Professional Documents

Culture Documents

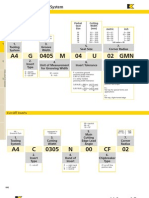

A 4 Groove Turn Tech Data

Uploaded by

Dingo BkOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A 4 Groove Turn Tech Data

Uploaded by

Dingo BkCopyright:

Available Formats

A4 Groove & Turn Technical Data

Application Guidelines

When groove width is greater than insert width, two methods are possible: 1. 1. Multiple Pass Grooving

Use the widest possible insert width to achieve optimal chip control and tool life. Make grooves 1, 2, and 3 first...then connect with passes 4 and 5. For passes 4 and 5, the material removed should be no more than 0.8 times the insert width.

A4 TOP NOTCH

2.

2. Grooving and Turning

For small and unstable workpieces, this is the preferred method to reduce vibrations experienced when axial grooving. The depth of cut in longitudinal turning should generally be 60%-70% of the groove width. Turning in both directions improves tool life.

A3

A. depth > width

B. width > depth

Choosing the Best Method: A. When the groove depth is greater than the groove width, multiple pass

plunge grooving offers the best results.

B. When the groove width is greater than the groove depth, groove & turn

(plunge/longitudinal turning) is easier and faster.

Finish Profiling

When finish profile machining internal chamfers or radii, take into account that the effective feed rate and chip cross section are reduced (the tool is cutting in both radial and axial directions). The accompanying drawing (left) shows the suggested processing sequence for the final pass, to reduce vibrations.

A4 Grooving Tool Application Guidelines

Always use good general machining practices. Make the machine and workpiece setup as rigid as possible. Integral shank toolholders offer the best rigidity. They should be your first toolholder choice, when possible. When changing inserts, make sure the new insert locates securely against the toolholders positive stop. Never tighten the clamping screw without an insert in the pocket. Toolholder extension out of the tool block should be as short as possible. Inserts should cut as close to center as possible or slightly above. Dwell time in bottom of groove should be less than three revolutions. Recommended cutting speeds and feeds are a starting point. Adjust, as necessary, for optimum tool life and chip control.

B61

GROOVING & CUT-OFF TOOLS A2

You might also like

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsFrom EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsRating: 5 out of 5 stars5/5 (1)

- Constant Cutter Load: You Will LearnDocument7 pagesConstant Cutter Load: You Will LearntsaladygaNo ratings yet

- Chainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosFrom EverandChainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosNo ratings yet

- Milling: General Mill InformationDocument11 pagesMilling: General Mill Informationsravan_inboxNo ratings yet

- 6 Thread MillingDocument6 pages6 Thread MillingAmey A. NaikNo ratings yet

- Wood Turning - The Lathe and Its Accessories, Tools, Turning Between Centres Face-Plate Work, Boring, PolishingFrom EverandWood Turning - The Lathe and Its Accessories, Tools, Turning Between Centres Face-Plate Work, Boring, PolishingNo ratings yet

- 09 Strip LayoutDocument28 pages09 Strip LayoutvivekNo ratings yet

- Design Recommendations for Screw Machine ProductsDocument23 pagesDesign Recommendations for Screw Machine Productsashwin josephNo ratings yet

- Boring HeadDocument2 pagesBoring HeadJM ReynanciaNo ratings yet

- Drilling and Thread CuttingDocument11 pagesDrilling and Thread CuttingSami SamiNo ratings yet

- Press Tool CalculationDocument76 pagesPress Tool CalculationPrashant AmbadekarNo ratings yet

- 9 Strip LayoutDocument26 pages9 Strip LayoutMohan RanganNo ratings yet

- Lathe Facing Operation Reduces Cylindrical Workpiece LengthDocument32 pagesLathe Facing Operation Reduces Cylindrical Workpiece Lengthusmaniqbal15No ratings yet

- General Design Rules For MachiningDocument30 pagesGeneral Design Rules For MachiningSarath Chandra82% (11)

- 2nd Btech MECH 2021-22 MCMT Ses-K4 PDFDocument14 pages2nd Btech MECH 2021-22 MCMT Ses-K4 PDFGopi TNo ratings yet

- Drilling Machine Process GuideDocument14 pagesDrilling Machine Process GuideElfa Noprianri PutraNo ratings yet

- General Milling Operations GuideDocument10 pagesGeneral Milling Operations GuideEdwardNo ratings yet

- Quiz1 ReviewerDocument17 pagesQuiz1 ReviewerJag MasterNo ratings yet

- Strip LayoutDocument35 pagesStrip LayoutJay PatelNo ratings yet

- Cutting Tools in Industrial AutomationDocument22 pagesCutting Tools in Industrial AutomationShazeenNo ratings yet

- Bengkel ReportDocument5 pagesBengkel ReportPaih DtNo ratings yet

- Class Notes ManufacturingDocument13 pagesClass Notes ManufacturingRajangam VeeruchinnanNo ratings yet

- Chapter 5 - CNC ToolingDocument50 pagesChapter 5 - CNC ToolingDani AbHalimNo ratings yet

- Tools Required: Boring BitsDocument10 pagesTools Required: Boring BitsSai SudheerNo ratings yet

- Module2: Design and Calculations of Piercing & Blanking DieDocument89 pagesModule2: Design and Calculations of Piercing & Blanking DieVipul MetaNo ratings yet

- Sheet Metal ProcessesDocument30 pagesSheet Metal ProcessesJagdish KolteNo ratings yet

- Tolerancies Generals EstampacioDocument2 pagesTolerancies Generals EstampacioAlbert SolsonaNo ratings yet

- Bending and drilling machine processesDocument4 pagesBending and drilling machine processesKelly LuluNo ratings yet

- Lathe Operating InstructionsDocument24 pagesLathe Operating InstructionsJoão BraganteNo ratings yet

- Metrology & Workshop Practice ComponentsDocument48 pagesMetrology & Workshop Practice ComponentsAliah IzzahNo ratings yet

- Insert Shape ... : R S C T DDocument11 pagesInsert Shape ... : R S C T DskidamdnevnoNo ratings yet

- General turning guide - chip thickness, speeds & feedsDocument10 pagesGeneral turning guide - chip thickness, speeds & feedsShanmugam BalasubramaniamNo ratings yet

- A LatheDocument7 pagesA LathePassmore DubeNo ratings yet

- Lathe: A Lathe in Building 35Document32 pagesLathe: A Lathe in Building 35srajubasavaNo ratings yet

- Shop Practice Number 4Document9 pagesShop Practice Number 4JantzenCaliwliwNo ratings yet

- Escorts Agri Machinery Group: Ishwarchand Vidya Sagar Institute of TechnologyDocument52 pagesEscorts Agri Machinery Group: Ishwarchand Vidya Sagar Institute of TechnologySarvesh NayakNo ratings yet

- WSTP 1 ReviewerDocument14 pagesWSTP 1 ReviewerHallaresjosh 30No ratings yet

- CNC Router CAM Setup: Create Pocket ToolpathsDocument15 pagesCNC Router CAM Setup: Create Pocket ToolpathsRadiša ĆirkovićNo ratings yet

- Ch-6 Reaming, Boring, BroachingDocument47 pagesCh-6 Reaming, Boring, BroachingAnkush AhirraoNo ratings yet

- Unit 2 - Drilling 29Document41 pagesUnit 2 - Drilling 29normanjames966No ratings yet

- Chapter 2 Different Types of FixturesDocument20 pagesChapter 2 Different Types of FixturesaragawNo ratings yet

- Drilling OperationsDocument9 pagesDrilling Operationslindobuhledandelion0No ratings yet

- DrillingDocument36 pagesDrillingMax LuxNo ratings yet

- Everything You Need to Know About LathesDocument5 pagesEverything You Need to Know About LathesAugusto MonjardimNo ratings yet

- Manufacturing EngineeringDocument70 pagesManufacturing EngineeringPRINCE RAJNo ratings yet

- Exp No 10 DrillingDocument11 pagesExp No 10 DrillingM IRFANNo ratings yet

- Lab Sheet MillingDocument5 pagesLab Sheet MillingLalang Laut BestNo ratings yet

- Progressive Die Design: Training ObjectiveDocument5 pagesProgressive Die Design: Training ObjectiveHimanshu sharmaNo ratings yet

- Woodworking Tools and Methods NAVEDTRA 14043Document62 pagesWoodworking Tools and Methods NAVEDTRA 14043Jonathan Delos SantosNo ratings yet

- Press ToolDocument71 pagesPress Toolamolnjainajgmail.com 7507254906No ratings yet

- Vertical Milling Machine Operation: Read All Operating Instructions Carefully Before Attempting Any Machining Operations!Document31 pagesVertical Milling Machine Operation: Read All Operating Instructions Carefully Before Attempting Any Machining Operations!sonu sainiNo ratings yet

- Threads and Thread Cutting Operations: Arul R ApmechDocument22 pagesThreads and Thread Cutting Operations: Arul R ApmecharulsivagiriNo ratings yet

- CIMT Important Lathe Machine QuestionsDocument11 pagesCIMT Important Lathe Machine QuestionsChandu ReddyNo ratings yet

- DV07PUB4 Study GuideDocument5 pagesDV07PUB4 Study Guidebadboys123No ratings yet

- Fabrication of 360 Angular Drilling MachineDocument28 pagesFabrication of 360 Angular Drilling MachineDinesh KumarNo ratings yet

- MCTD LabDocument38 pagesMCTD LabnidhidarklordNo ratings yet

- cm-614 ManualDocument10 pagescm-614 Manualkcc2012No ratings yet

- A 4 Mod KM Tooling Id SystemDocument1 pageA 4 Mod KM Tooling Id SystemDingo BkNo ratings yet

- A 4 Modular Tool Holder Id SystemDocument1 pageA 4 Modular Tool Holder Id SystemDingo BkNo ratings yet

- A 4 Mod Blade Sid SystemDocument1 pageA 4 Mod Blade Sid SystemDingo BkNo ratings yet

- A 4 Holder Id SystemDocument1 pageA 4 Holder Id SystemDingo BkNo ratings yet

- a4InsertId ApplicationDocument2 pagesa4InsertId ApplicationDingo BkNo ratings yet

- A 3 Deep Grooving Tech DataDocument2 pagesA 3 Deep Grooving Tech DataDingo BkNo ratings yet

- A 3 Insert Id SystemDocument1 pageA 3 Insert Id SystemDingo BkNo ratings yet

- A 3 Tool Holder Id SystemDocument1 pageA 3 Tool Holder Id SystemDingo BkNo ratings yet

- A 2 Holder Id SystemDocument1 pageA 2 Holder Id SystemDingo BkNo ratings yet

- A 2 Insert Id SystemDocument1 pageA 2 Insert Id SystemDingo BkNo ratings yet

- A 2 Cutoff Tech DataDocument1 pageA 2 Cutoff Tech DataDingo BkNo ratings yet

- A 2 Cutoff Tech DataDocument1 pageA 2 Cutoff Tech DataDingo BkNo ratings yet