WPSDocument13 pagesEn Iso 15614-12 (E) Direnc WPSfecriiletkenNo ratings yet

- Cost Break Down Weld Split TeeDocument5 pagesCost Break Down Weld Split TeetoylovechomNo ratings yet

- NDT ACC CriteriaDocument6 pagesNDT ACC Criteriavsnaiduqc100% (1)

- (BS en 639-1995) - Common Requirements For Concrete Pressure Pipes Including Joints and Fittings.Document26 pages(BS en 639-1995) - Common Requirements For Concrete Pressure Pipes Including Joints and Fittings.Mohammed SalahNo ratings yet

- x80 Line Pipe For Large Diameter High Strength PipelineDocument15 pagesx80 Line Pipe For Large Diameter High Strength PipelineAnonymous AlhzFE9EVNNo ratings yet

- Catalog Fabricante TechnipDocument9 pagesCatalog Fabricante Technipjimy GutiérrezNo ratings yet

- CSWIP-WI-1-91 9th Edition November 2010Document8 pagesCSWIP-WI-1-91 9th Edition November 2010Thamaraikani ManiNo ratings yet

- Why Is Preheating NecessaryDocument3 pagesWhy Is Preheating NecessaryahmedNo ratings yet

- European Structural Steel Standard EN 10025: 2004: Explanation and Comparison To Previous StandardsDocument8 pagesEuropean Structural Steel Standard EN 10025: 2004: Explanation and Comparison To Previous StandardsMarcos Arce MoralesNo ratings yet

- ASWP Manual - Section 1 - IntroductionDocument17 pagesASWP Manual - Section 1 - Introductionjmvm56No ratings yet

- Gas Tungsten Arc WeldingDocument15 pagesGas Tungsten Arc Weldingsushant47No ratings yet

- Structural SteelworkDocument24 pagesStructural SteelworkJohnson SunderNo ratings yet

- Welding StandardsDocument14 pagesWelding Standardsrusf123100% (1)

- Welding CodeDocument14 pagesWelding CodeKureiNo ratings yet

- Welding StandardsDocument14 pagesWelding Standardsnikidragon4u100% (1)

- D-Steel Pipe&Special1Document13 pagesD-Steel Pipe&Special1alep azizNo ratings yet

- Performance of Fittings For Use With Gasketed Mechanical Couplings Used in Piping ApplicationsDocument4 pagesPerformance of Fittings For Use With Gasketed Mechanical Couplings Used in Piping ApplicationsDarwin DarmawanNo ratings yet

- International StandardsDocument4 pagesInternational StandardsBASKARANNo ratings yet

- List of International Standards: API Standards Block (25 Nos.)Document4 pagesList of International Standards: API Standards Block (25 Nos.)Siva baalan100% (1)

- StandardsDocument7 pagesStandardsMoch Rafi AnugrahNo ratings yet

- ASME B31.3 Daily Exam 2 SolutionDocument3 pagesASME B31.3 Daily Exam 2 SolutionAdil HasanovNo ratings yet

- Electrical HazardsDocument37 pagesElectrical HazardsAdil HasanovNo ratings yet

- Final Exam (Closed) Answer SheetDocument1 pageFinal Exam (Closed) Answer SheetAdil HasanovNo ratings yet

- Asme Sec 5Document16 pagesAsme Sec 5Adil HasanovNo ratings yet

- Project QAQC Inspector - Quality MSDocument4 pagesProject QAQC Inspector - Quality MSAdil HasanovNo ratings yet

- BGAS Experience FormDocument2 pagesBGAS Experience FormAdil HasanovNo ratings yet

- BGAS Experience Form (May 16)Document2 pagesBGAS Experience Form (May 16)Adil HasanovNo ratings yet

- BgasslideshowDocument55 pagesBgasslideshowAdil Hasanov100% (1)

- New-NDT 15A - Experience Claim Form (Rev. 2)Document2 pagesNew-NDT 15A - Experience Claim Form (Rev. 2)Adil HasanovNo ratings yet

- New-NDT 15A - Experience Claim Form (Rev. 2)Document4 pagesNew-NDT 15A - Experience Claim Form (Rev. 2)Adil HasanovNo ratings yet

- New-NDT 15A - Experience Claim Form (Rev. 2)Document2 pagesNew-NDT 15A - Experience Claim Form (Rev. 2)Adil HasanovNo ratings yet

- RTI - Rev.2010 (NDT2A 2B Course Notes)Document191 pagesRTI - Rev.2010 (NDT2A 2B Course Notes)Adil Hasanov100% (1)

- Cswip 3.1 Part 4Document7 pagesCswip 3.1 Part 4Emad Daghagheleh100% (2)

- RTI - Rev.2010 (NDT2A 2B Course Notes)Document191 pagesRTI - Rev.2010 (NDT2A 2B Course Notes)Adil Hasanov100% (1)

- Ultrasonic Inspection Report Appendix 2aDocument1 pageUltrasonic Inspection Report Appendix 2aAdil HasanovNo ratings yet

- TestDocument6 pagesTestAdil Hasanov100% (2)

- Ttransition JointsDocument15 pagesTtransition JointsAdil HasanovNo ratings yet

- Multiple Choice 60Document8 pagesMultiple Choice 60Adil Hasanov100% (1)

- NDT Report Check List Appendix 2Document4 pagesNDT Report Check List Appendix 2Adil Hasanov100% (1)

- Steel Design: By: Engr. John Paul O. Santos, SO2Document16 pagesSteel Design: By: Engr. John Paul O. Santos, SO2jomarie apolinarioNo ratings yet

- Coating Standards PDFDocument5 pagesCoating Standards PDFHanuman RaoNo ratings yet

- Interplate 317: Product DescriptionDocument4 pagesInterplate 317: Product DescriptionMohamed NouzerNo ratings yet

- The Word Manufacture First Appeared in English in 1567 and Is Derived From The Latin Manu FactusDocument8 pagesThe Word Manufacture First Appeared in English in 1567 and Is Derived From The Latin Manu Factushassan9705No ratings yet

- 8670-Nesco Exhibition Hall No-08-Boq-R2 PDFDocument13 pages8670-Nesco Exhibition Hall No-08-Boq-R2 PDFyash shahNo ratings yet

- Heat Treatment - SummaryDocument57 pagesHeat Treatment - SummaryRathoreNo ratings yet

- 250 PSI WWP Iron Body Check Valves: 250 PSI/17.2 Bar Non-Shock Cold WaterDocument1 page250 PSI WWP Iron Body Check Valves: 250 PSI/17.2 Bar Non-Shock Cold WaterRobertoNo ratings yet

- BOEHLER Q T 309L TIG RodDocument1 pageBOEHLER Q T 309L TIG RodbrayanNo ratings yet

- Grinding Final NotesDocument21 pagesGrinding Final NotesGaikwad Aniket100% (1)

- Approved Methodologies: To Which LECO Instruments ConformDocument5 pagesApproved Methodologies: To Which LECO Instruments ConformG_ASantosNo ratings yet

- Especificaciones Valvula Nibco F 617Document1 pageEspecificaciones Valvula Nibco F 617Ascencio RubenNo ratings yet

- Deewane: IES & GATE: Material ScienceDocument33 pagesDeewane: IES & GATE: Material ScienceMayank SaxenaNo ratings yet

- High-Strength Carbon-Manganese Steel of Structural Quality: Standard Specification ForDocument3 pagesHigh-Strength Carbon-Manganese Steel of Structural Quality: Standard Specification ForLeonardo GomideNo ratings yet

- 5104-Gala-Silent Check ValveDocument1 page5104-Gala-Silent Check ValveNam ĐỗNo ratings yet

- AWS D10 4 86R Recommended Practices PDFDocument44 pagesAWS D10 4 86R Recommended Practices PDFwi100% (1)

- Single Length Replacement Overland Conveyors: D. Foo, AustraliaDocument6 pagesSingle Length Replacement Overland Conveyors: D. Foo, AustraliaKeen Moore Duran100% (1)

- WPS A36 For PipesDocument3 pagesWPS A36 For PipesJuan AvellaNo ratings yet

- Material SpecificationDocument9 pagesMaterial SpecificationMuthu GaneshNo ratings yet

- Duplex Stainless Steel Welding - Best PracticesDocument4 pagesDuplex Stainless Steel Welding - Best PracticesjosemiguelzuNo ratings yet

- Fisher F5 Tips Tricks Apr 2013 Rev21Document49 pagesFisher F5 Tips Tricks Apr 2013 Rev21christianNo ratings yet

- 18-311 ReportDocument17 pages18-311 ReportRoll no.17 Shubham PatelNo ratings yet

- Carbono EquivalenteDocument81 pagesCarbono EquivalenteRemmy Torres VegaNo ratings yet

- EHB en 9-MaterialsDocument57 pagesEHB en 9-MaterialsAnonymous 1hOgJqwZuzNo ratings yet

- Efekt: Typ: Underground Hydrant - Dn80 Pn10 / Pn16Document2 pagesEfekt: Typ: Underground Hydrant - Dn80 Pn10 / Pn16Ovidiu MafteiNo ratings yet

- Sunnen Honing Techniques: Above and Beyond HoningDocument12 pagesSunnen Honing Techniques: Above and Beyond HoningHenry OlguinNo ratings yet

- Experiment No 1 Introduction To Hand Tools: HacksawDocument16 pagesExperiment No 1 Introduction To Hand Tools: HacksawTamzid rahmanNo ratings yet

- Fasteners and Screw Threads: ISO Standards HandbookDocument6 pagesFasteners and Screw Threads: ISO Standards HandbookMuhammed Abo-FandoodNo ratings yet

- Class 3Document11 pagesClass 3Muhammad Jamshaid KhanNo ratings yet