Professional Documents

Culture Documents

Drilling Application: Name of Company: Well Name & Number: Date

Uploaded by

laxmikant1983Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Drilling Application: Name of Company: Well Name & Number: Date

Uploaded by

laxmikant1983Copyright:

Available Formats

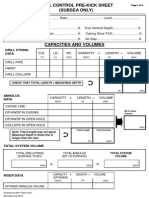

Name of Company: Well Name & Number: Microsoft Excel 97 Date: August 14, 2013

DESIGN DATA

Drilling Application

DRILL STRING DESIGN

BHA DATA D. Collars Hevi-Wt.

BUOYANCY FACTOR

Depth For This Design, ft? = Density of Fluid for This Design, ppg? = Maximum WOB, lbs? = Margin of Overpull, lbs? = Hole Deviation, deg? = Neutral Point Design Factor, (0-1.0)? = Tensile Safety Factor, (0-1.0)? = Collapse Safety Factor? =

Length, ft? = Weight, ppf? =

DRILL PIPE DATA Drill Pipe 1 Drill Pipe 2

1.000

Drill Pipe 3

0.85

Tensile Rating, lbs? = Corrected Wt., ppf? = Collapse, psi? =

BHA RESULTS Length DC

NP = Neutral Point NP from bit Air Wt BHA

#DIV/0!

Drill Pipe 1

#DIV/0!

Drill Pipe 2

#DIV/0!

Drill Pipe 3

DRILL PIPE RESULTS

Maximum Length, ft Length to Run or Length to Run and Reach TD, ft Cumulative String Weight in Air, lbs Cumulative String Weight in Mud, lbs

COLLAPSE VERIFICATION

0 #DIV/0! #DIV/0! #DIV/0!

Drill Pipe 1

#DIV/0! #DIV/0! #DIV/0! #DIV/0!

0 #DIV/0!

Hydrostatic Pressure at Bottom of Drill Pipe Maximum Length, ft THE END

#DIV/0! #DIV/0!

See Tables starting in cell I5 for properties of Used Drill Pipe API Premium

Those who use the Margin of Overpull in drill string design do so on the premise the difference between the maximum normal working load and the load on each pipe section would be equal. There fore, when tension is applied to free the stuck pipe, each section can tolerate the

You might also like

- Drill String DesignDocument1 pageDrill String DesignmalikshababNo ratings yet

- Drilling Application: Hole Diameter, In? Mud WT? Hole Diameter, In? Mud WT?Document1 pageDrilling Application: Hole Diameter, In? Mud WT? Hole Diameter, In? Mud WT?Abdul Hameed OmarNo ratings yet

- Drillstring DesignDocument1 pageDrillstring DesignberrouiNo ratings yet

- Driller Module Workbook 5 Sedco Forex Modular Training ProgramDocument3 pagesDriller Module Workbook 5 Sedco Forex Modular Training ProgramKaleem UllahNo ratings yet

- IPM IDPT Well Engineering Module Wellheads and FishingDocument11 pagesIPM IDPT Well Engineering Module Wellheads and FishingrenatoNo ratings yet

- 4163 Drilling Systems Product Sheet Ds5Document2 pages4163 Drilling Systems Product Sheet Ds5juanNo ratings yet

- Drilling Technology and Costs - Chapter - 6Document51 pagesDrilling Technology and Costs - Chapter - 6zdq02No ratings yet

- Driller Module Workbook 4 Sedco Forex Modular Training ProgramDocument3 pagesDriller Module Workbook 4 Sedco Forex Modular Training ProgramKaleem UllahNo ratings yet

- Stimulation 4Document27 pagesStimulation 4DVScherbakovNo ratings yet

- Section04 - Setting Up The Rig & Spudding The WellDocument7 pagesSection04 - Setting Up The Rig & Spudding The WellMohamed ElshoraNo ratings yet

- 03 - Functions of Drilling Fluids BMS 2013Document27 pages03 - Functions of Drilling Fluids BMS 2013Slim.BNo ratings yet

- SPE 178888 Stuck Pipe PreventionDocument16 pagesSPE 178888 Stuck Pipe Preventionبيرش امينNo ratings yet

- Stripping OperationsDocument4 pagesStripping Operationshosam aliNo ratings yet

- 13-Bit Selection & Operating ConditionsDocument116 pages13-Bit Selection & Operating ConditionsMehdi SoltaniNo ratings yet

- Basics of Well ControlDocument45 pagesBasics of Well ControlRocard NgomaNo ratings yet

- IWCF Subsea Vertical Kill Sheet - API Field Units - Revised July 2010Document4 pagesIWCF Subsea Vertical Kill Sheet - API Field Units - Revised July 2010rverretNo ratings yet

- Assortment of Mini ApplicationsDocument1 pageAssortment of Mini ApplicationsAbdul Hameed OmarNo ratings yet

- Simulador Well ControlDocument8 pagesSimulador Well Controlivan villabonaNo ratings yet

- Chapter 1 Introduction To Well PlanningDocument6 pagesChapter 1 Introduction To Well PlanningjcszfobNo ratings yet

- Drilling Well Control: Eng. Karim ZakariaDocument20 pagesDrilling Well Control: Eng. Karim ZakariaRizwan FaridNo ratings yet

- AC-0049 Well Design RulesDocument5 pagesAC-0049 Well Design RulesairlinemembershipNo ratings yet

- Drillstring Design: Ref: Drilling Eng'G. by Neal AdamsDocument26 pagesDrillstring Design: Ref: Drilling Eng'G. by Neal AdamsKaelel BilangNo ratings yet

- Wireline Rig Up On Bails For Deepwater Rig Correlation PDFDocument1 pageWireline Rig Up On Bails For Deepwater Rig Correlation PDFgugal KumarNo ratings yet

- P&A Techniques for Offshore WellsDocument150 pagesP&A Techniques for Offshore WellsHamed SadeghiNo ratings yet

- Stuck Point WorksheetDocument5 pagesStuck Point Worksheetjose perozoNo ratings yet

- Stuck Pipe WorksheetDocument1 pageStuck Pipe WorksheetMino MinoNo ratings yet

- Re Entry Work: Setting WhipstocksDocument3 pagesRe Entry Work: Setting WhipstocksAnilNo ratings yet

- Greater Kick Tolerance and Fewer Casing Strings With Dual Gradient DrillingDocument31 pagesGreater Kick Tolerance and Fewer Casing Strings With Dual Gradient DrillingNekyneky NekyNo ratings yet

- Altamirov DishniDocument95 pagesAltamirov DishniEmersonJParedes100% (1)

- Drill String Notes and Calculations 157Document9 pagesDrill String Notes and Calculations 157Pilar AmayaNo ratings yet

- The Ideal Bit Drag Bits: Fishtail Type Natural Diamond Polycrystalline Diamond Compact (PDC)Document45 pagesThe Ideal Bit Drag Bits: Fishtail Type Natural Diamond Polycrystalline Diamond Compact (PDC)ShourovjossNo ratings yet

- Drilling Vibration Mitigation PDFDocument1 pageDrilling Vibration Mitigation PDFNabil BenmakhloufNo ratings yet

- 4.500 in 18.90 PPF 0.430 in SM2535-125 VAM HTF-NR Ref. 27-11-17Document1 page4.500 in 18.90 PPF 0.430 in SM2535-125 VAM HTF-NR Ref. 27-11-17Ahmed Elwany100% (1)

- Formation Pressure While Drilling Technology - Game Changer in Drilling Overpressured ReservoirsDocument6 pagesFormation Pressure While Drilling Technology - Game Changer in Drilling Overpressured ReservoirsJamalNo ratings yet

- 100 Quesions With AnswerDocument15 pages100 Quesions With Answernabil heddadNo ratings yet

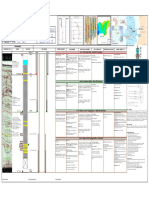

- Banda East Well Montage 28sept08 A4 SizeDocument1 pageBanda East Well Montage 28sept08 A4 SizeSyed IrtazaNo ratings yet

- IWCF by Eng. Abd El-Salam 11-2020Document166 pagesIWCF by Eng. Abd El-Salam 11-2020Mohamed Othman0% (1)

- 1ST2 - Etapa 17.5in - BHA#03 - PDC Bit+PD-X6+MWDDocument1 page1ST2 - Etapa 17.5in - BHA#03 - PDC Bit+PD-X6+MWDAntonio Hdez JmnzNo ratings yet

- Rotary Bottom Hole Assembly: at The End of This Lecture, YOU Should Be Able ToDocument19 pagesRotary Bottom Hole Assembly: at The End of This Lecture, YOU Should Be Able Toburak kamaliNo ratings yet

- UAS Drill String Design and Hole ProblemDocument37 pagesUAS Drill String Design and Hole Problemsbaluwel100% (1)

- BHA#006 8.5in PDXceed +EcoScope+ TeleScopeDocument1 pageBHA#006 8.5in PDXceed +EcoScope+ TeleScopeKelly Cubillos quirozNo ratings yet

- Well Control Worksheet For A Surface Bop Stack: CANNON 1-21Document2 pagesWell Control Worksheet For A Surface Bop Stack: CANNON 1-21scrbdgharaviNo ratings yet

- Effect of Hole Cleaning on Drilling RateDocument7 pagesEffect of Hole Cleaning on Drilling RateazeazeazeNo ratings yet

- Drilling Problems and SolutionsDocument60 pagesDrilling Problems and SolutionsMuhd EizadNo ratings yet

- Wellbore Skematic DrawingsDocument74 pagesWellbore Skematic DrawingsMino MinoNo ratings yet

- Well InterventionDocument83 pagesWell InterventionJosue FishNo ratings yet

- Managed Pressure Drilling Modeling & Simulation (A Case Study)Document8 pagesManaged Pressure Drilling Modeling & Simulation (A Case Study)Mejbahul SarkerNo ratings yet

- Well Control Principles & Procedures Subsea BOPDocument5 pagesWell Control Principles & Procedures Subsea BOPKRNo ratings yet

- 1) Anusha A/P Nagaih 2) Melinda Mallini A/P Loudersamy 3) Sangeetha A/P Balaram 4) Vinohthinii A/P R Tamilselvan 5) Youssif SamiDocument17 pages1) Anusha A/P Nagaih 2) Melinda Mallini A/P Loudersamy 3) Sangeetha A/P Balaram 4) Vinohthinii A/P R Tamilselvan 5) Youssif Samitashh raoNo ratings yet

- Section05 - Routine Drilling OperationsDocument31 pagesSection05 - Routine Drilling OperationsMohamed ElshoraNo ratings yet

- Basic Drilling FormulasDocument30 pagesBasic Drilling FormulasKevin AtochaNo ratings yet

- Round Trip Ton-Miles CalculationDocument2 pagesRound Trip Ton-Miles CalculationKenaouia BahaaNo ratings yet

- 1 IntrotoDrilling ESCertification v1 1 6180305 01Document79 pages1 IntrotoDrilling ESCertification v1 1 6180305 01Ricardo VillarNo ratings yet

- Subsea Exercise No. 8: Complete The Following Questions Based On The Data GivenDocument3 pagesSubsea Exercise No. 8: Complete The Following Questions Based On The Data GivenOgbodu Ejiro DesmondNo ratings yet

- Section02 Drilling ApparatusDocument31 pagesSection02 Drilling ApparatusMohamed ElshoraNo ratings yet

- Section 4Document21 pagesSection 4Mahmoud EzzatNo ratings yet

- JarPro Jarring Analysis SoftwareDocument4 pagesJarPro Jarring Analysis Softwareeleceron7919No ratings yet

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsFrom EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsNo ratings yet

- Electromagnetic Well Logging: Models for MWD / LWD Interpretation and Tool DesignFrom EverandElectromagnetic Well Logging: Models for MWD / LWD Interpretation and Tool DesignRating: 5 out of 5 stars5/5 (1)

- Short On RMR-systemDocument3 pagesShort On RMR-systemlaxmikant1983No ratings yet

- KU Geology 1Document34 pagesKU Geology 1Fawad Ahmed100% (3)

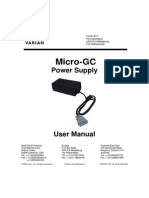

- The Analysis of CarbonDioxide in Natural GasDocument4 pagesThe Analysis of CarbonDioxide in Natural GasBimo Gunners RespatiNo ratings yet

- Combining the RMR, Q, and RMi classification systems for rock massDocument2 pagesCombining the RMR, Q, and RMi classification systems for rock masslaxmikant1983No ratings yet

- Distance Learning Drilling Calculations Part 1Document211 pagesDistance Learning Drilling Calculations Part 1Eddy Rochmadi100% (2)

- 6 Geosteering BasicsDocument60 pages6 Geosteering Basicslaxmikant1983100% (2)

- cp501269 Rev4Document40 pagescp501269 Rev4laxmikant1983No ratings yet

- Rheology Technical Buletin PDFDocument16 pagesRheology Technical Buletin PDFlaxmikant1983No ratings yet

- STANDARD LEGEND - Petroleum EngineeringDocument212 pagesSTANDARD LEGEND - Petroleum Engineeringarobertomedeiros100% (3)

- QA-RD7AE-V8 English API Formula SheetDocument4 pagesQA-RD7AE-V8 English API Formula SheetYogesh GavaliNo ratings yet

- Direction Well Trajectory DesignDocument10 pagesDirection Well Trajectory Designlaxmikant1983No ratings yet

- Drilling BasicsDocument29 pagesDrilling BasicsSyed ShaiqNo ratings yet

- Instrument Maintenance Procedure: Pt. Petrokimia Nusantara InterindoDocument2 pagesInstrument Maintenance Procedure: Pt. Petrokimia Nusantara Interindolaxmikant1983No ratings yet

- ICICI - CC - Customer CareDocument9 pagesICICI - CC - Customer CareRamakrishnan PadmanabanNo ratings yet

- CRS Report For Congress: Tsunamis: Monitoring, Detection, and Early Warning SystemsDocument21 pagesCRS Report For Congress: Tsunamis: Monitoring, Detection, and Early Warning Systemslaxmikant1983No ratings yet

- LOT PlotsDocument6 pagesLOT Plotslaxmikant1983No ratings yet

- CP501267 Rev02 PDFDocument15 pagesCP501267 Rev02 PDFlaxmikant1983No ratings yet

- Ton Mile EplainedDocument4 pagesTon Mile Eplainedlaxmikant1983No ratings yet

- IMP02-022!4!2001-00 Zero Check of Flow Transmitter (Micro Motion Type)Document2 pagesIMP02-022!4!2001-00 Zero Check of Flow Transmitter (Micro Motion Type)laxmikant1983No ratings yet

- IMP02-001-4-1999-01 Nuclear LS CalDocument3 pagesIMP02-001-4-1999-01 Nuclear LS Callaxmikant1983No ratings yet

- IMP02-019!3!2001-00 Philips LCL TR 3 CalDocument3 pagesIMP02-019!3!2001-00 Philips LCL TR 3 Callaxmikant1983No ratings yet

- Ton Mile TM For Coring OperationDocument2 pagesTon Mile TM For Coring Operationlaxmikant1983No ratings yet

- IMP02-020!4!2001-00 Check Schenk ParameterDocument2 pagesIMP02-020!4!2001-00 Check Schenk Parameterlaxmikant1983No ratings yet

- Calculate Annular Velocity and Pump Output Using Diameters and Flow RatesDocument2 pagesCalculate Annular Velocity and Pump Output Using Diameters and Flow RatesgateauxboyNo ratings yet

- Slug Calculation Barrels of Slug Required For A Desired Lenght of Dry PipeDocument2 pagesSlug Calculation Barrels of Slug Required For A Desired Lenght of Dry Pipelaxmikant1983No ratings yet

- Rig Component PDFDocument23 pagesRig Component PDFjim carry93% (30)

- Calculate Annular Velocity and Pump Output Using Diameters and Flow RatesDocument2 pagesCalculate Annular Velocity and Pump Output Using Diameters and Flow RatesgateauxboyNo ratings yet

- Bulk Denstiy CalculationDocument2 pagesBulk Denstiy CalculationNolan JohnsonNo ratings yet

- Slug Calculation Barrels of Slug Required For A Desired Lenght of Dry PipeDocument2 pagesSlug Calculation Barrels of Slug Required For A Desired Lenght of Dry Pipelaxmikant1983No ratings yet

- Ton Mile TM For Setting CasingDocument2 pagesTon Mile TM For Setting Casinglaxmikant1983No ratings yet